Complete pneumatic steel plate cleaning system

A cleaning system and all pneumatic steel technology, applied in cleaning methods and utensils, cleaning methods using liquids, drying solid materials, etc., can solve the problems of poor cleaning effect of the full pneumatic steel plate/circuit board system, and avoid electric shocks. Danger of sparks igniting volatile solvents, saving liquid, good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

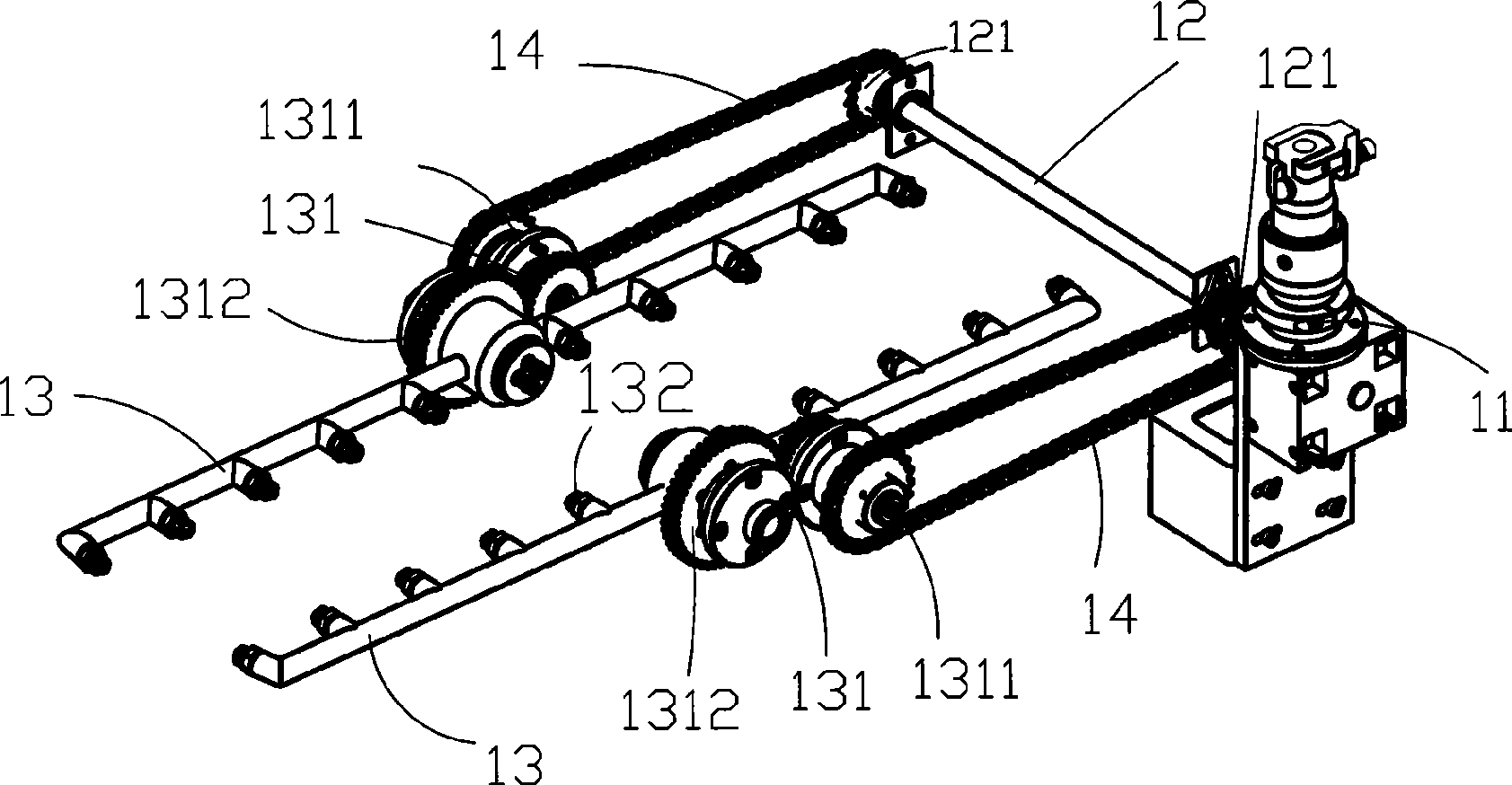

[0015] Below in conjunction with accompanying drawing and implementation just the present invention will be described in further detail:

