Production technology of liner of tennis

A production process and liner technology, which is applied in the field of tennis liner production technology, can solve the problems of simple process, inability to guarantee the production efficiency, quality and physical properties of tennis liner, production equipment and process without specific quantitative parameter support, etc. problem, to achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

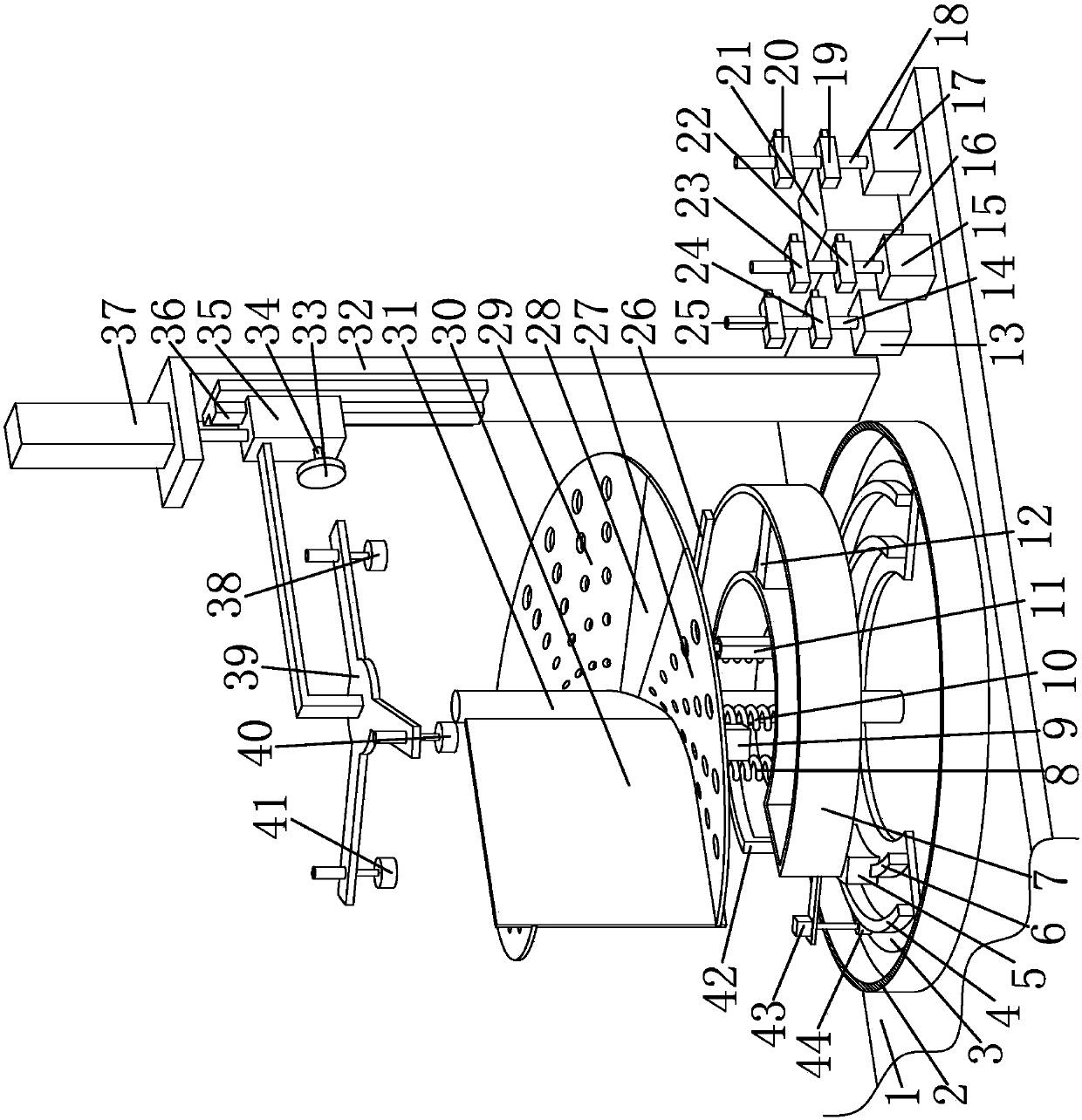

