Patents

Literature

37results about How to "Improve cleaning and drying effect" patented technology

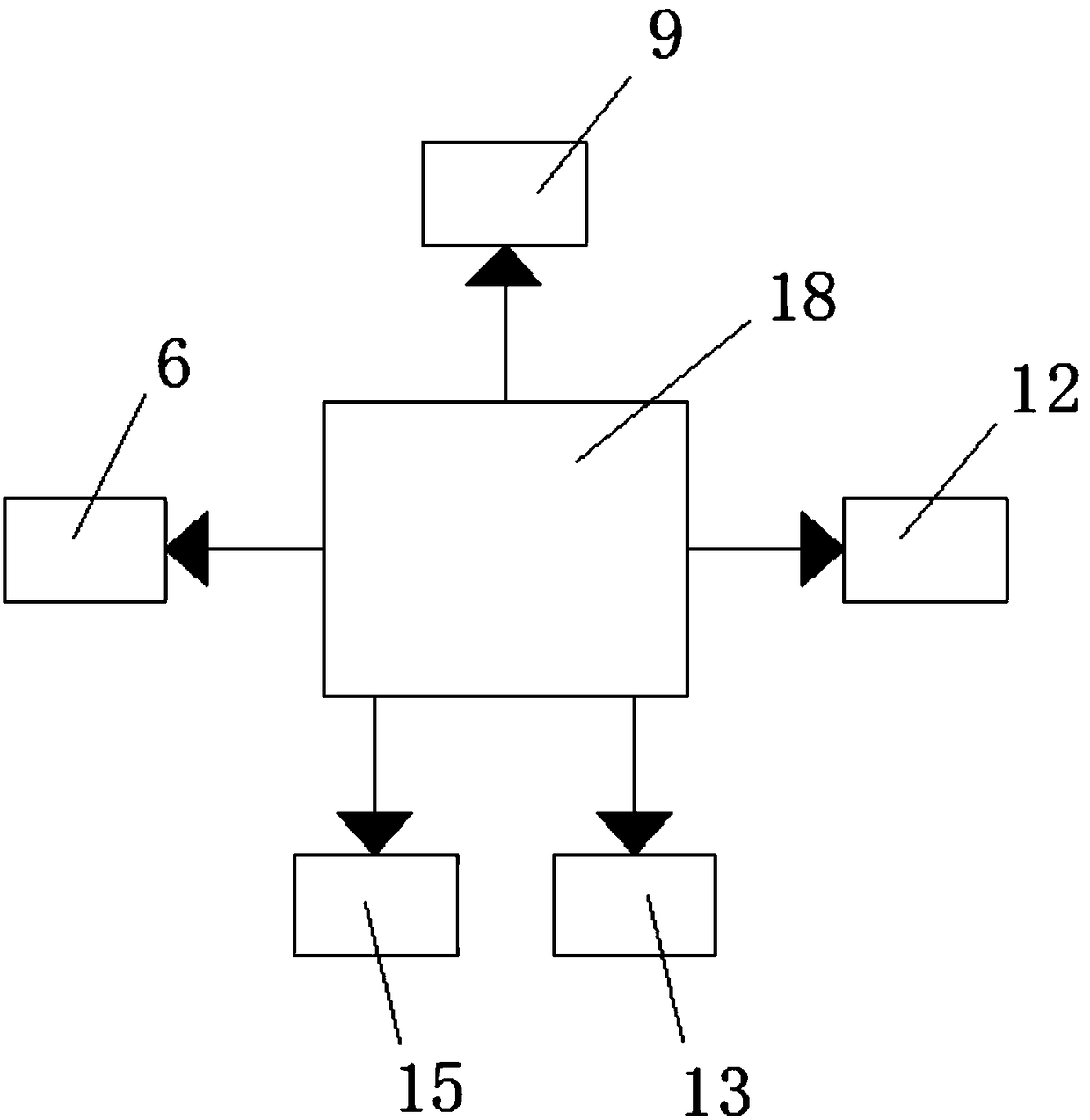

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

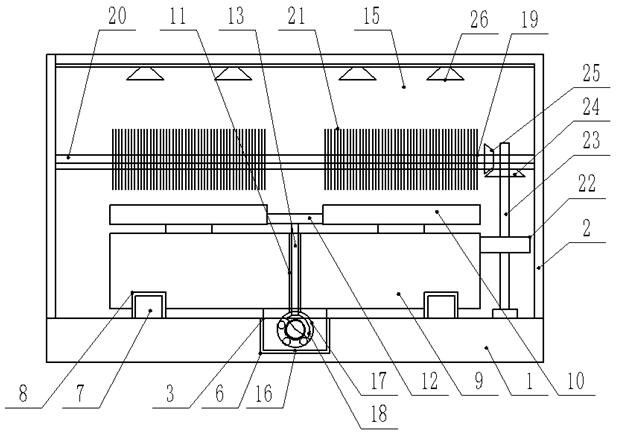

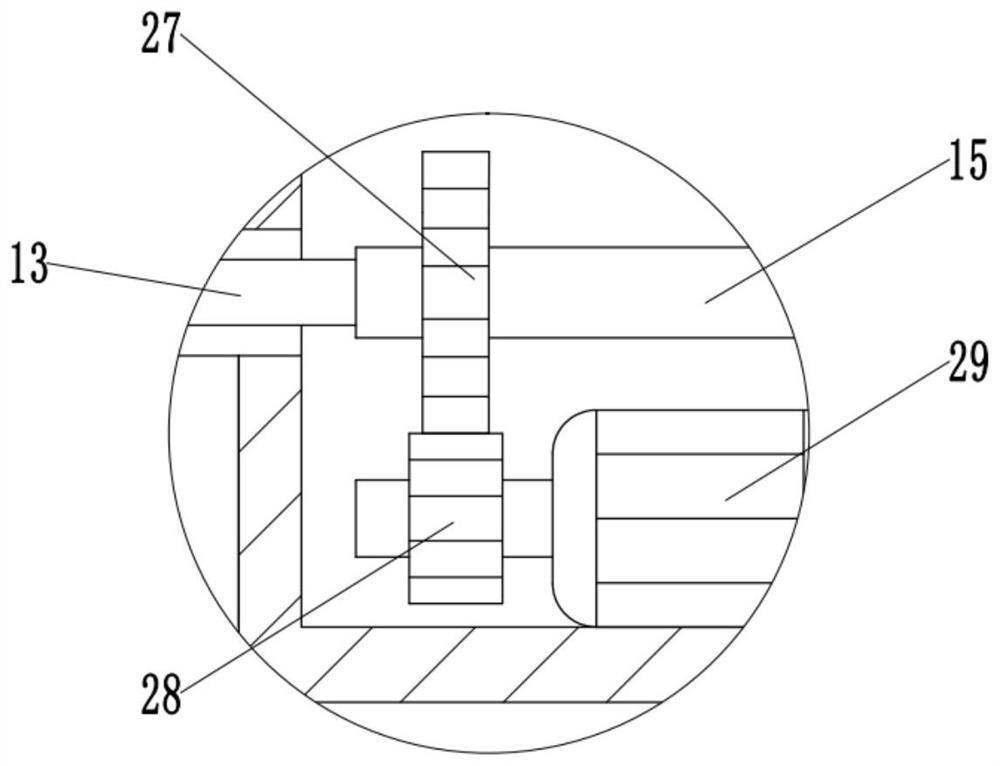

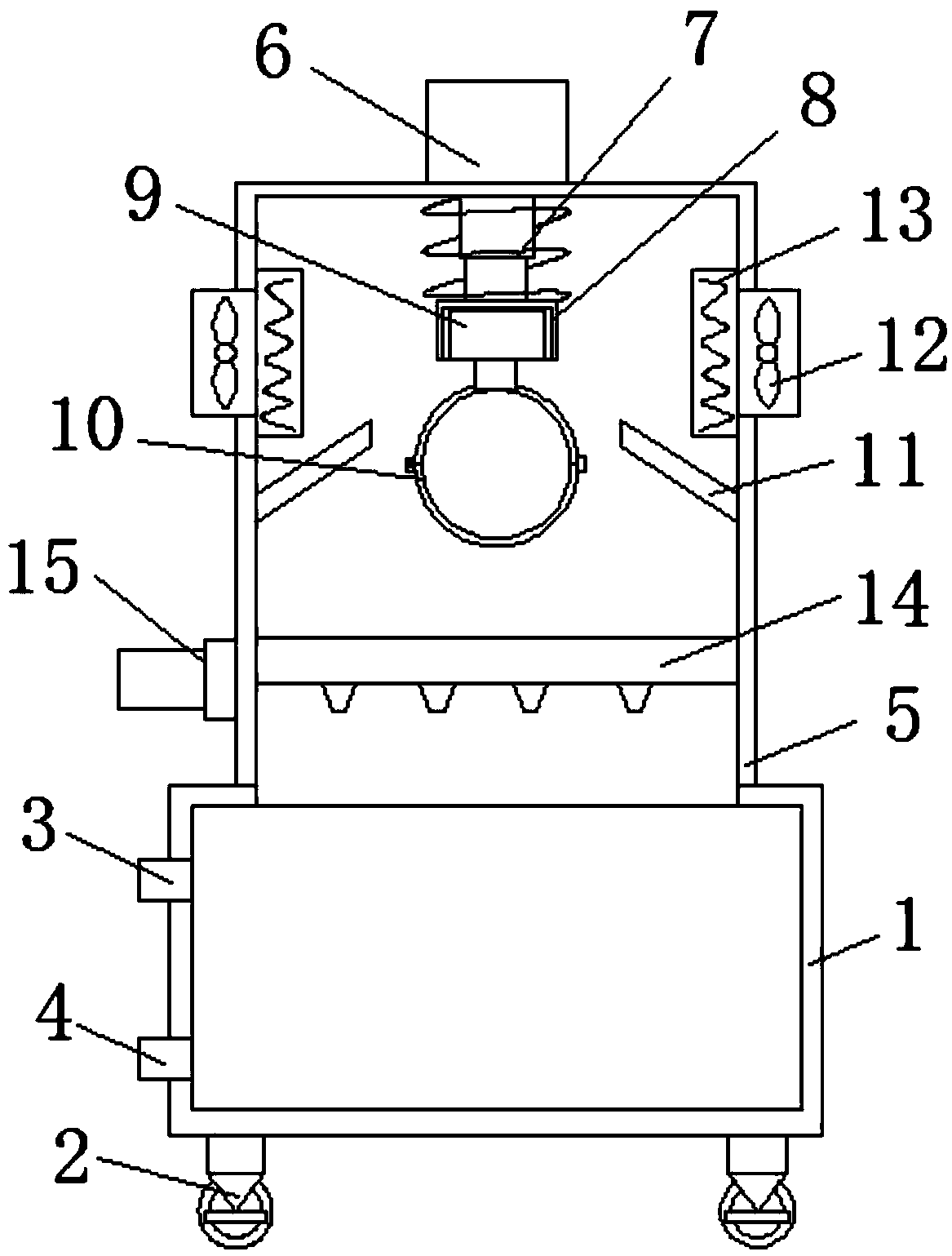

Device for carrying out washing, drying and impurity removing on wheat

ActiveCN108043809ASave waterGood effectDrying gas arrangementsDrying solid materialsEngineeringMechanical engineering

