Integrated aftertreatment system for use in pencil production lines

A production line and integrated technology, applied in the direction of using liquid cleaning methods, drying solid materials, drying gas layout, etc., can solve the problems that restrict the development of enterprises, the quality of pencils is not high, and the number of pencils is limited, so as to improve product quality and save Labor and financial resources, the effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

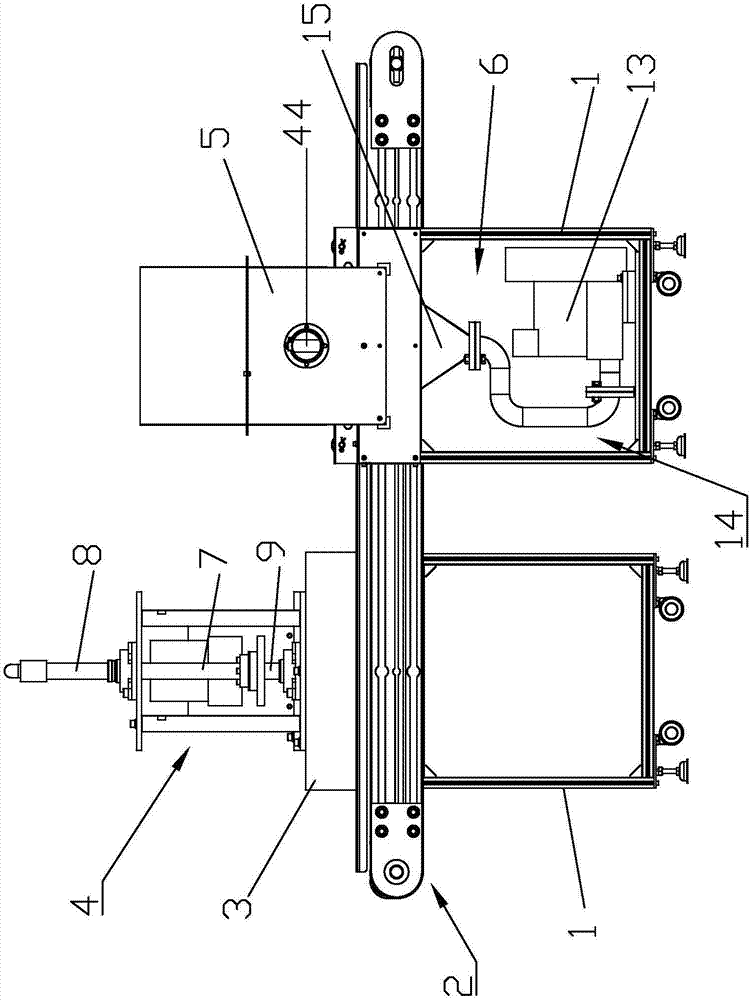

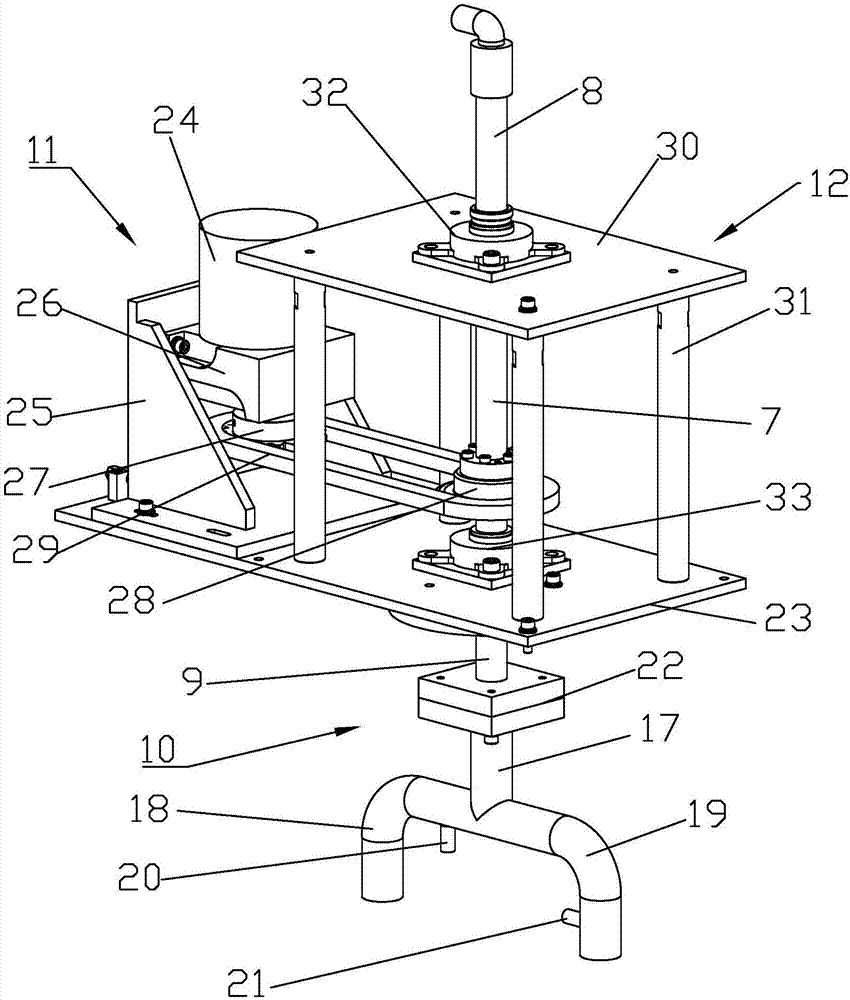

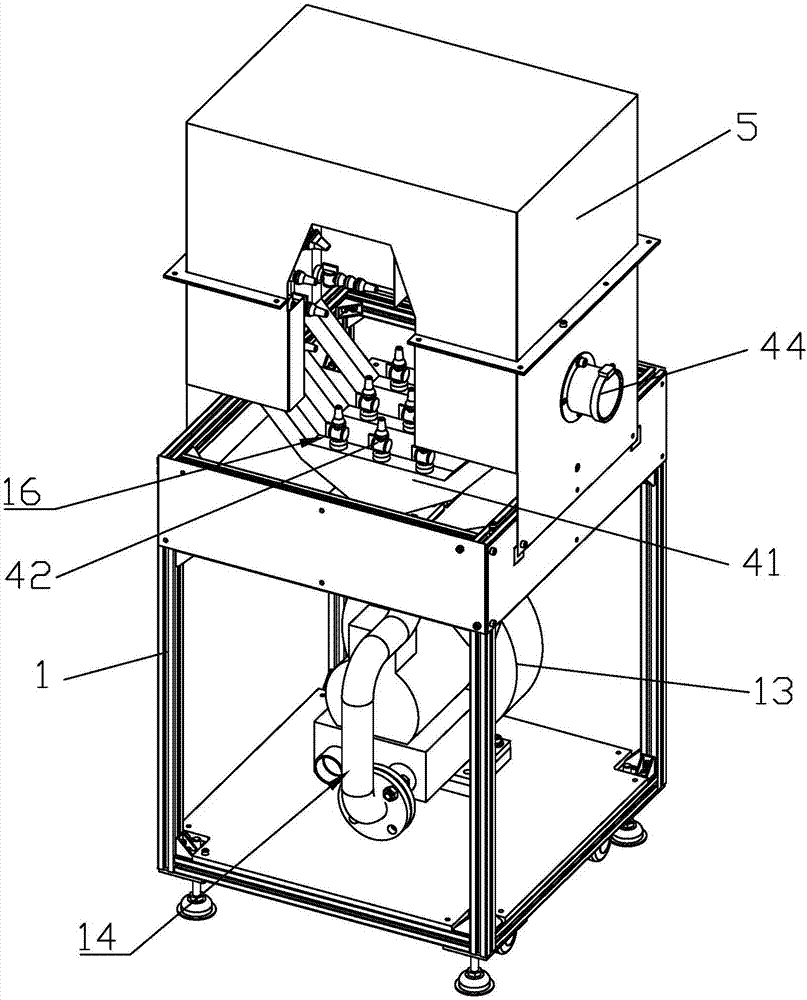

[0035] Such as Figure 1 to Figure 7 As shown, the integrated post-processing system used in the pencil production line includes a frame 1 and a conveying device 2. The conveying device 2 is arranged on the frame 1. A cleaning room 3 is provided on the left side of the conveying device 2. Inside the cleaning room 3 A cleaning device 4 is provided, a drying chamber 5 is provided on the right side of the conveying device 2, and a drying device 6 is arranged in the drying chamber 5. The cleaning device 4 includes a cleaning shaft 7, a cleaning pipe and a spray assembly 10, and the cleaning pipe includes an upper cleaning pipe 8 and the lower cleaning pipe 9, the upper cleaning pipe 8 is connected to the upper end of the cleaning shaft 7, the lower cleaning pipe 9 is connected to the lower end of the cleaning shaft 7, the lower cleaning pipe 9 is connected to the spray assembly 10, and the middle part of the cleaning shaft 7 is connected to a rotating mechanism 11. Both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com