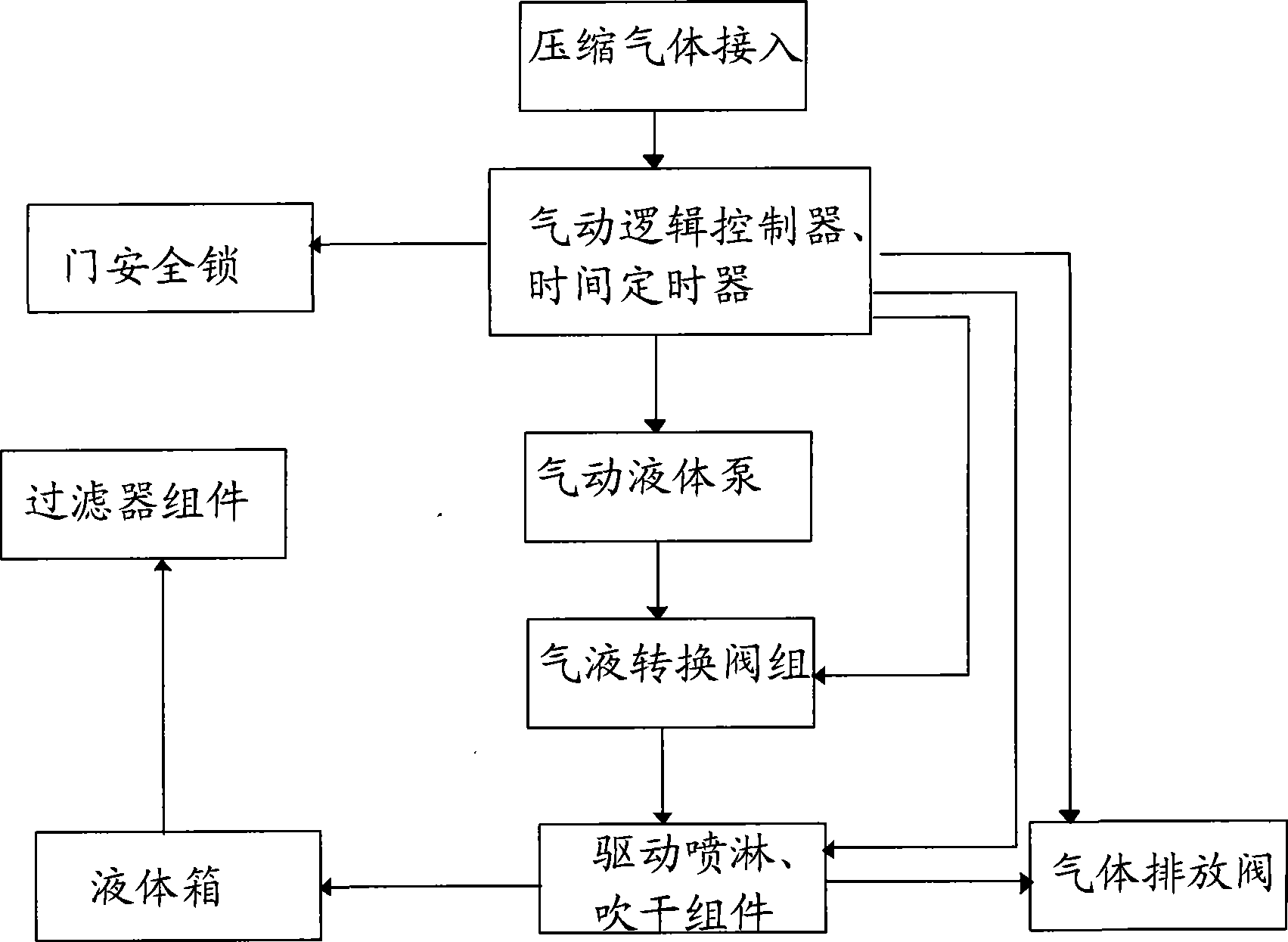

[0016] Such as figure 1 Shown: The fully pneumatic steel plate cleaning system includes after the compressed gas is connected, the pneumatic logic controller and time timer can select the cleaning time and mode; when not working, the door will be locked safely; After the gas-liquid conversion valve group, drive the spraying and drying components; then the cleaned solution returns to the liquid tank, is filtered through the filter component and returns to the pneumatic liquid pump, and the gas-liquid pump is turned on to drive the gas-liquid conversion valve group to spray and blow. The air discharge valve can exhaust the air after drying the components.

[0017] Among them, the pneumatic logic controller and time timer can be set to directly enter the process of spraying and drying components or enter the process of directly driving the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com