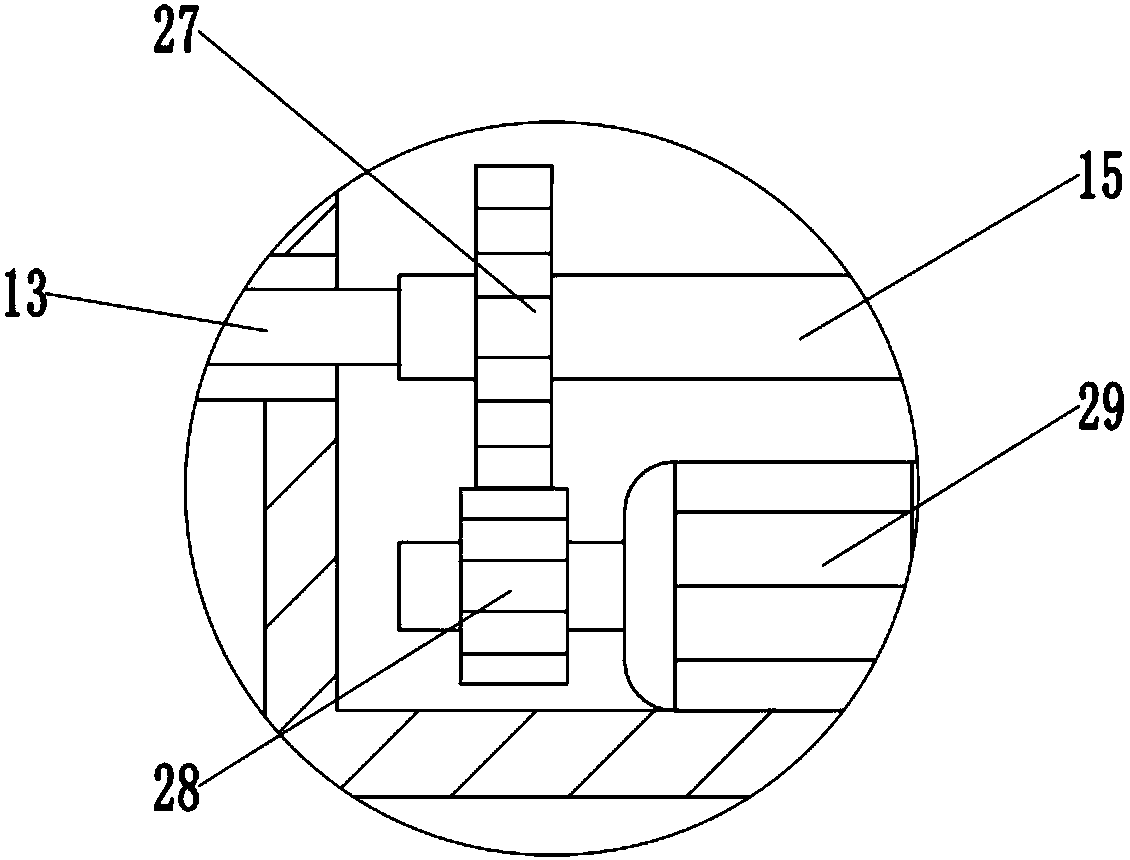

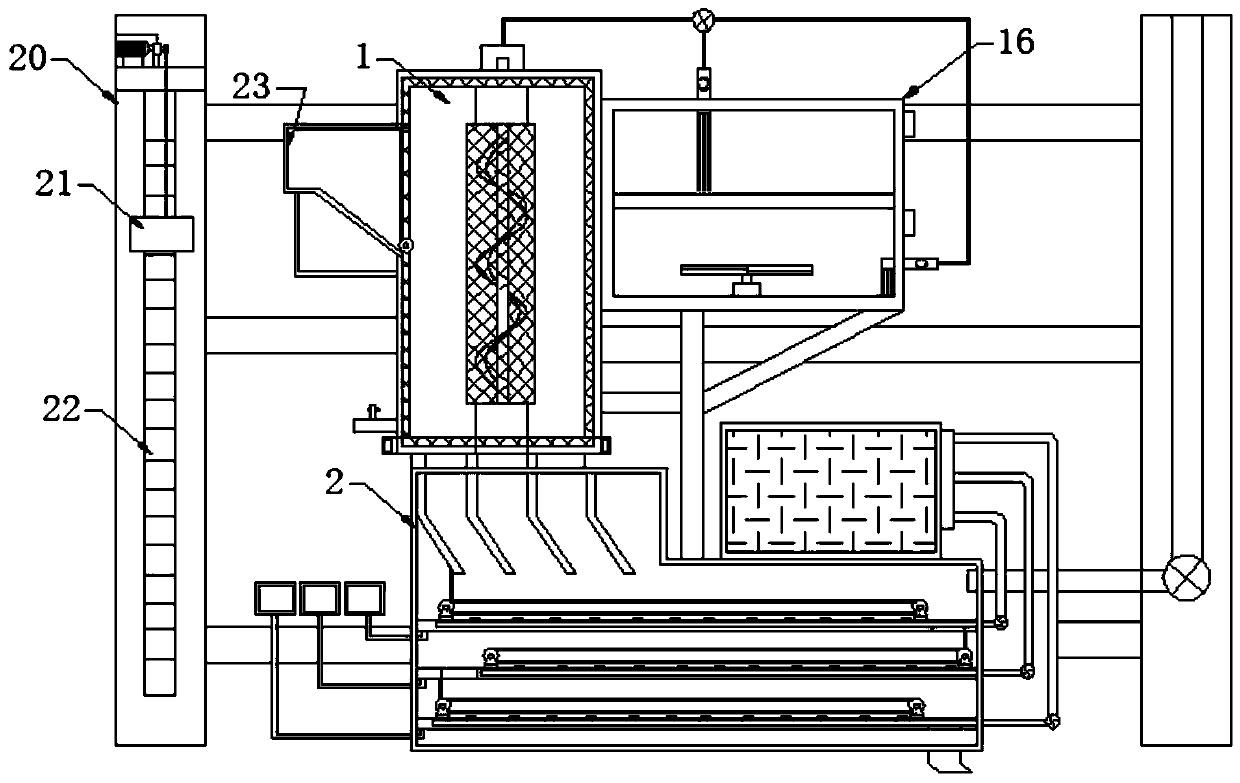

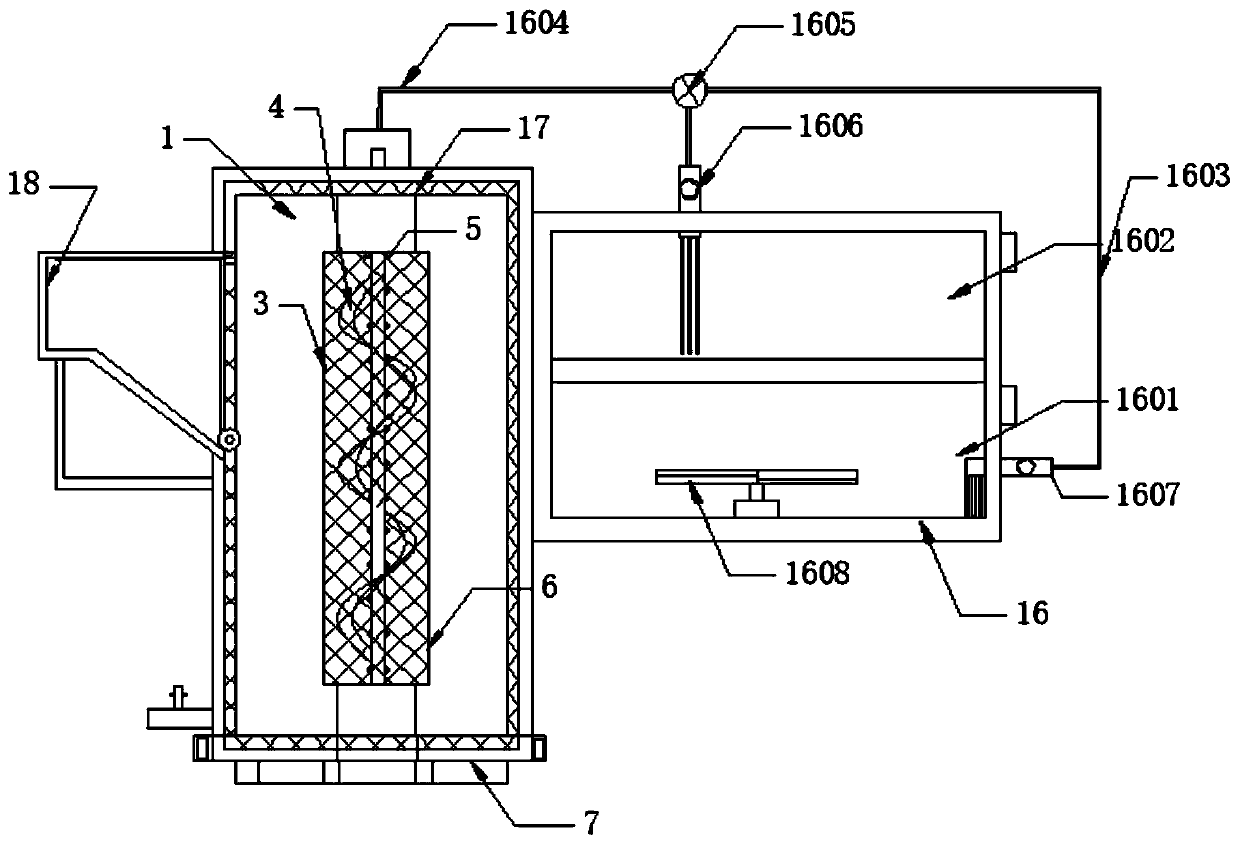

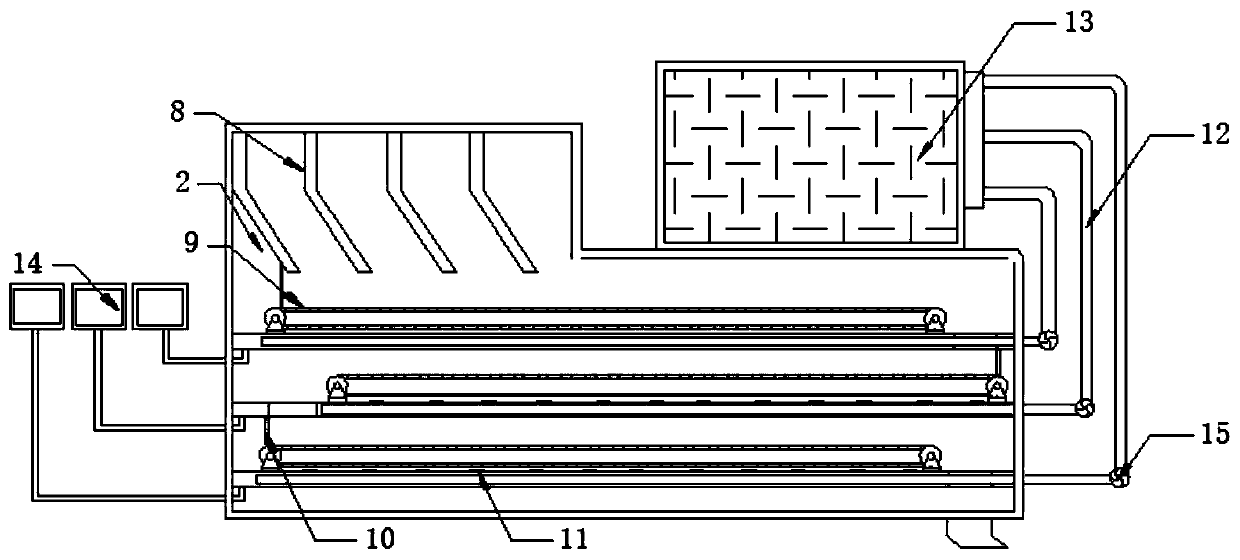

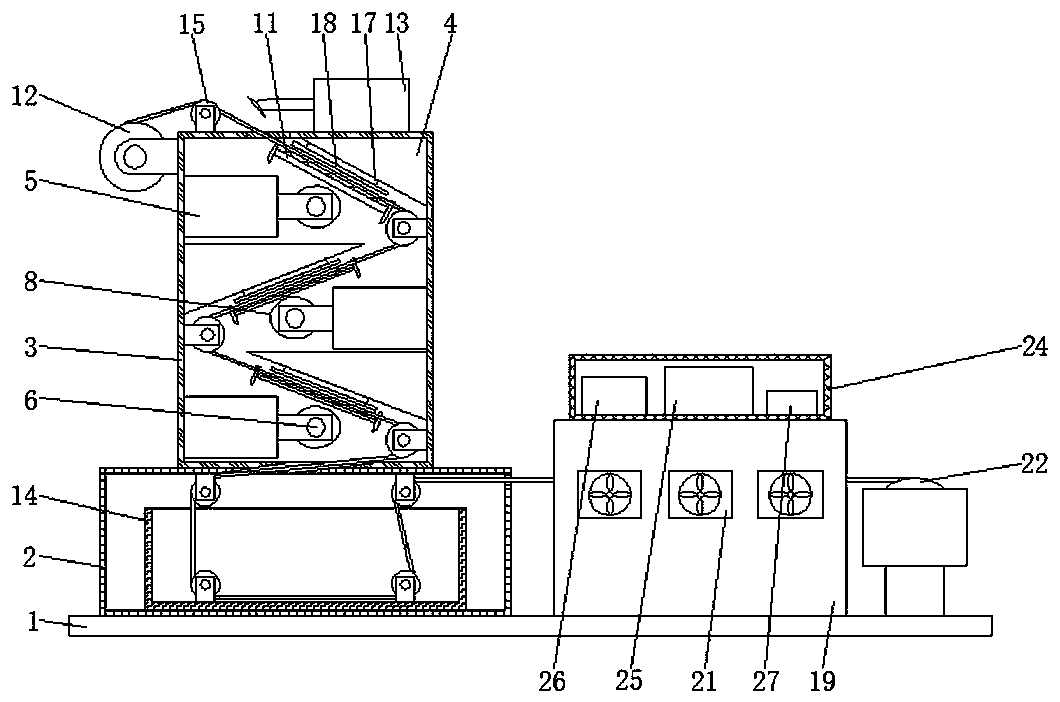

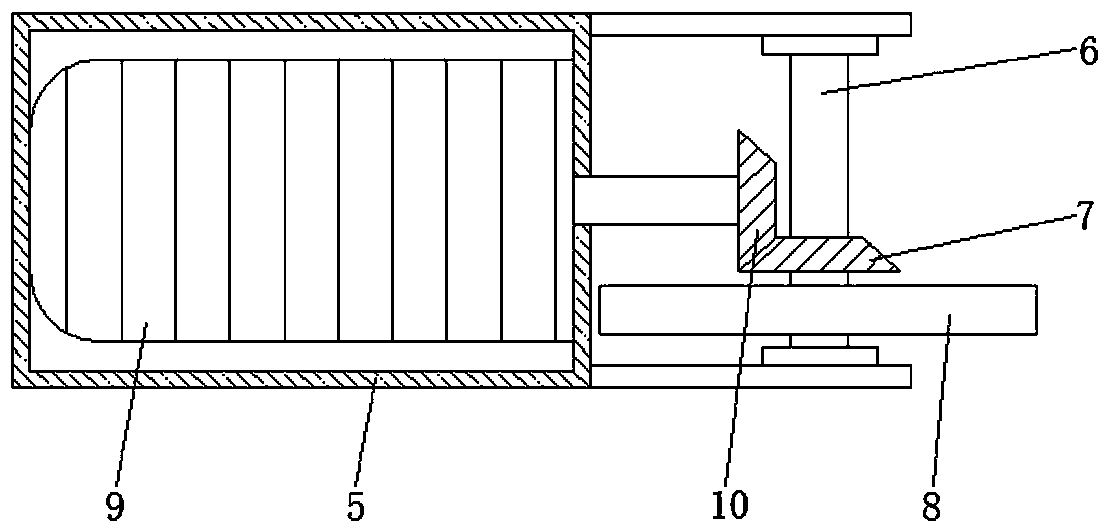

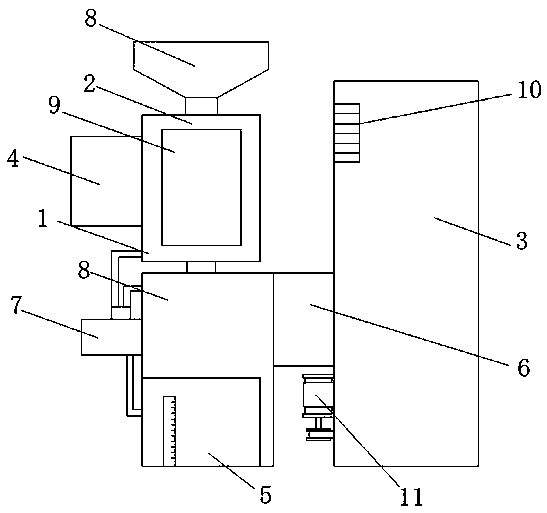

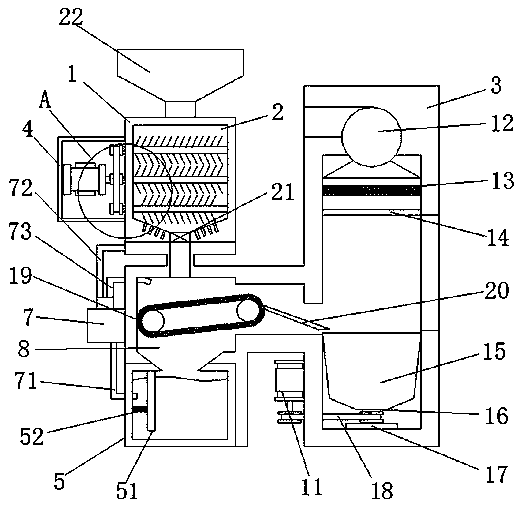

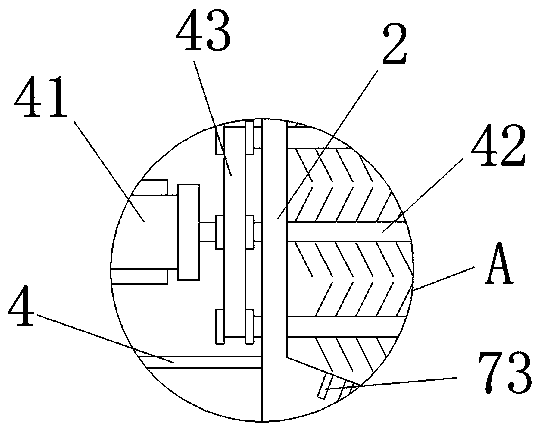

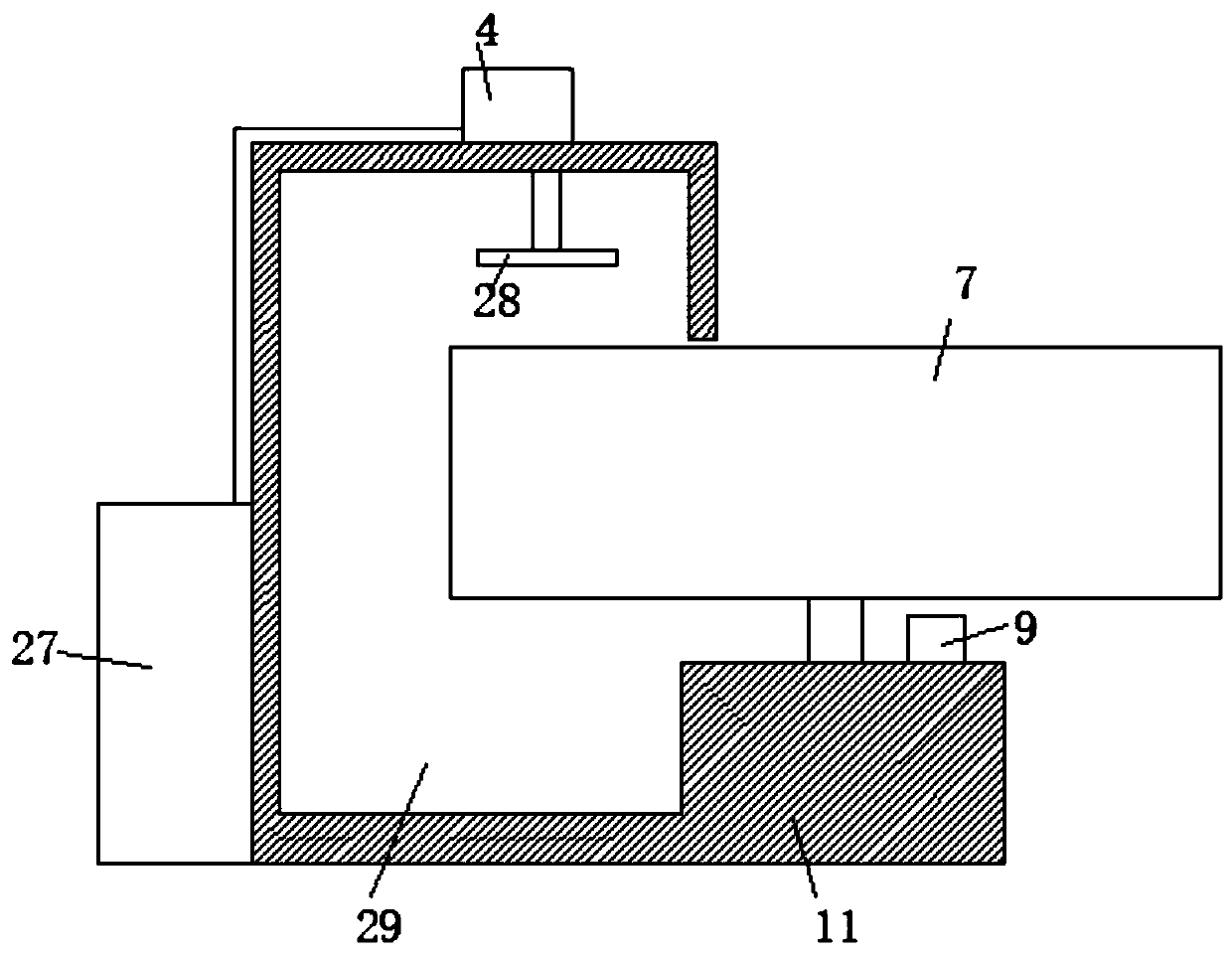

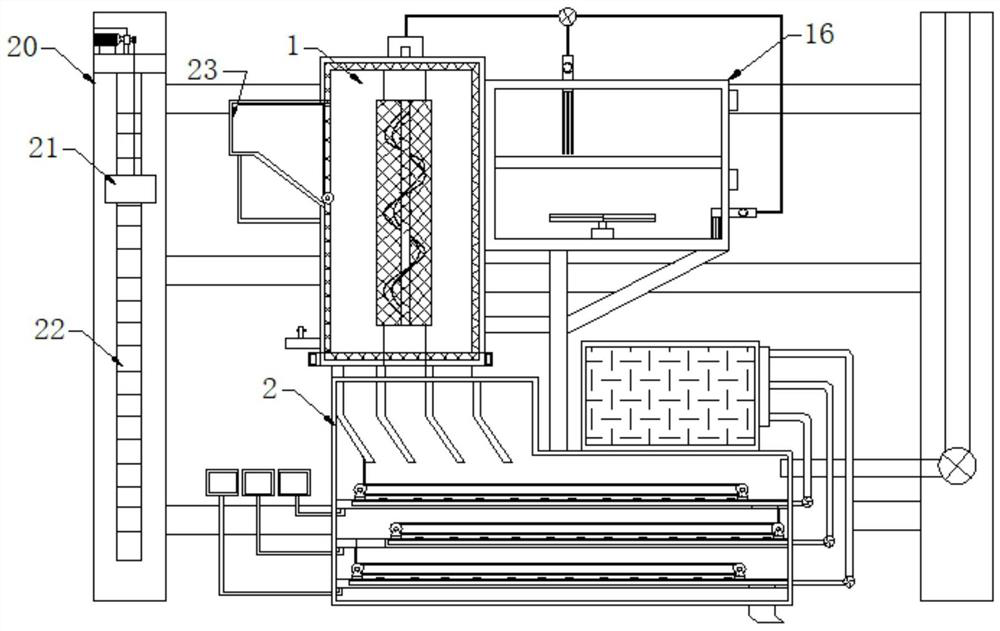

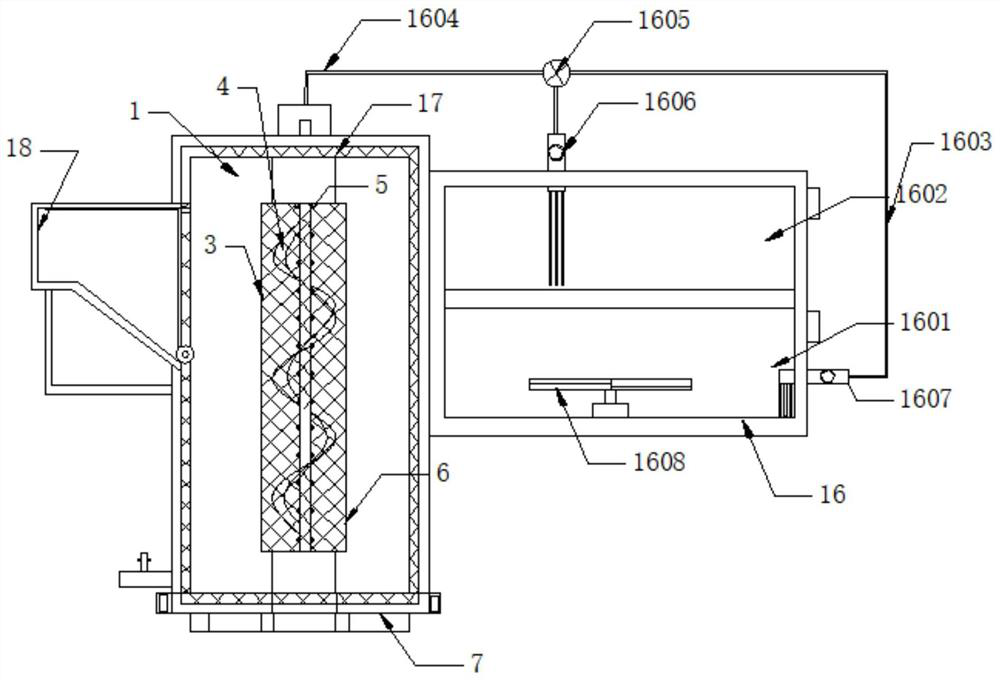

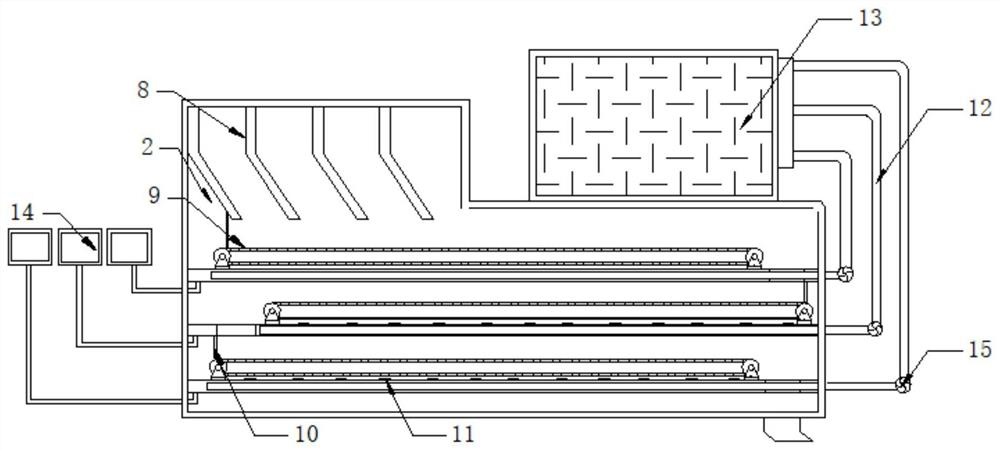

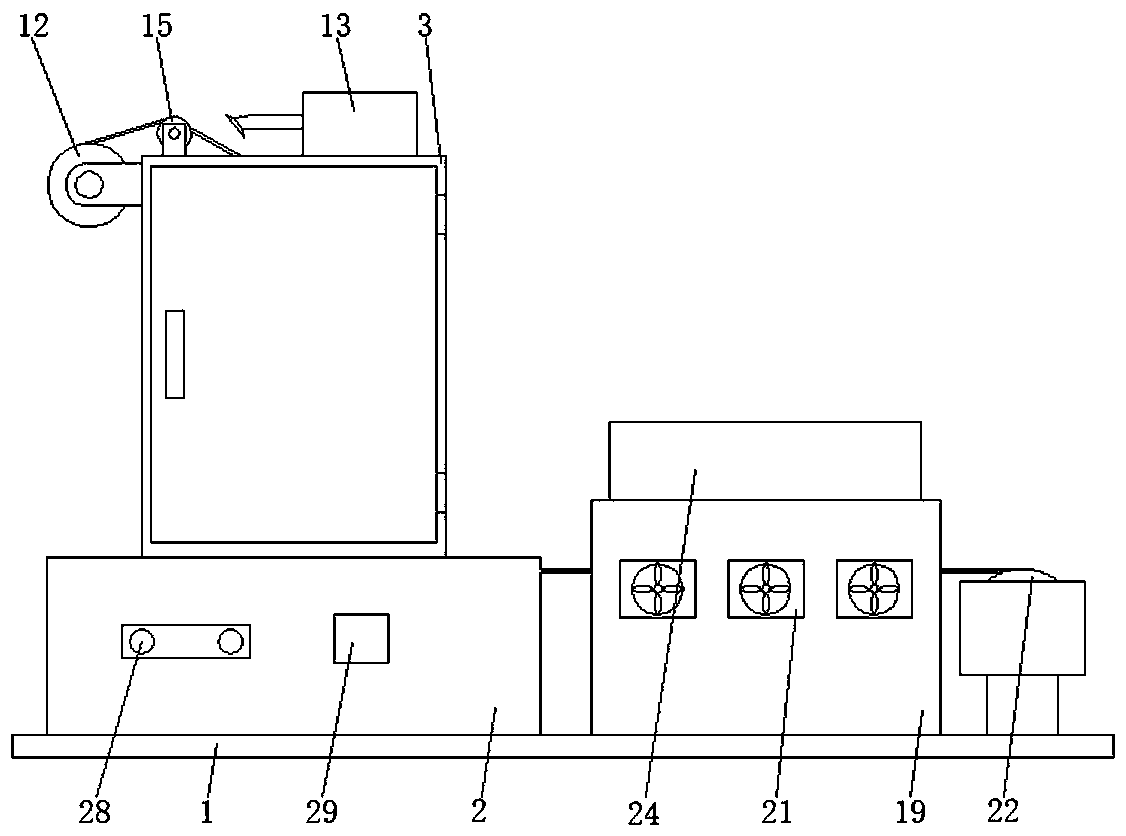

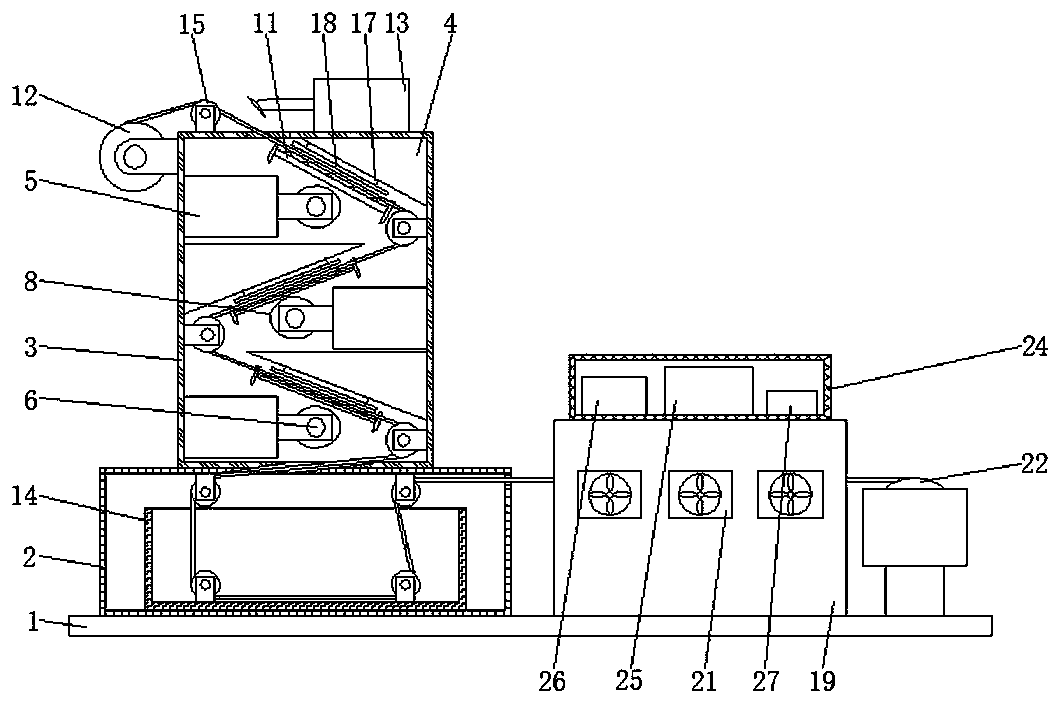

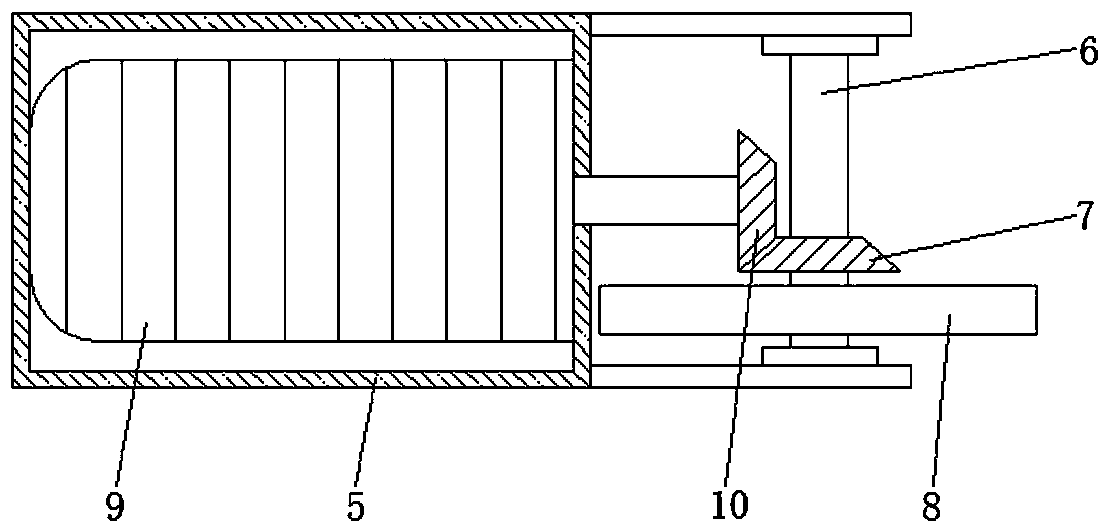

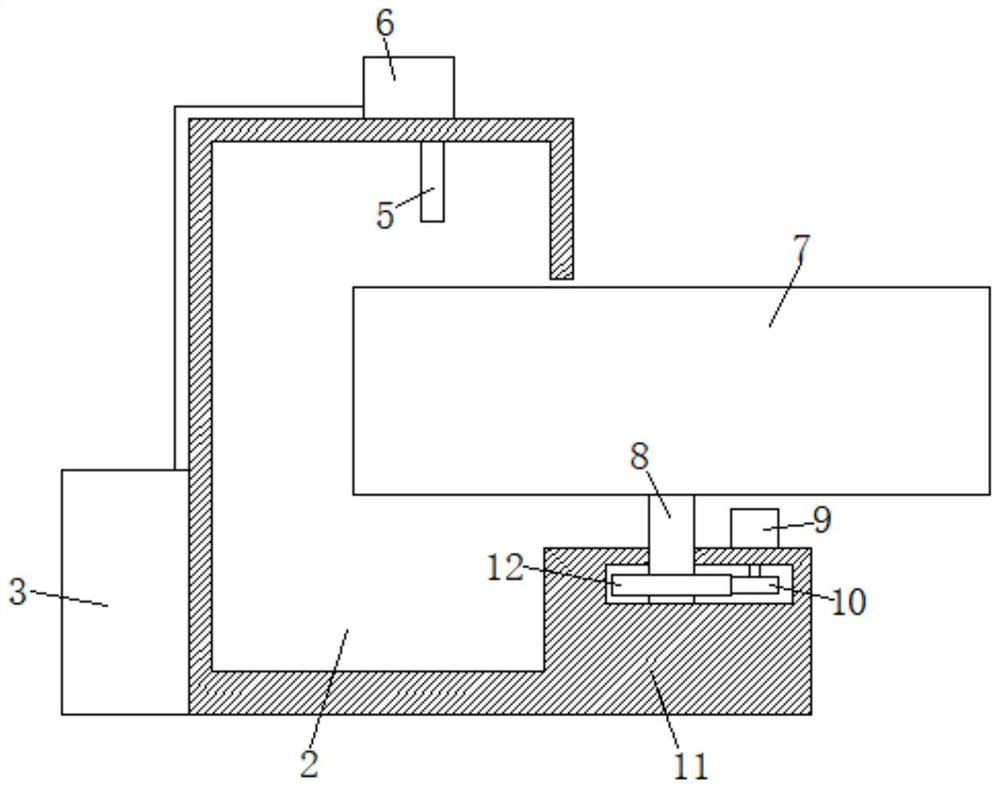

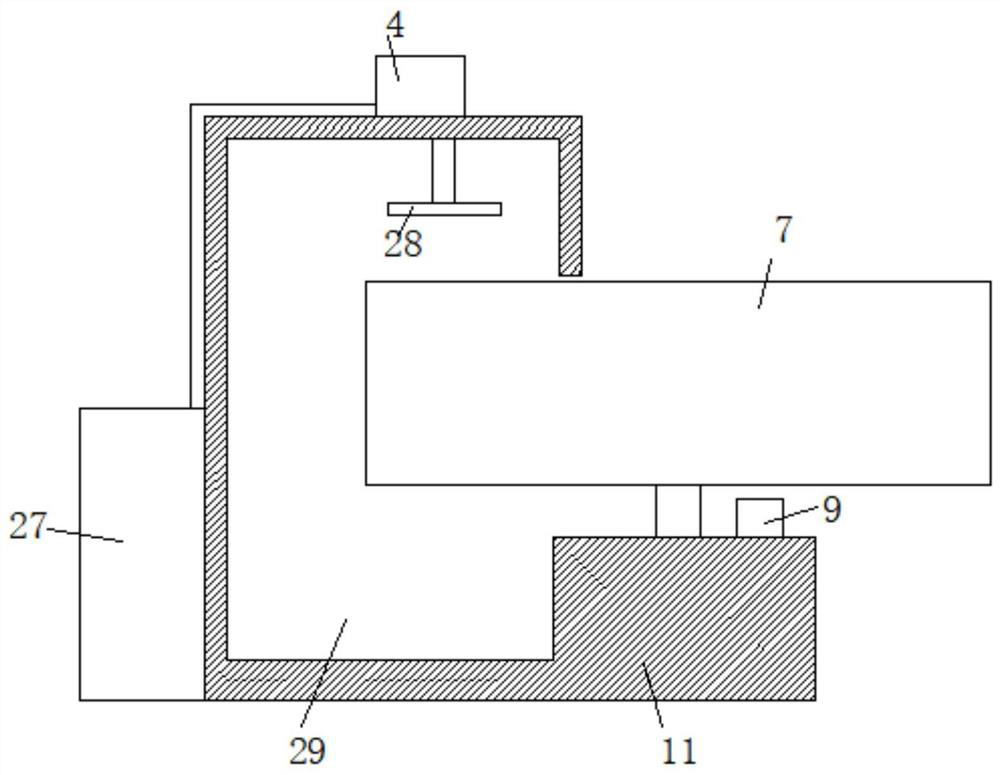

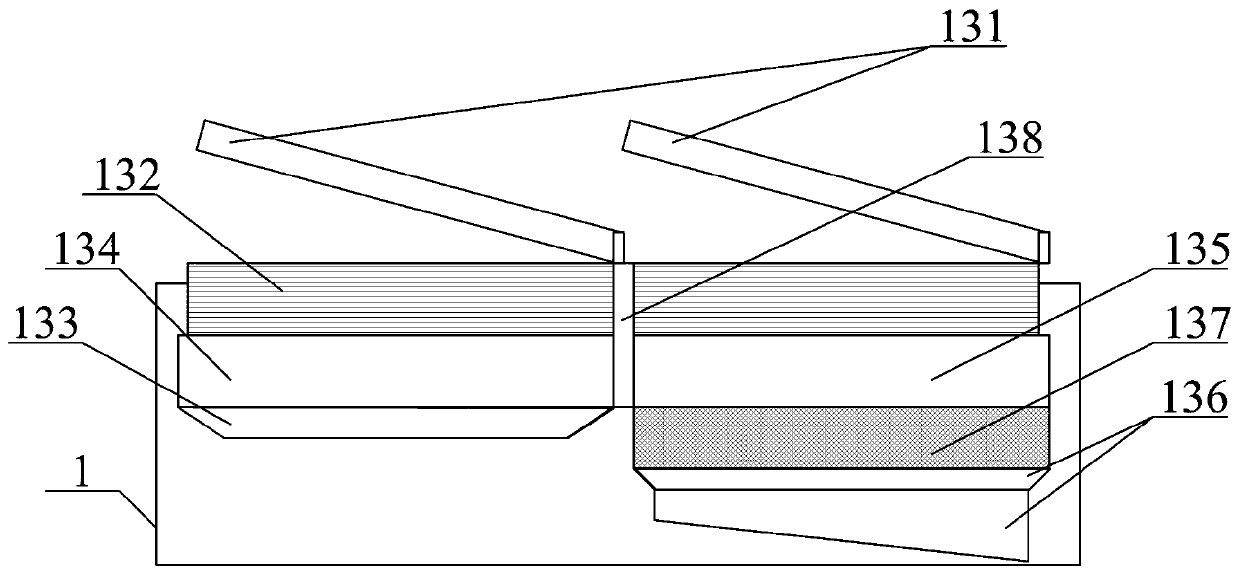

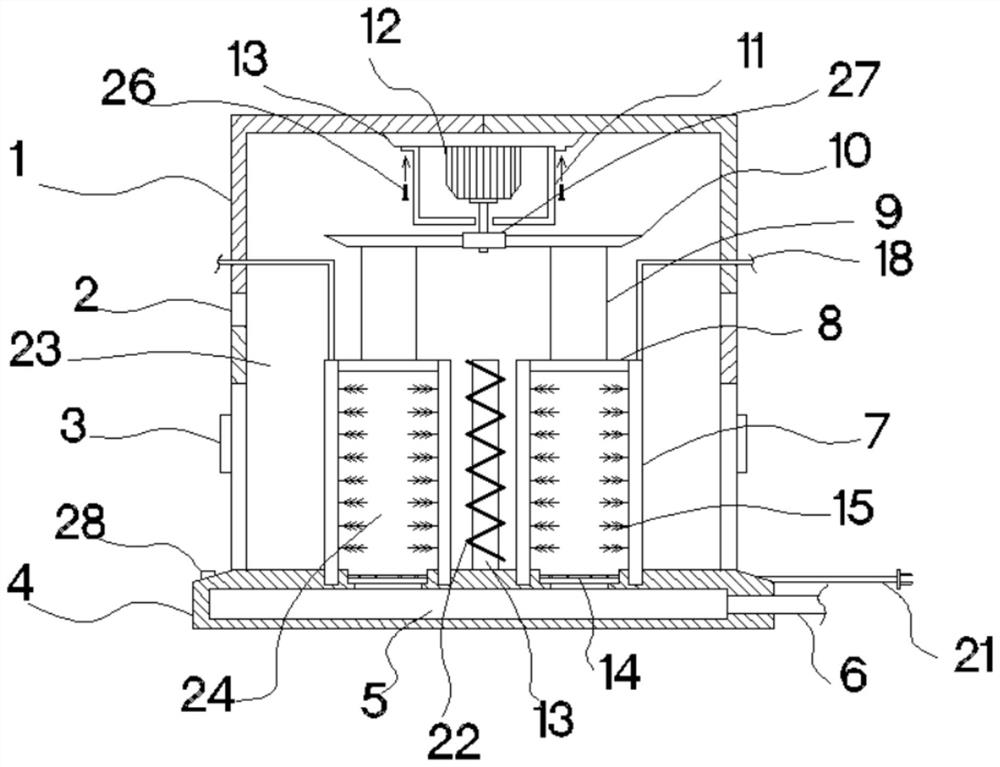

The invention discloses a device for carrying out washing, drying and impurity removing on wheat. The device comprises a machine frame, a cleaning barrel, a drying box and a filtering box, wherein thecleaning barrel is fixedly arranged on the inner wall of the left side of the machine frame; a first rotating shaft is rotationally arranged in the cleaning barrel, a plurality of material turning plates are uniformly arranged on the first rotating shaft, and a cleaning disc is fixedly arranged on the top wall of the cleaning barrel; and a first filter screen is fixedly arranged inside the filtering box; the drying box is fixedly arranged on the inner wall of the machine frame, a partition plate is fixedly arranged in the drying box, the interior of the drying box is divided into a driving chamber and a drying chamber by the partition plate, and the drying chamber communicates with the cleaning barrel. According to the device, second filter screens, cavities and the filtering box are arranged to fully collect and recycle the cleaning water for washing the wheat, so that the water resources are saved; a drying box is further arranged, the wheat is dried by using a hot fan and spiral blades, so that the cleaning and drying effects are excellent, and the economic benefits are improved.

