Wafer back surface cleaning and drying device and wafer back surface cleaning and drying system and method

A technology for drying devices and wafers, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unsatisfactory cleaning and drying effects, and the cleaning and drying methods cannot cover the entire or overlap the back of the wafer, etc. Achieve the effect of improving cleaning and drying effect, effective cleaning and drying, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

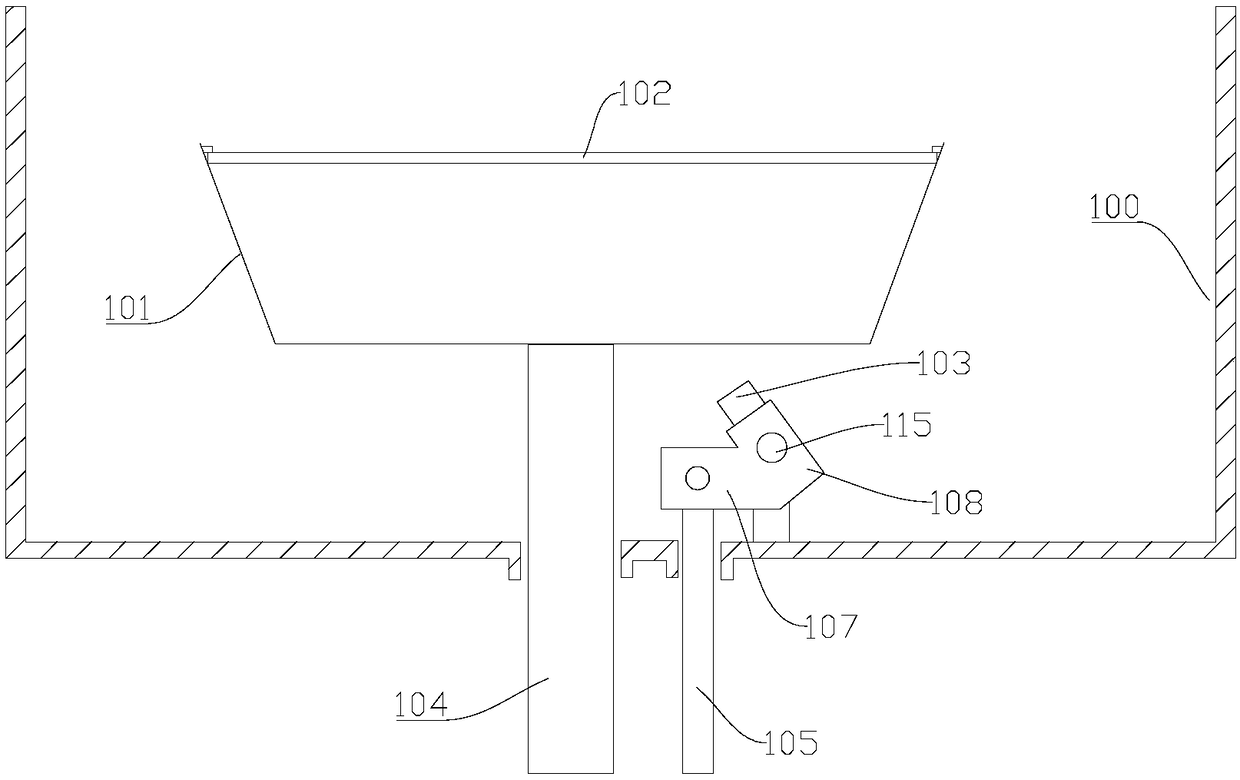

[0031] see figure 1 As shown, Embodiment 1 of the present invention provides a wafer backside cleaning and drying device including a wafer clamping device 101, a first driving device and a spraying mechanism. The wafer clamping device 101 is used to carry a wafer 102; the first driving device The device is used to drive the wafer clamping device 101 to rotate; the spraying mechanism is used to clean and dry the backside of the wafer; the spraying mechanism includes a nozzle 103, and the spraying path of the nozzle 103 to the backside of the wafer gradually changes from the center of the backside of the wafer Move to the edge of the back side of the wafer. In this embodiment, no improvement is made to the wafer clamping device 101, which is a prior art. Therefore, the description of the wafer clamping device 101 involved in the following embodiments is only used to more fully describe the present invention technical solutions and more clearly embody the features of the present...

