Stainless steel annular air knife

An annular air, stainless steel technology, applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using gas flow, etc., can solve the problems of unusable air knives, waste of enterprise costs, and unfavorable intensive economic and social development, etc. To achieve the effect of simple structure, not easy to damage, good cleaning and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

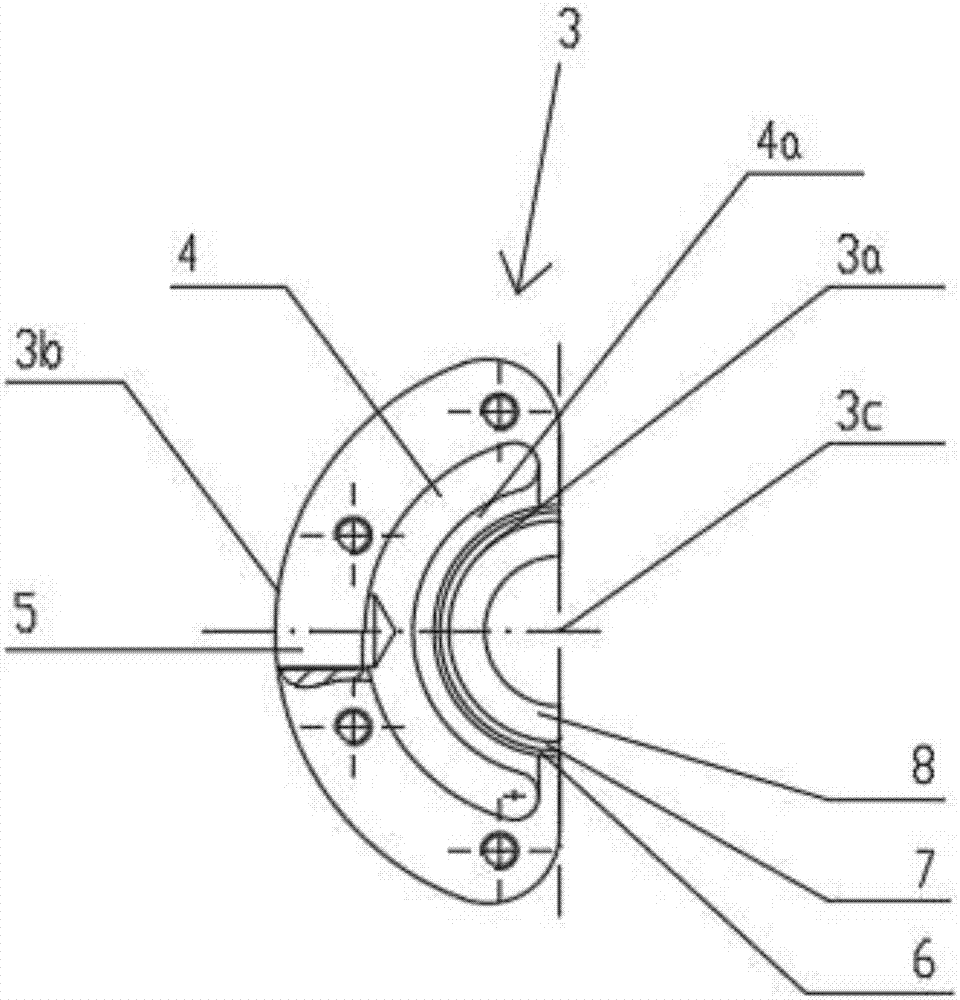

[0015] Such as Figure 1 to Figure 5 As shown, a stainless steel annular air knife is formed by connecting two identical semicircular air knife bodies 1. The air knife body 1 is provided with a cover plate 2 and a bottom plate 3 connected by bolts, and a buffer groove 4 is arranged on the bottom plate 3. The outer side 3b of the bottom plate 3 is provided with an air inlet 5 communicating with the buffer tank 4 , and the inner side wall 4a of the buffer tank 4 near the center 3c of the bottom plate 3 is lower than the other side walls of the buffer tank 4 . After the cover plate 2 and the bottom plate 3 are connected, an air outlet is formed on the inner wall 4a of the buffer tank 4 near the center 3c of the bottom plate 3 .