Owner:安徽双全面粉有限公司

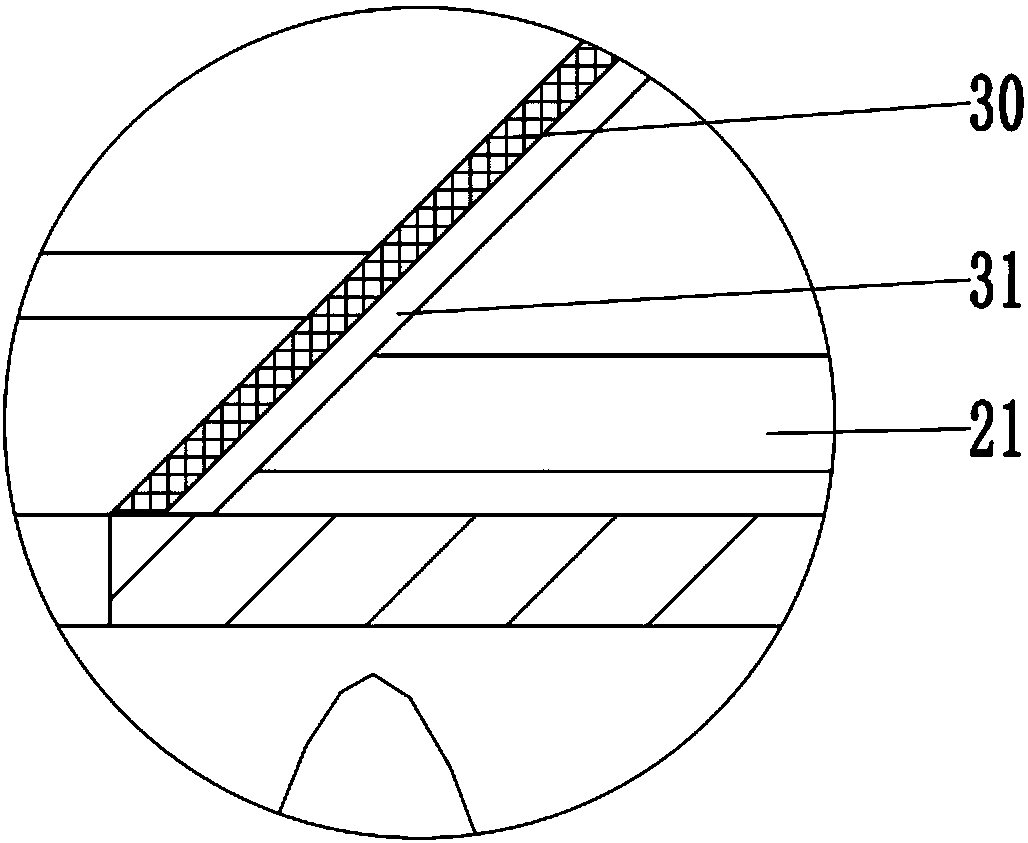

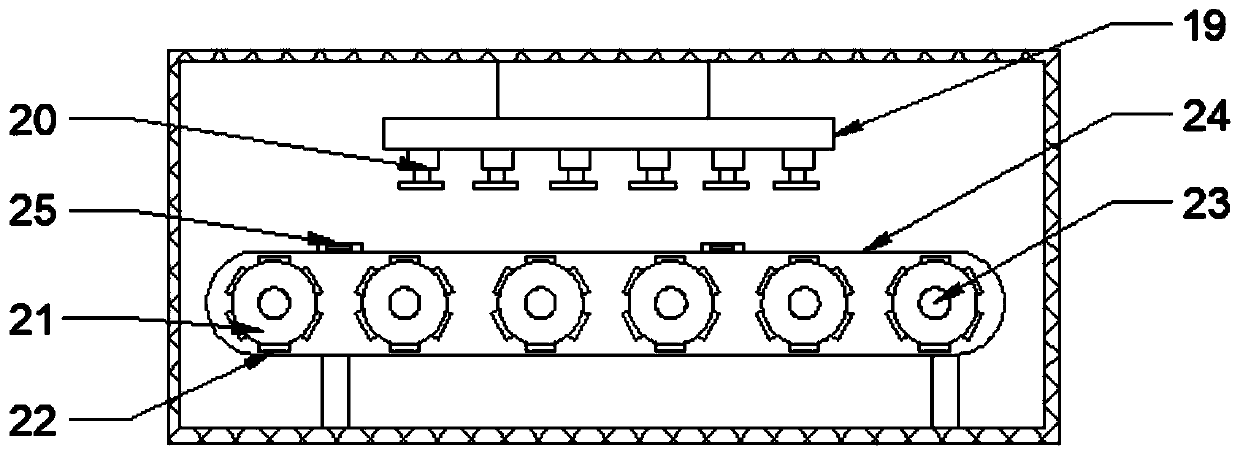

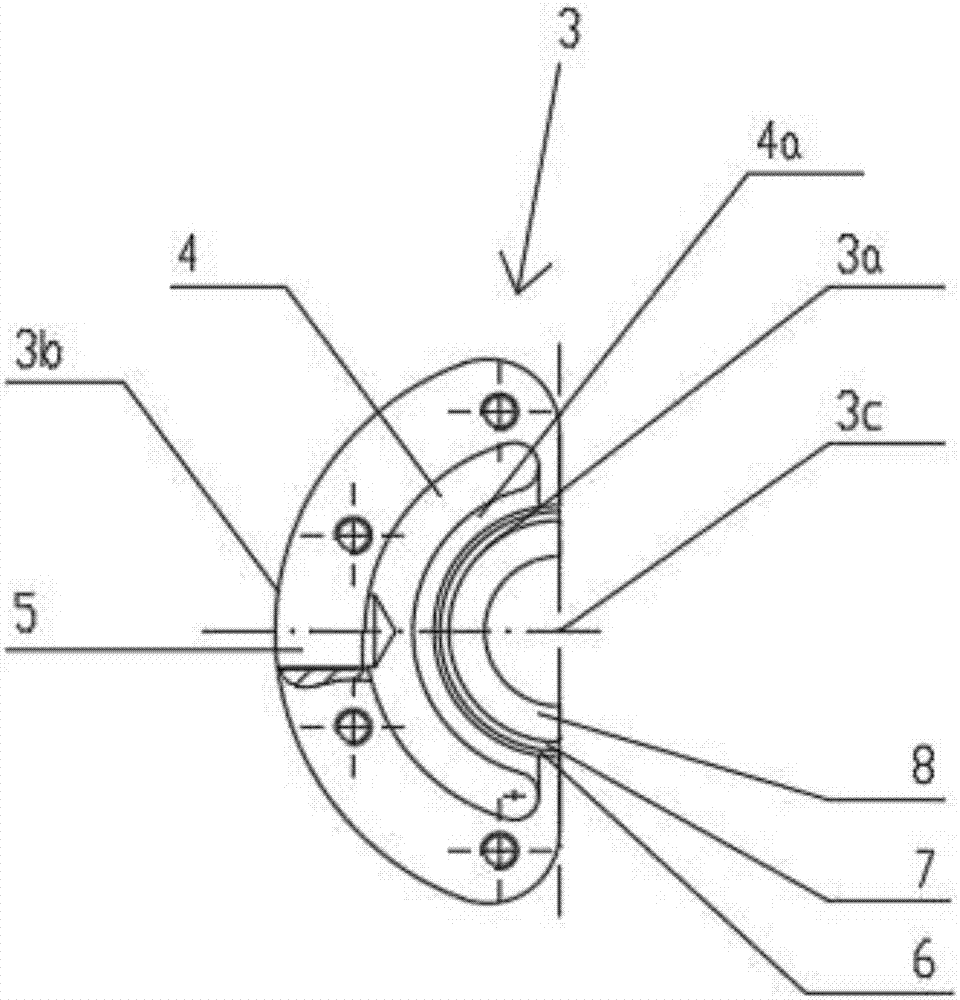

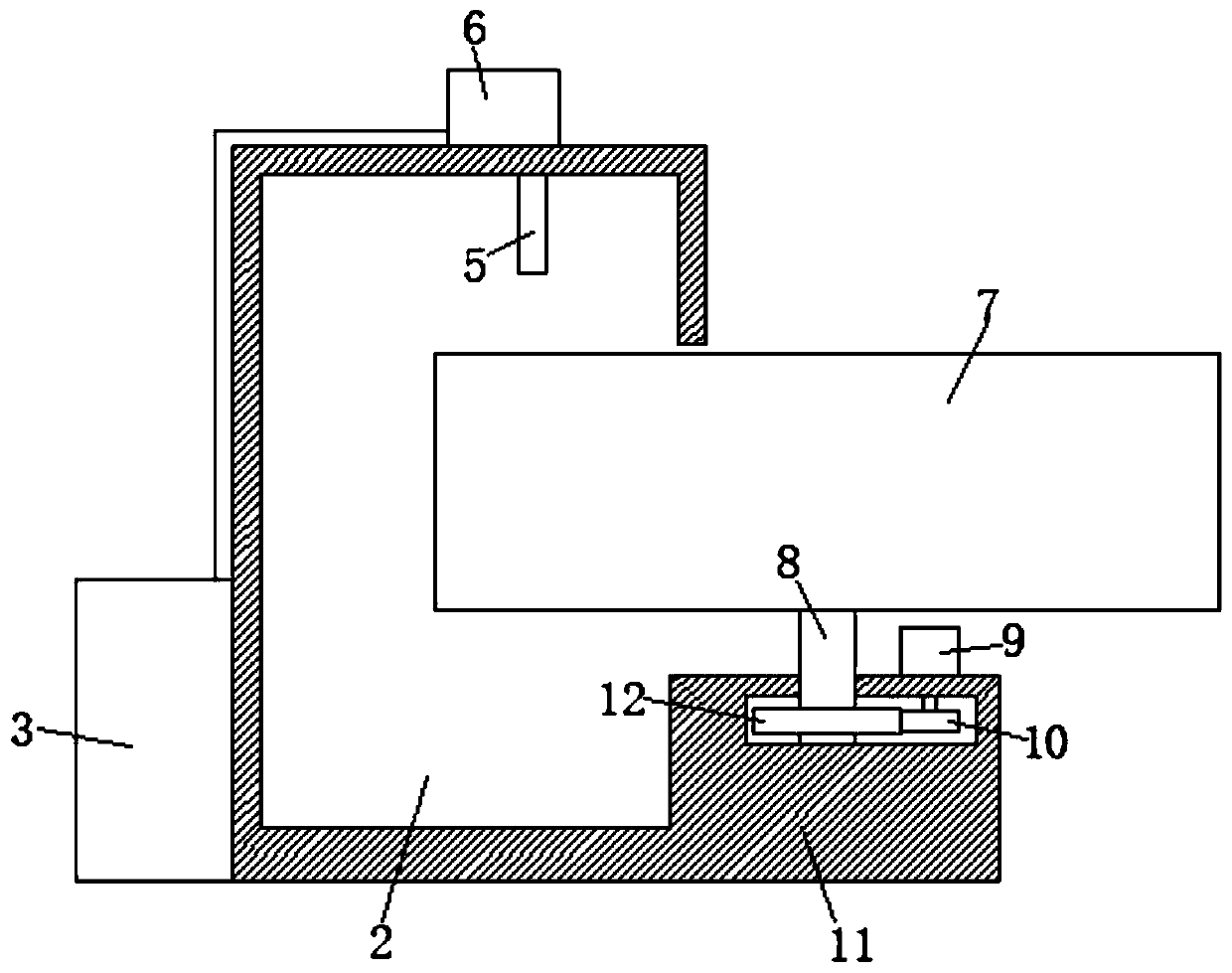

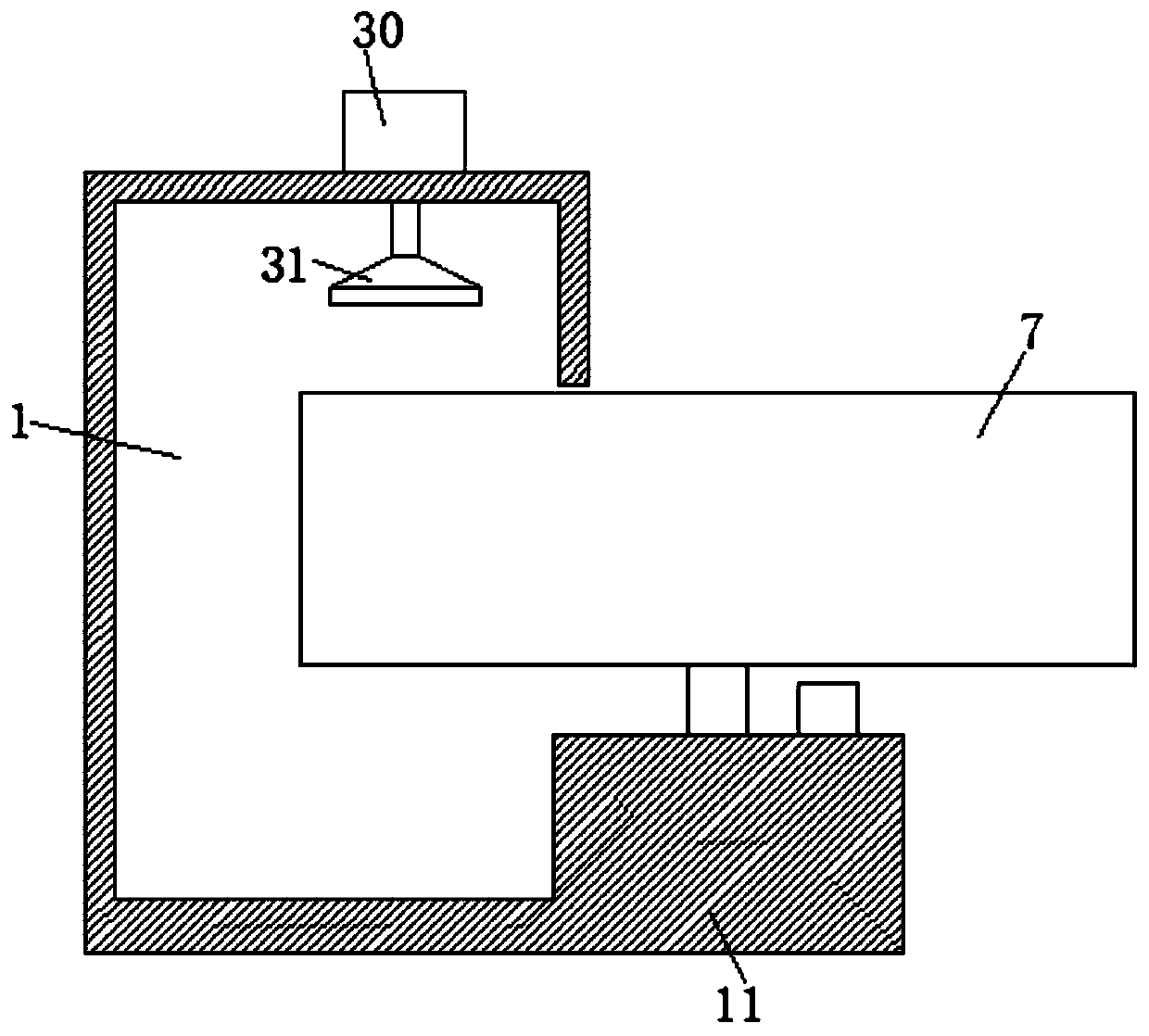

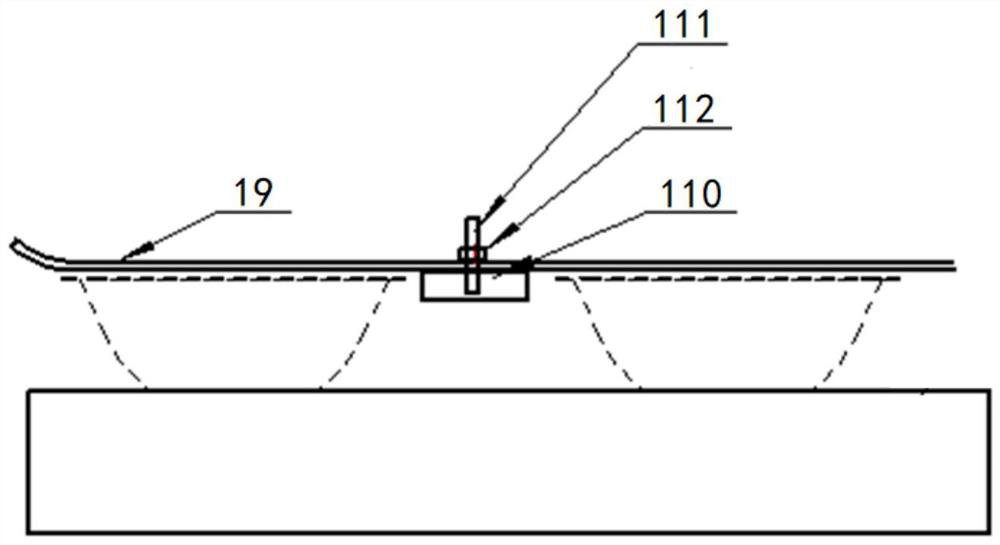

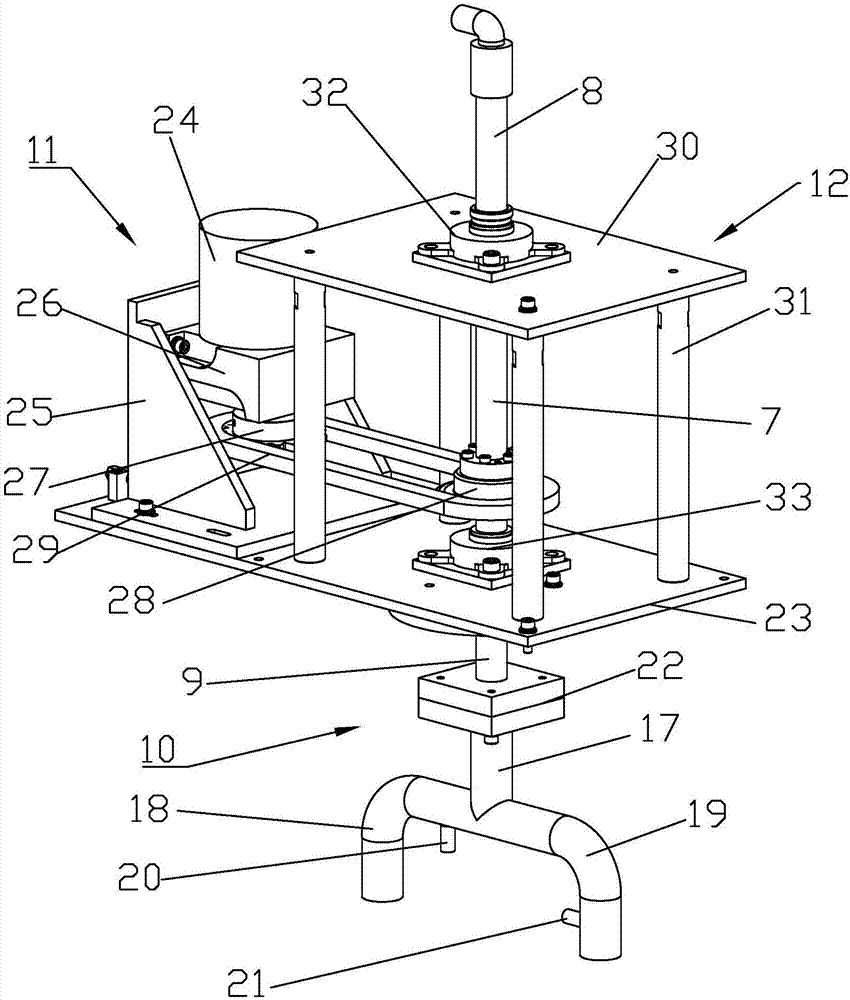

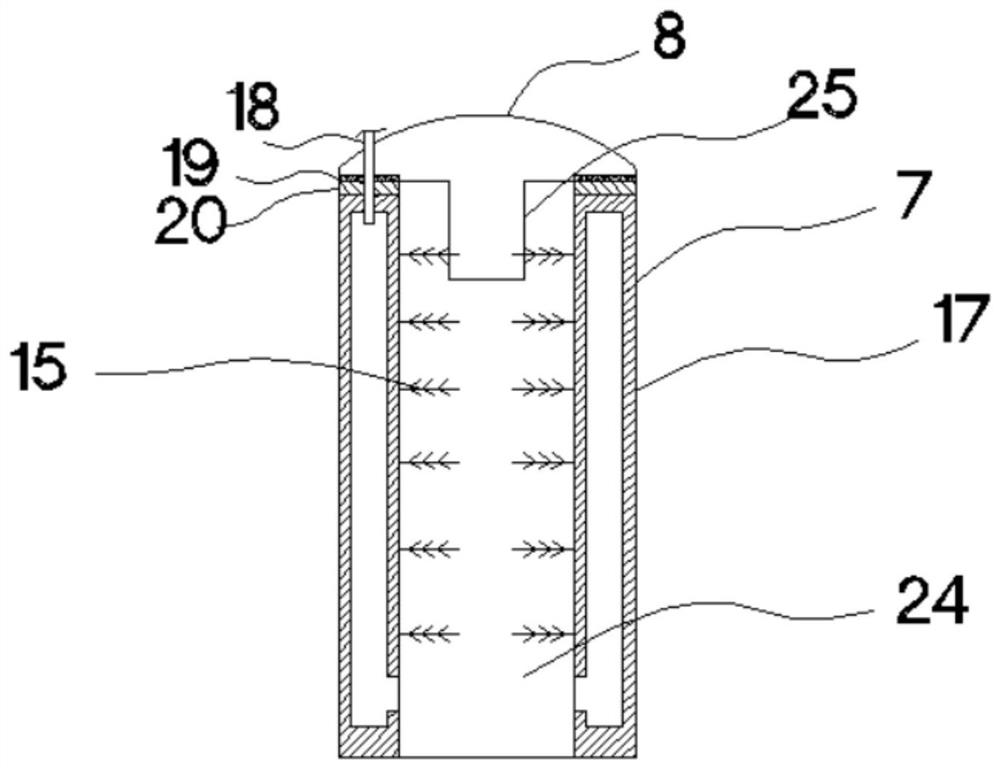

Wafer back surface cleaning and drying device and wafer back surface cleaning and drying system and method

InactiveCN108122813ASimple device structureEffective cleaning and dryingSemiconductor/solid-state device manufacturingEngineeringNozzle

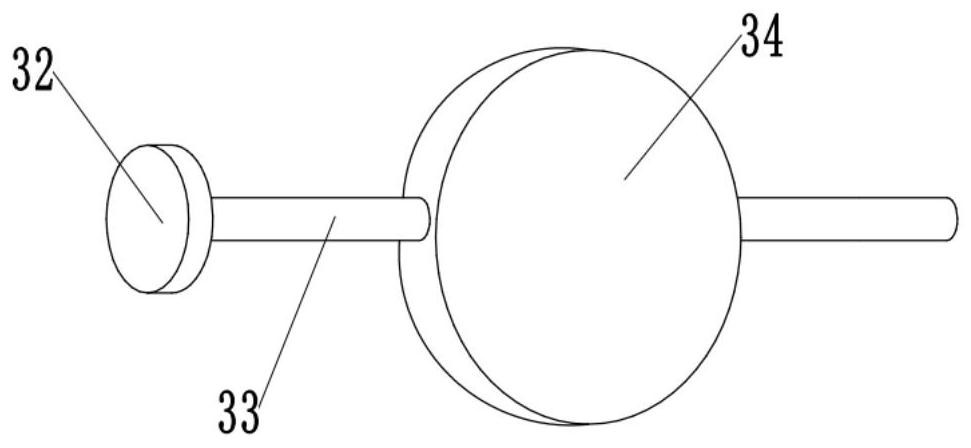

The invention relates to the technical field of wafer back surface cleaning equipment, and particularly relates to a wafer back surface cleaning and drying device and a wafer back surface cleaning anddrying system and method. The wafer back surface cleaning and drying device comprises a wafer clamping device, a first driving device and a spraying mechanism, wherein the wafer clamping device is used for carrying a wafer; the first driving device is used for driving the wafer clamping device to rotate; the spraying mechanism is used for cleaning and drying the back surface of the wafer; and thespraying mechanism comprises a nozzle, and the spraying path of the nozzle for the back surface of the wafer gradually moves from the center of the back surface of the wafer to the edge of the back surface of the wafer. The wafer back surface cleaning and drying system comprises the wafer back surface cleaning and drying device. According to the invention, the back surface of the whole wafer canbe cleaned and dried, the device is simple in structure, and the overlapping of cleaning and drying areas can be realized according to requirements, thereby achieving effective cleaning and drying forthe back surface of the wafer, and improving the cleaning and drying effect of the back surface of the wafer.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

Cleaning and drying device for woollen sweater processing

InactiveCN111575962AGuaranteed purityEasy to operateLiquid/gas/vapor article treatmentTextile treatment machine arrangementsSolenoid valveStructural engineering

The invention discloses a cleaning and drying device for woollen sweater processing. The cleaning and drying device comprises a mounting rack. The mounting rack is mounted at the top of a base. A cleaning box and a liquor mixing box are mounted at the top of the base. The liquor mixing box communicates with the cleaning box through a water pipe. A solenoid valve and a pressure pump are arranged onthe water pipe. A containing mechanism is arranged in the cleaning box. A limiting sliding rail is arranged at the position, corresponding to the containing mechanism, in the cleaning box. A limitingblock is mounted at the bottom end of the limiting sliding rail. A vibration mechanism and an extrusion and rubbing cleaning mechanism are arranged at the position, corresponding to the containing mechanism, of one side of the mounting rack. A stirring mechanism and a heater are arranged on the liquor mixing box. The top of the liquor mixing box is connected with the bottom of a drying box through a fixed frame. A drying mechanism is arranged on the drying box and communicates with an air heater through a division pipe. The cleaning and drying device is convenient to use, good in cleaning anddrying effect, high in drying efficiency and work efficiency and capable of reducing the labor intensity of workers.

Owner:WUJIANG CITY QIDU TOWN MIAOGANG YADI KNITTING GARMENT FACTORY

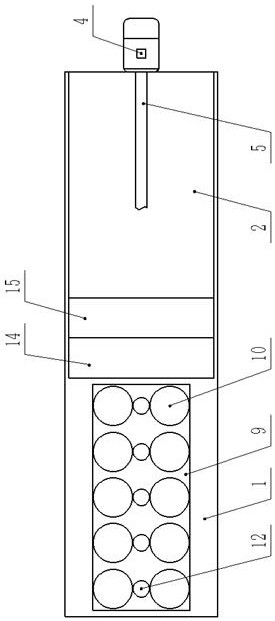

Fruit cleaning device

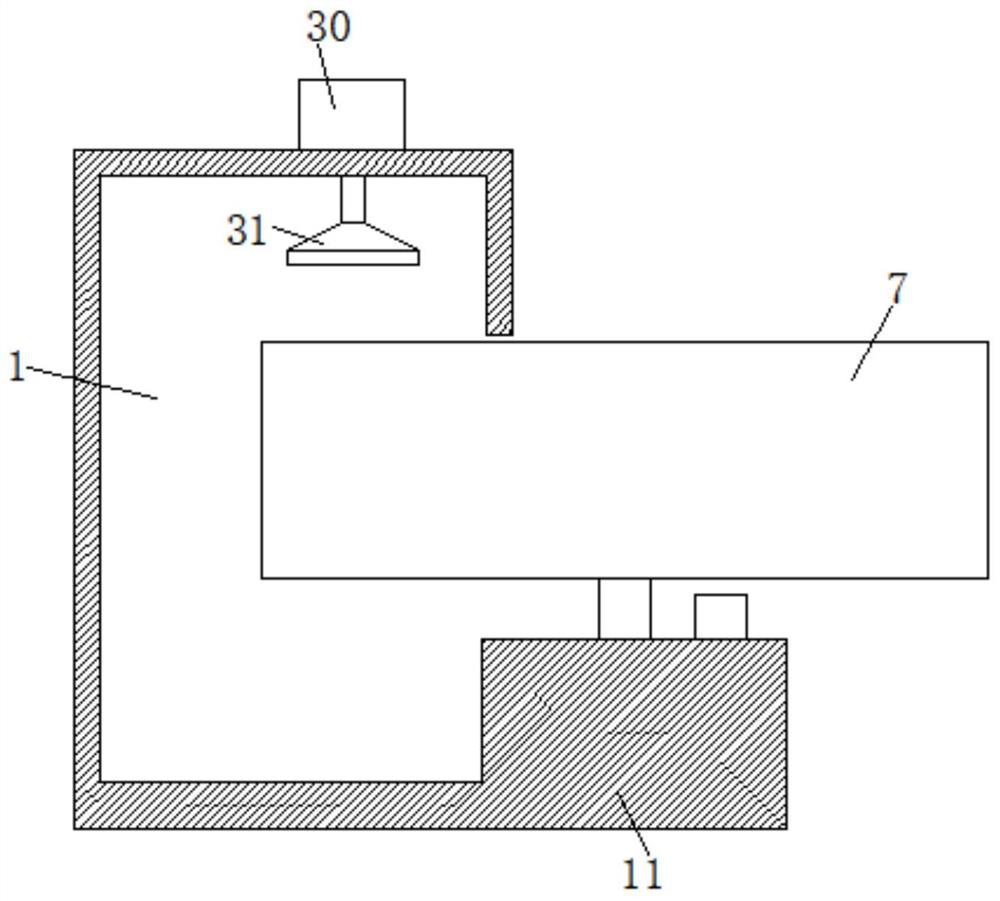

The invention discloses a fruit cleaning device, which comprises a cleaning box, and is in the shape of a rectangular shell. A motor is vertically arranged at the center of the outer wall of a top plate, and an output end thereof faces downward and extends into the interior of the cleaning box. A hollow round rod-shaped cleaning core is coaxially arranged along the output end of the motor, and a plurality of nozzles for spraying cleaning liquid or clean water to the inner cavity of the cleaning box are arranged vertically along the wall of the core, and the nozzle and the cleaning core are connected. a stirring fan blade is spirally arranged from the upper side to the lower side of the outer wall of the cleaning core, a protective net cover is disposed on the outer side of the cleaning core, the stirring fan blade is covered inside. An upper part of the side wall of the cleaning box is provided with an openable feeding hopper, and a bottom of the cleaning box is provided with an openable discharge opening; and a drying chamber is located directly below the discharge opening of the cleaning box for drying the washed fruit of the cleaning box. The device can clean the fruit thoroughly and quickly, and can be widely used in the field of equipment manufacturing.