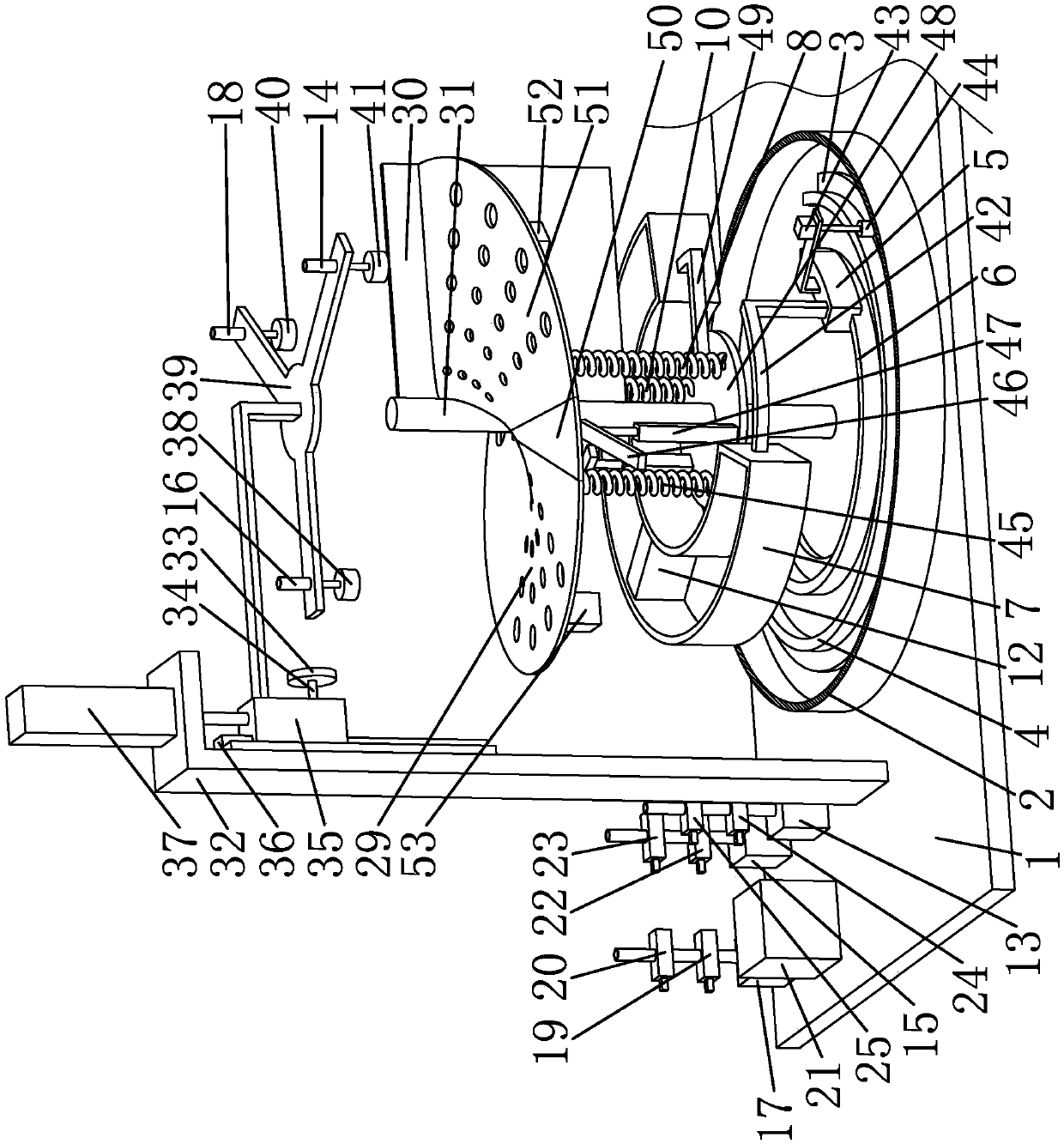

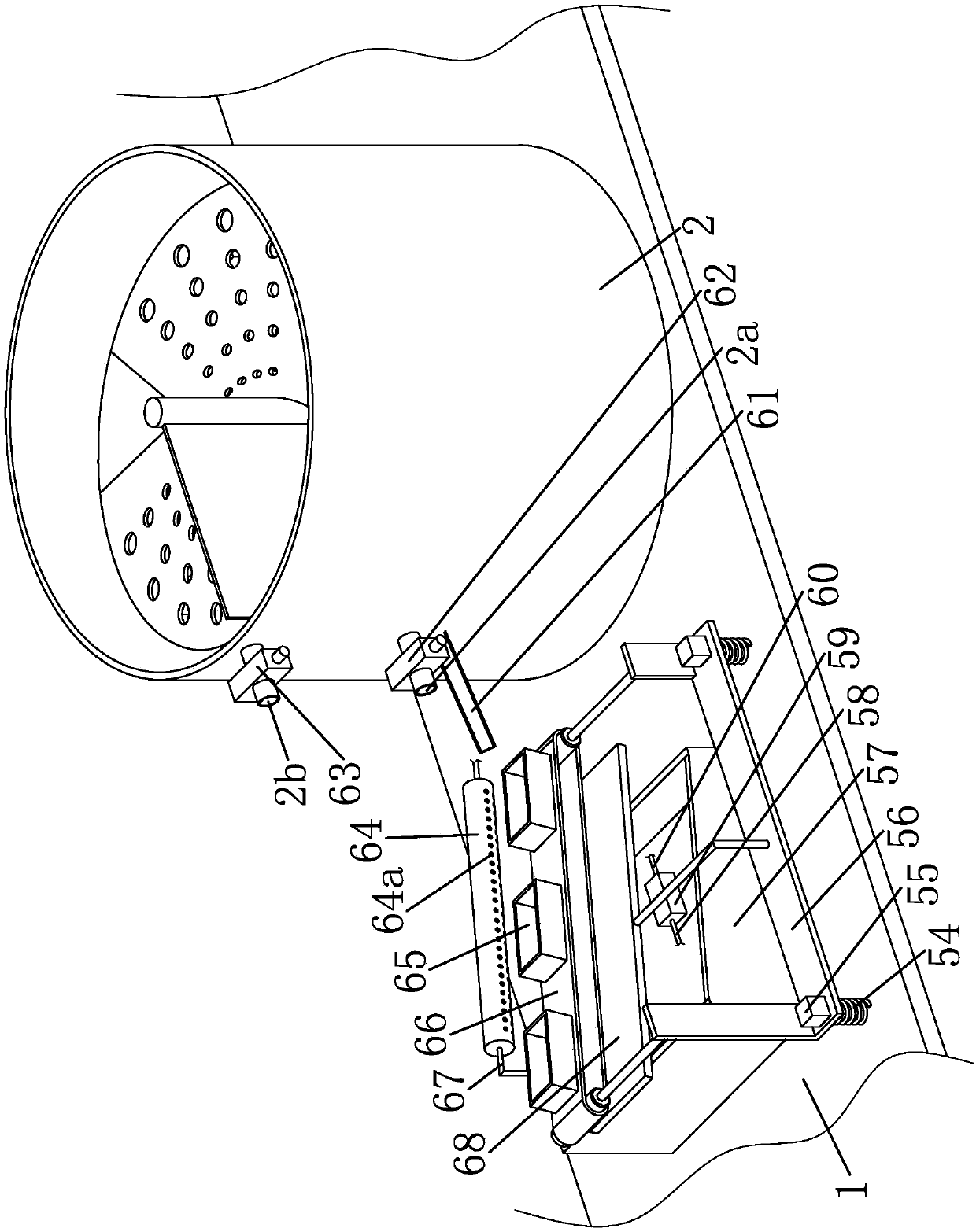

[0072] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0073] The production process of the tennis liner, the production process comprises the following steps:

[0074] S1. Put natural rubber, butadiene rubber, isoprene rubber and chloroprene rubber into the mixer according to the parts by mass, the rotating speed is 90-110r / min, the temperature is maintained at 120-140°C, and the heat preservation is 2-6min to obtain the pre-mixed mixture. Mixture; In the present embodiment, the mixer is an existing product available on the market, and natural rubber, butadiene rubber, isoprene rubber and chloroprene rubber are put into the mixer in parts by mass, and the rotating speed is 100r / min, keep the temperature at 130°C, keep the temperature for 3min, and obtain the premix;

[0075...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com