Embodiment 2

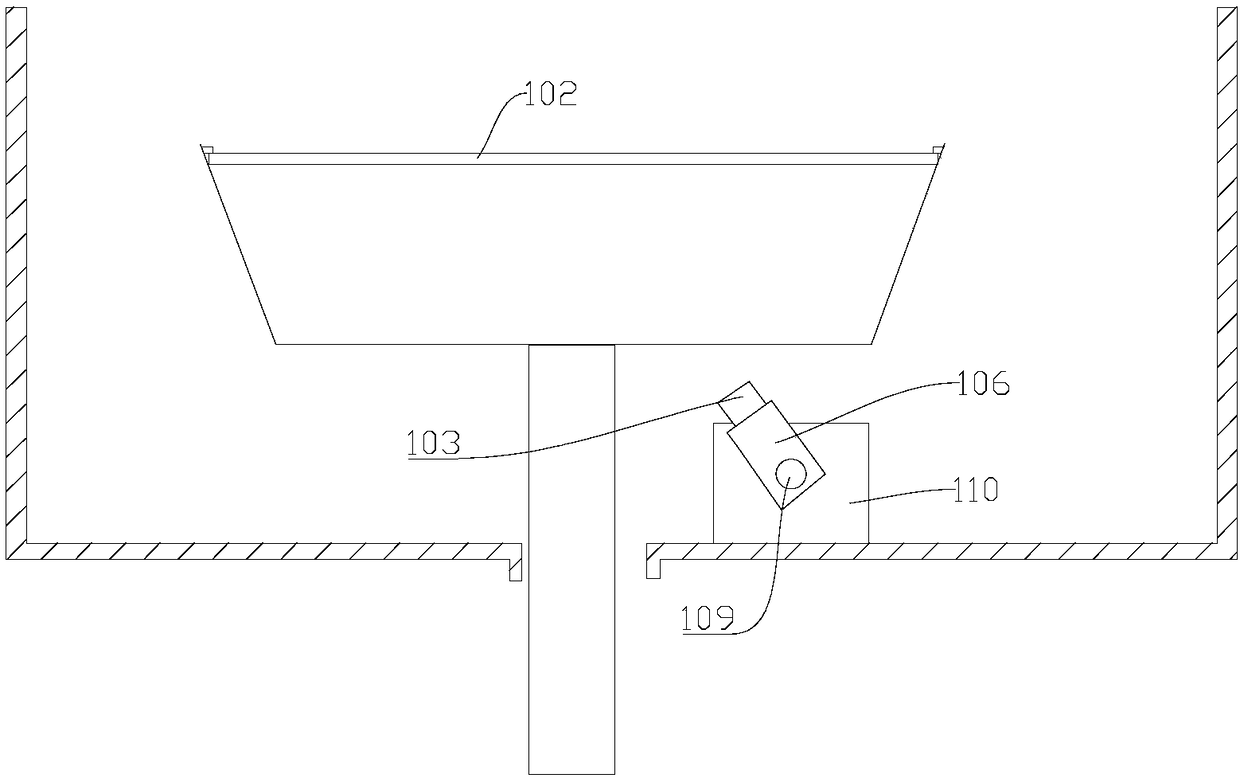

[0046] The second embodiment also provides a cleaning and drying device for the back of the wafer. The cleaning and drying device for the back of the wafer in this embodiment describes another implementation of the injection mechanism. In addition to the technical solution of the first embodiment It also belongs to the second embodiment and will not be described again.

[0047] see figure 2 As shown, in this embodiment, the injection mechanism includes a movable block 106 and a nozzle 103; the nozzle 103 is installed on the movable block 106, and the movable block 106 is installed on the second rotating shaft 109, and the second rotating shaft 109 is connected with the fourth rotating shaft through a gear or a synchronous belt. The driving device is driven, and the fourth driving device can be a motor 110; the motor rotates so that the angle of the second rotating shaft 109 is changed, so that the movable block 106 is deflected, and the movement of the movable block 106 drive...