Owner:WUHAN BUSINESS UNIV

Multifunctional nursing department self-cleaning type towel storage device

InactiveCN107049677AImprove the display effectConvenient instructionsOther washing machinesWashing machine with receptaclesWater storageAutomatic control

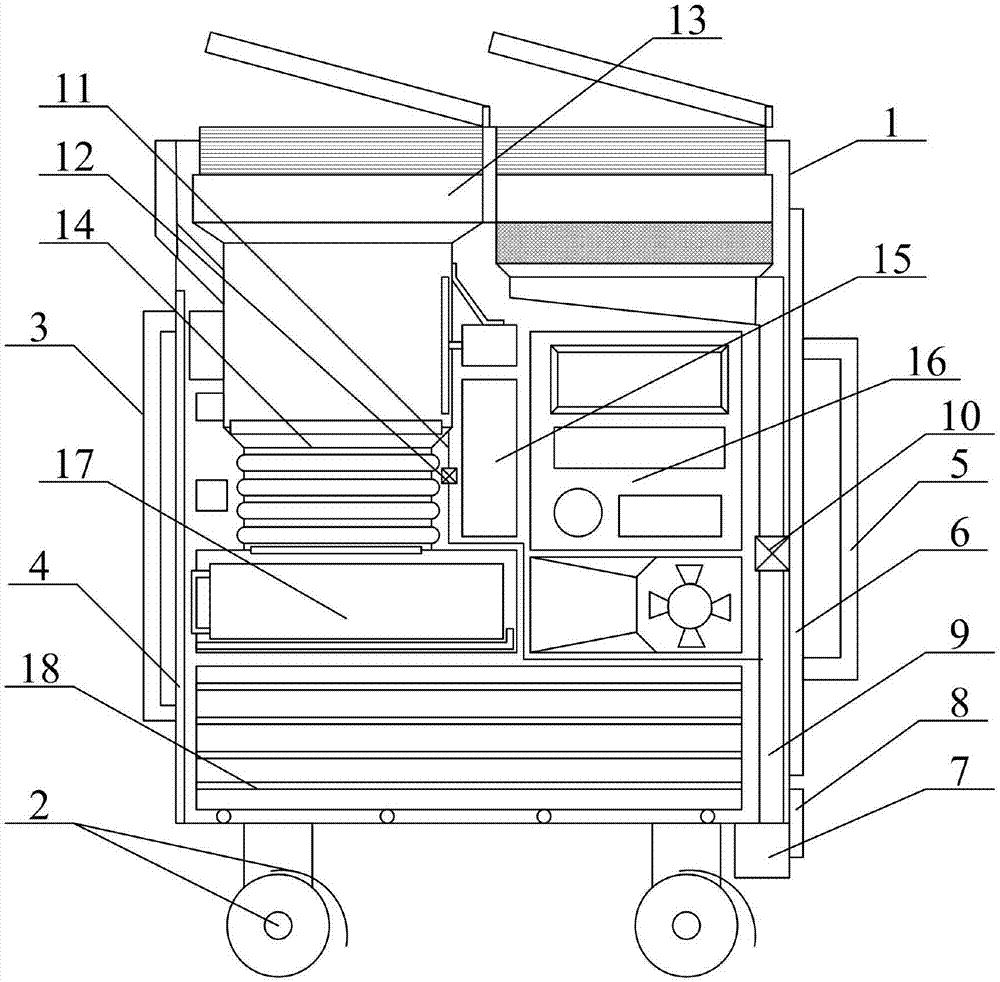

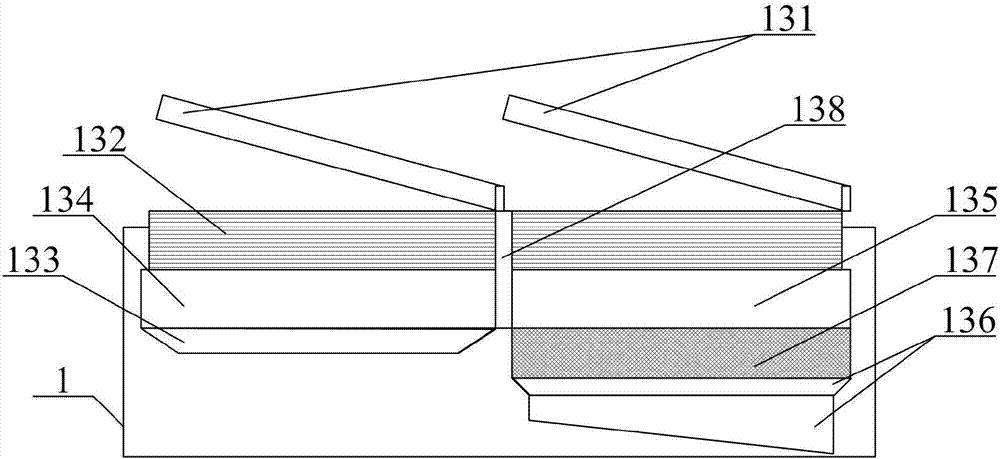

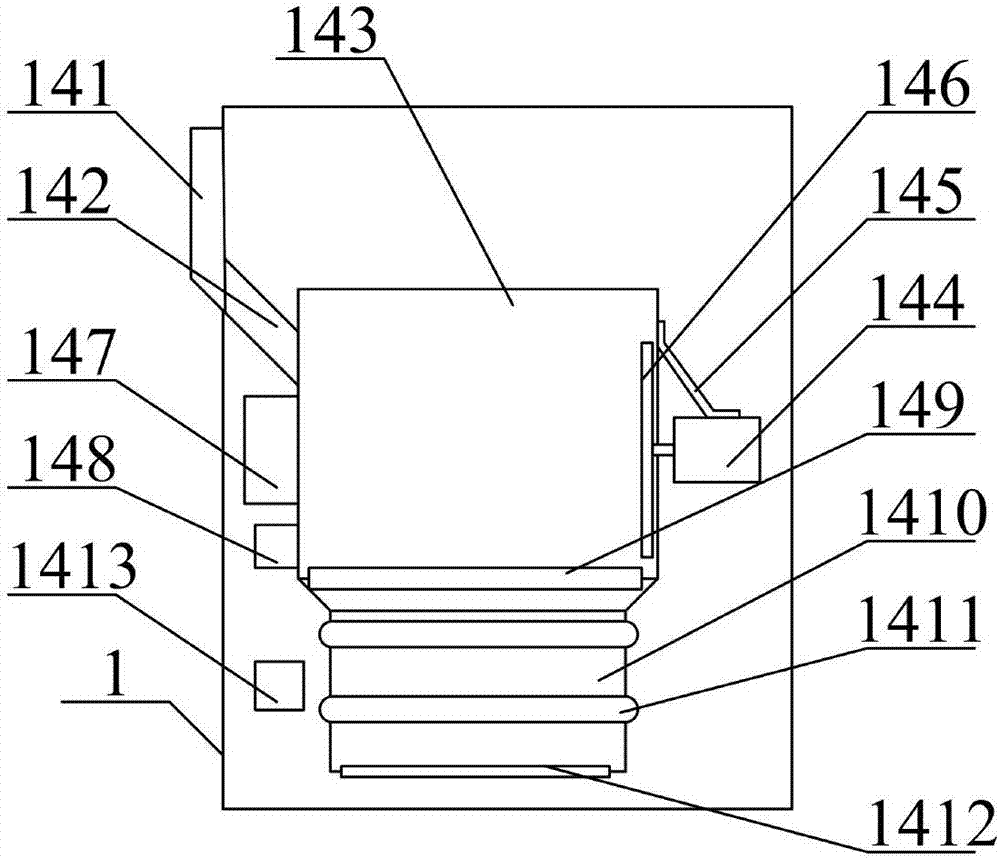

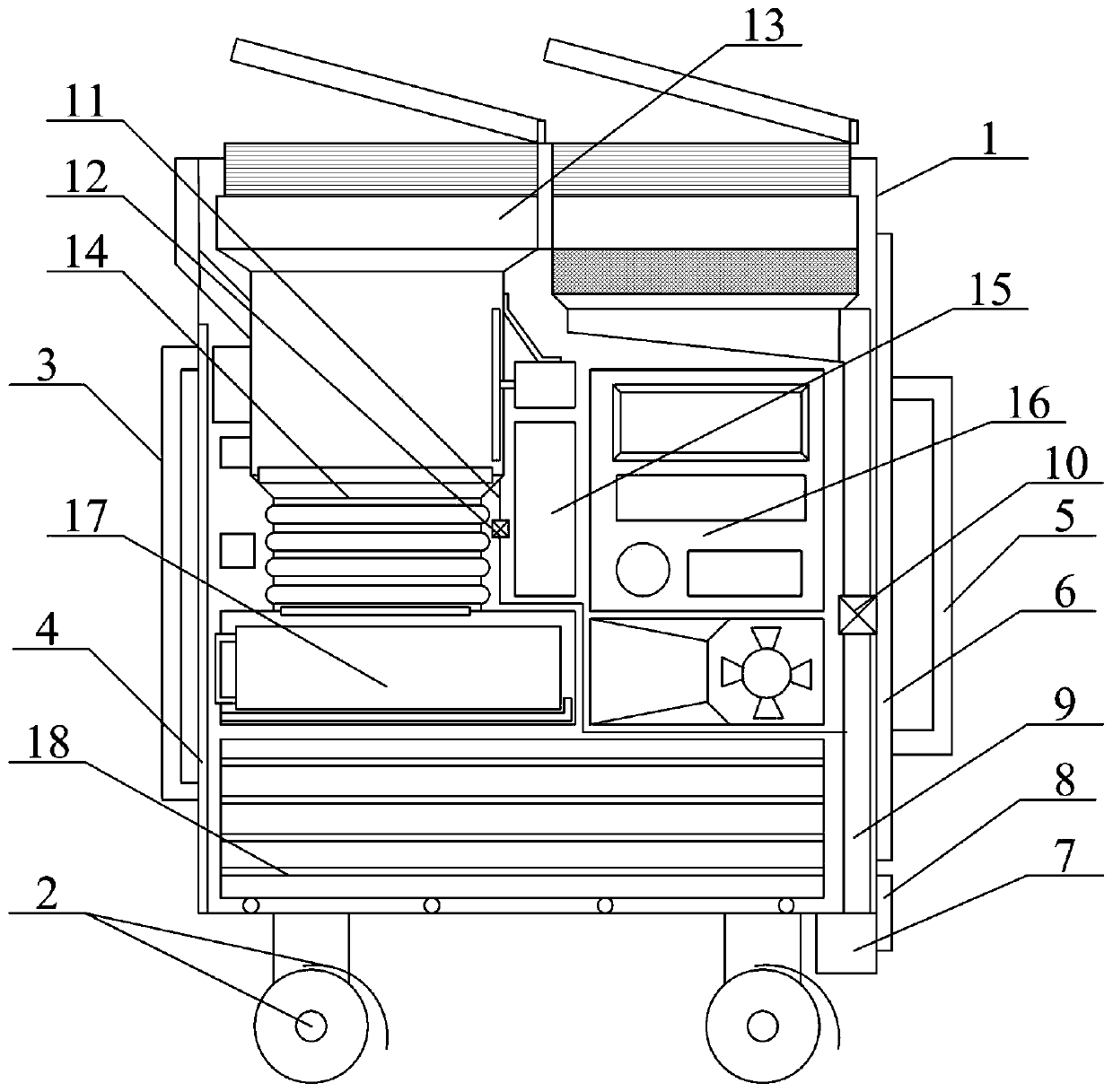

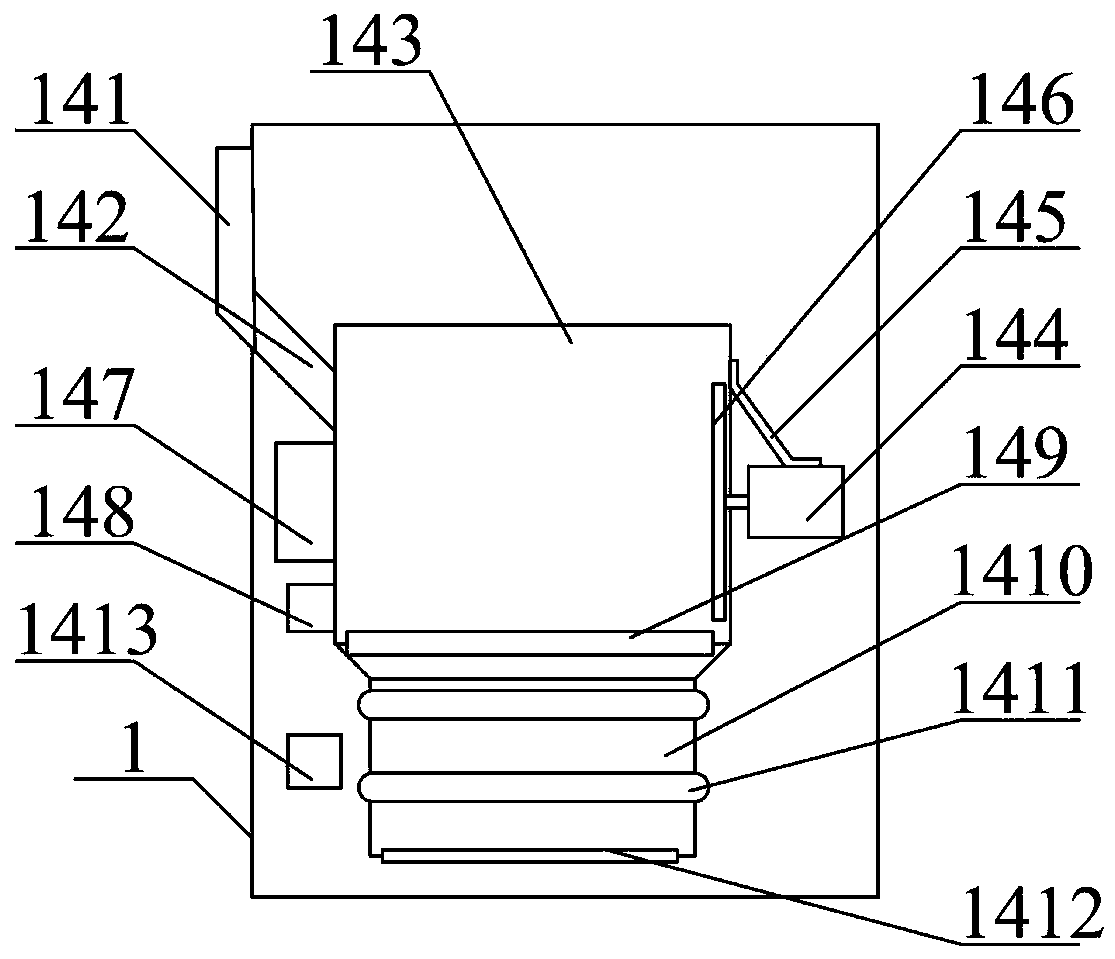

The invention provides a multifunctional nursing department self-cleaning type towel storage device. The multifunctional nursing department self-cleaning type towel storage device comprises a moving box, moving wheels, a left-side pull rod, a left-side pull door, a right-side pull rod, a right-side pull door, a waste water storage box, a storage box mounting plate, a water outlet pipe, a primary electromagnetic valve, a metal hose, a secondary electromagnetic valve, a towel separating and placing box device, a cleaning and brushing machine, a control cabinet, an intelligent controller device, a cooler device and a towel temporary storage cabinet device. A display screen is electrically connected with the output end of a controller; an alarm is electrically connected with the output end of the controller; a main control switch is electrically connected with the input end of the controller, so that the working state of the device is displayed and indicated in real time and the intelligent degree is higher; and an intelligent power distribution cabinet is electrically connected with the control cabinet through a line bank, so that the multifunctional nursing department self-cleaning type towel storage device is favorable for realizing manual control and automatic control, facilitates operation, increases the operating function, and is convenient to use and convenient to popularize and use.

Owner:杨继芳

Integrated cleaning and drying equipment for textile cloth and working process thereof

ActiveCN108277600AImprove bindingFast and efficient cleaningSucessive textile treatmentsLiquid/gas/vapor removal by gas jetsElectric machineryEngineering

The invention discloses integrated cleaning and drying equipment for textile cloth and relates to the technical field of production processing equipment for textile cloth. The equipment comprises a baseplate, a cleaning box is fixedly connected to the top of the baseplate, and a beat pounding box is fixedly connected to the top of the cleaning box; a wedge block and a motor box are fixedly connected to the inner wall of the beat pounding box separately, rotation shafts are rotatably connected to one side of the motor box through a supporting rack, and first bevel gears and rotation cams sleevethe rotation shafts from top to bottom in sequence; a motor is fixedly connected to the interior of the motor box. According to the integrated cleaning and drying equipment for the textile cloth anda working process thereof, the cleaning and drying effect is greatly improved, the cleaning and drying efficiency is well improved, production personnel do not need to spend a large amount of time incleaning and drying the textile cloth, the textile cloth is quickly and efficiently subjected to cleaning and drying integrated treatment, and great convenience is provided for production personnel toconduct production work of the textile cloth.

Owner:泉州台商投资区国进信息技术有限公司

Electroplated silicon wafer cleaning and drying device for integrated circuit board production

ActiveCN110404874ASave human effortImprove work efficiencyDrying gas arrangementsSemiconductor/solid-state device manufacturingIntegrated circuitWaste management

The invention discloses an electroplated silicon wafer cleaning and drying device for integrated circuit board production. The cleaning and drying device comprises an electroplated silicon wafer, andthe cleaning and drying device comprises a cleaning tank, an accommodating tank and a plurality of clamping devices, wherein a partition plate is arranged in the accommodating tank and divides the space in the accommodating tank into an upper cavity and a lower cavity, a plurality of vibrating parts are arranged on the partition plate, transferring water is contained in the upper cavity, and a vibrating plate is arranged in the lower cavity; the bottom end of the cleaning tank is located in the transferring water, a cleaning solution is contained in the cleaning tank, a mounting frame is arranged above the cleaning tank, the bottom ends of the clamping devices are located in the cleaning tank, and the top ends of the clamping devices are all connected with the mounting frame; and the electroplated silicon wafer is located in the clamping device. According to the device, the structure design is reasonable, the operation is simple, the cleaning and drying efficiency of the electroplatedsilicon wafer is effectively improved, the cleaning and drying effects of the electroplated silicon wafer are improved, meanwhile, the operation of the whole device is more flexible, and higher practicability is achieved.

Owner:深圳市荣之鑫科技有限公司

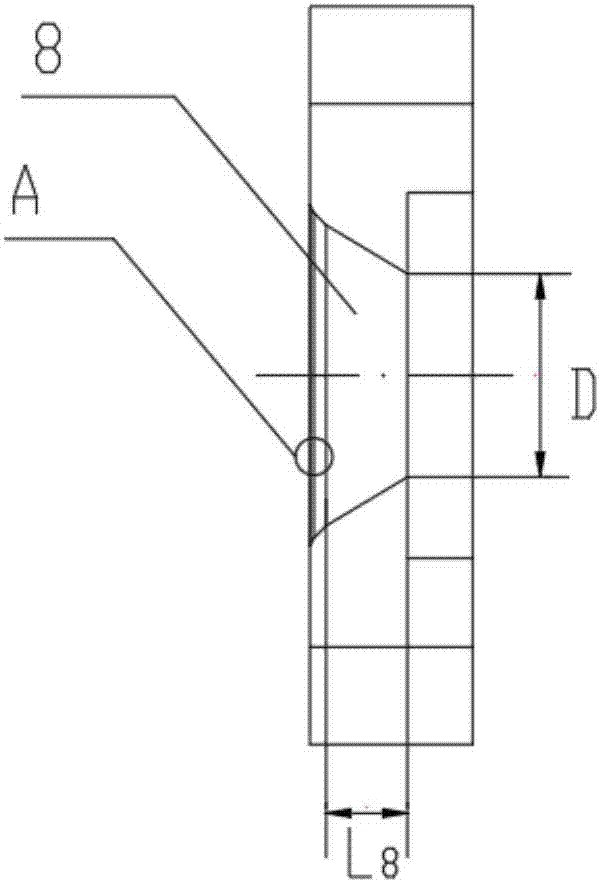

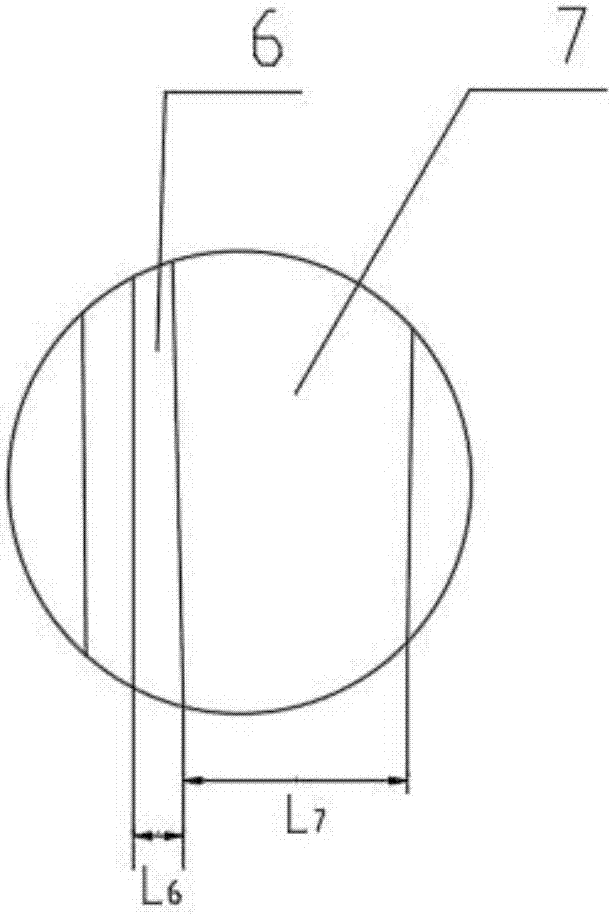

Stainless steel annular air knife

The invention discloses a stainless steel annular air knife. The stainless steel annular air knife is formed by connecting two same semicircle-shaped air knife bodies, each air knife body is provided with a cover plate and a bottom plate which are mutually connected through bolts, a buffer groove is formed in each bottom plate, an air inlet communicating with the corresponding buffer groove is formed in the outer side of each bottom plate, and the inner side wall of the side, close to the center of the corresponding bottom plate, of each buffer groove is lower than the other side walls of the corresponding buffer groove. The stainless steel annular air knife is simple in structure, durable and not prone to being damaged, and achieves better cleaning and drying effects at the same time.

Owner:CHONGQING TAISHAN CABLE

Cloth cleaning equipment for textile equipment

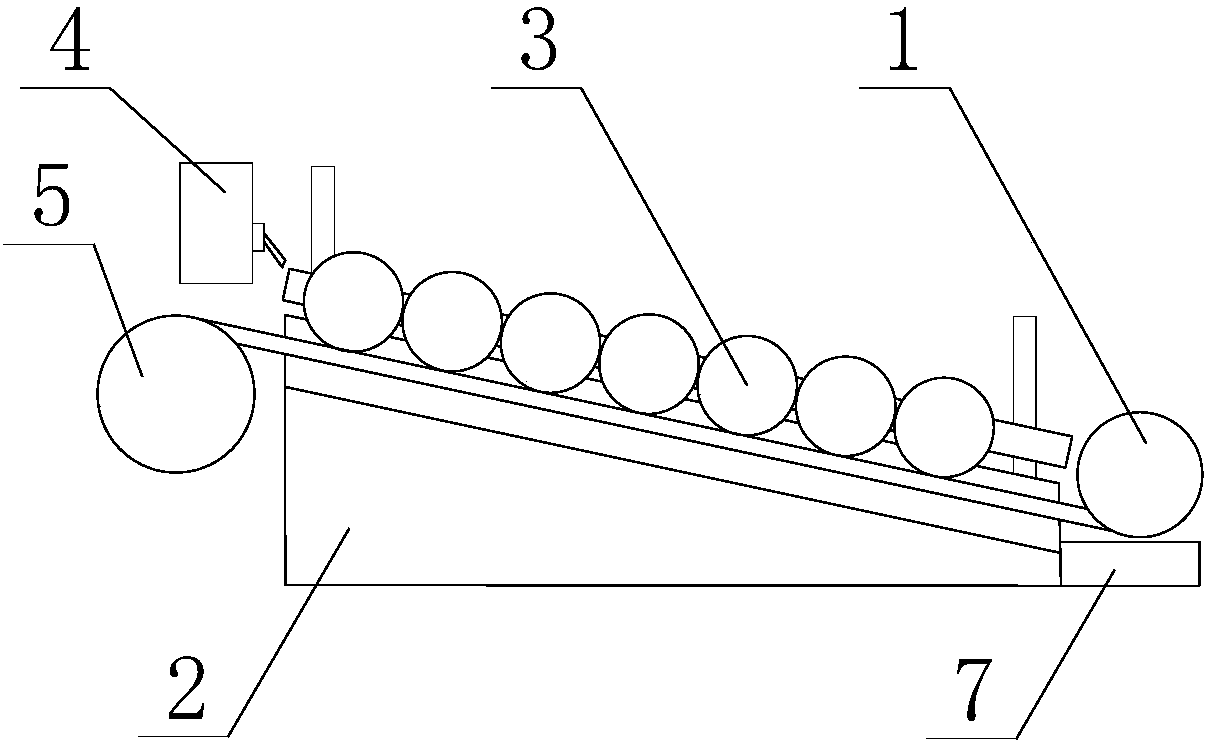

ActiveCN105671832BAchieve cleaningEfficient cleaning and squeezingTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsMechanical engineeringExtrusion

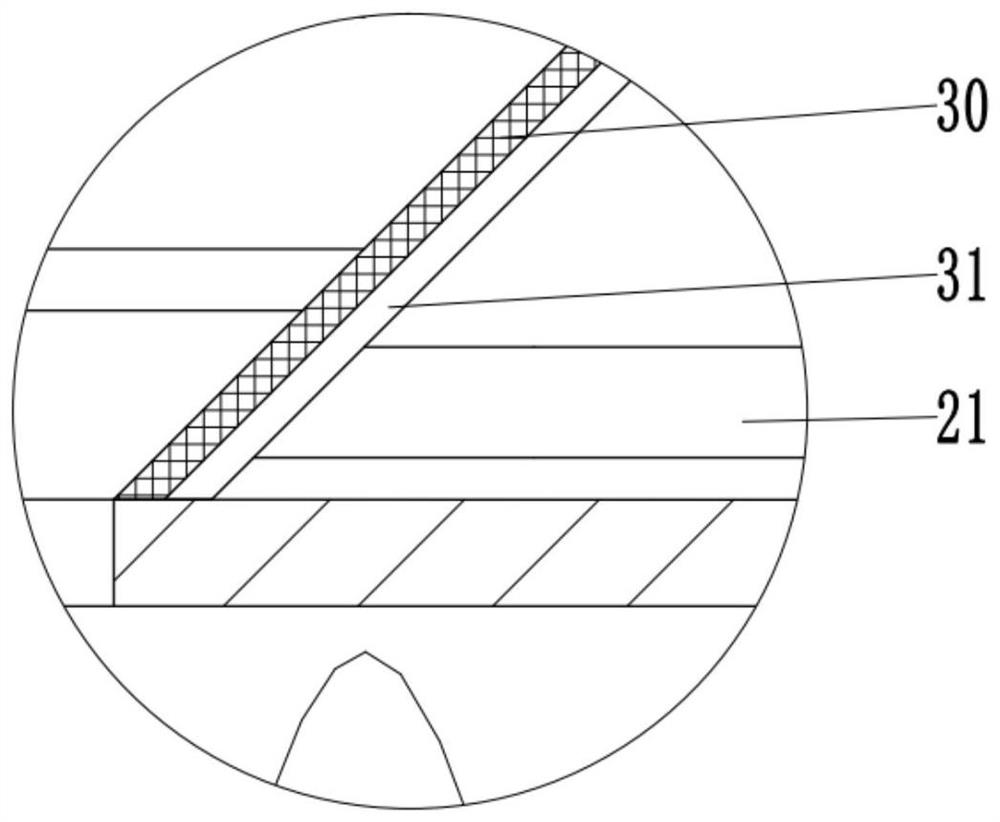

The invention discloses a cloth cleaning device for a textile device. A supporting table and a plurality of extrusion rollers above the supporting table form an extrusion channel which is obliquely arranged from low to high; in the working process, cloth to be cleaned enters the extrusion channel from the lower end of the extrusion channel and is discharged from the high end of the extrusion channel; meanwhile, a cleaning device jets cleaning liquid from the high end of the extrusion channel to the cloth; the cleaning liquid soaks the cloth from high to low so that the cleaning liquid can flow to the rear end of the cloth from the front end of the cloth, and finally the cleaning liquid is collected in a collecting groove; the extrusion rollers perform multi-stage rolling on the soaked cloth at the same time, and the cloth can be cleaned and extruded. The cloth cleaning device for the textile device is reasonable in structural design, the feeding direction of the cloth and the extrusion direction of the extrusion rollers are opposite to the direction of the cleaning liquid under the action of gravity, efficient cleaning and extruding drying of the cloth are achieved, the cleaning efficiency is greatly improved, and the cleaning drying effect is improved.

Owner:ANHUI LIANGLIANG TEXTILE CO LTD

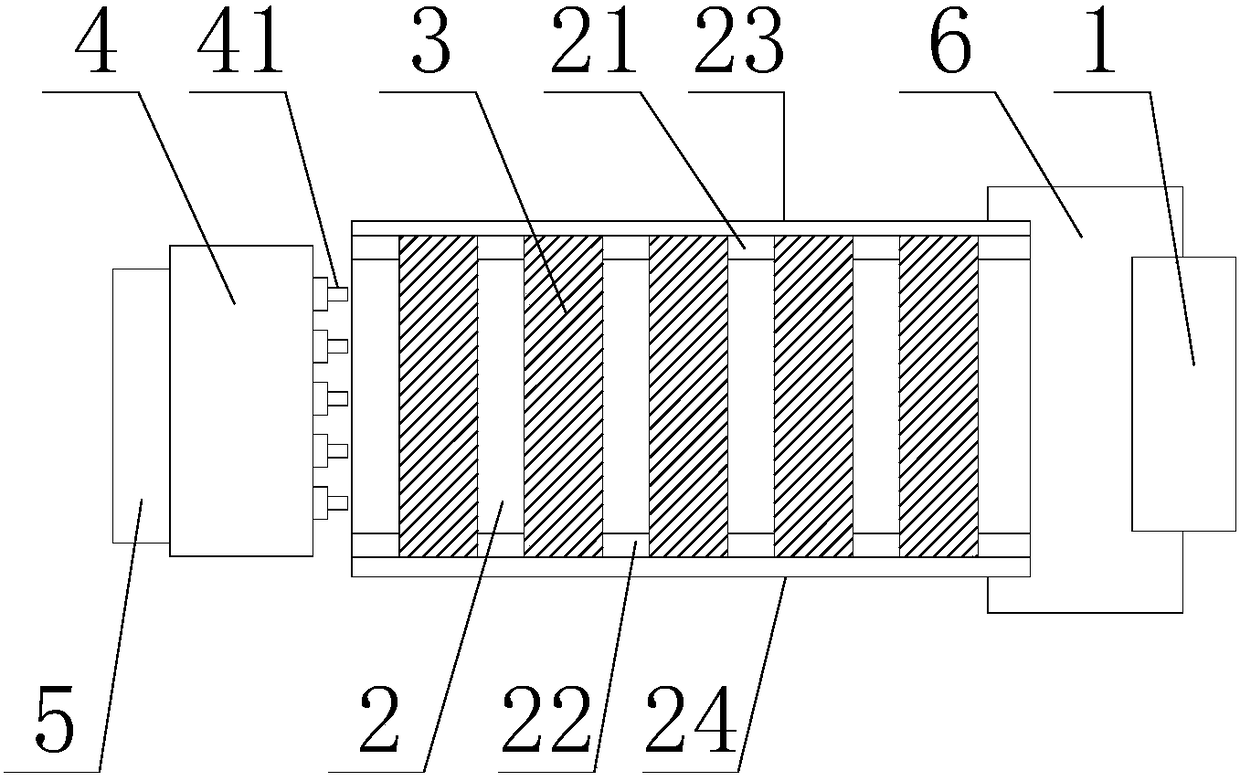

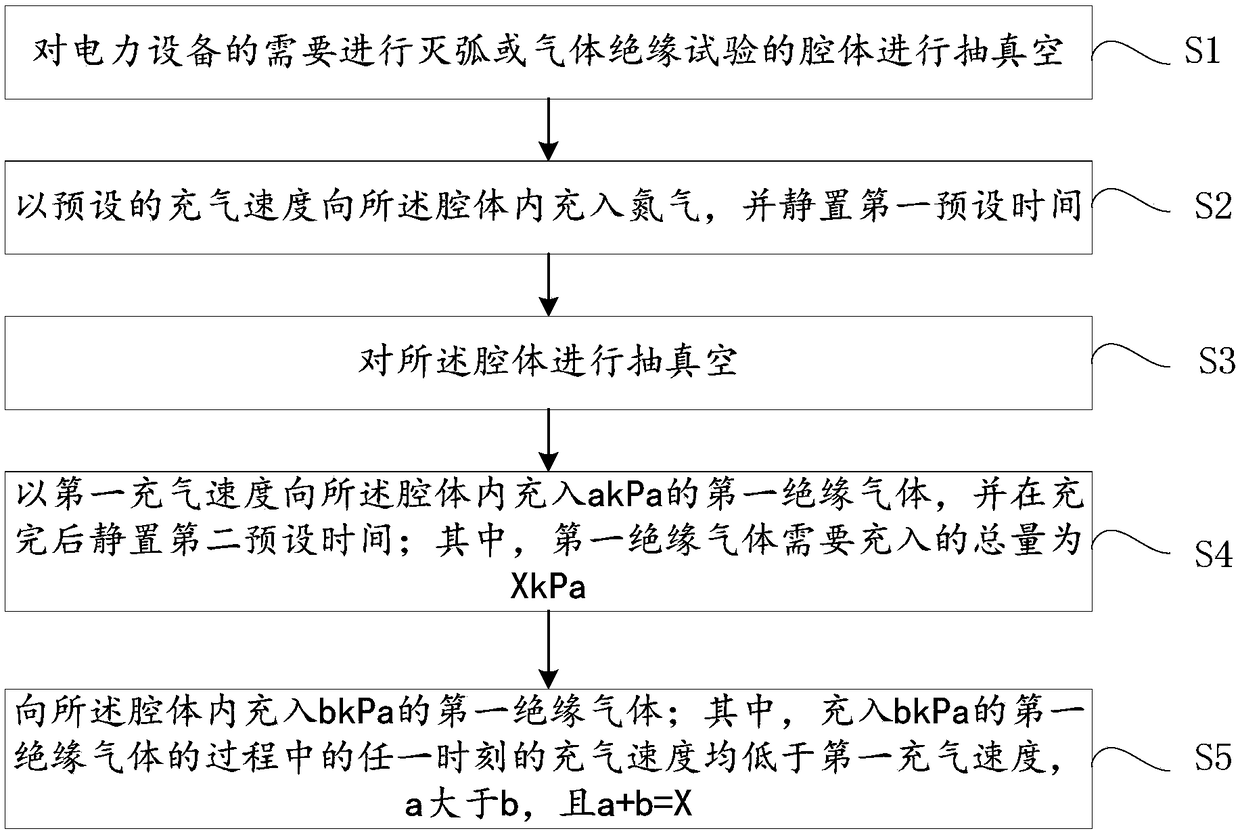

Insulating gas inflating method for electrical equipment

InactiveCN108870066AThere will be no violent collisionsImprove cleaning and drying effectFluid handledContainer filling under pressureNitrogenNitrogen gas

