Intelligent document binding machine

A binding machine, intelligent technology, applied in the field of binding machines, can solve the problems of poor applicability, low degree of automation, low operation efficiency, etc., and achieve the effect of easy automatic control, easy control, stable and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

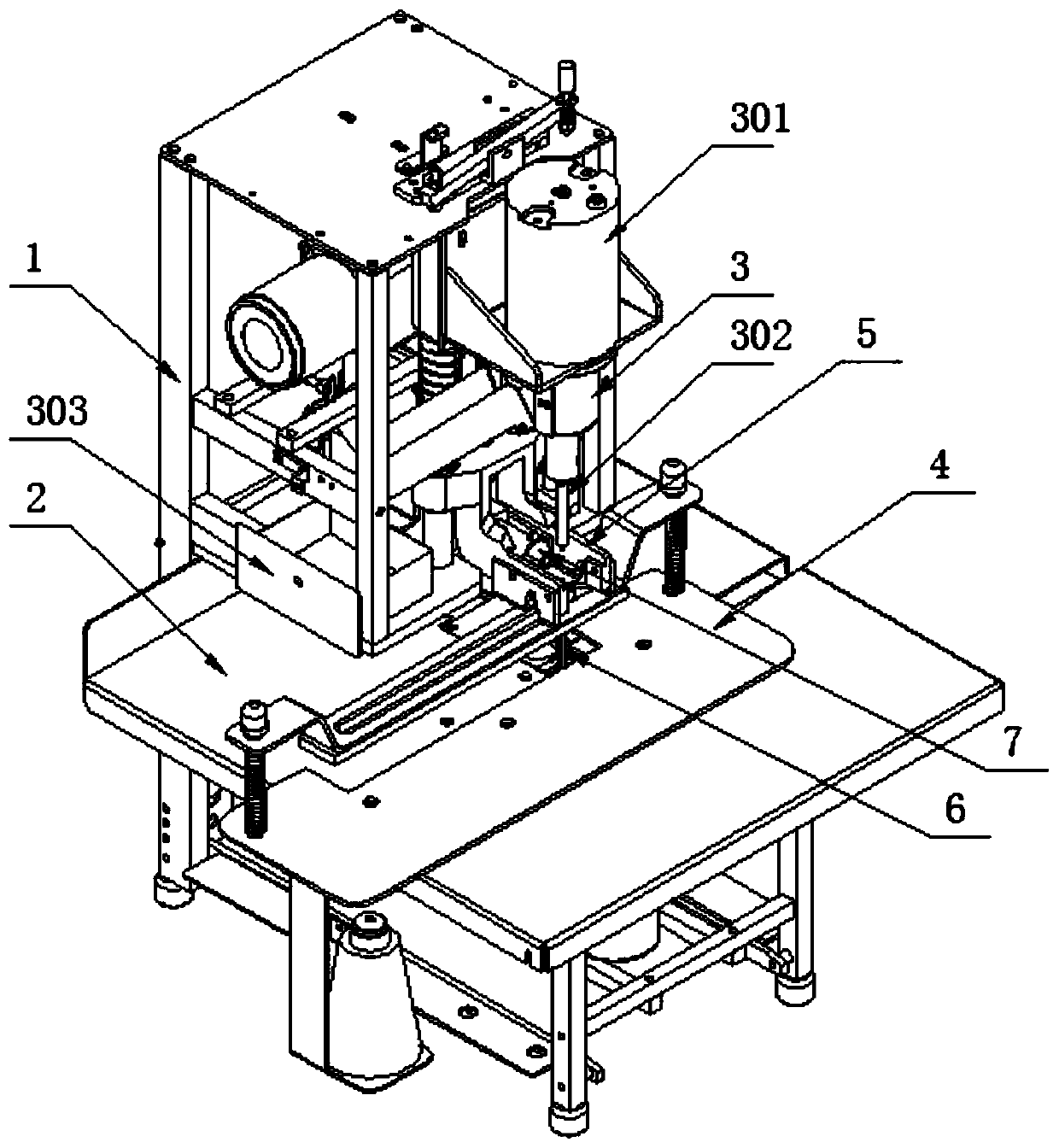

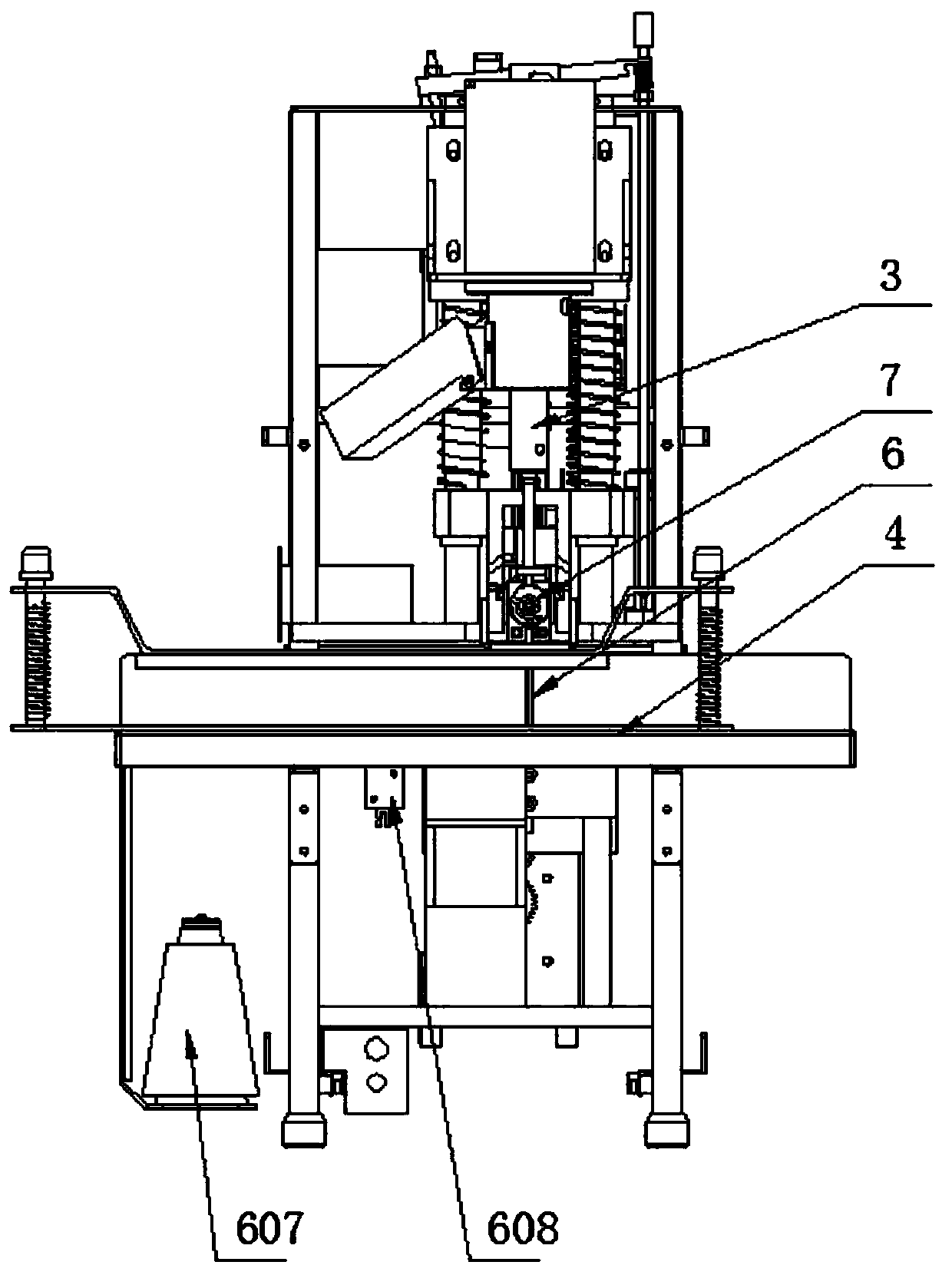

