Head part folding device for plastic bag

A folding device and plastic bag technology, applied in packaging and other directions, can solve the problems of easy rebound and lift, bulky, and there is no specific mode for the reset time of the bag pressing hook, and achieves the effect of stable and reliable operation and compact overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

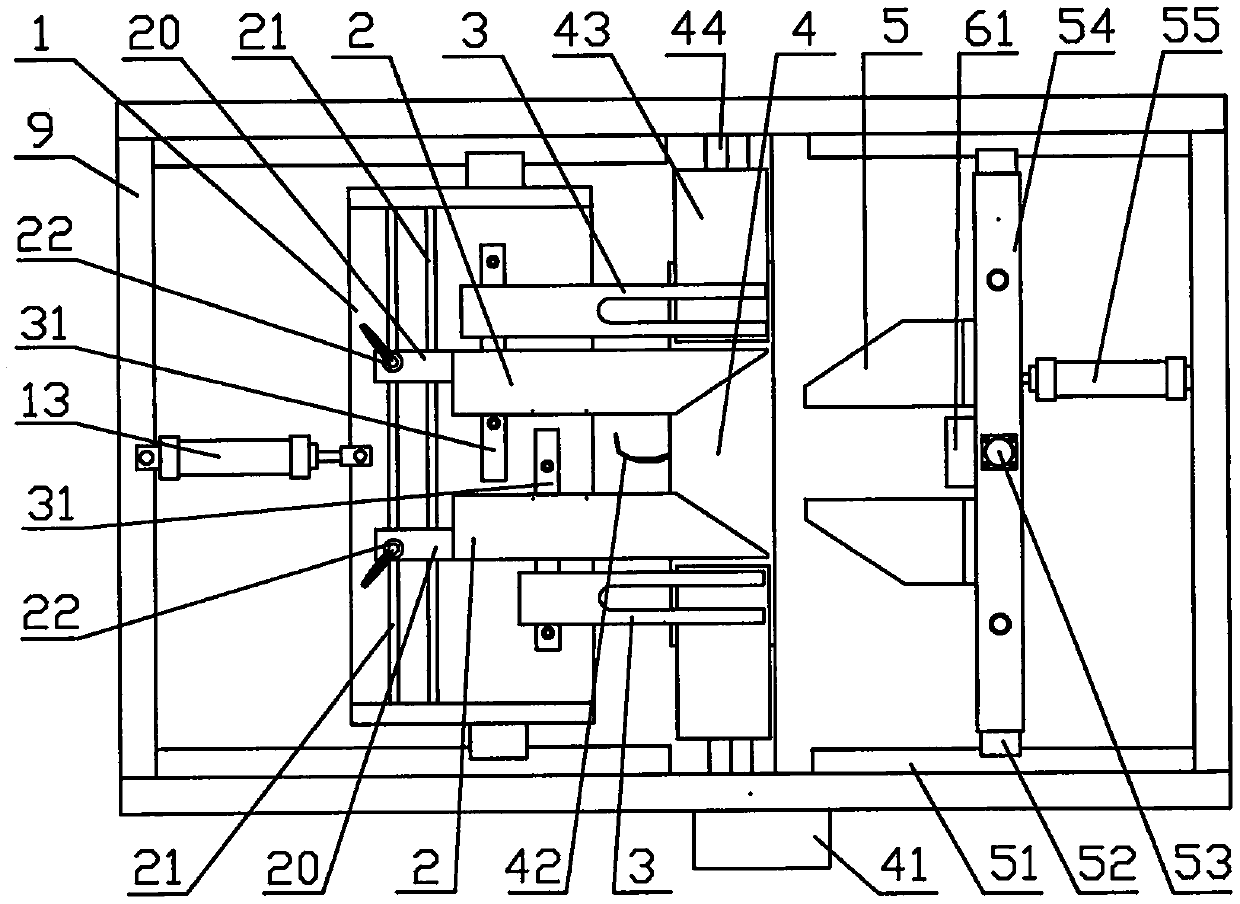

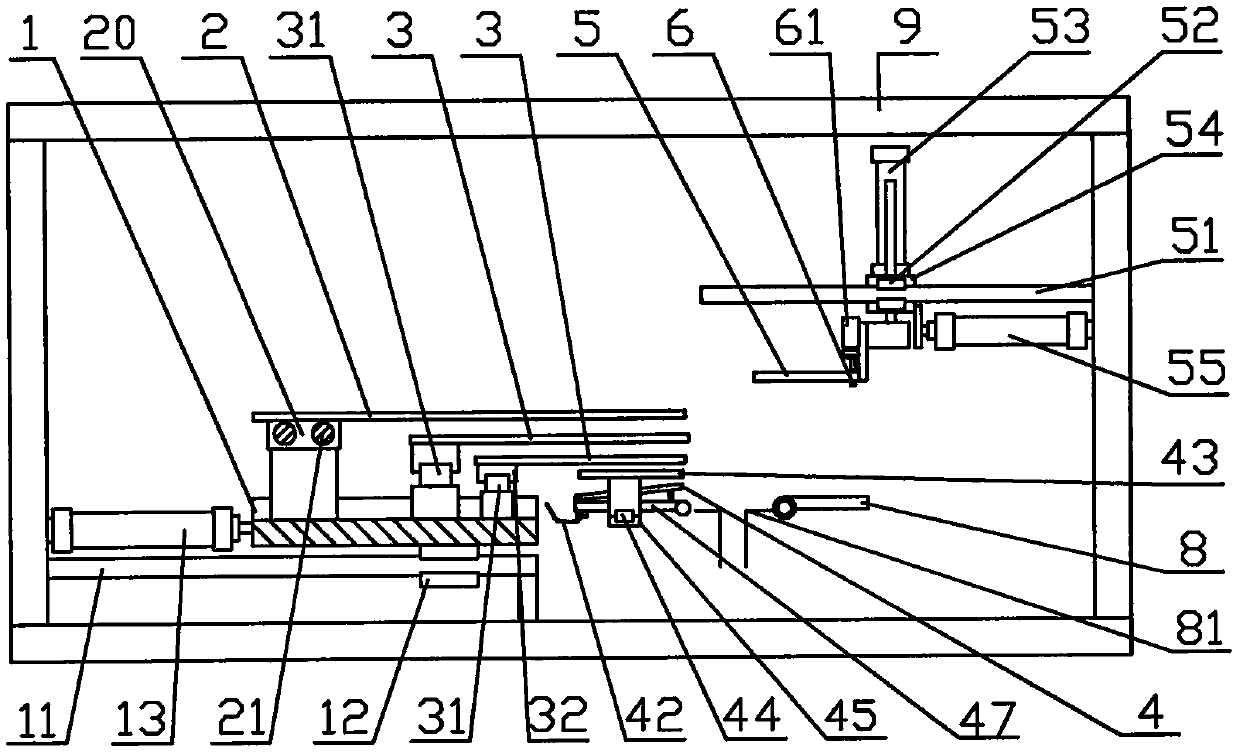

[0053] Embodiment one, such as figure 1 figure 2Shown: in the front portion of frame 1, folding flap is installed, and folding flap comprises flap 4, flip frame 47, swing cylinder 41, spring 48, and the front side of flap 4 is hinged on the front of flap frame 47. Side, a spring 48 is connected between the rear side of the flip frame 47 and the front side of the flap 4, the left and right ends of the flip frame 47 are rotated and installed on both sides of the frame 9, on one side of the frame 9 A swing cylinder 41 is installed, and the drive shaft of the swing cylinder 41 is connected with an end of the flip frame 47; Block 45, push pedal cylinder 46, install a linear guide rail and push pedal guide rail 44 below the board turning frame 47 left and right, slide and install a push pedal slider 45 respectively at the two ends of push pedal guide rail 44, push pedal slider 45 A push pedal 43 is respectively connected on the top, and a push pedal cylinder 46 is respectively c...

