Roller device for precision textile cloth

A technology for textile fabrics and rolls, which is applied in the field of roll devices for precision textile fabrics, can solve the problems of single winding function, inability to perform drying treatment, and damage to fabrics, so as to improve the cleaning and drying effect and improve the protection of winding. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

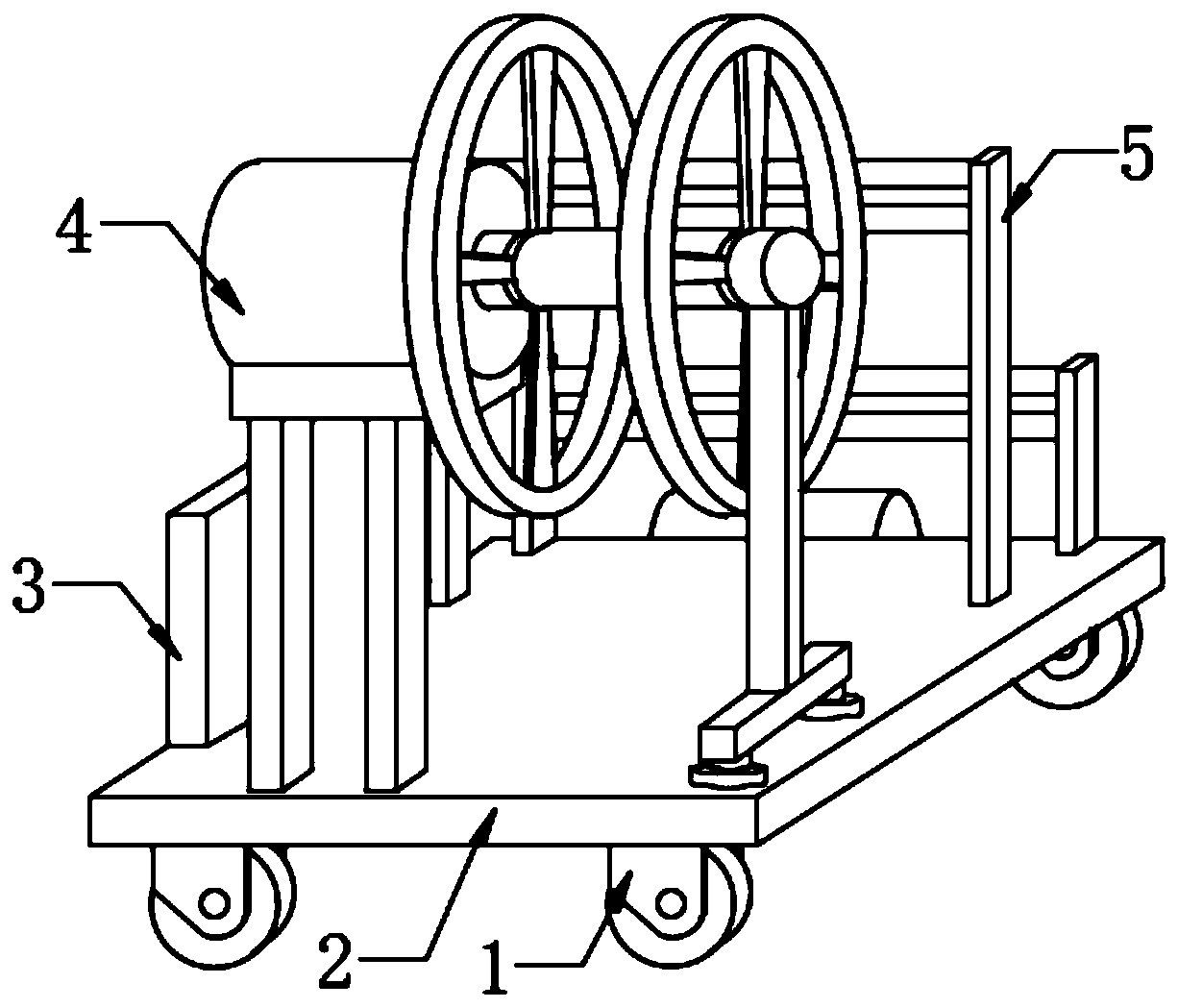

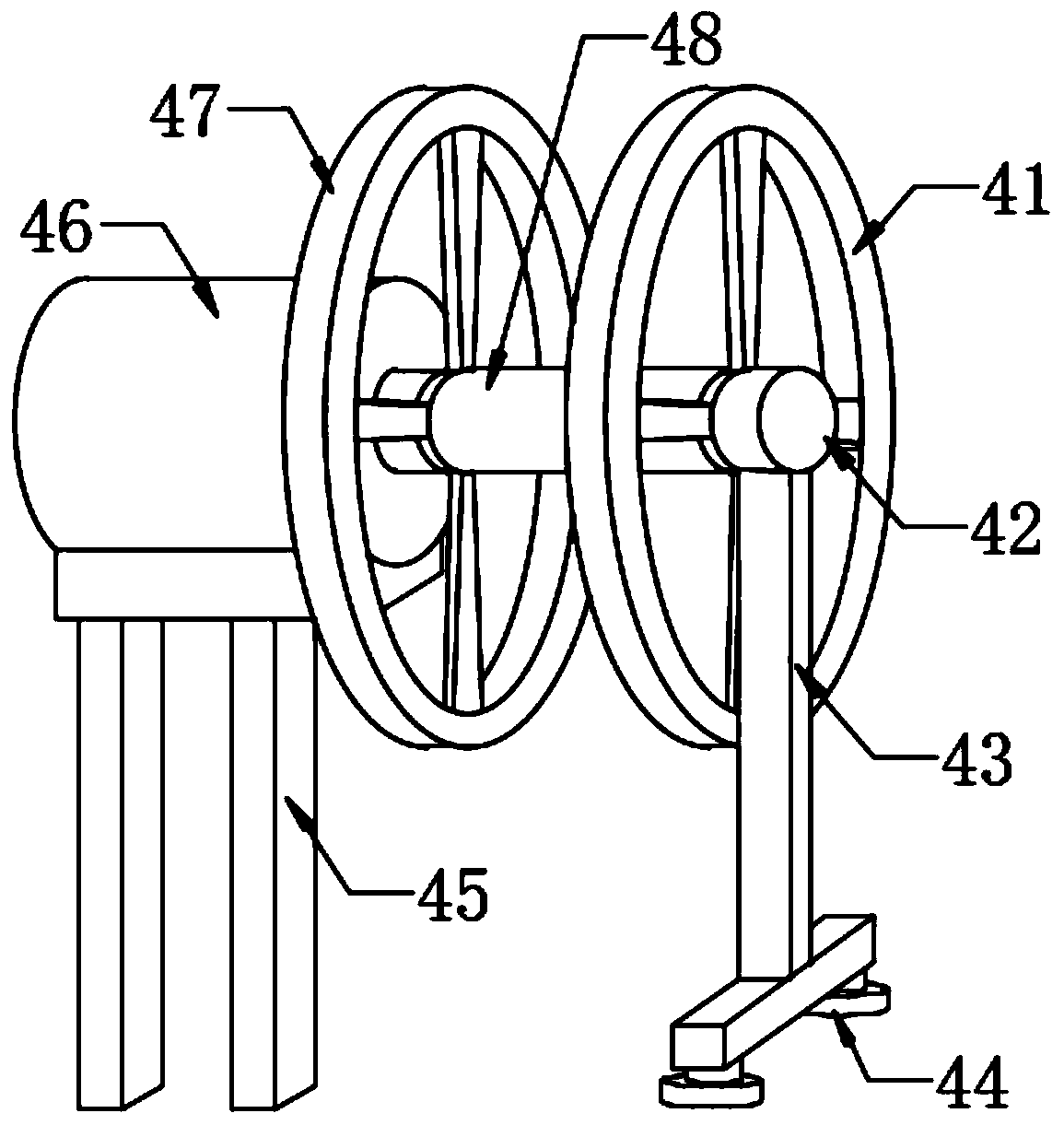

