Liquid ejecting head, liquid ejecting unit, and liquid ejecting apparatus

A technology of liquid jet head and nozzle, applied in printing and other directions, to achieve the effect of effective monitoring and position alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

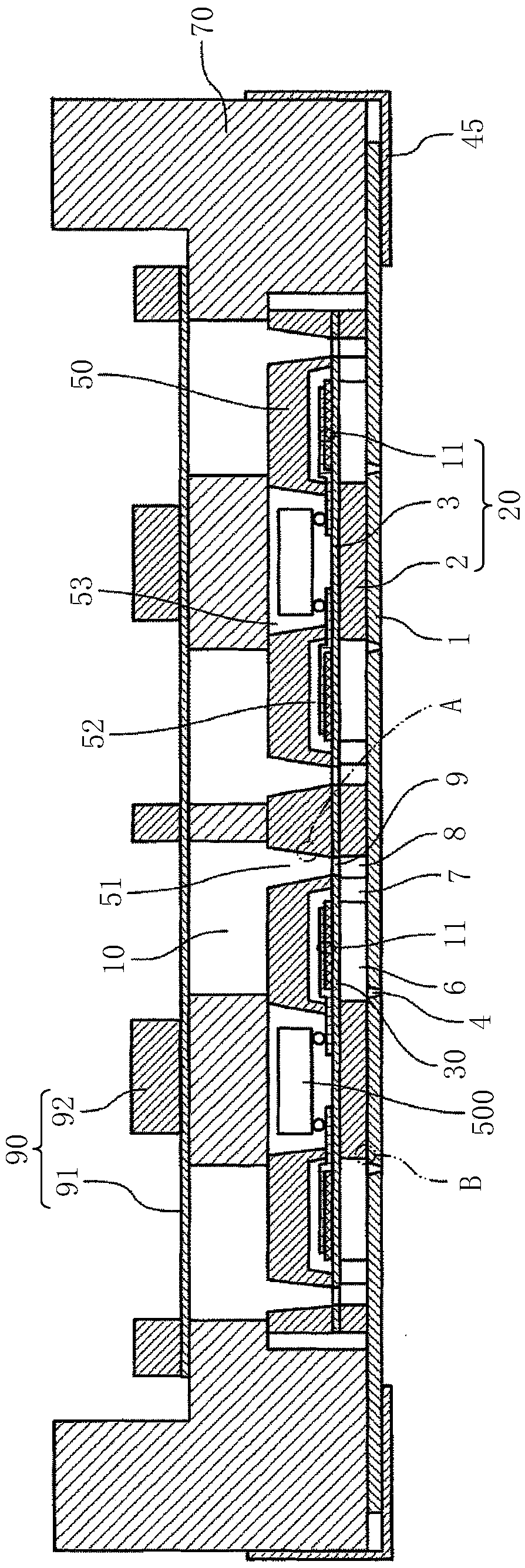

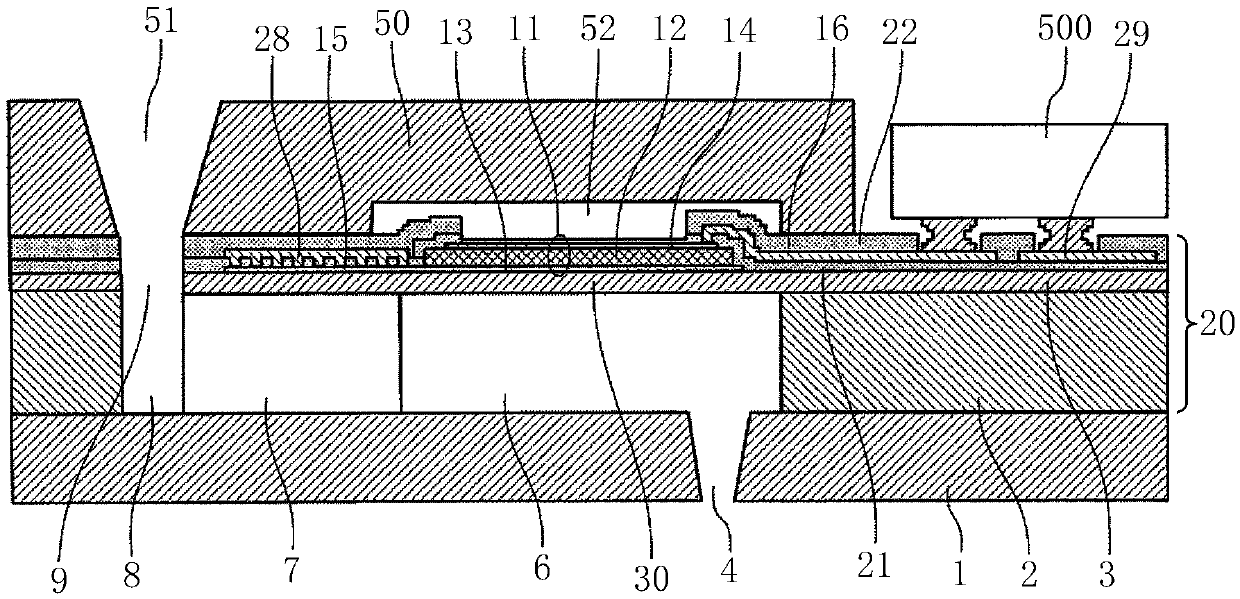

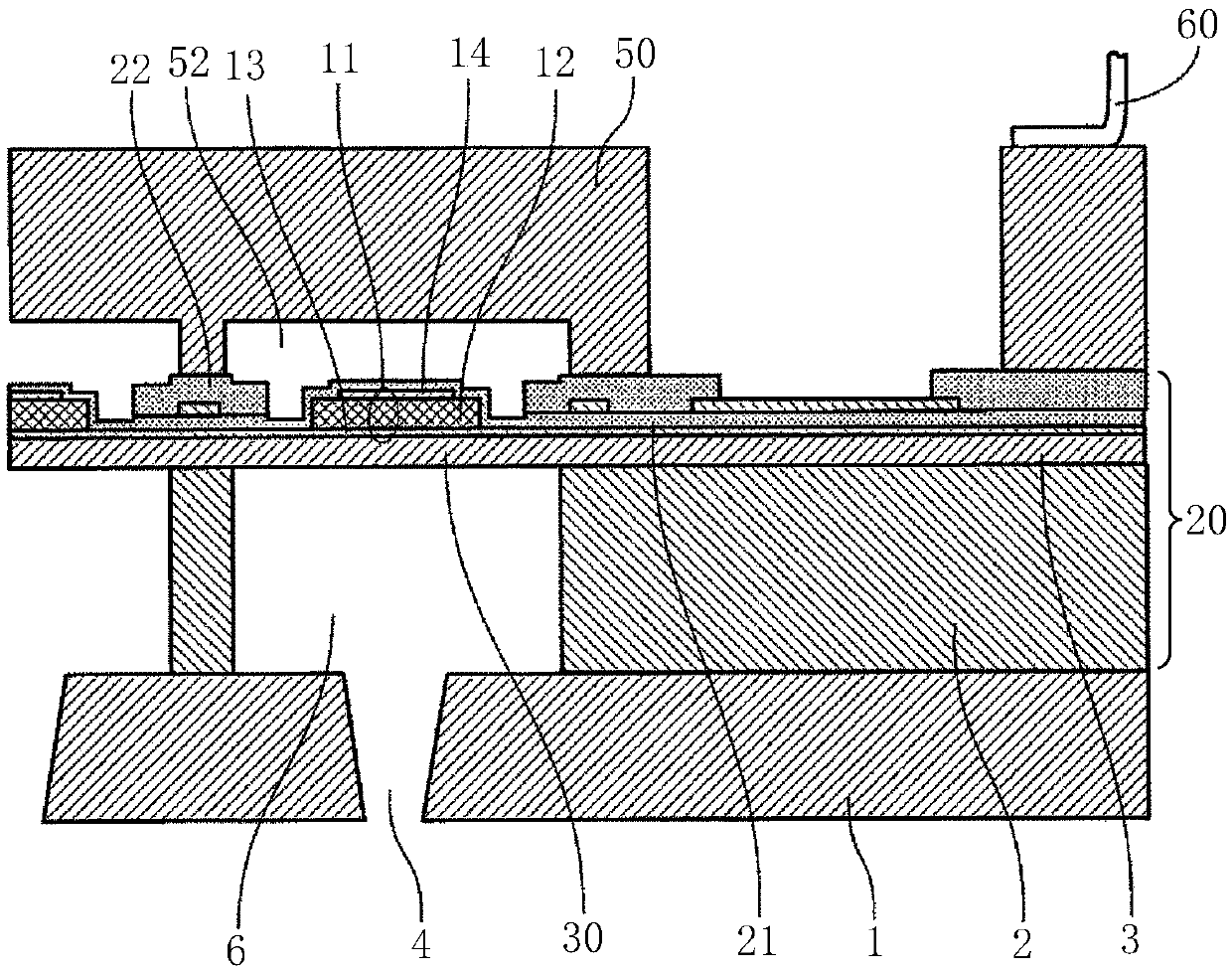

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Regarding the first embodiment of the liquid discharge head according to the present invention, refer to Figure 1 to Figure 3 to illustrate. figure 1 is a cross-sectional explanatory diagram along a direction perpendicular to the nozzle arrangement direction of the shower head, figure 2 yes figure 1 Explanatory drawing of enlarged cross-section of main part, image 3 It is a cross-sectional explanatory view of main parts along the nozzle arrangement direction of the head.

[0028] The liquid discharge head 100 includes a nozzle plate 1, a flow channel plate 2, a vibration plate member 3 as a wall member, a piezoelectric element 11 as a pressure generating element, a holding base plate 50, a wiring member 60 such as an FPC, and a common liquid chamber member 70. , Cover member 45 .

[0029] Here, the portion constituted by the flow channel plate 2 , the vibrating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com