A post-processing device and process for nano-added composite doped soft ferrite core

A soft magnetic ferrite and post-processing device technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of transferring magnetic cores, investing a lot of manpower, and occupying a large space, etc., to reduce the burden on workers , reduce costs and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

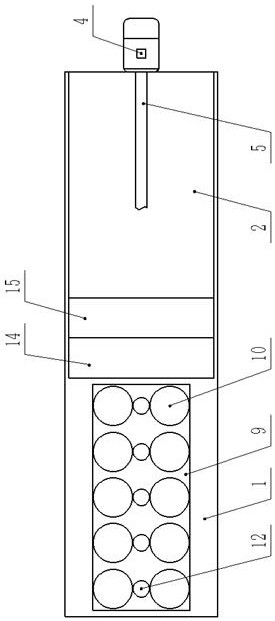

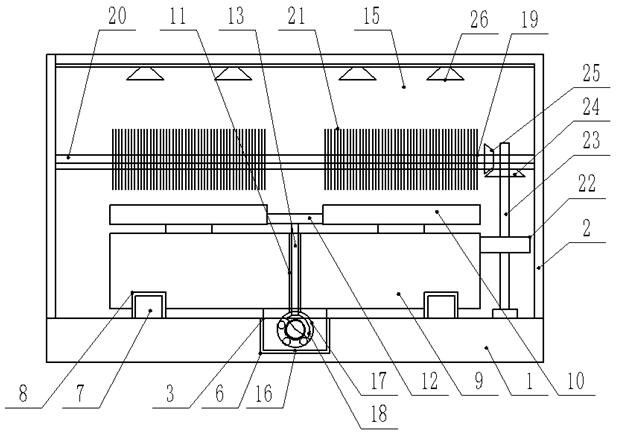

[0012] Embodiment 1: see figure 1 , figure 2 Now, a nano-additive composite doped soft ferrite core post-processing device provided by the present invention is described, which includes a base 1, and a working cover 2 is provided on the upper end of the base 1 and along one side of its length direction. Base 1 upper end is provided with mobile worktable mechanism 3, and described mobile worktable mechanism 3 comprises rotating motor 4, screw mandrel 5, rectangular slot 6, slide rail 7, chute 8 and workbench 9, and described workbench 9 upper end And along its width direction, both sides are evenly provided with disc-shaped placement racks 10, and the inner cavity of the upper end of the workbench 9 is uniformly provided with a vertical through groove 11, and the upper end of the workbench 9 corresponds to the vertical through groove 11 positions are respectively provided with drive gears 12, said vertical through grooves 11 are respectively provided with worms 13, said work ...

Embodiment 2

[0013] Example 2: see figure 1 , figure 2Now, a nano-additive compound doped soft ferrite core post-processing device provided by the present invention will be described. The upper part of the opening end of the working cover 2 and along the moving direction of the worktable 9 are sequentially provided with the drying Dry box body 14 and cleaning box body 15, described drying box body 14 and cleaning box body 15 bottoms all open without end plate, described drying box body 14 is provided with ultrasonic dryer, described cleaning box body 15 An ultrasonic cleaning machine is provided inside, and a brush cleaning mechanism 19 is provided at the bottom of the cleaning box 15 .

Embodiment 3

[0014] Embodiment 3: see figure 1 , figure 2 , a kind of nano-adding composite doped soft ferrite magnetic core post-processing device provided by the present invention is now described, the brush cleaning mechanism 19 is formed by the middle part of the bottom end of the cleaning box 15 and is movable along its length direction. The rotating shaft 20 that has, the bristles 21 that are evenly provided on the outside of the rotating shaft 20 and corresponding to the position of the disc-shaped placement frame 10, the water spray head 26 that is provided with in the cleaning box 15 and is located above the rotating shaft 20 position , corresponding to the transmission gear 22 provided on the side of one end side in the width direction of the workbench 9, the transmission shaft 23 connected to the center of the transmission gear 22 in the vertical direction, and the driving gear set on the upper end of the transmission shaft 23 in the vertical direction 24 and the driven gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com