The invention discloses an insulating gas inflating method for electrical equipment. The method comprises the steps that 1, a cavity to be subjected to arc extinguishing or gas insulating tests of theelectrical equipment is vacuumized; 2, nitrogen is inflated into the cavity at a preset inflating speed, and standing is carried out for a first preset time; 3, the cavity is vacuumized; and 4, a kPaof first insulating gas is inflated into the cavity at a first inflating speed, and standing is carried out for a second preset time after inflating is finished, wherein the inflating sum amount of the first insulating gas is X kPa; 5, b kPa of first insulating gas is inflated into the cavity, the inflating speed at any time in the process of inflating b kPa of first insulating gas is lower thanthe first inflating speed, a is larger than b, and the sum of a and b is equal to X. The whole inflating process of insulating gas is safe and smooth.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

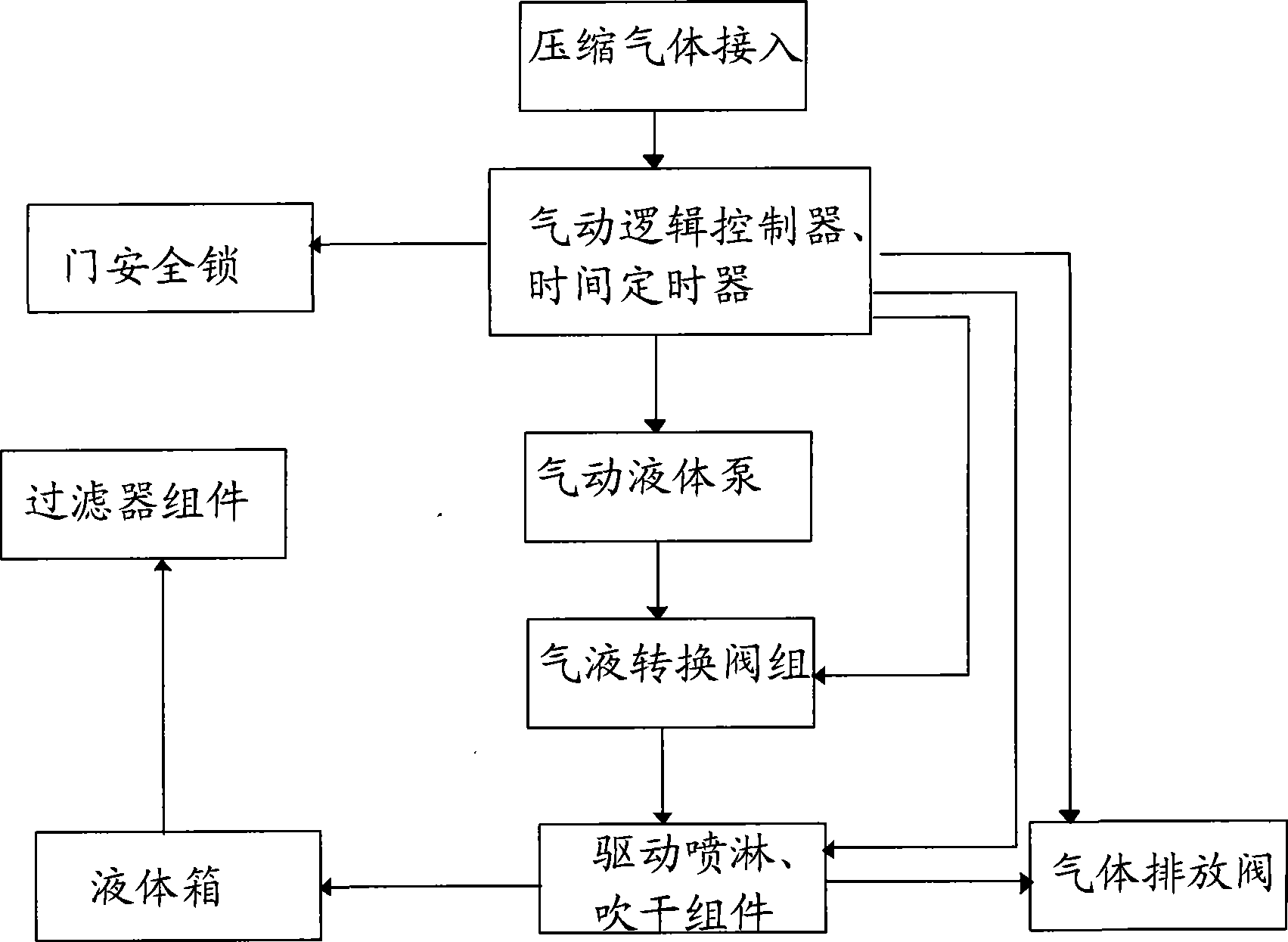

Complete pneumatic steel plate cleaning system

ActiveCN101412028AGood cleaning and drying effectAvoid the risk of ignition of volatile solventsDrying solid materials without heatCleaning using liquidsElectricityEngineering

The invention relates to a total pneumatic steel plate cleaning system. After compressed gas is introduced, a pneumatic logic controller and a timer can select cleaning time and mode; when the system works, a door is locked safely, and a gas-liquid pump is started to drive a gas-liquid conversion valve set and then drive a spraying and drying component; and solution after cleaning flows back to a liquid box; after being filtered by a filter component, the solution returns to the gas-liquid pump; and the gas-liquid pump is started to drive the gas-liquid conversion valve set and then drive the spraying and drying component, and a gaseous emission valve can draft air and exhaust. The cleaning system has the advantages that both a cleaning component and an airing component of the system are driven by a pneumatic motor to rotate, so the cleaning system not only has good cleaning and airing effects, but also saves liquid; by adopting the pressure spraying principle to clean, workable solvent comprises water and volatile solvent such as isopropyl alcohol; and by adopting the total pneumatic logic control principle and the total pneumatic driving, the cleaning system does not use electricity at all, so as to avoid danger that electric spark inflames the volatile solvent, thus the cleaning system is safe and reliable.