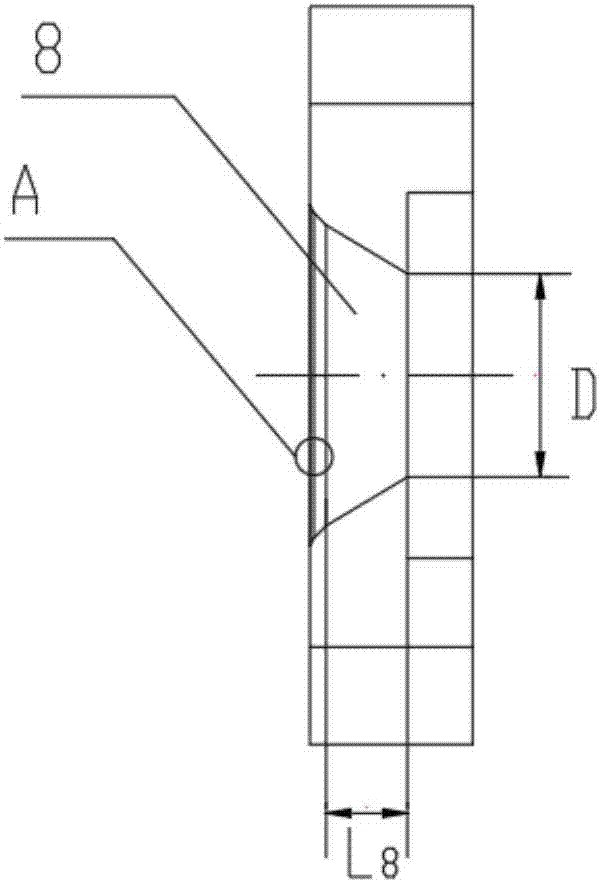

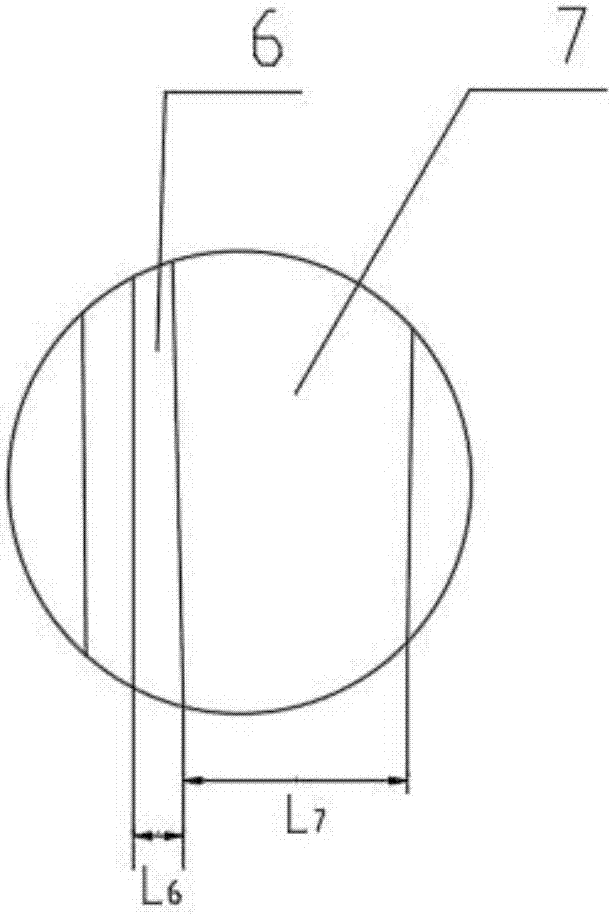

[0016] The inner side 3a of the bottom plate 3 is provided with a first tapered surface 6, a second tapered surface 7, and a third ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com