Embodiment 3

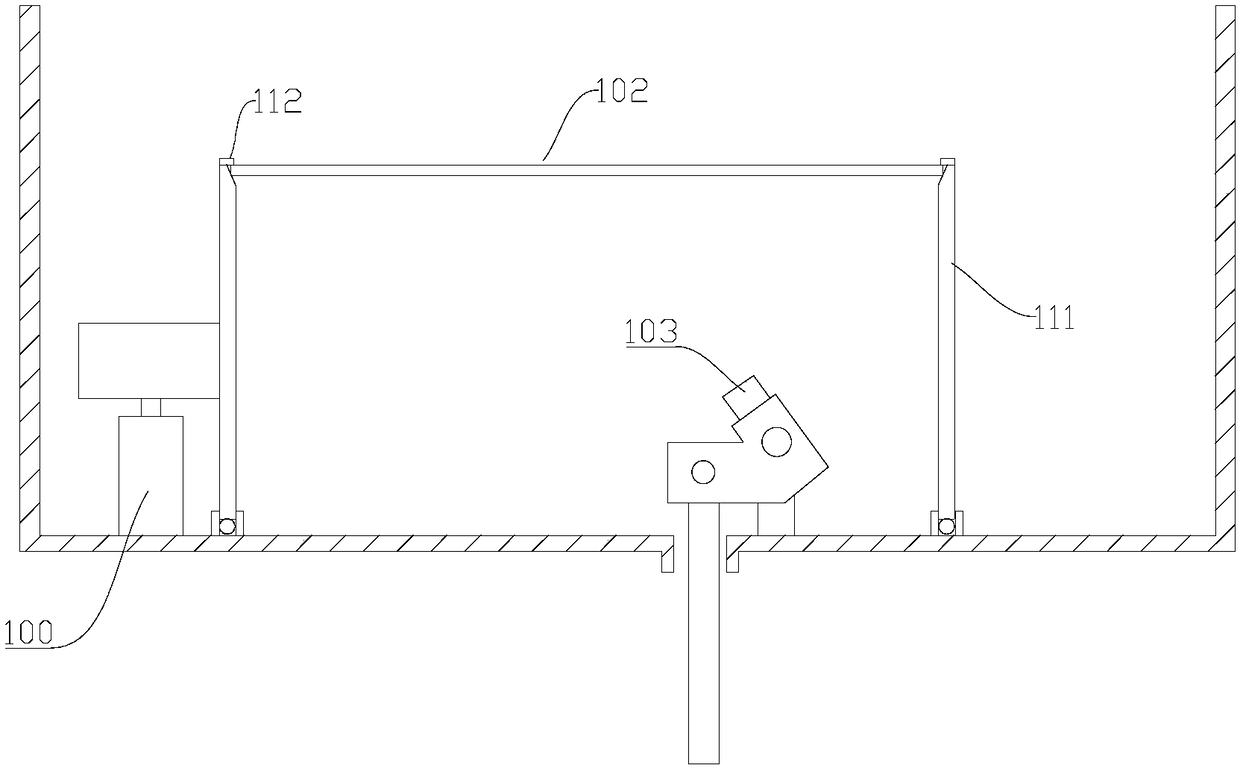

[0049] The third embodiment also provides a cleaning and drying device for the back of the wafer. The cleaning and drying device for the back of the wafer in this embodiment describes another implementation of the wafer clamping device 101. Other embodiments The technical solution of Embodiment 1 or Embodiment 2 also belongs to Embodiment 3 and will not be described again.

[0050] see image 3 As shown, in this embodiment, the wafer clamping device 101 includes a barrel ring 111 and a plurality of fixing clips 112, and the plurality of fixing clips 112 are evenly distributed along the circumference of the barrel ring 111; The outer third driving device 113 is driven, and the third driving device 113 drives the bucket rim 111 to rotate through gear transmission. The third driving device 113 is a motor 110. The injection mechanism is located within the circle of the barrel circle 111 . The bottom of the barrel ring is limited in the limiting groove, and there are balls betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com