Workpiece conveying mechanism for glass tube production pot furnace

A technology of transmission mechanism and glass tube, which is applied in the field of processing equipment, can solve the problems of inaccurate transmission position, high cost and risk, and weak continuous workability, etc., to achieve fast transmission response, strong sustainable work ability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

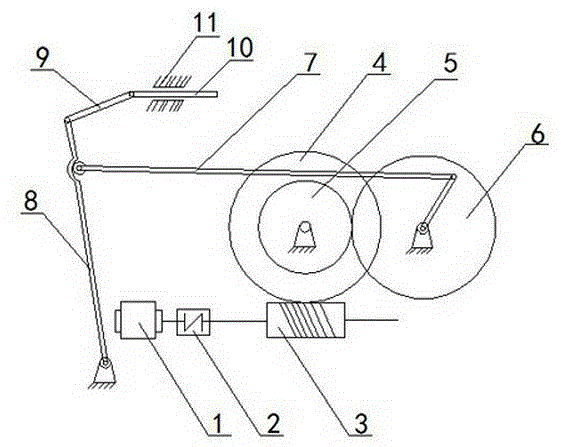

[0019] Such as figure 1 Shown: the present invention comprises motor 1, worm screw 3, worm wheel 4, pinion 5, bull gear 6, front connecting rod 7, rocking bar 8, rear connecting rod 9, push block 10 and frame 11, the rotating shaft of motor 1 and The worm 3 is connected, the worm 3 is meshed with the worm wheel 4, the pinion 5 is connected with the worm wheel 4, the large gear 6 is connected with the small gear 5, and one end of the front connecting rod 7 is connected with the large gear One side of the rocker 6 is rotationally connected, the other end of the front link 7 pushes the middle part of the rocker 8, one end of the rocker 8 is fixed and rotationally connected, the other end of the rocker 8 is rotationally connected with the push block 10 through the rear link 9, and the front The other end of the connecting rod 7 is rotationally connected with the upper section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com