Telescopic cable box for prefabricated hollow concrete member and its application method

A technology of hollow concrete and telescopic wires, applied in the field of wire boxes, can solve problems such as inability to penetrate core pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

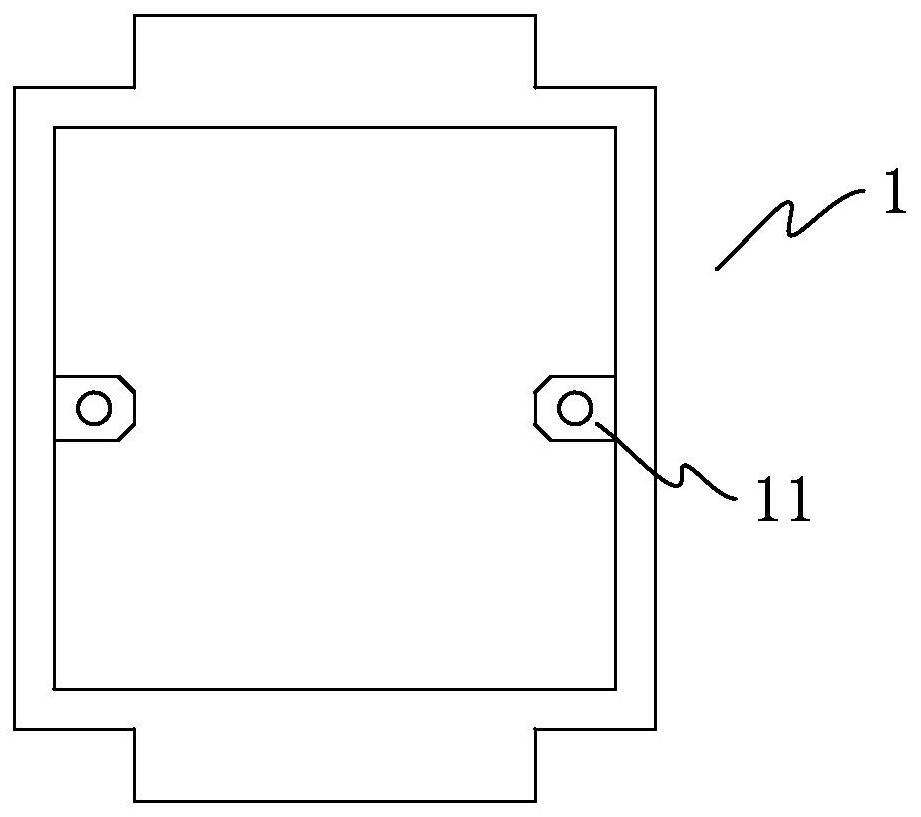

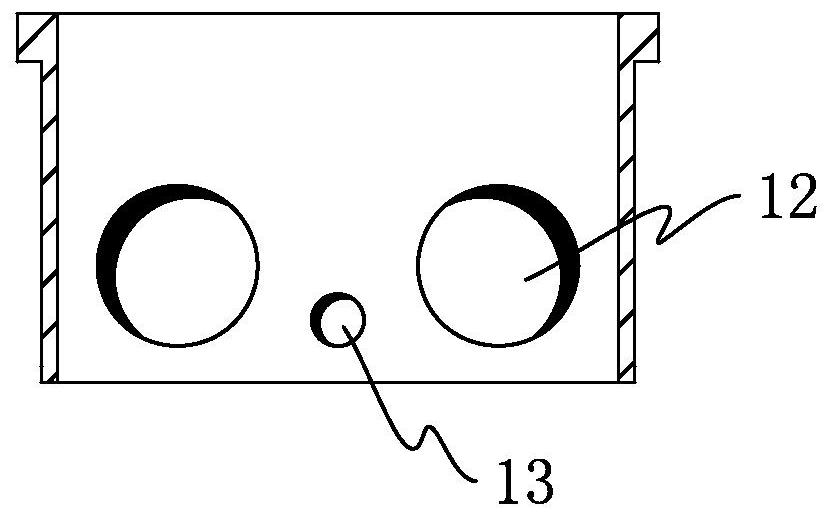

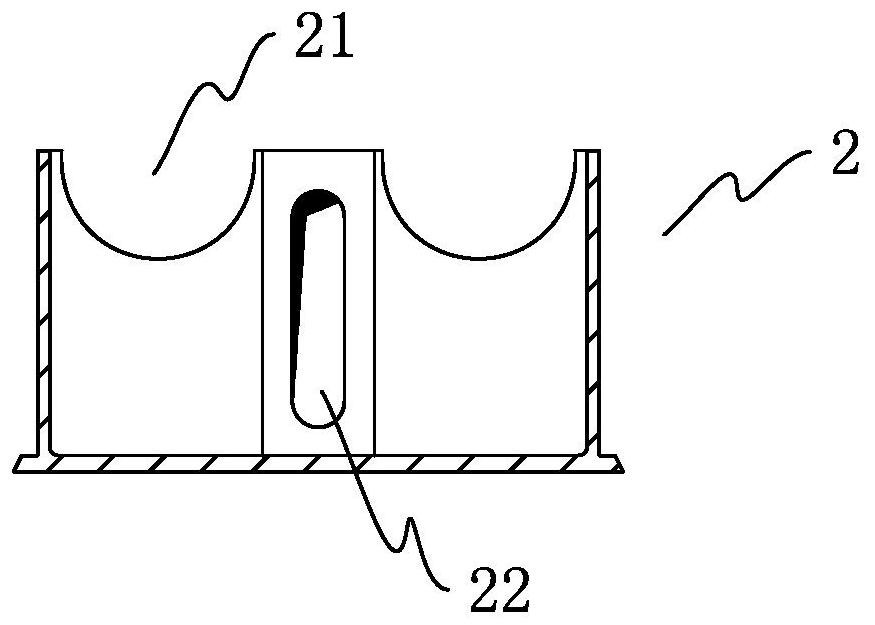

[0035] Such as Figure 1-12 As shown, a telescopic wire box for prefabricated hollow concrete components includes an outer box 1 and an inner box 2 nested together, the outer box 1 is surrounded by four sides; the inner box 2 is composed of four Two sides and a bottom surface are surrounded; the inner surfaces of two opposite sides in the outer box 1 are provided with projections 13; The chute 22; the width of the protrusion 13 is less than or equal to the width of the chute 22.

[0036] The depth of the upper part of the chute 22 is greater than the depth of the middle and lower parts of the chute 22; the upper longitudinal section size of the chute 22 is greater than or equal to the longitudinal section size of the projection 13; the middle part of the chute 22 is provided with A ramp that slopes upward and outward. The cross section of the chute 22 is oblong. The section of the protrusion 13 is circular.

[0037] The chute 22 is located on the rib protruding from the ou...

Embodiment 2

[0047] Such as Figure 13-14 As shown, compared with Example 1, a telescopic cable box for prefabricated hollow concrete members, the four sides of the outer box 1' are provided with two wire pipe holes, one left and one right; the four sides of the inner box 2' The upper part is provided with two semicircular grooves, one left and one right, corresponding to the positions of the wire pipe holes.

[0048] Two opposite side centers in the inner box 2' are provided with ribs 21 ', and the other two side centers are provided with ribs 22' with rectangular slideways.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com