Owner:SHENZHEN KANA TECH

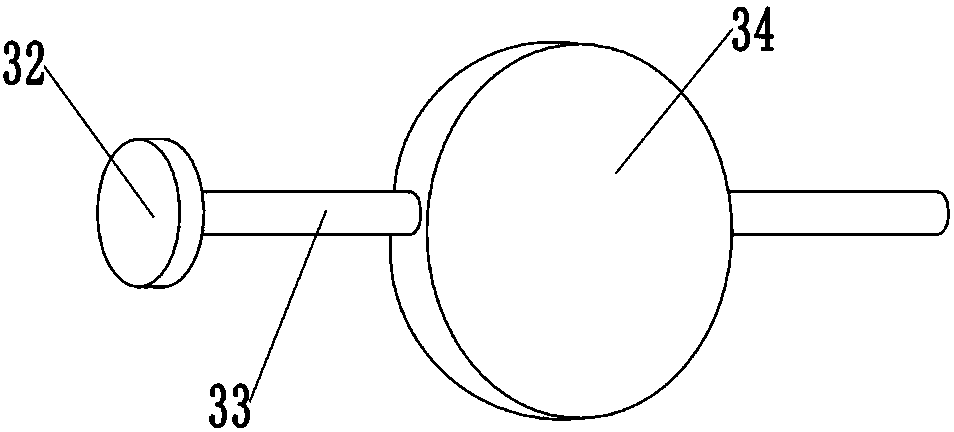

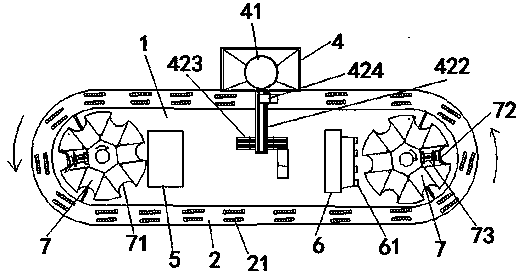

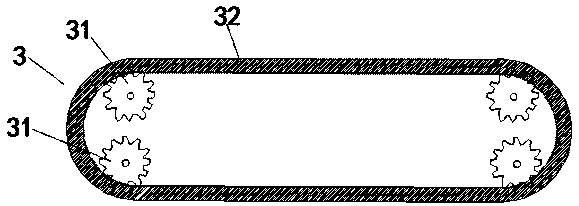

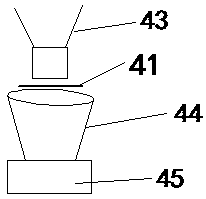

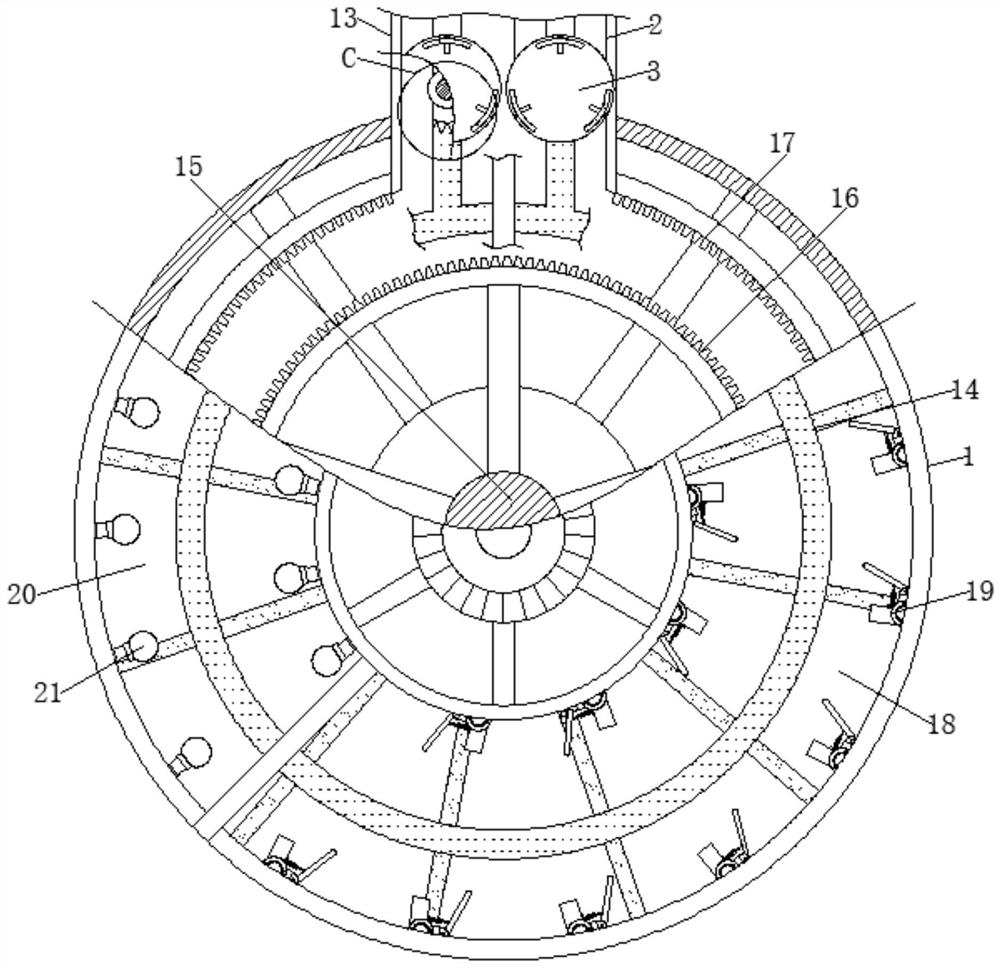

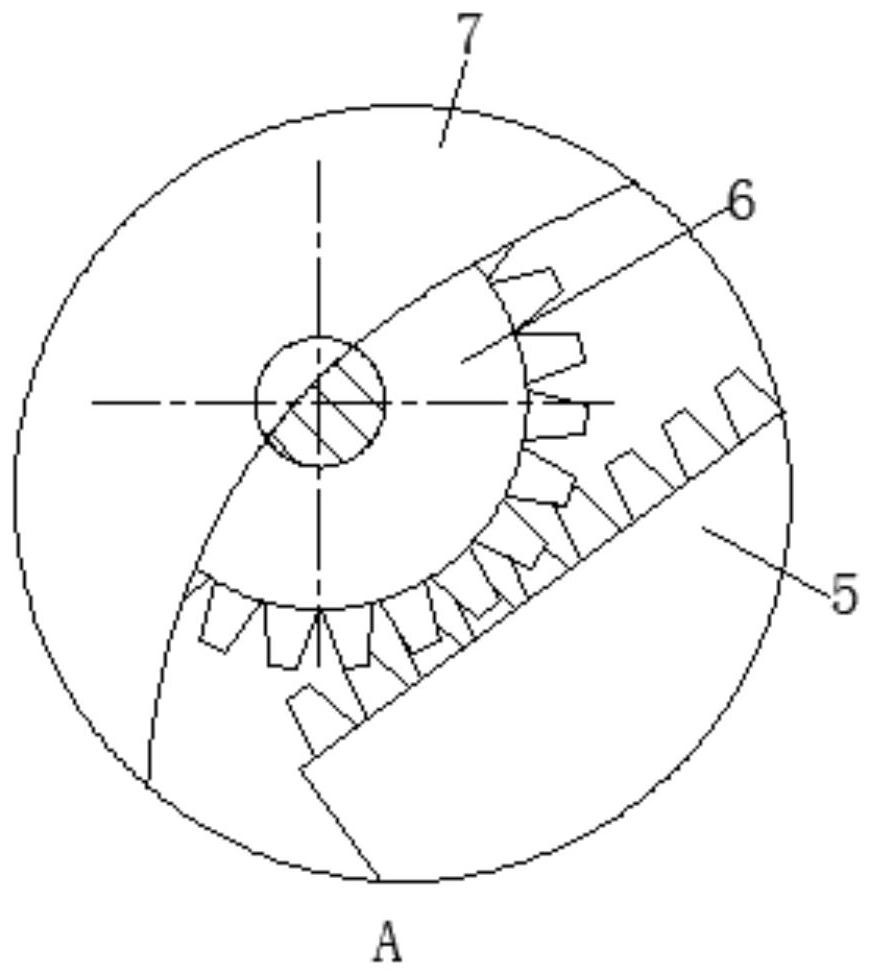

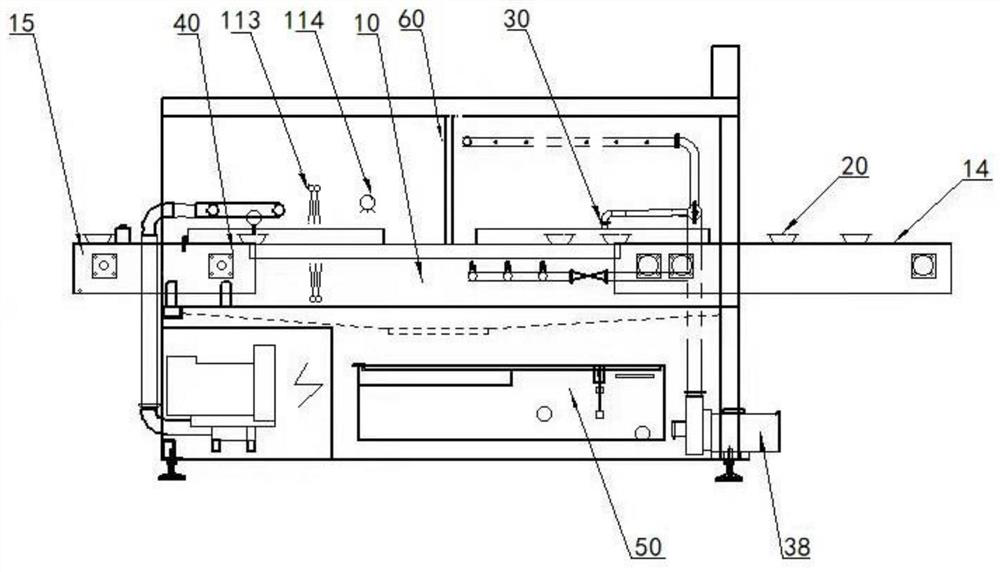

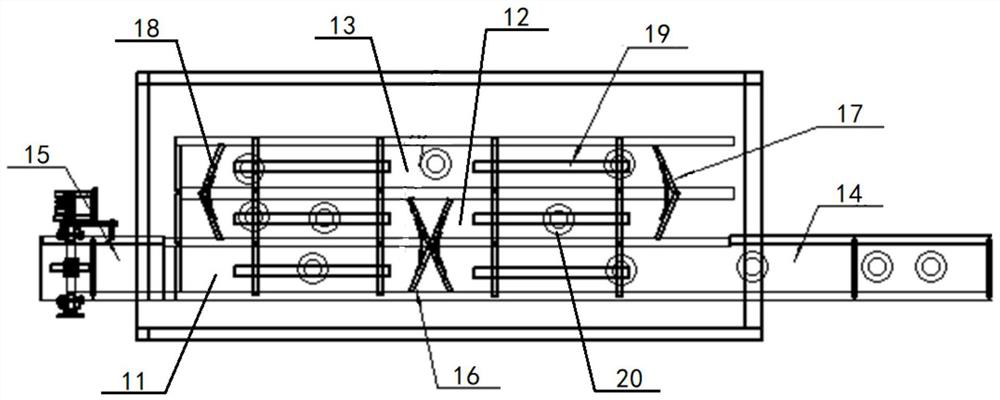

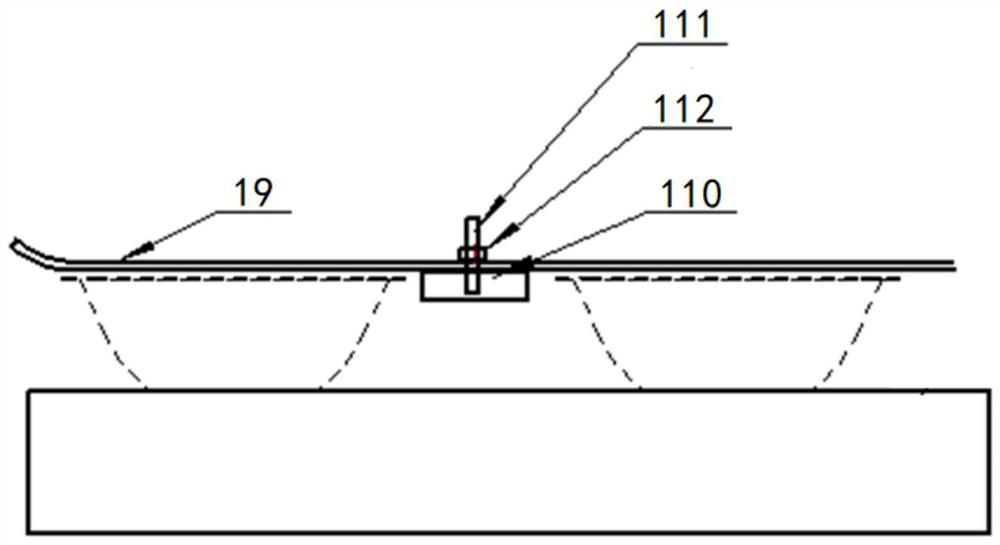

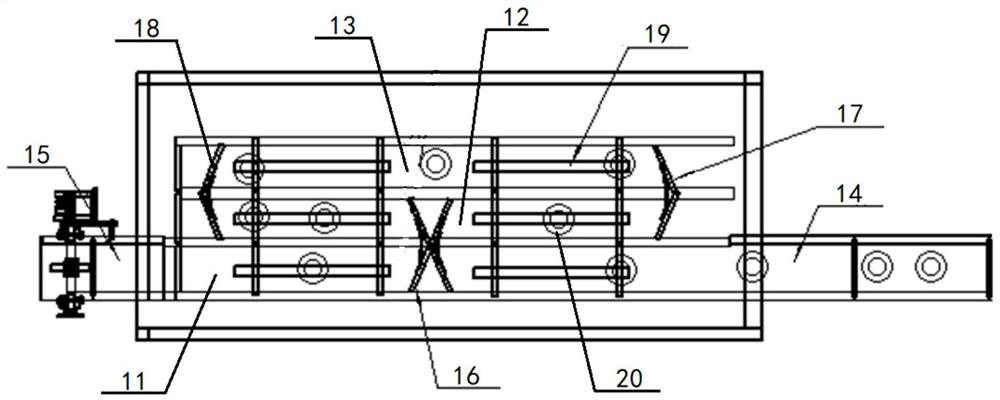

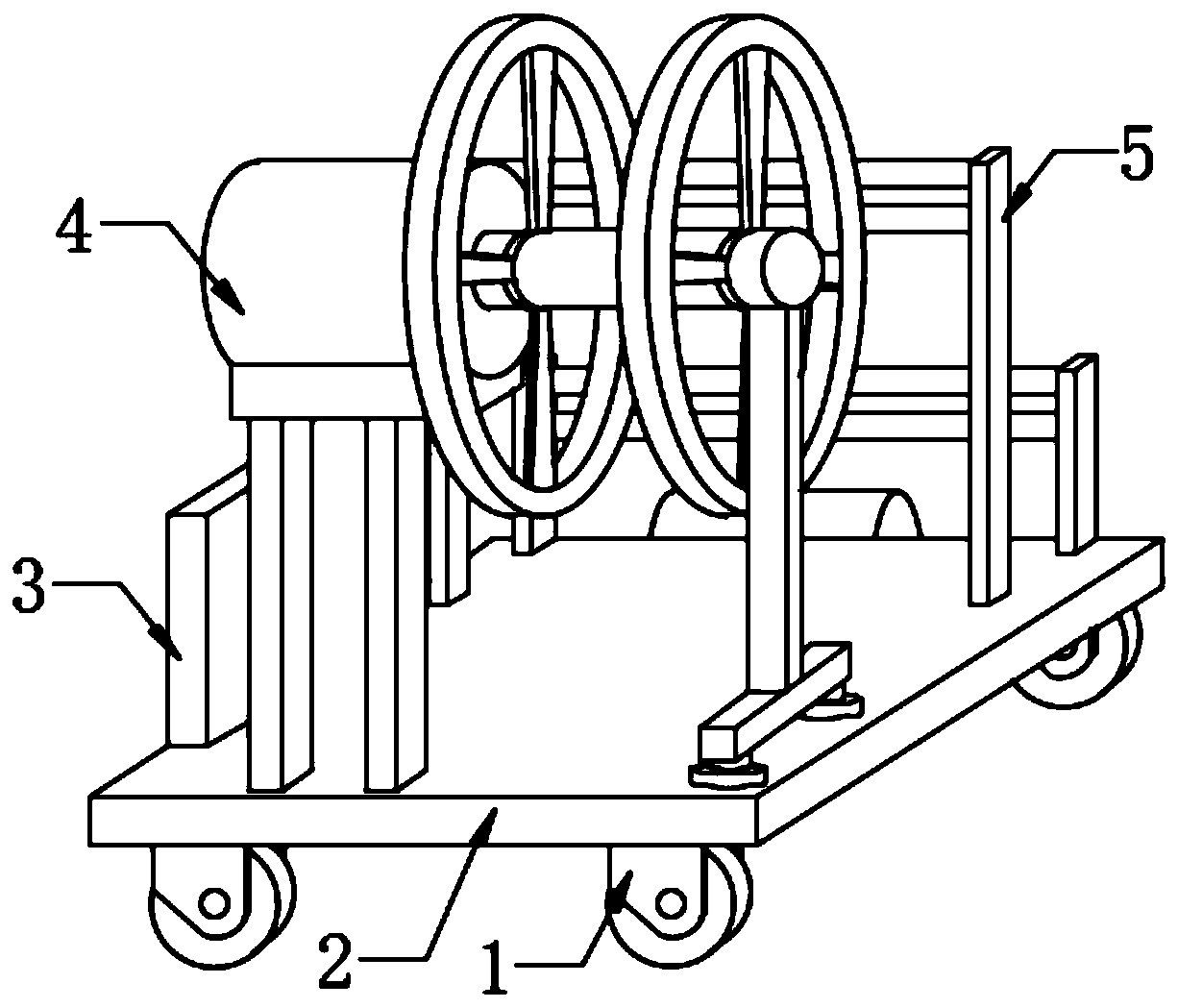

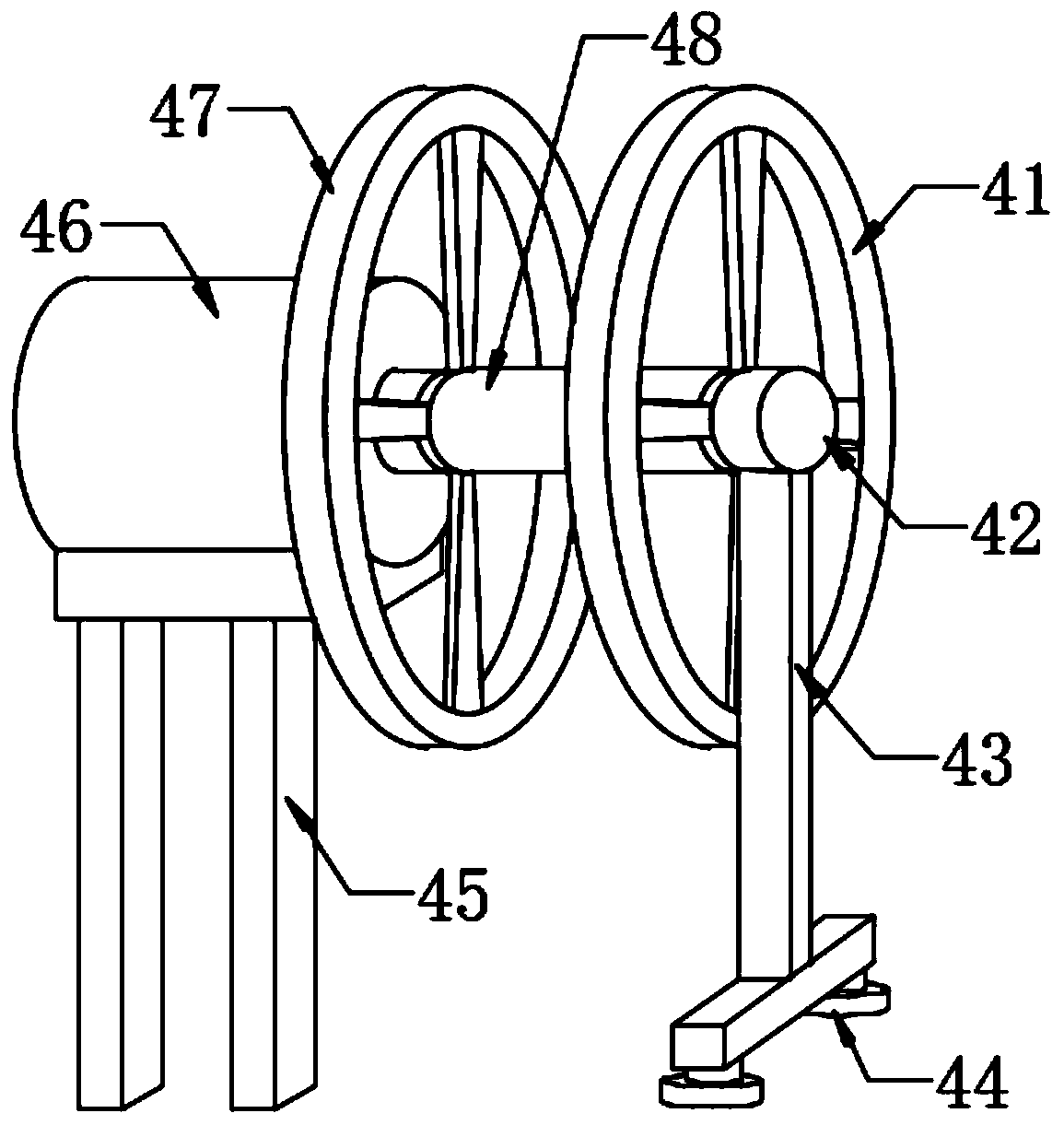

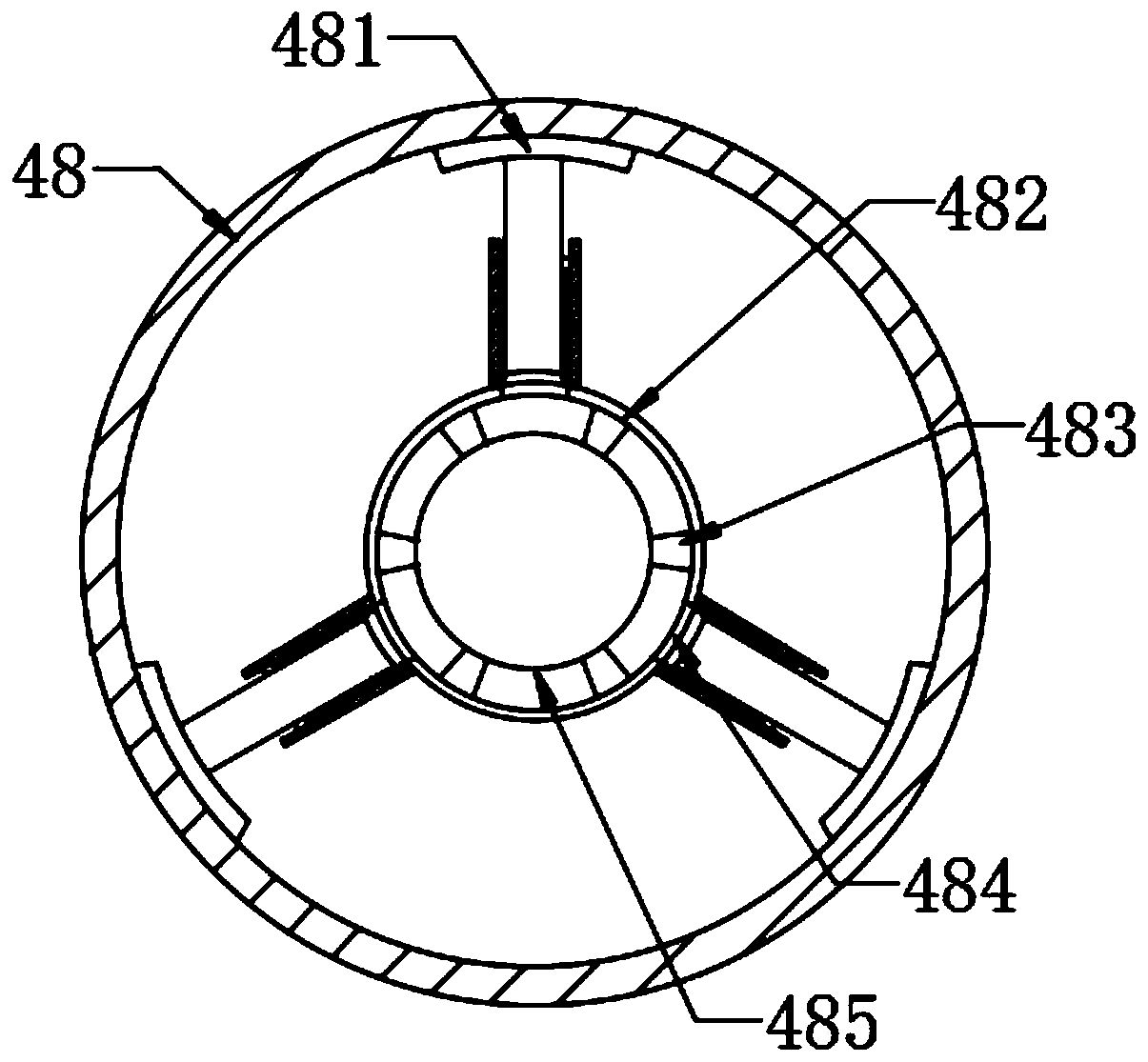

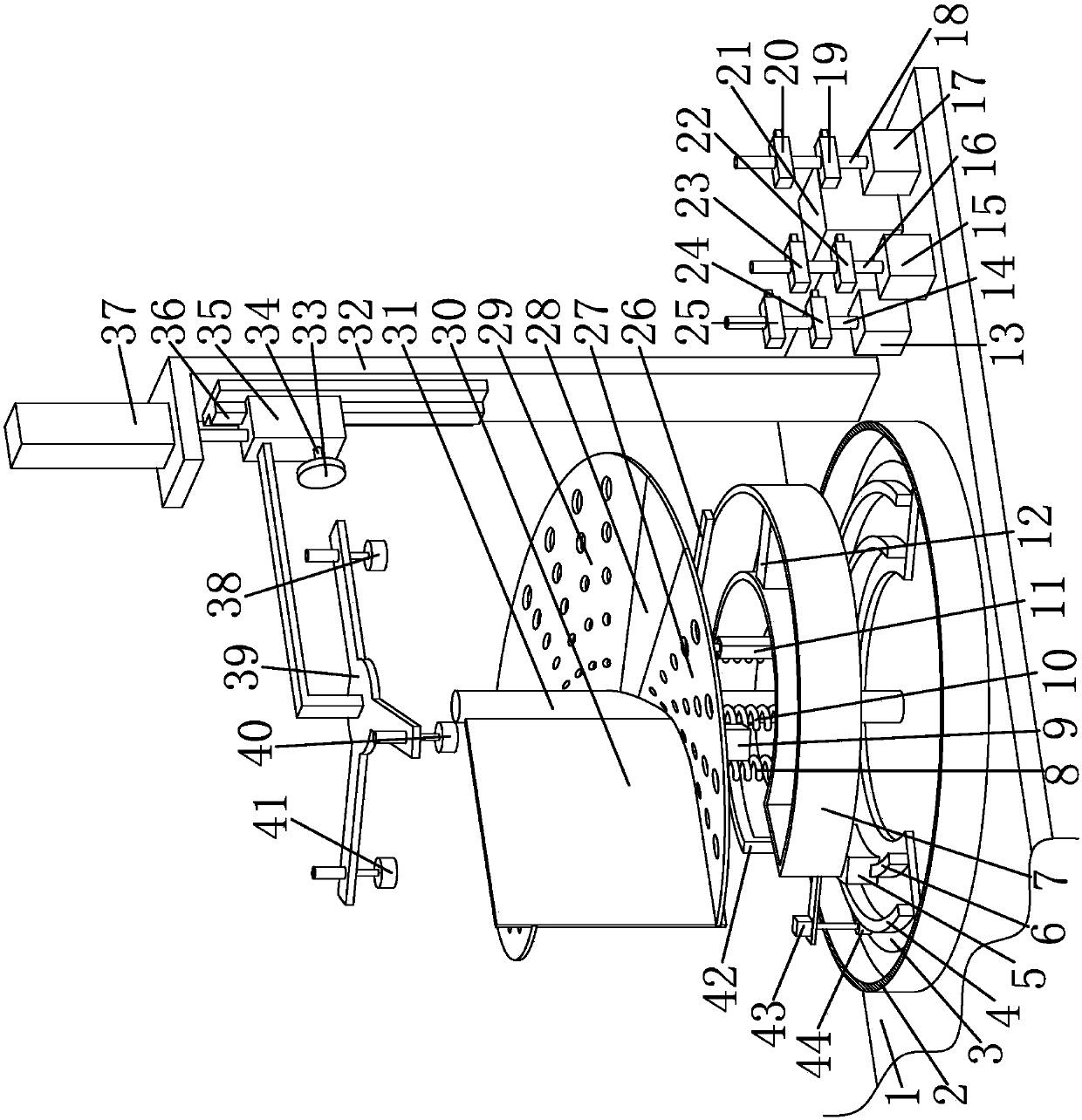

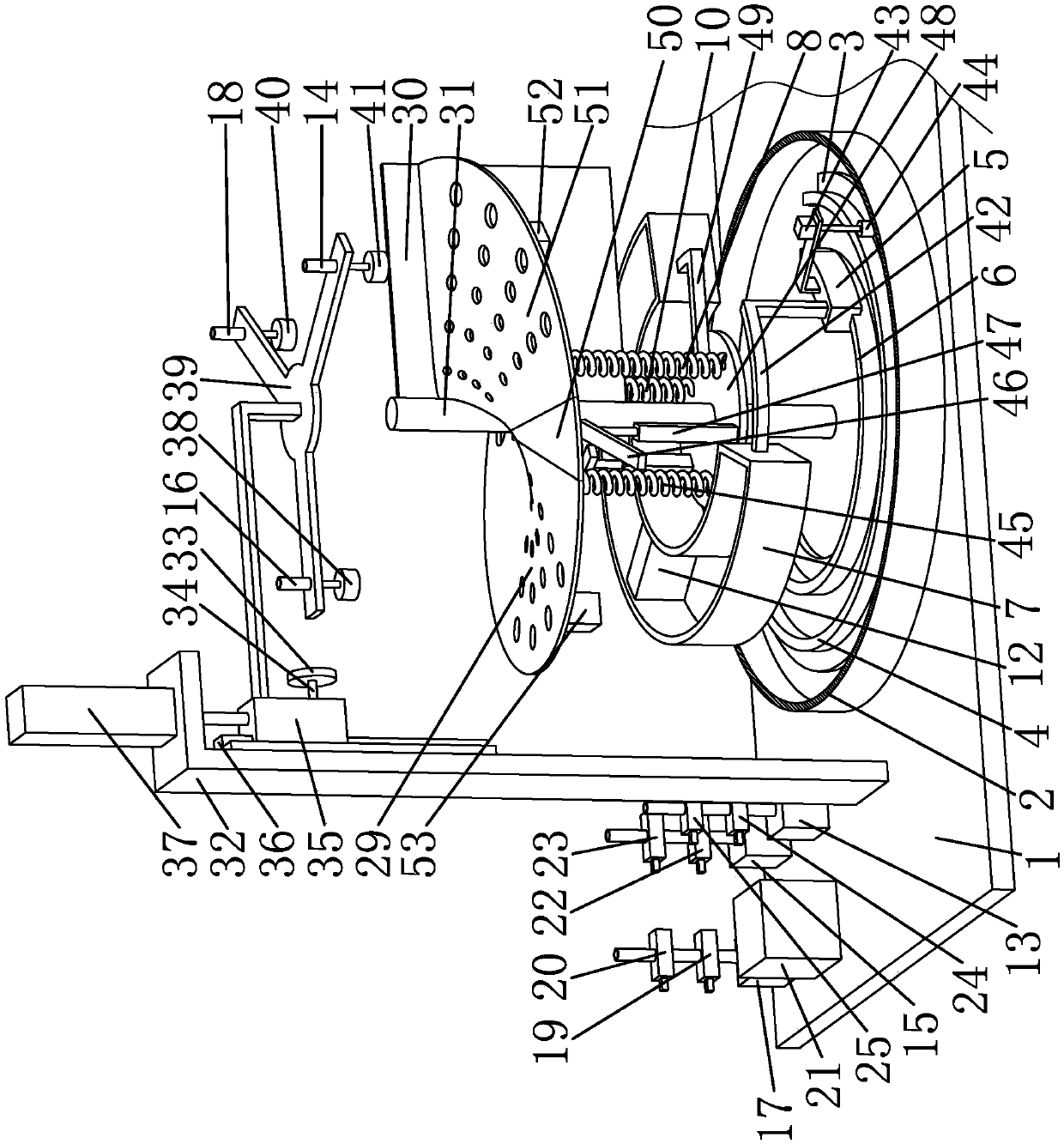

Apparatus and method for automatic filtering tobacco liquid

ActiveCN109499151ASave work space and timeReduced risk of production contaminationMoving filtering element filtersAutomatic filteringEngineering

The invention discloses an apparatus and a method for automatic filtering tobacco liquid. The apparatus for automatic filtering tobacco liquid comprises a worktable, a conveying rail for conveying a filter net and a rotating mechanism, wherein the conveying rail is arranged above the worktable; the rotating mechanism is arranged inside the worktable; the worktable is an annular structure; a filtering mechanism, a cleaning mechanism and a drying mechanism are respectively arranged on an annular path of the worktable; the conveying rail is connected with the rotating mechanism; and the rotatingmechanism drives the conveying rail to rotate along the annular path of the worktable. The apparatus and method can effectively integrate the conveying rail, the rotating mechanism, the filtering mechanism, the cleaning mechanism and the drying mechanism, so as to realize automatic operations of filtering, cleaning and drying, and improve the filtration efficiency without causing cross-contamination, thereby satisfying the operation demand of full-automatically filtering the tobacco liquid in large batches; and the apparatus and method have a strong promotion value.

Owner:CHINA TOBACCO GUANGDONG IND

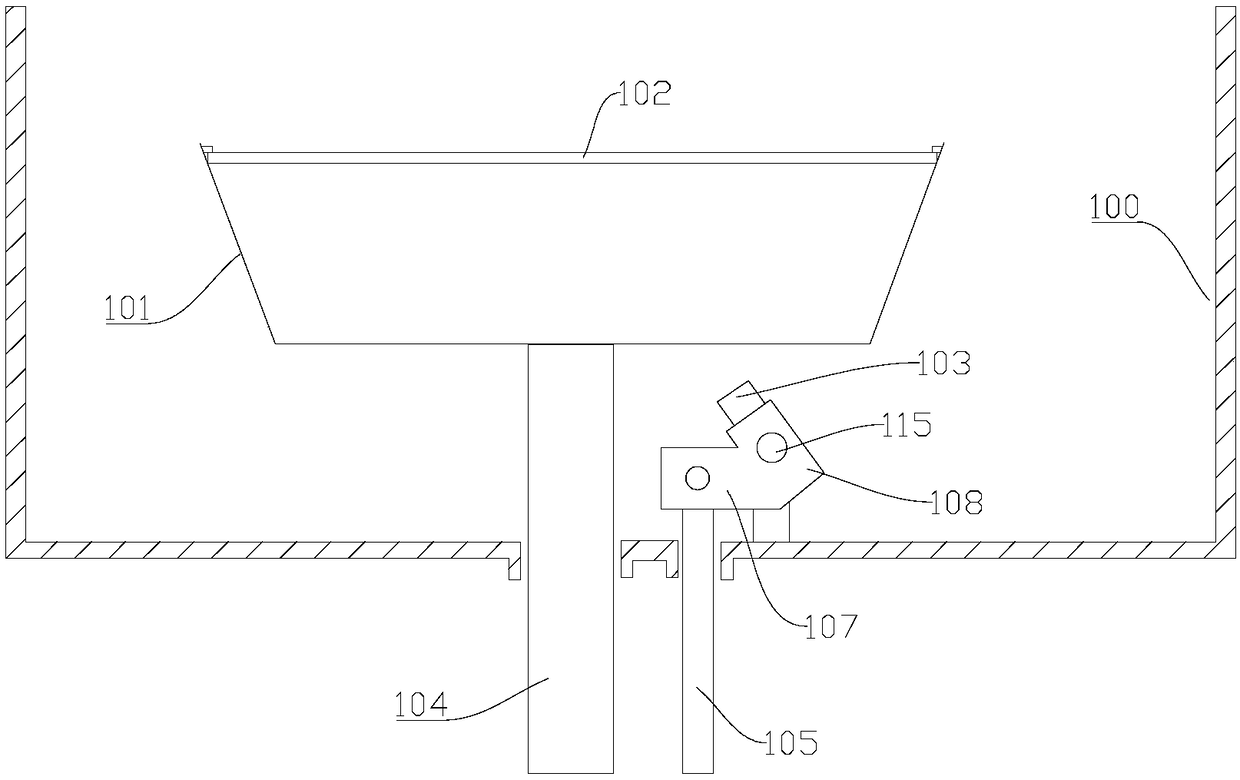

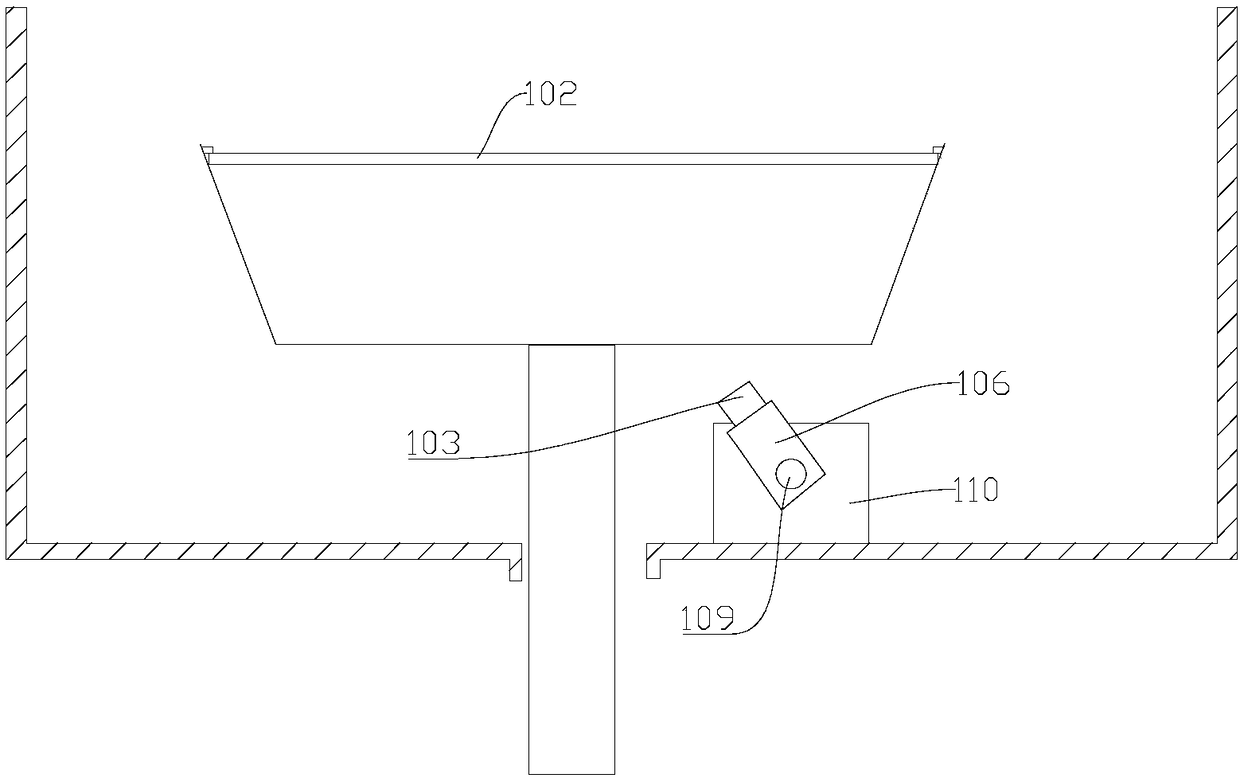

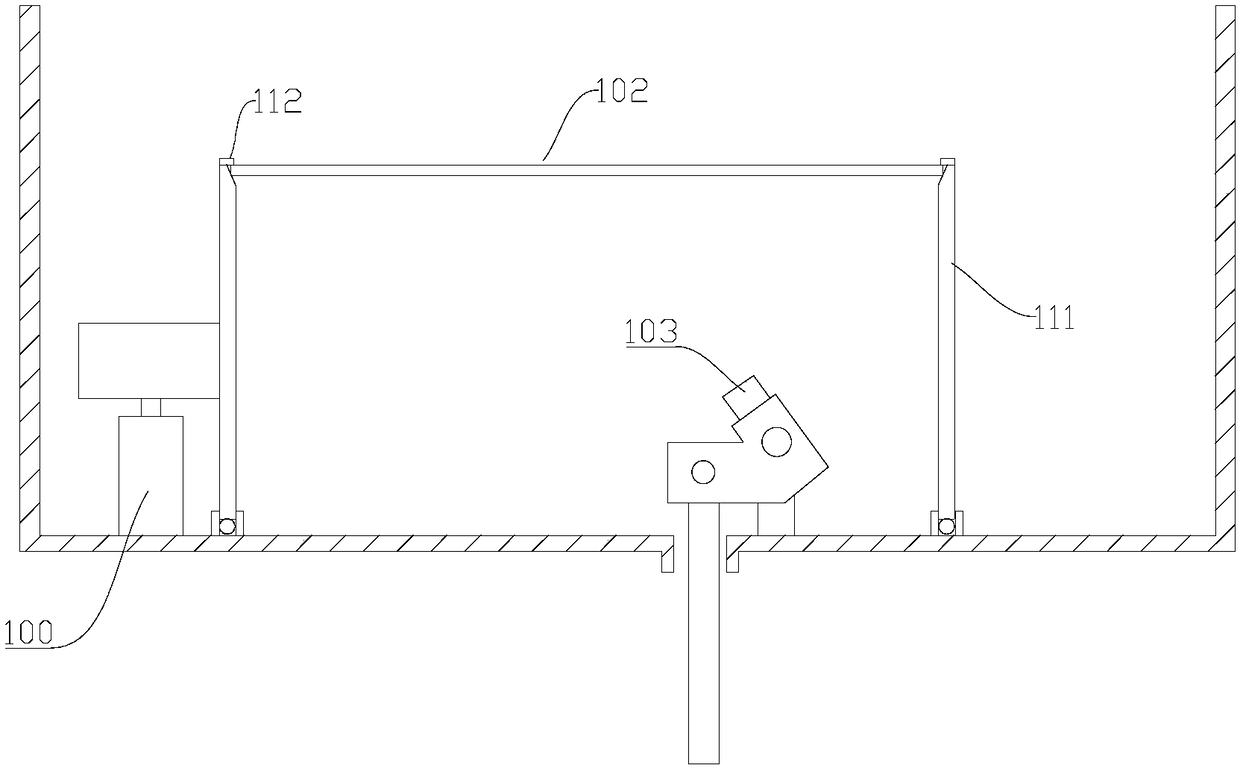

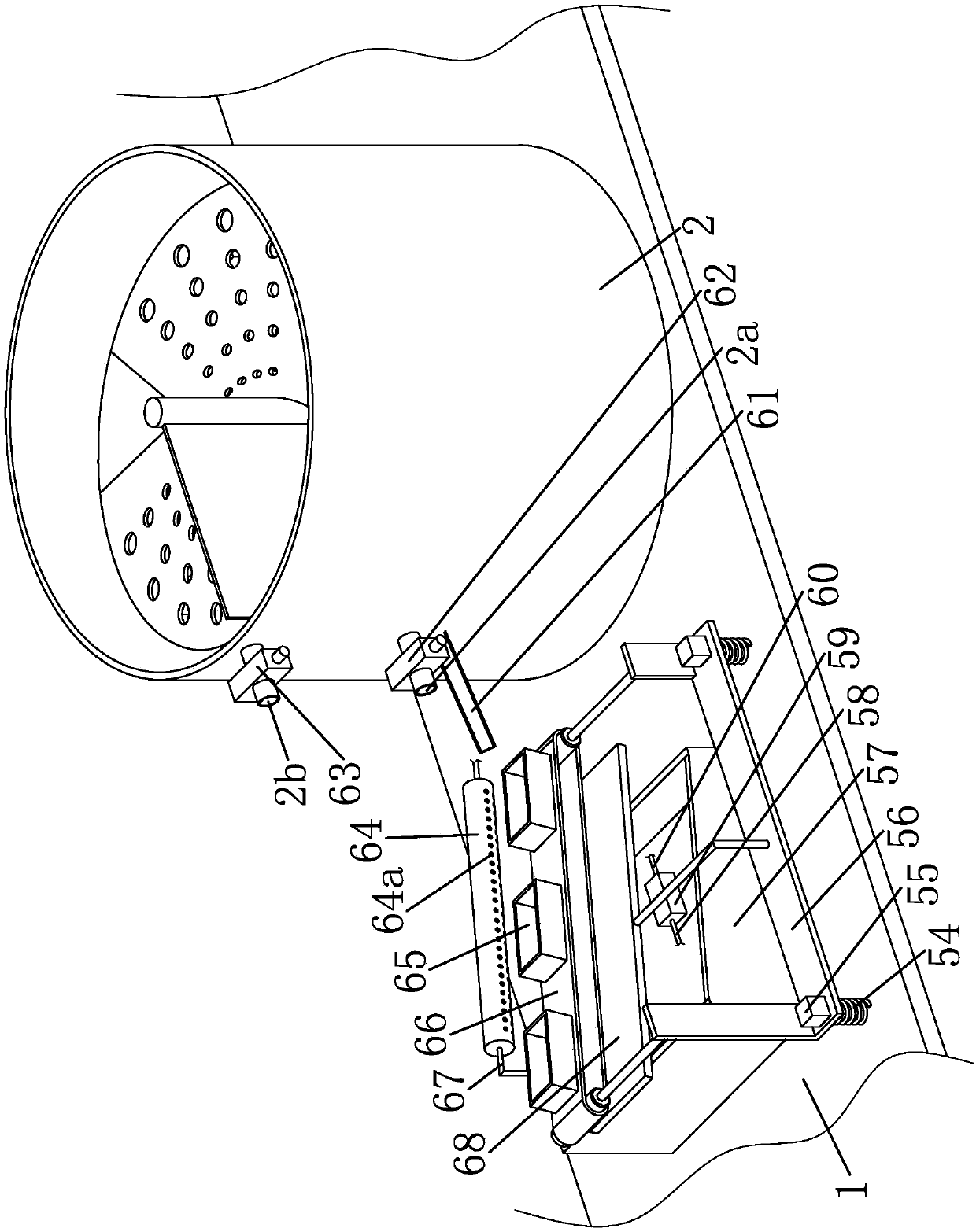

Processing device convenient for washing stropharia rugosoannulata

PendingCN109363202AAchieve cleaning effectTo achieve flipping effectFood treatmentSolenoid valveWater resources

The present invention relates to the technical field of stropharia rugosoannulata processing, particularly relates to a processing device convenient for washing stropharia rugosoannulata and solves problems that light processing of stropharia rugosoannulata is improved in labor costs and low in efficiency and besides a washing process also consumes a large amount of water resources. The processingdevice convenient for washing the stropharia rugosoannulata comprises a washing shell body and a drying shell body; the washing shell body comprises a washing bin, a machine shell, a conveying bin and a water tank; one side of the washing shell body is connected with a connection box; the washing shell body is connected with the drying shell body via the connection box; a top part of the washingbin is connected with a material feeding funnel; a bottom part of the washing bin is provided with a solenoid valve tube; the washing bin is connected with the conveying bin through the solenoid valvetube; a bottom part of the conveying bin is connected with the water tank; an inside of the washing bin is movably connected with washing rods; and an inside of the machine shell is fixedly connectedwith a second servo motor by bolts. The device is good in washing and drying effects, improves light processing efficiency, saves manpower and saves a lot of water, and is strongly practical.

Owner:贵州剑河珍源生态农业发展有限公司

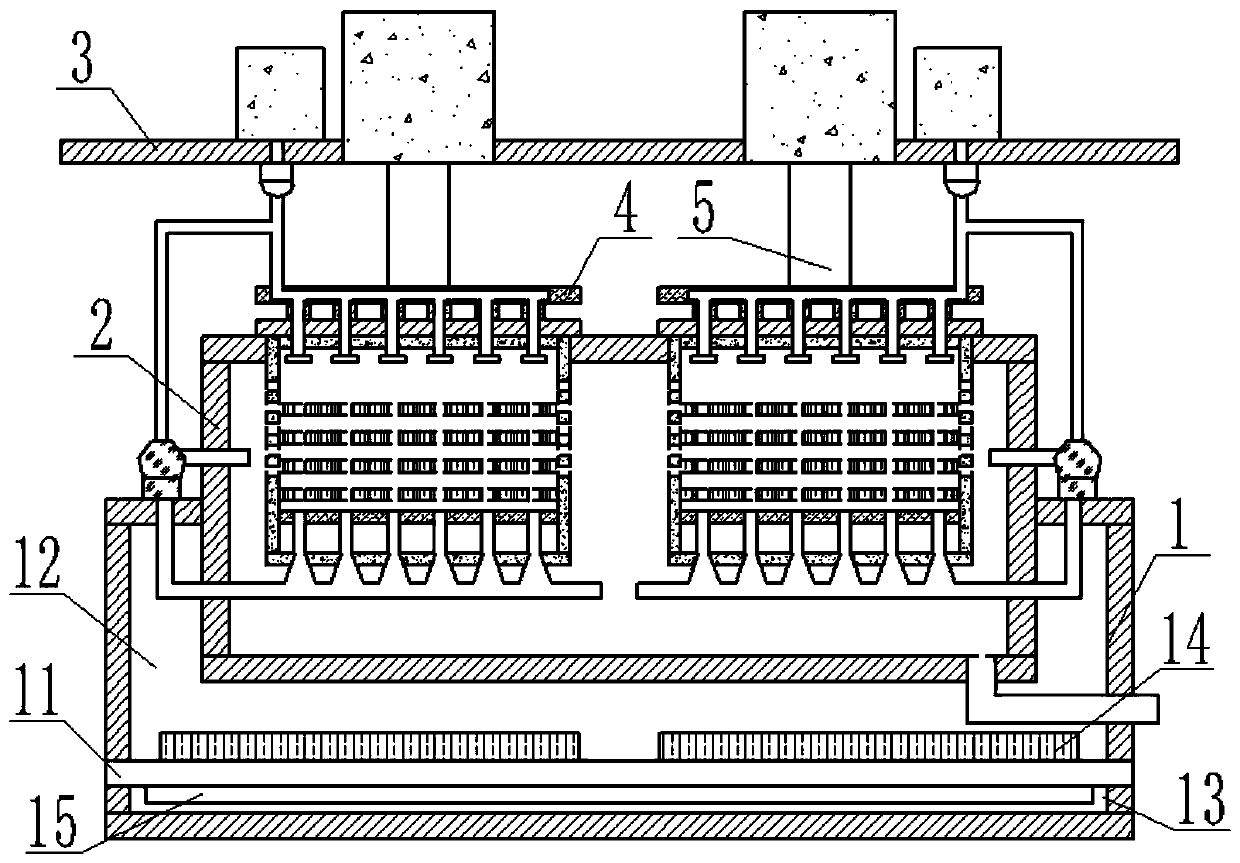

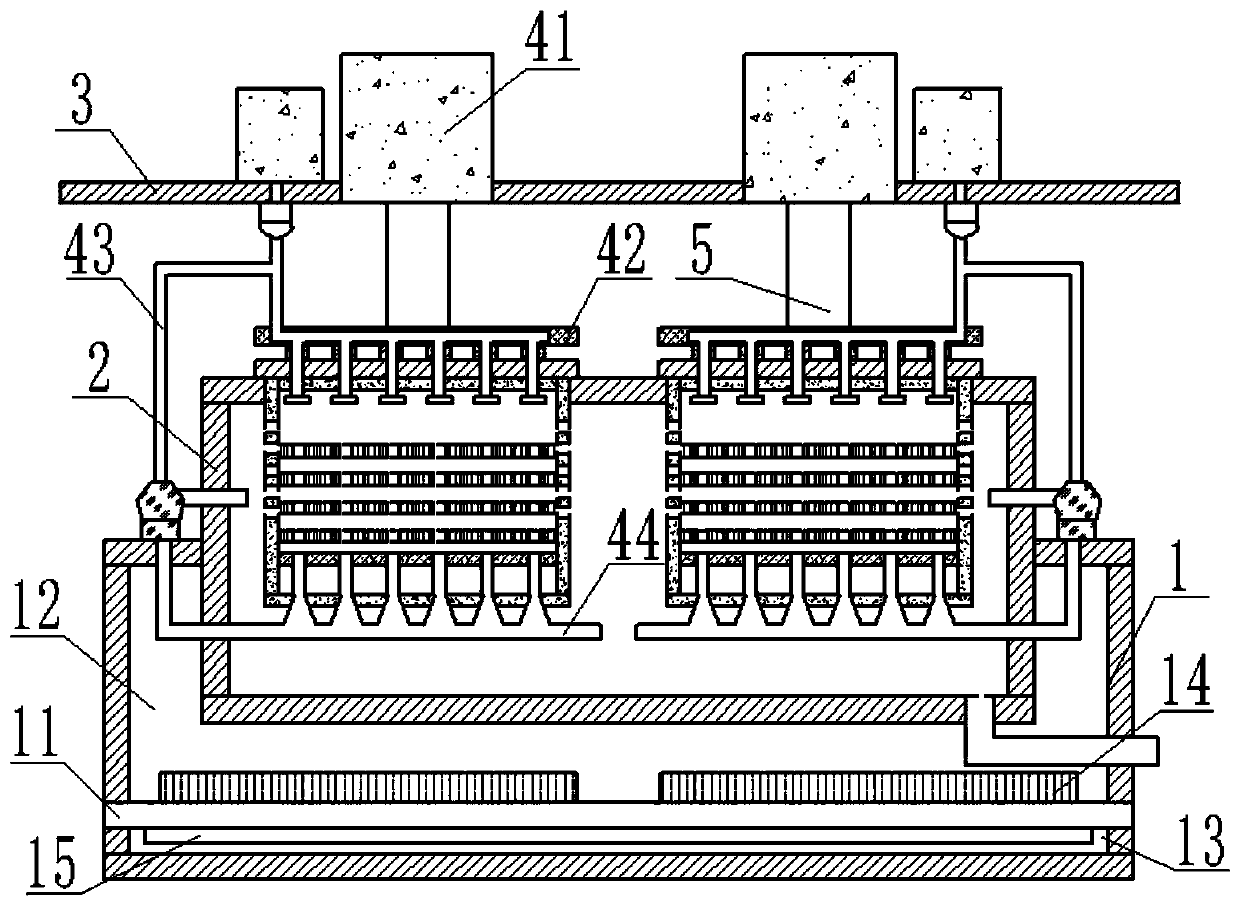

Processing device for third-generation semiconductor material

ActiveCN110211903AHigh degree of integrationFast conversionSemiconductor/solid-state device manufacturingSemiconductor materialsEngineering

The invention relates to the technical field of third-generation semiconductor materials, in particular to a processing device for a third-generation semiconductor material, and aims at solving the problems of low integration degree, low conversion speed and the like in the prior art; a solution is proposed as follows: the processing device comprises a processing table, wherein a corrosion chamber, a cleaning chamber and a drying chamber are arranged in the machining table; a mounting cavity is formed in the bottom of the processing table; a rotating mechanism is arranged in the mounting cavity; a rotating disc connected with the rotating mechanism is arranged on the processing table; the part of the rotating disc extends to the corrosion chamber, the cleaning chamber and the drying chamber; a plurality of placing grooves are formed in the circumferential direction of the upper end of the rotating disc at equal intervals, wherein three of the placing grooves are positioned in the corrosion chamber, the cleaning chamber and the drying chamber respectively; and a corrosion mechanism is arranged on the inner top of the corrosion chamber. The processing device disclosed by the invention has the advantages that the structure is reasonable, the corrosion, cleaning, washing and drying are integrated, the integration degree is high, and the feeding and processing can be continuously carried out.