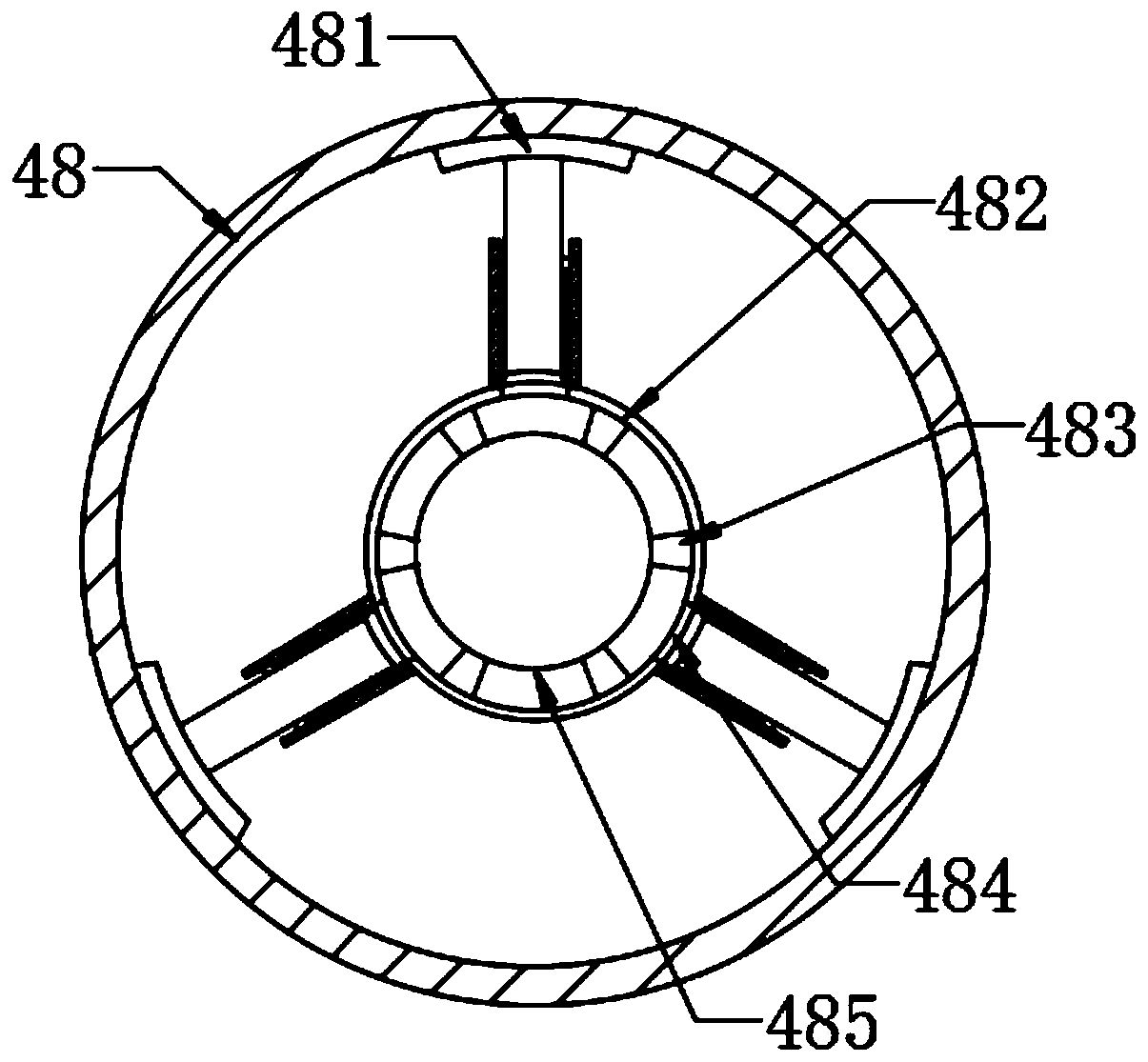

[0025] The invention provides a technical solution: as Figure 1-Figure 6 , a rolling device for precision textile fabrics, comprising a universal wheel 1, a bottom plate 2, a PLC controller 3, a roll protection mechanism 4 and a cleaning and drying mechanism 5, the universal wheel 1 is installed on the lower end surface of the bottom plate 2, and the left end of the bottom plate 2 A PLC controller 3 is provided on the surface, a roll protection mechanism 4 is provided on the front side of the upper end of the bottom plate 2, a cleaning and drying mechanism 5 is provided on the rear side of the upper end surface of the bottom plate 2, and the roll protection mechanism 4 includes a protective plate 41, a reinforcement cover 42, and a reinforcement cover 42. Column 43, anti-skid plate 44, column 45, gear motor 46, protective plate 2 47, winding rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com