Embodiment 2

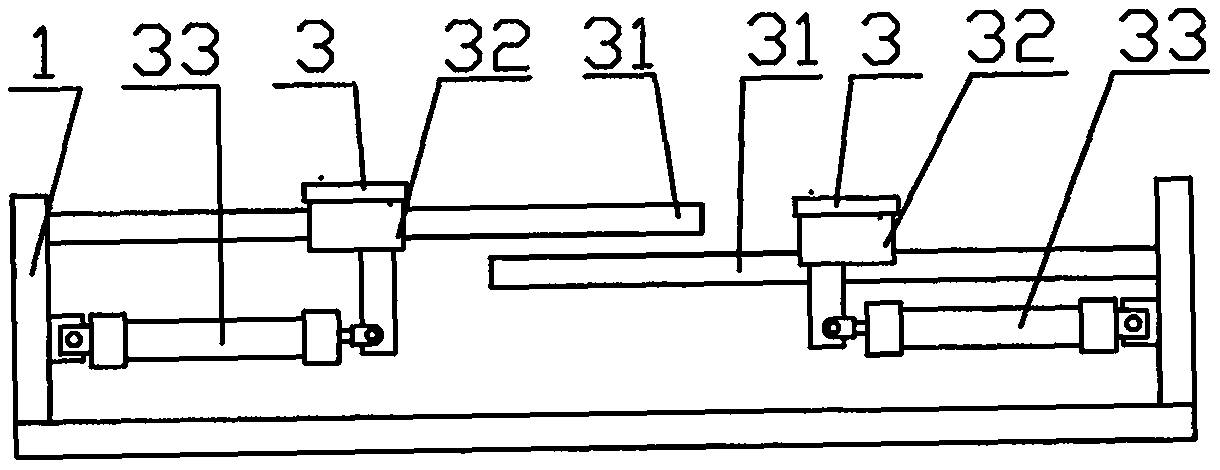

[0059] Embodiment two, the main difference of embodiment two is: as Figure 14 , Figure 15 As shown, firstly, the guide rail 21 is a rectangular plate-shaped body, and the slider 20 is an adjustment hole 23 arranged on the guide rail or the supporting plate 2; secondly, the U-shaped push-fold plate 3 is a rectangular There is no U-shaped gap on the strip plate; thirdly, the bag-pressing hook 42 is replaced by the bag-pressing rod 49; four, the indentation plate 6 is installed on the platen driving mechanism, and the guide rod cylinder is omitted. The indentation plate 6 is a plate-like body. Install a rectangular plate-shaped guide rail 21 horizontally on the slide table 1, set a plurality of mounting holes 24 on the guide rail 21, install two pallets 2 on the left and right on the guide rail 24, and set adjustment holes on the front of the pallet 2 23, pass the adjustment hole 23 with the set screw 22 and the supporting plate 2 is installed on the guide rail 21 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com