Owner:江苏守航实业有限公司

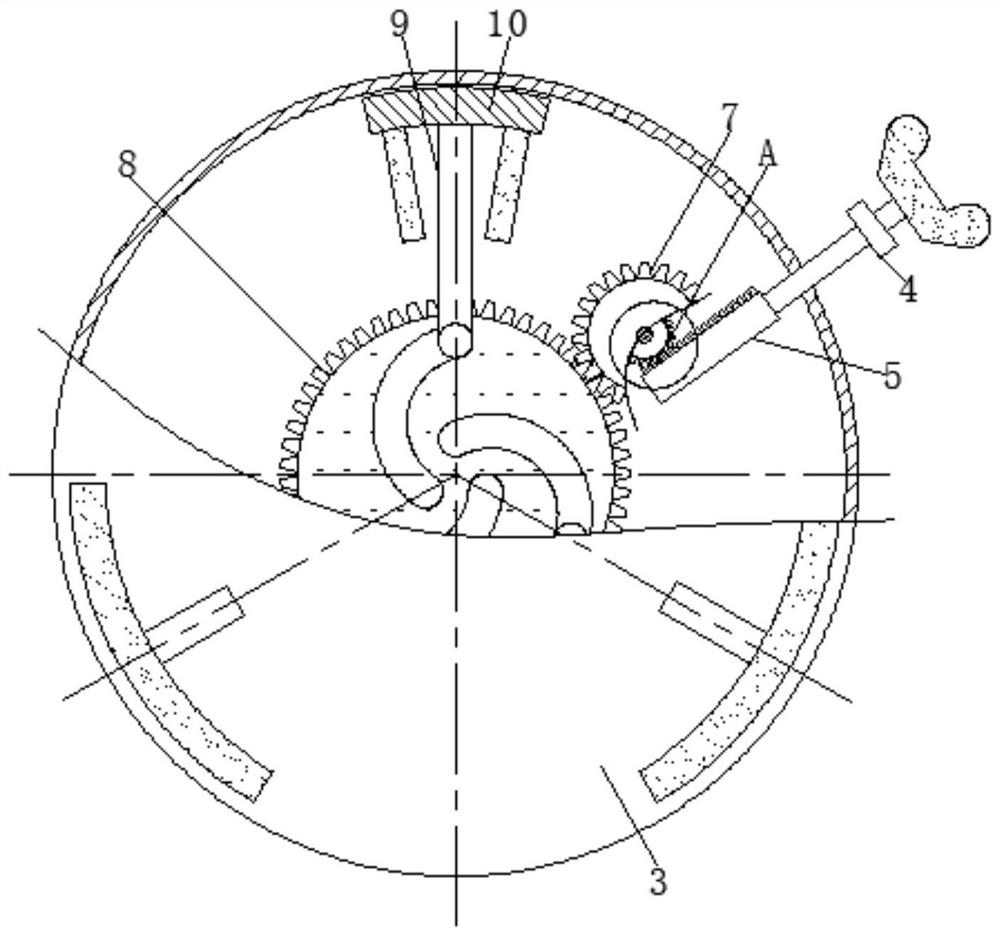

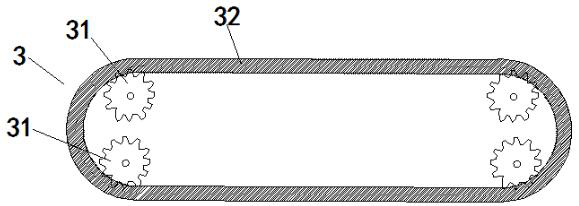

A handicraft cleaning and drying equipment based on new materials

ActiveCN112077071BQuick clampingQuick releaseCleaning using liquidsHeating arrangementGear wheelNew materials

Owner:邵阳市众兴工艺品有限公司

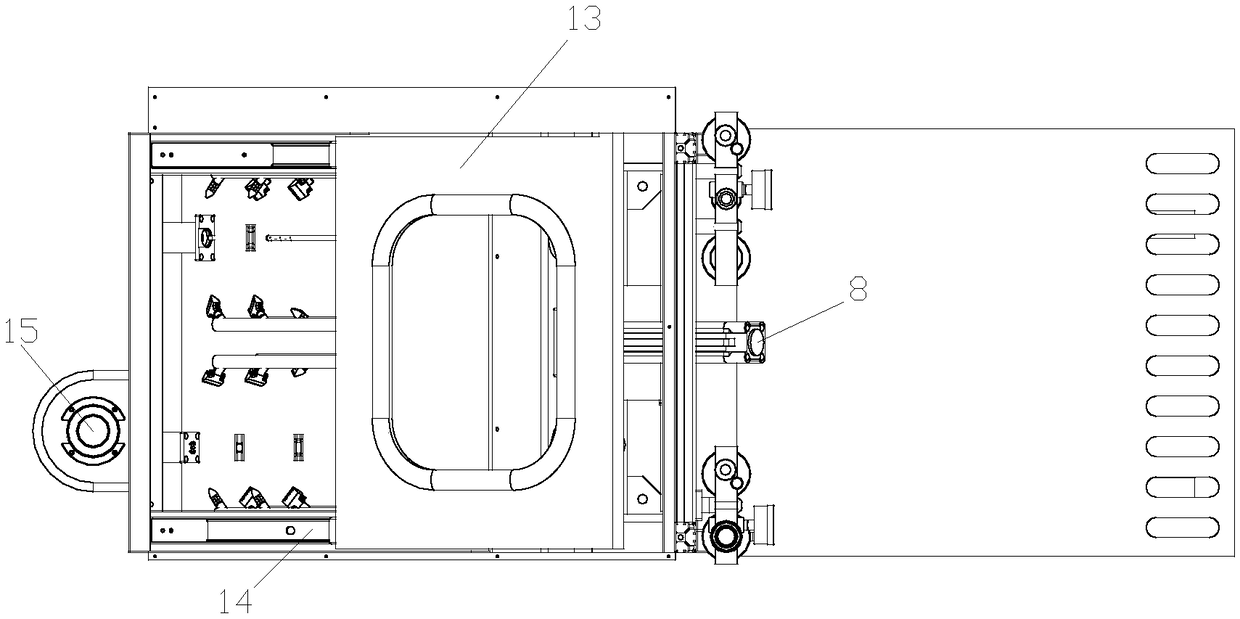

Pipeline Bowl Washing Machine

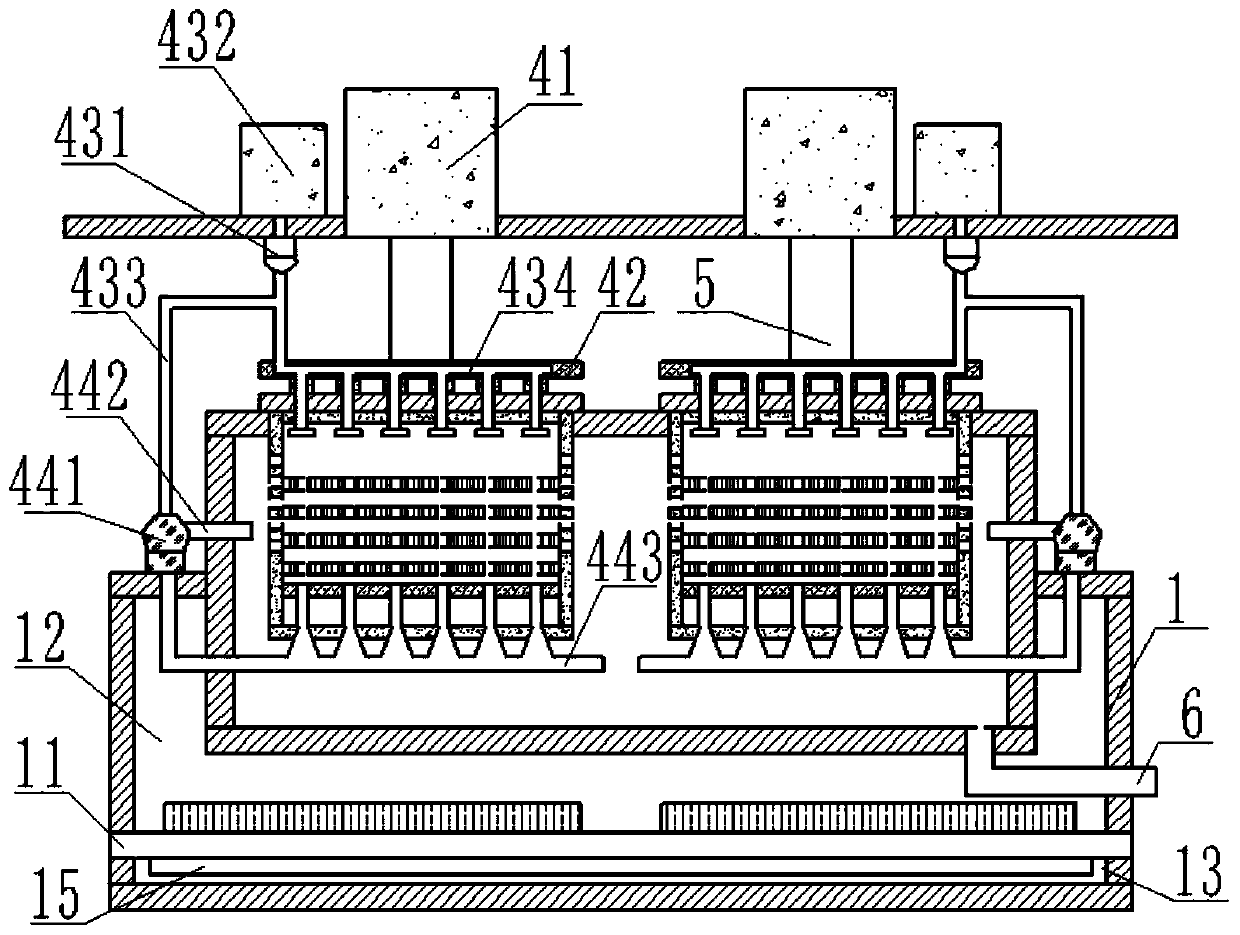

ActiveCN113814248BImprove cleaning efficiencyImprove cleaning qualityHollow article cleaningDrying gas arrangementsProcess engineeringAssembly line

The invention provides an assembly line type bowl cleaning machine, which includes a conveyor line consisting of three conveyors for continuously conveying the bowl. The drying assembly for bowl drying is separated by partitions. The cleaning assembly includes the first cleaning structure arranged on both sides of the conveying line, the second cleaning structure arranged below the conveying line, and the third cleaning structure arranged above the conveying line structure, the bowl is continuously reciprocated through the conveying line, and when it is transferred to the adjacent conveying line, the bowl and the contact surface of the conveying line will move relative to each other and change direction. There is no need to stop during the continuous conveying process, and the 360-degree full cleaning and drying without dead angle can be obtained through multiple reversing movements. It is suitable for industrial assembly line production and improves the cleaning efficiency and quality of the bowl.

Owner:长沙精功包装机械有限公司

A fruit cleaning device

ActiveCN110301657BGuaranteed cleaning qualityDry thoroughlyFood treatmentElectric machineryStructural engineering

The invention discloses a fruit cleaning device, which comprises a cleaning box, and is in the shape of a rectangular shell. A motor is vertically arranged at the center of the outer wall of a top plate, and an output end thereof faces downward and extends into the interior of the cleaning box. A hollow round rod-shaped cleaning core is coaxially arranged along the output end of the motor, and a plurality of nozzles for spraying cleaning liquid or clean water to the inner cavity of the cleaning box are arranged vertically along the wall of the core, and the nozzle and the cleaning core are connected. a stirring fan blade is spirally arranged from the upper side to the lower side of the outer wall of the cleaning core, a protective net cover is disposed on the outer side of the cleaning core, the stirring fan blade is covered inside. An upper part of the side wall of the cleaning box is provided with an openable feeding hopper, and a bottom of the cleaning box is provided with an openable discharge opening; and a drying chamber is located directly below the discharge opening of the cleaning box for drying the washed fruit of the cleaning box. The device can clean the fruit thoroughly and quickly, and can be widely used in the field of equipment manufacturing.

Owner:WUHAN BUSINESS UNIV

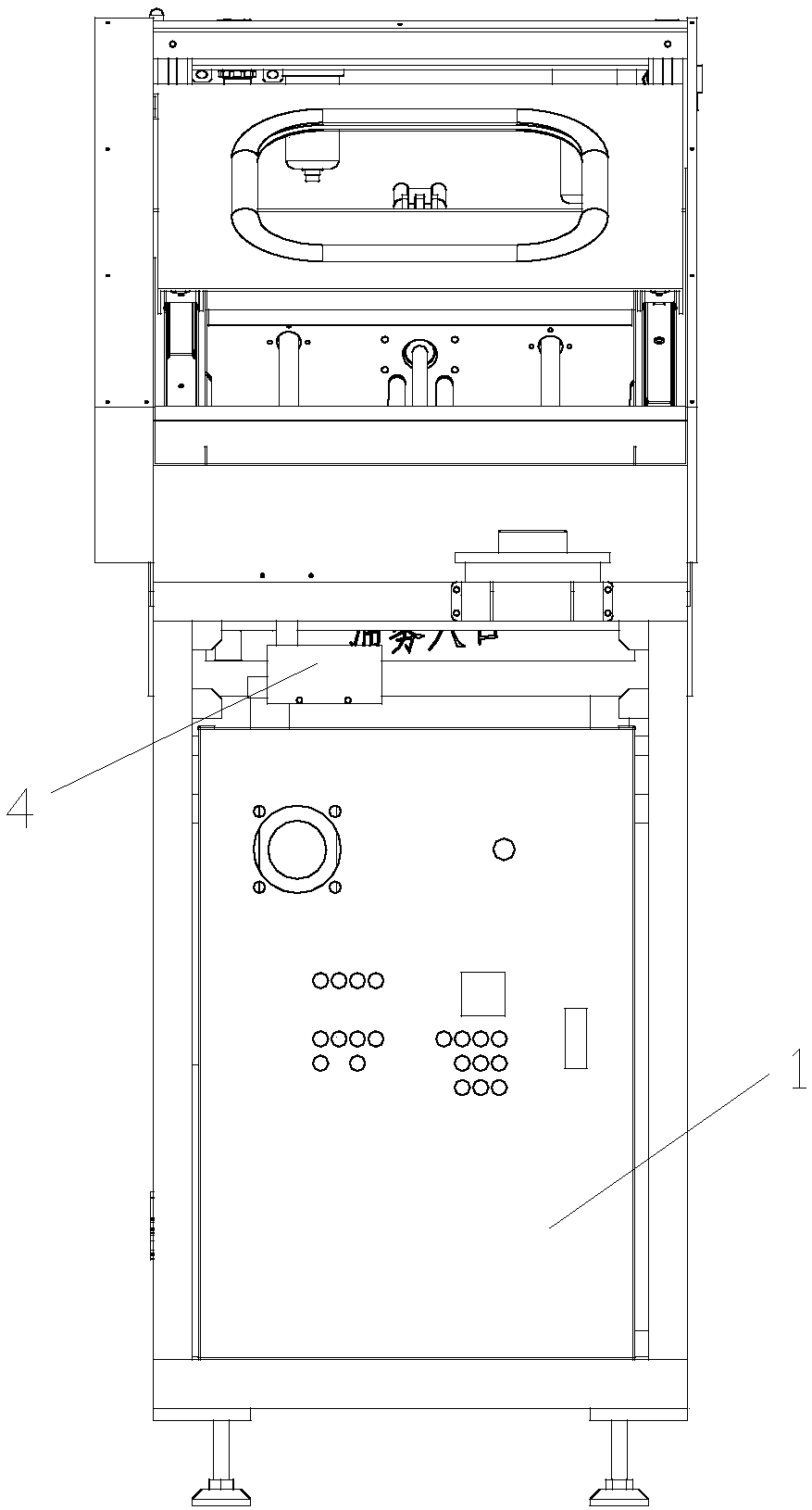

Assembly line type bowl body cleaning machine

ActiveCN113814248AImprove cleaning efficiencyImprove cleaning qualityHollow article cleaningDrying gas arrangementsAssembly lineTransfer line

The invention provides an assembly line type bowl body cleaning machine. The assembly line type bowl body cleaning machine comprises a conveying line which is used for continuously conveying bowls and composed of three conveyors, a cleaning assembly for cleaning the bowl bodies is arranged on the front portion of the conveying line, a drying assembly for drying the bowl bodies is arranged on the rear portion of the conveying line, and the conveying line is separated through partition plates, and the cleaning assembly comprises first cleaning structures arranged on the two sides of the conveying line, a second cleaning structure arranged below the conveying line and a third cleaning structure arranged above the conveying line. The bowl bodies are continuously conveyed in a reciprocating mode through the conveying line, when the bowl bodies are moved to the adjacent conveying line, the contact faces of the bowl bodies and the conveying line move relatively and are reversed, reversing is completed through guiding devices on the two sides of the conveying line, the bowl bodies do not need to be stopped in the continuous conveying process, 360-degree dead-corner-free sufficient cleaning and drying are achieved through multiple times of reversing movement, the assembly line type bowl body cleaning machine is suitable for industrial assembly line type production, and the bowl body cleaning efficiency and quality are improved.

Owner:长沙精功包装机械有限公司

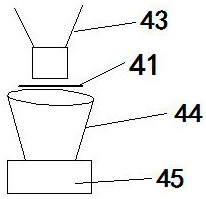

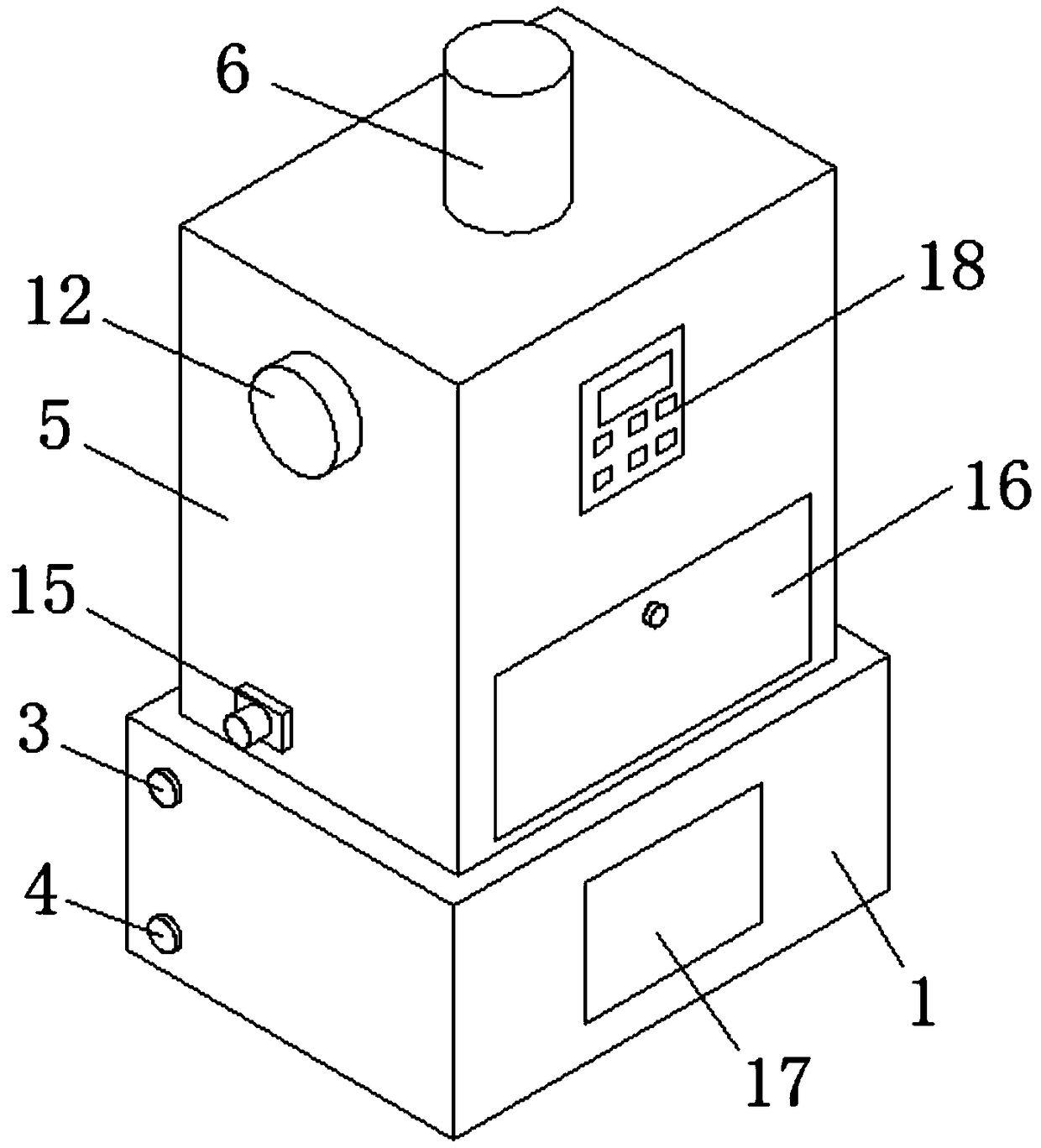

A two-station wind-cut dryer

ActiveCN106123555BImprove cleaning efficiencyReasonable handlingDrying gas arrangementsAir filterWind shear

The invention discloses a two-station wind shear drying machine, and relates to the field of cleaning dryers. The two-station wind shear drying machine comprises an electric cabinet, a worktable, a wind shear drying mechanism, a vacuum generator, an electrostatic oil mist fan and an air filter; the wind shear drying mechanism is fixed on the worktable; the electrostatic oil mist fan and the air filter are arranged on one side of the wind shear drying mechanism; two workpiece placing stations are arranged on the worktable; the wind shear drying mechanism at least includes an outer wind shear pipe, a polishing cylinder and a wind nozzle; the outer wind shear pipe is connected with external air pressure power; the wind nozzle is mounted on the outer wind shear pipe; the polishing cylinder pushes the outer wind shear pipe to regularly swing on the stations; and the bottoms of the stations are connected with the vacuum generator for sucking and discharging oil stains. The two-station wind shear drying machine can perform universal drying according to specific conditions of the workpieces, cleans the workpieces with different structures through the two added stations, is excellent in cleaning and drying effects and reasonable in oil mist treatment, and can effectively improve the workpiece cleaning efficiency.

Owner:TAKAHASHI METAL MFG SUZHOU

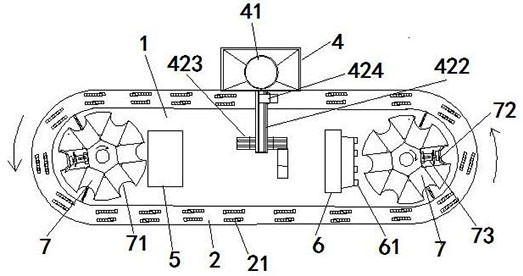

A kind of equipment and method for automatic filtration of tobacco material liquid

ActiveCN109499151BImprove work efficiencyReduce labor intensityMoving filtering element filtersControl engineeringProcess engineering

The invention discloses a device and a method for automatically filtering tobacco material liquid. The automatic filtering equipment for tobacco material liquid includes a workbench, a conveying track for conveying filter nets, and a rotary mechanism. The conveying track is set above the workbench, and the turntable is set inside the workbench; the workbench is ring-shaped structure, the circular path of the workbench is respectively provided with a filter mechanism, a cleaning mechanism and a drying mechanism; the conveying track is connected with the rotary mechanism, and the rotary mechanism drives the conveying track to rotate along the circular path of the workbench. The invention effectively integrates the conveying track, the rotary mechanism, the filtering mechanism, the cleaning mechanism and the drying mechanism, realizes the automatic operation of filtering, cleaning, and drying, and ensures that the filtering efficiency is improved while preventing cross-contamination. The operation requirement of automatically filtering the feed liquid for tobacco has a strong promotion value.

Owner:CHINA TOBACCO GUANGDONG IND

An integrated textile fabric washing and drying equipment and its working process

ActiveCN108277600BConvenient production workImprove cleaning and drying effectSucessive textile treatmentsLiquid/gas/vapor removal by gas jetsRotational axisElectric machinery

The invention discloses integrated cleaning and drying equipment for textile cloth and relates to the technical field of production processing equipment for textile cloth. The equipment comprises a baseplate, a cleaning box is fixedly connected to the top of the baseplate, and a beat pounding box is fixedly connected to the top of the cleaning box; a wedge block and a motor box are fixedly connected to the inner wall of the beat pounding box separately, rotation shafts are rotatably connected to one side of the motor box through a supporting rack, and first bevel gears and rotation cams sleevethe rotation shafts from top to bottom in sequence; a motor is fixedly connected to the interior of the motor box. According to the integrated cleaning and drying equipment for the textile cloth anda working process thereof, the cleaning and drying effect is greatly improved, the cleaning and drying efficiency is well improved, production personnel do not need to spend a large amount of time incleaning and drying the textile cloth, the textile cloth is quickly and efficiently subjected to cleaning and drying integrated treatment, and great convenience is provided for production personnel toconduct production work of the textile cloth.

