Screwless glasses frame

A screw mirror and mirror frame technology, applied in the field of mirror frames, can solve the problems of uncleaned bolt joints, affecting the use effect, and prone to metal rust, etc., and achieves the effect of simple connection form, convenient installation, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

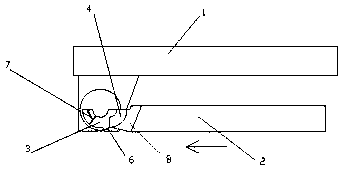

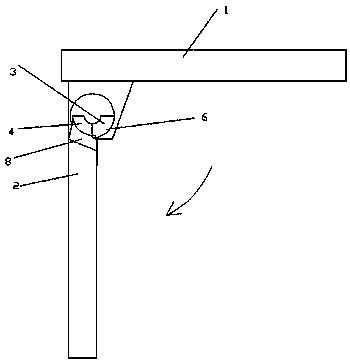

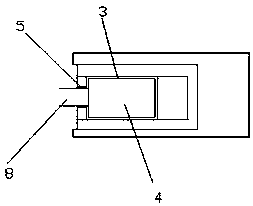

[0011] The figure shows an embodiment of the screwless spectacle frame of the present invention, which includes a spectacle frame 1 and a spectacle frame 2 arranged on both sides of the spectacle frame. The annular rotation groove 3 arranged on the mirror frame, the annular rotation groove is set at 180°, cooperates with the annular rotation groove and is arranged on the fan-shaped rotating block 4 on the mirror frame, the fan-shaped rotating block is set at 90°, and the fan-shaped rotating block passes through the connecting plate 8 Connected with the mirror frame, an annular opening 5 is arranged on the outside of the annular rotating groove, a connecting plate is arranged on the annular opening, and a fan-shaped rotating block inlet 6 is arranged on the annular opening, and the fan-shaped rotating block inlet is arranged on the inner side of the mirror frame.

[0012] The height of the annular rotating groove is greater than that of the annular opening.

[0013] An elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com