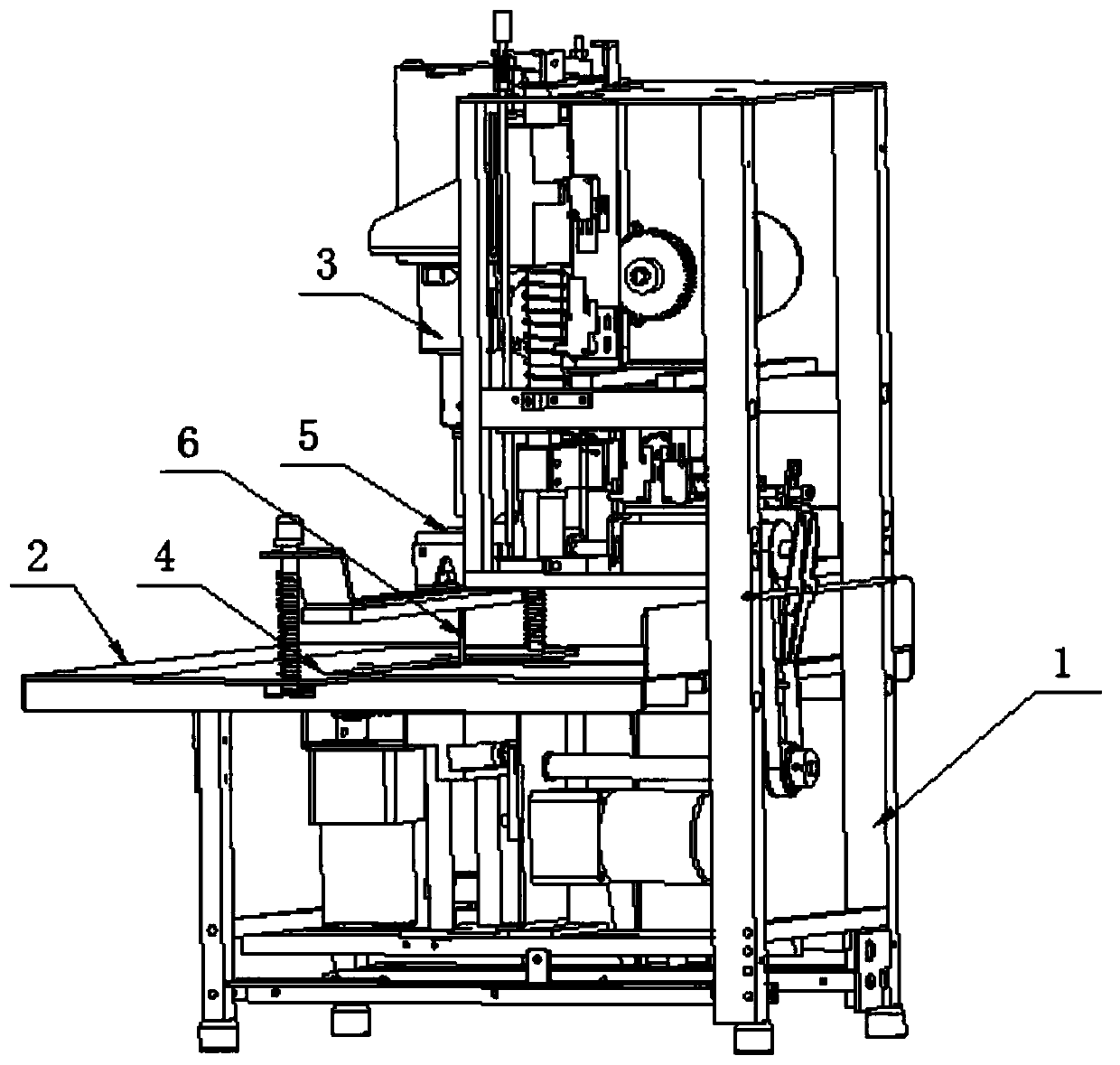

[0060] An intelligent document binding machine comprises a frame 1, a working platform 2, an automatic drill mechanism 3 and a controller, the middle part of the frame is provided with a working platform, and the upper part of the frame is provided with an automatic drill mechanism. The automatic drill mechanism includes a drill motor 301, a drill 302, and a chip cleaning box 303. The drill motor drives the drill to rotate to drill holes in the binding, and the drilling chips are extruded one by one from the inner channel of the drill to the chip cleaning box. The automatic drilling mechanism can adopt the punching rotary cutter of the automatic punching and binding machine.

[0061] The innovation of the present invention is: also include:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com