Owner:泉州台商投资区国进信息技术有限公司

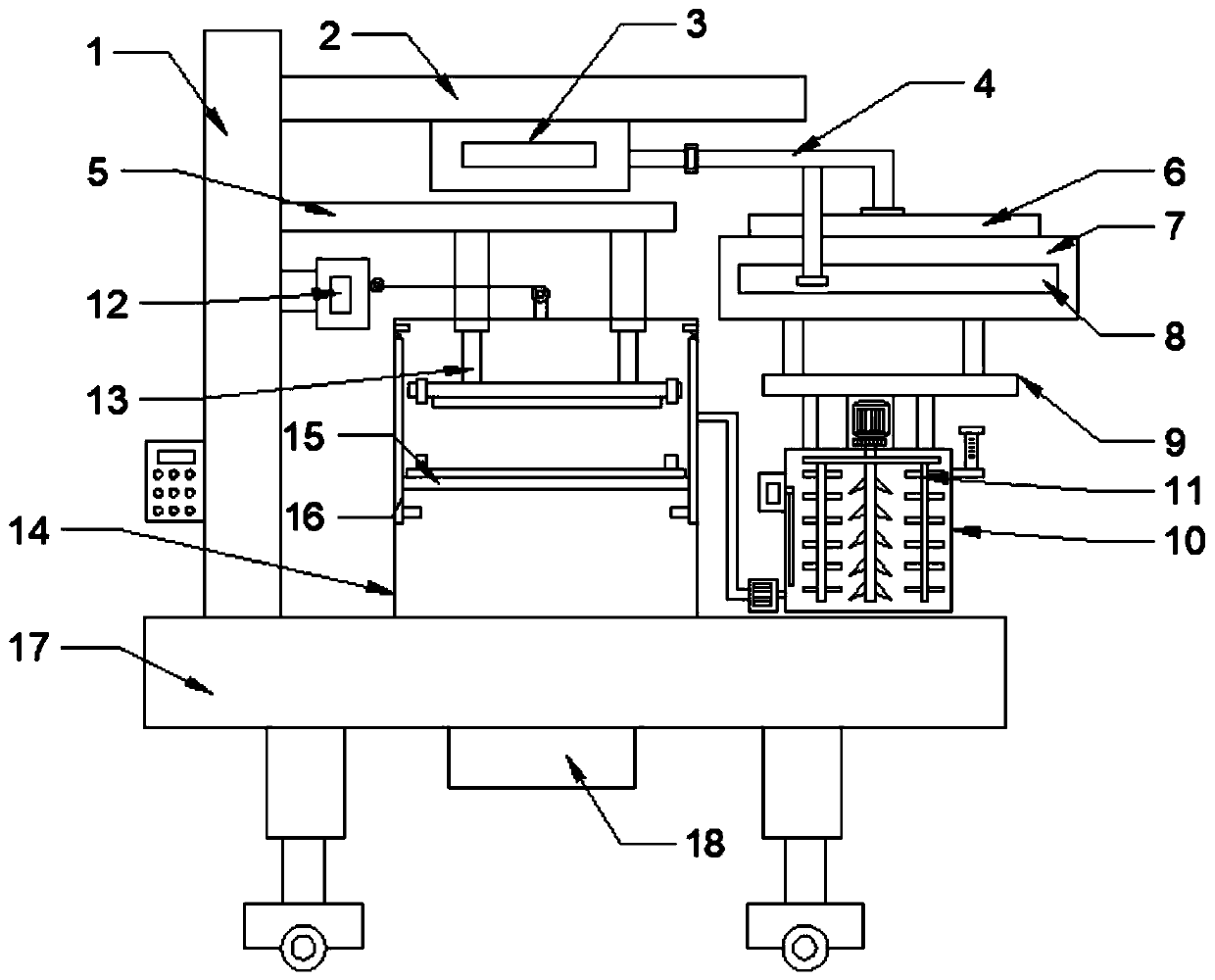

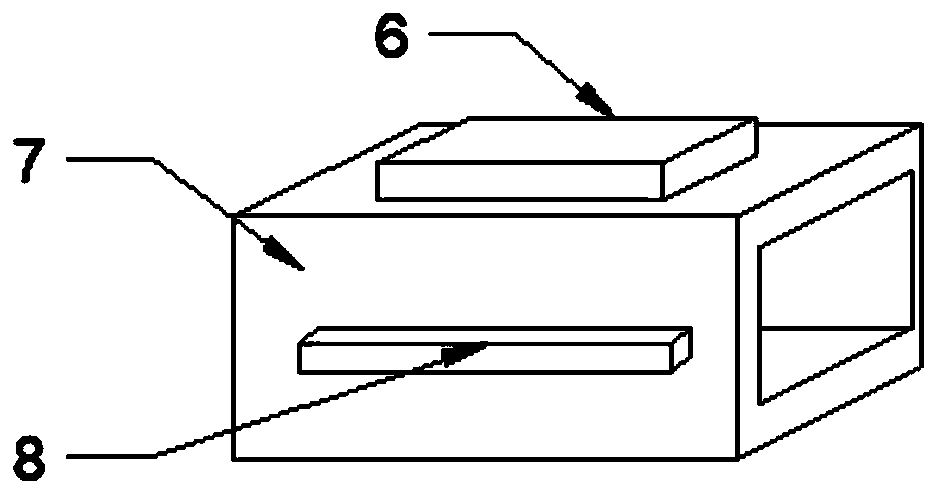

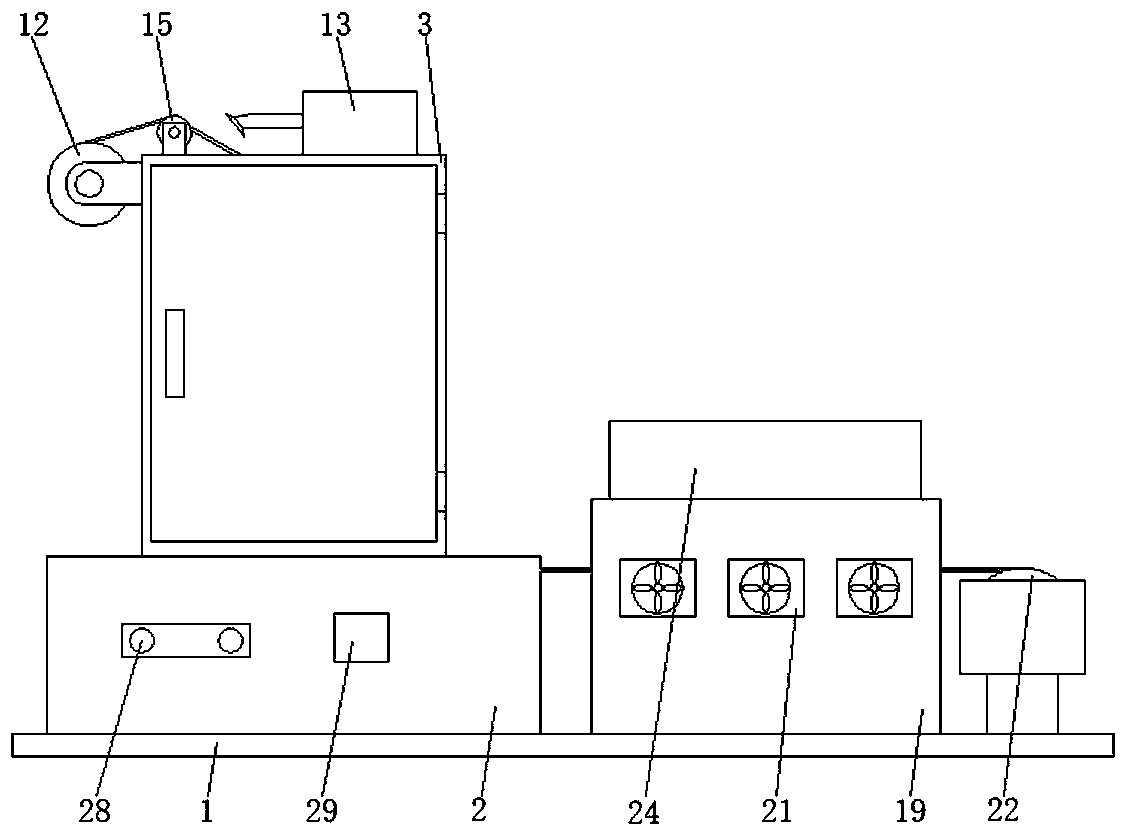

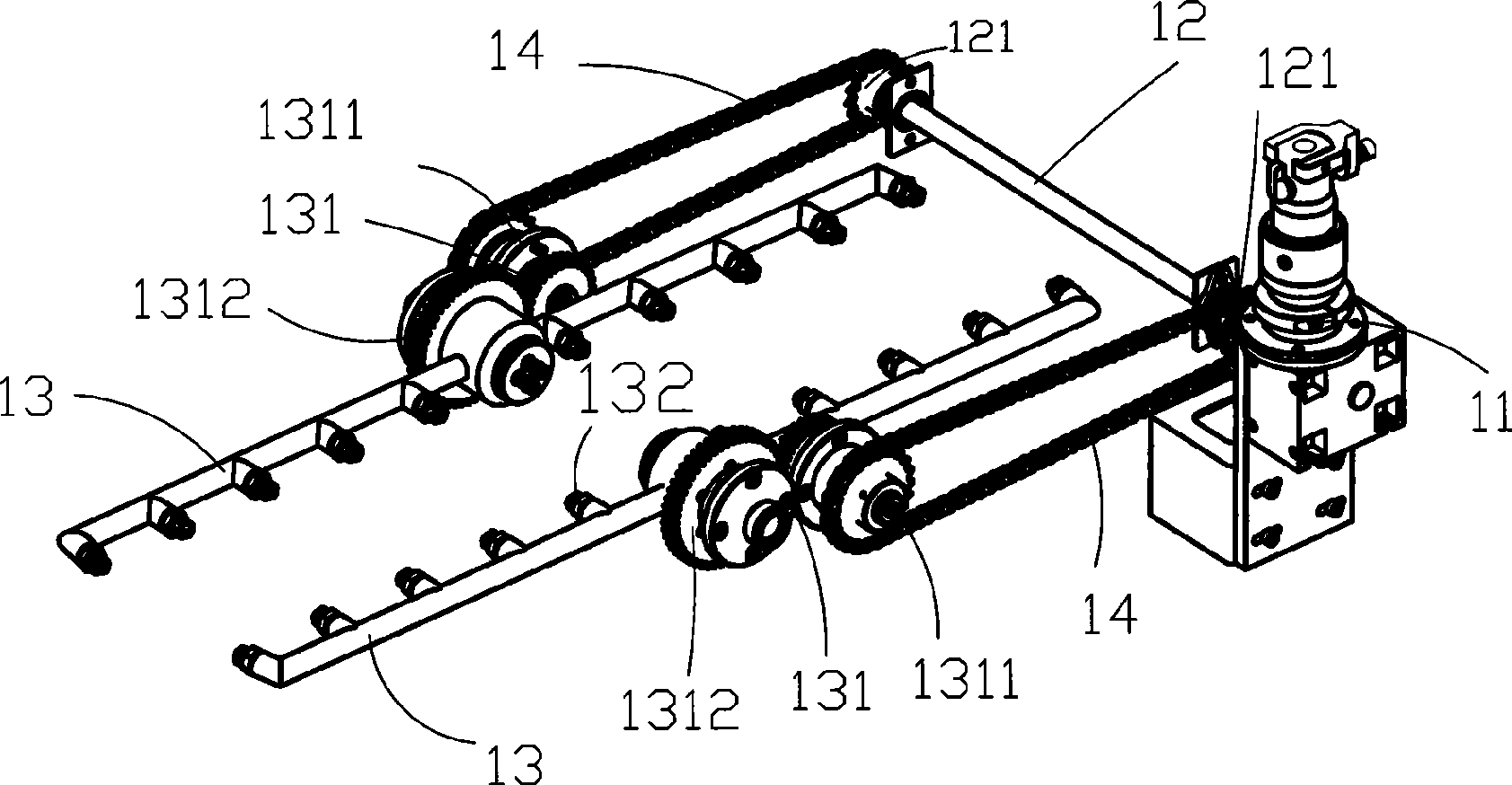

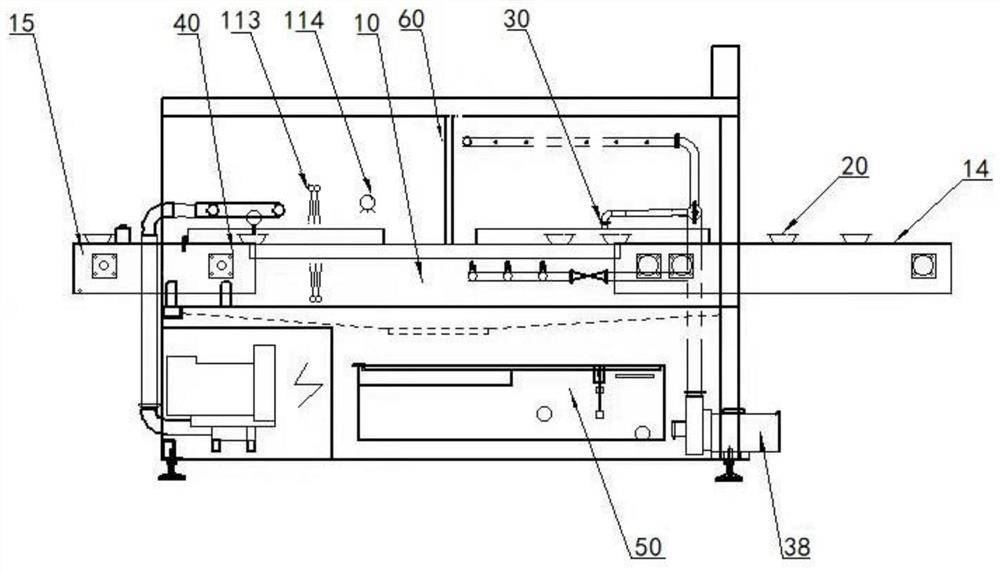

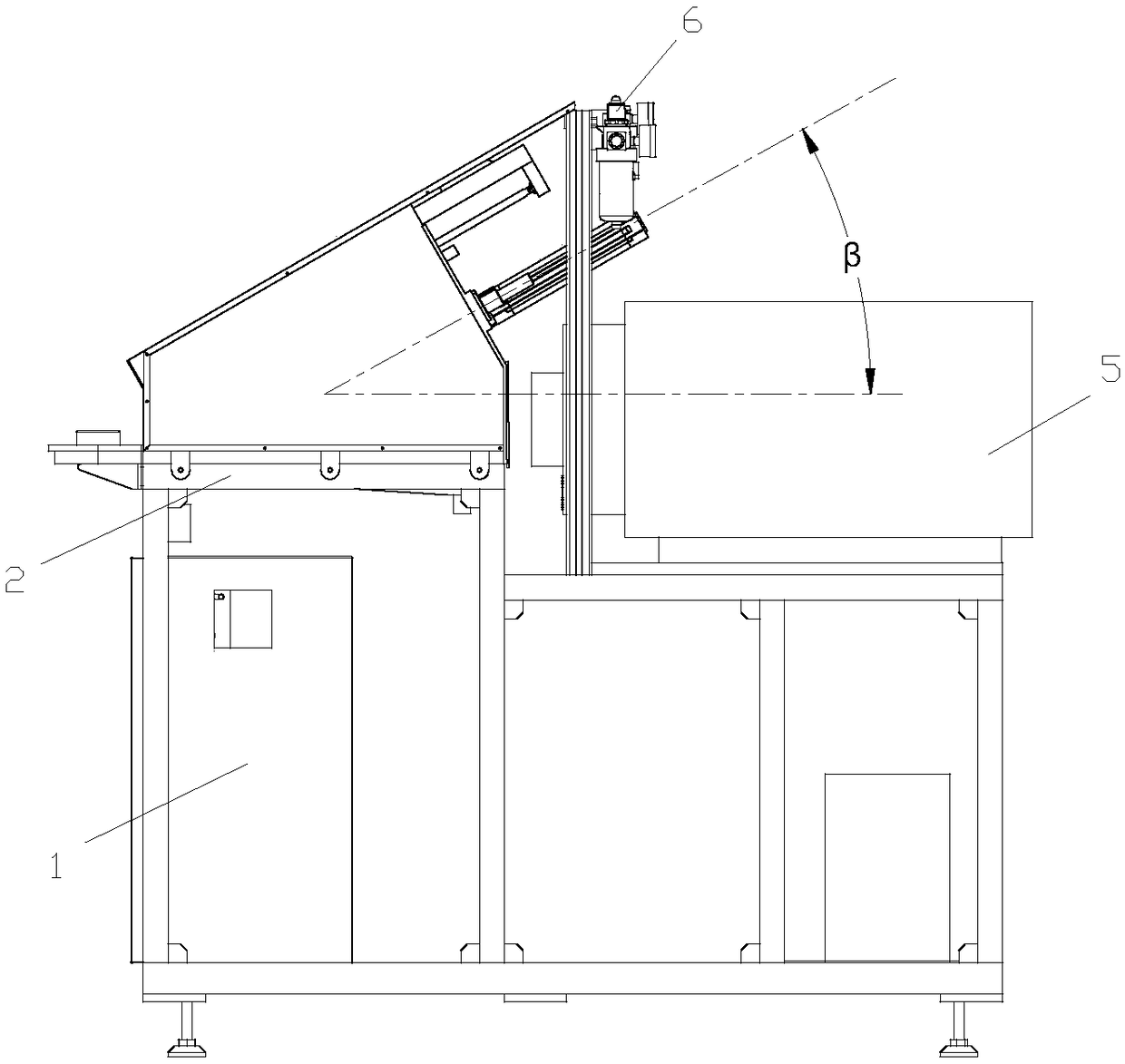

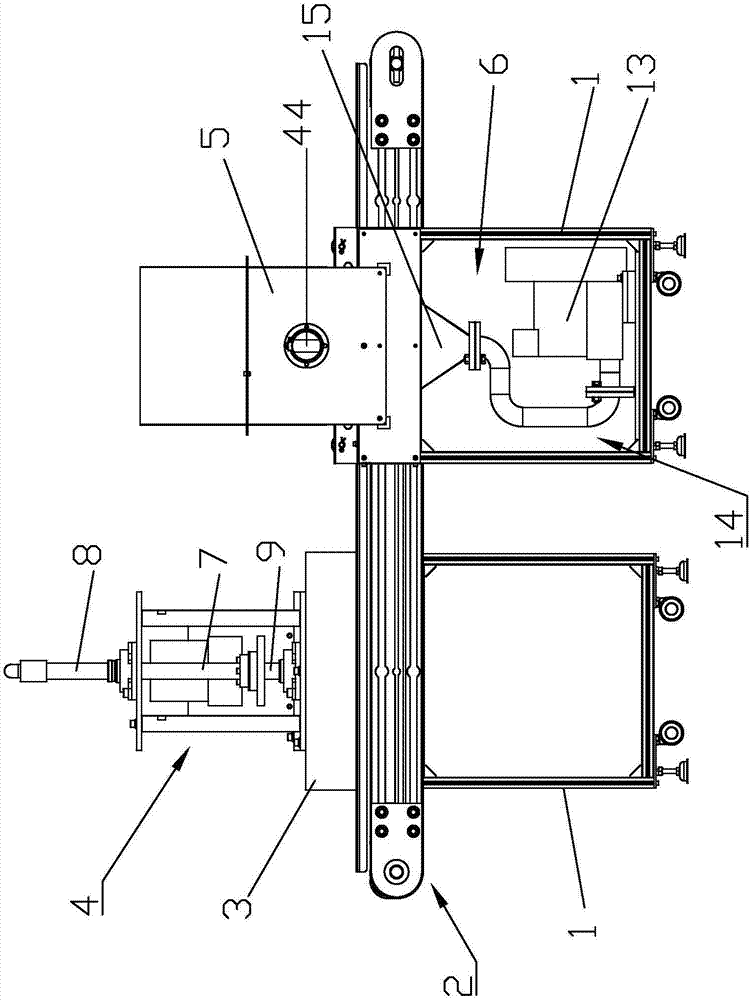

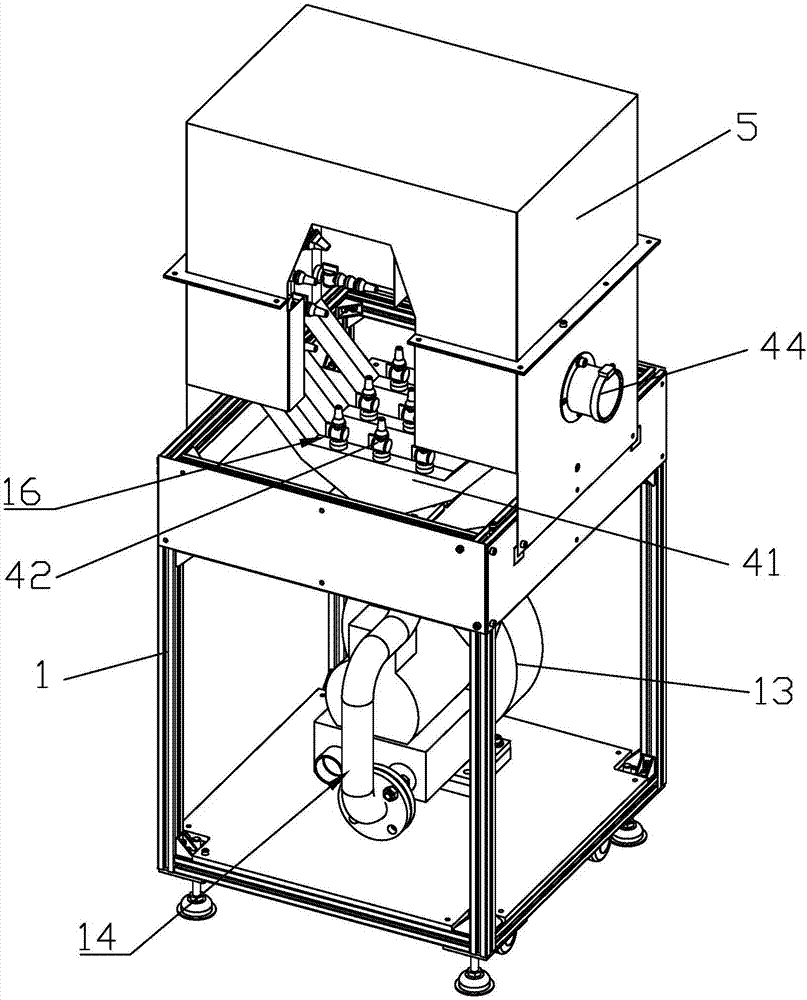

Integrated aftertreatment system for use in pencil production lines

ActiveCN106269641BSolve cleaning and drying problemsImprove cleaning efficiencyDrying gas arrangementsDrying machines with progressive movementsProduction lineAgricultural engineering

The invention discloses an integrated aftertreatment system used in a pencil production line. The system comprises a rack and a conveying device; a cleaning room is arranged on the left side of the conveying device, a cleaning device is arranged in the cleaning room, a drying room is arranged on the right side of the conveying device, a drying device is arranged in the drying room, and the cleaning device comprises a cleaning shaft, a cleaning pipe and a spraying assembly; the cleaning pipe comprises an upper cleaning pipe body and a lower cleaning pipe body; the lower cleaning pipe body is connected with the spraying assembly, the middle of the cleaning shaft is connected with a rotating mechanism, fixing mechanisms are arranged at the two ends of the cleaning shaft, and the drying device comprises an air blower, an air outlet pipe assembly, an air flow distribution chamber and a distribution pipe assembly; the air blower is connected with the air outlet pipe assembly which is connected with the air flow distribution chamber, and the air flow distribution chamber is connected with the distribution pipe assembly which is arranged in the drying room. The system is simple in structure, scientific, convenient, high in pertinence, high in automation degree, good in cleaning and drying effect, and capable of greatly improving the product quality and well solving the cleaning and drying problems of pencil production.

Owner:ZHEJIANG PENGSHENG STATIONERY CO LTD

Roller device for precision textile cloth

ActiveCN109896317BSolve the problem of insufficient protective measuresImprove winding protectionWebs handlingElectric machineryStructural engineering

Owner:南通柯林纺织品有限公司

A post-processing device and process for nano-added composite doped soft ferrite core

ActiveCN109755014BReduce the burden onImprove work efficiencyInductances/transformers/magnets manufactureCircular discGear wheel

The invention discloses a postprocessing device for a nanomaterial-added and co-doped soft magnetic ferrite core, and a process implemented by the device. The device comprises a base, wherein a working housing is arranged at the upper end of the base along one lengthwise side of the base; a moving working table mechanism is arranged at the upper end of the base, and comprises a rotating motor, a screw rod, a rectangular elongated slot, a sliding rail, a chute, and a working table; disc-shaped placement racks are uniformly and movably arranged at the upper end of the working table and along thetwo widthwise sides of the working table; vertical straight slots are uniformly formed on the inner cavity at the upper end of the working table; driving gears are arranged at the upper end of the working table in positions corresponding to the vertical straight slots; worms are respectively arranged in the vertical straight slots; and a drying box body and a cleaning box body are arranged in theworking housing.

Owner:天津北磁科技有限公司

A device for washing, drying and removing impurities of wheat

ActiveCN108043809BLow costRealize the collectionDrying gas arrangementsDrying solid materialsWater useAgricultural engineering

The invention discloses a device for carrying out washing, drying and impurity removing on wheat. The device comprises a machine frame, a cleaning barrel, a drying box and a filtering box, wherein thecleaning barrel is fixedly arranged on the inner wall of the left side of the machine frame; a first rotating shaft is rotationally arranged in the cleaning barrel, a plurality of material turning plates are uniformly arranged on the first rotating shaft, and a cleaning disc is fixedly arranged on the top wall of the cleaning barrel; and a first filter screen is fixedly arranged inside the filtering box; the drying box is fixedly arranged on the inner wall of the machine frame, a partition plate is fixedly arranged in the drying box, the interior of the drying box is divided into a driving chamber and a drying chamber by the partition plate, and the drying chamber communicates with the cleaning barrel. According to the device, second filter screens, cavities and the filtering box are arranged to fully collect and recycle the cleaning water for washing the wheat, so that the water resources are saved; a drying box is further arranged, the wheat is dried by using a hot fan and spiral blades, so that the cleaning and drying effects are excellent, and the economic benefits are improved.

Owner:安徽双全面粉有限公司

A processing device for third-generation semiconductor materials

ActiveCN110211903BHigh degree of integrationFast conversionSemiconductor/solid-state device manufacturingSemiconductor materialsMechanical engineering

The present invention relates to the technical field of third-generation semiconductor materials, and in particular to a processing device for third-generation semiconductor materials. Aiming at the problems of low integration and slow conversion speed in the prior art, the following solutions are proposed, including processing The processing table is provided with a corrosion chamber, a cleaning chamber and a drying chamber. The bottom of the processing table is provided with an installation cavity. The installation cavity is provided with a rotating mechanism. The processing table is provided with a rotating The turntable connected by the mechanism, the part of the turntable extends to the corrosion chamber, the cleaning chamber and the drying chamber. The upper end of the turntable is provided with a plurality of placement grooves at equal intervals in the circumferential direction, and three of the placement grooves are respectively located in the corrosion chamber, the cleaning chamber and the drying chamber. In the cleaning chamber and the drying chamber, an corrosion mechanism is installed on the inner top of the corrosion chamber. The invention has a reasonable structure, integrates corrosion cleaning, flushing and drying, has a high degree of integration, and can continuously carry out material feeding and processing.

Owner:江苏守航实业有限公司

A self-cleaning towel storage device in a multifunctional nursing department

InactiveCN107049677BImprove the display effectConvenient instructionsOther washing machinesWashing machine with receptaclesWater storageAutomatic control

The invention provides a multifunctional nursing department self-cleaning type towel storage device. The multifunctional nursing department self-cleaning type towel storage device comprises a moving box, moving wheels, a left-side pull rod, a left-side pull door, a right-side pull rod, a right-side pull door, a waste water storage box, a storage box mounting plate, a water outlet pipe, a primary electromagnetic valve, a metal hose, a secondary electromagnetic valve, a towel separating and placing box device, a cleaning and brushing machine, a control cabinet, an intelligent controller device, a cooler device and a towel temporary storage cabinet device. A display screen is electrically connected with the output end of a controller; an alarm is electrically connected with the output end of the controller; a main control switch is electrically connected with the input end of the controller, so that the working state of the device is displayed and indicated in real time and the intelligent degree is higher; and an intelligent power distribution cabinet is electrically connected with the control cabinet through a line bank, so that the multifunctional nursing department self-cleaning type towel storage device is favorable for realizing manual control and automatic control, facilitates operation, increases the operating function, and is convenient to use and convenient to popularize and use.

Owner:杨继芳

A fully automatic plastic box washing and drying machine

ActiveCN112044900BReduce occupancyEfficient recyclingHollow article cleaningDrying gas arrangementsWater storageStructural engineering

The invention discloses a fully automatic cleaning and drying machine for plastic boxes, which comprises a machine body, a base is provided at the bottom of the machine body, and a cleaning and drying chamber is arranged in the body; the bottom of the cleaning and drying chamber is provided with a plurality of annular slots, and the ring The slots are distributed in a circular structure; a circular sleeve is inserted into and fixed in the circular slots, a hollow part is provided in the center of the circular sleeve, and an annular water storage chamber is provided in the circular sleeve, and a plurality of water storage chambers are arranged on the circular sleeve. The cavity and the hollow part are connected to each other; the inner wall of the round sleeve is fixed with a plurality of hard shavings; the groove bottom of the annular slot is provided with a concave part, and an elastic metal plate is welded and fixed in the concave part. The invention has a simple structure, can clean and dry the plastic box at the same time, does not need to be divided into two equipment for cleaning, reduces the space occupation of the equipment, and has good cleaning and drying effects; it can effectively recycle and reuse water resources, reducing waste Necessary waste.

Owner:康熹自动化设备(广州)有限公司

Production technology of liner of tennis

InactiveCN110152255AImprove qualityImprove physical performanceHollow non-inflatable ballsDomestic articlesEngineeringSilica gel

The invention provides a production technology of a liner of a tennis. Through the production technology, the technical problems that an existing forming technology is simple, production equipment anda production technology are not supported by specific and quantitative parameters, and the production efficiency, quality, physical performance and the like of the liner of the tennis cannot be guaranteed are solved. The production technology of the liner of the tennis comprises the following steps that S1, natural rubber, butadiene rubber, isoprene rubber and chloroprene rubber are placed into amixing machine in parts by mass, the rotating speed is 90-110 r / min, the temperature is maintained to be 120-140 DEG C for 2-6 min, and a premix is obtained; and S2, the premix in the S1 is placed into a stirring machine firstly, then carbon black, clay, mica powder and liquid silica gel are placed into the stirring machine by mass fraction to be stirred for 15-30 min, after even mixing, sulphur,magnesium oxide, an accelerant and a softener are put into the stirring machine by mass fraction to be stirred for 3-8 min, and after sufficient and even mixing, a required mixing blank is obtained.The production technology has the advantage of high production efficiency.

Owner:孙艳

Cleaning and drying integration device for producing tea, and using method thereof

InactiveCN108812942AEasy to cleanEasy to operatePre-extraction tea treatmentEngineeringSmall footprint

The invention discloses a cleaning and drying integration device for producing tea. The device comprises a water tank, four universal wheels are symmetrically mounted at the corners of the bottom of the water tank, a shell is welded to the top of the water tank, an electric actuator is fixedly mounted at the middle part of the top of the shell, the output shaft of the electric actuator body penetrates through the shell and is fixedly connected with a mounting frame, a variable frequency motor is fixedly mounted in the mounting frame, the output shaft of the variable frequency motor is fixedlyconnected with a tea leaf storage box, baffle plates are welded to the inner middle part of the shell, blowers are mounted at the upper ends of two sides of the shell, electric heating tubes are mounted at positions, at the air outlet ends of the blowers, in the shell, and a spraying tube is mounted at the inner bottom end of the shell. The device has the advantages of simple and reasonable structure design, convenience in operation, easiness in adjustment, small occupied area, easiness in movement, good cleaning and drying effect on the tea leaves, increase of the working efficiency, good safety and stability, wide application range, and facilitation of promotion.

Owner:广东御品茶缘茶叶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com