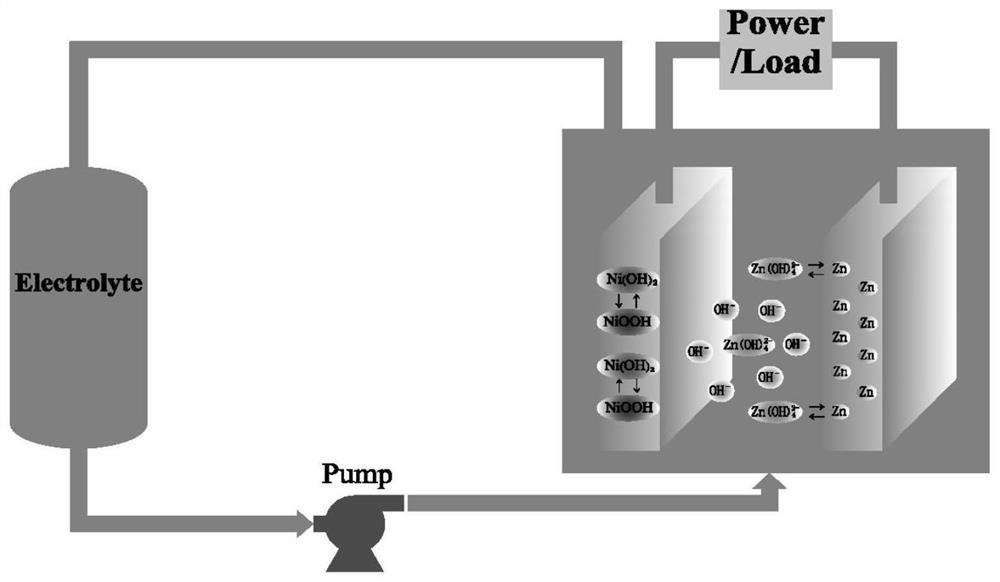

A zinc-nickel flow battery

A liquid flow battery and flow battery technology, applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve problems such as no diaphragm, no current conduction, and limited battery overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

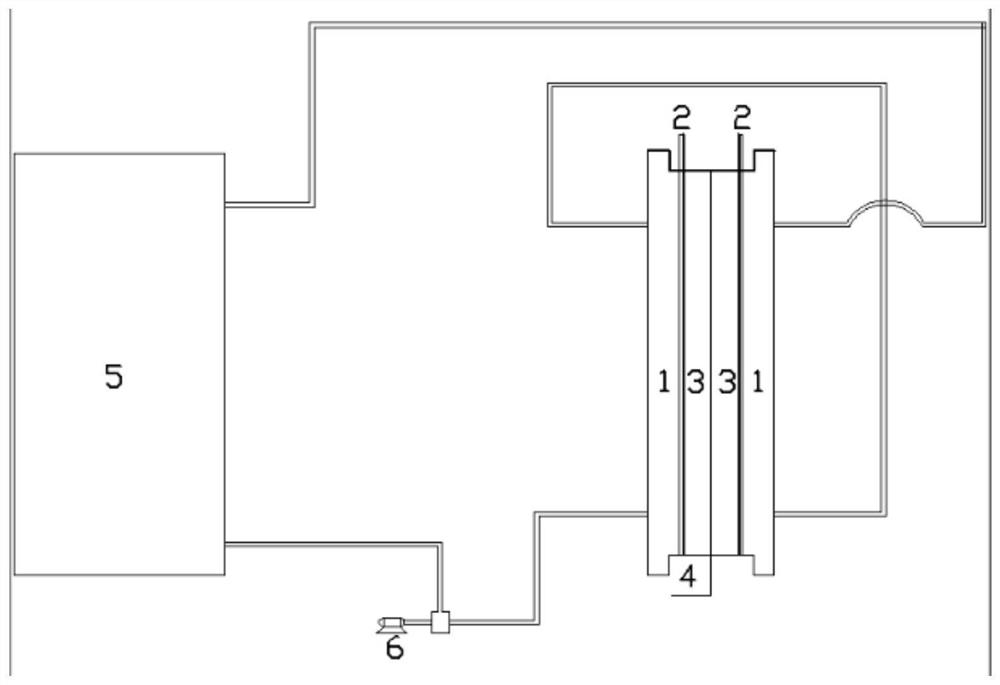

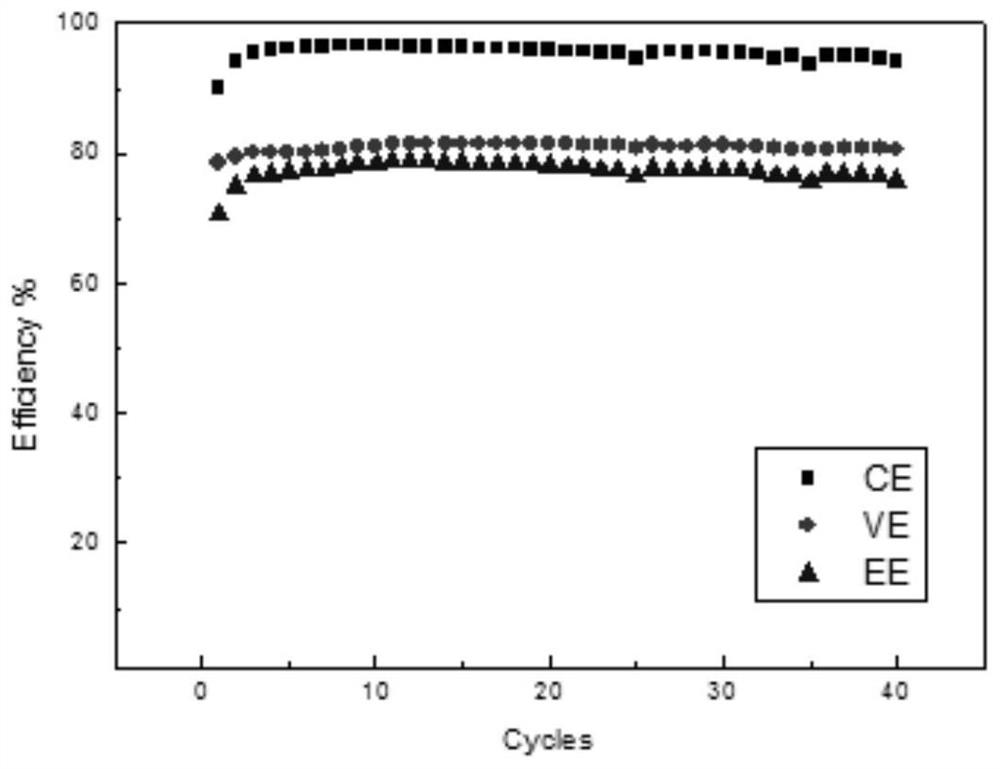

Embodiment 1

[0024] The effective area of the positive and negative electrodes of the zinc-nickel dual-flow battery is 6*6cm; the material of the positive electrode current collector is graphite, and the positive electrode is coated with nickel hydroxide on the carbon felt matrix and the side close to the current collector, and the coating amount is 0.8g / cm 2 , the thickness of the positive and negative electrodes is 5mm, and the negative electrode is a deposited carbon felt electrode. The positive and negative electrodes are enclosed in an electrode frame with a thickness of 4mm; the electrolyte in the electrolyte storage tank flows through the positive electrode through the pump, and continues to flow through the negative electrode after flowing out from the positive electrode. , and finally flow back from the negative electrode to the liquid storage tank. The electrolyte is a KOH aqueous solution containing zinc ions at a concentration of 0.4mol / L, and the alkali concentration is 8mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com