Omni-directional vision mirror system

An all-round, sight-mirror technology, applied in the field of vehicle engineering, can solve the problems of blind spots, poor streamline, and large wind resistance for drivers, and achieve the effect of improving aesthetics and spaciousness, reducing vehicle scraping accidents, and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

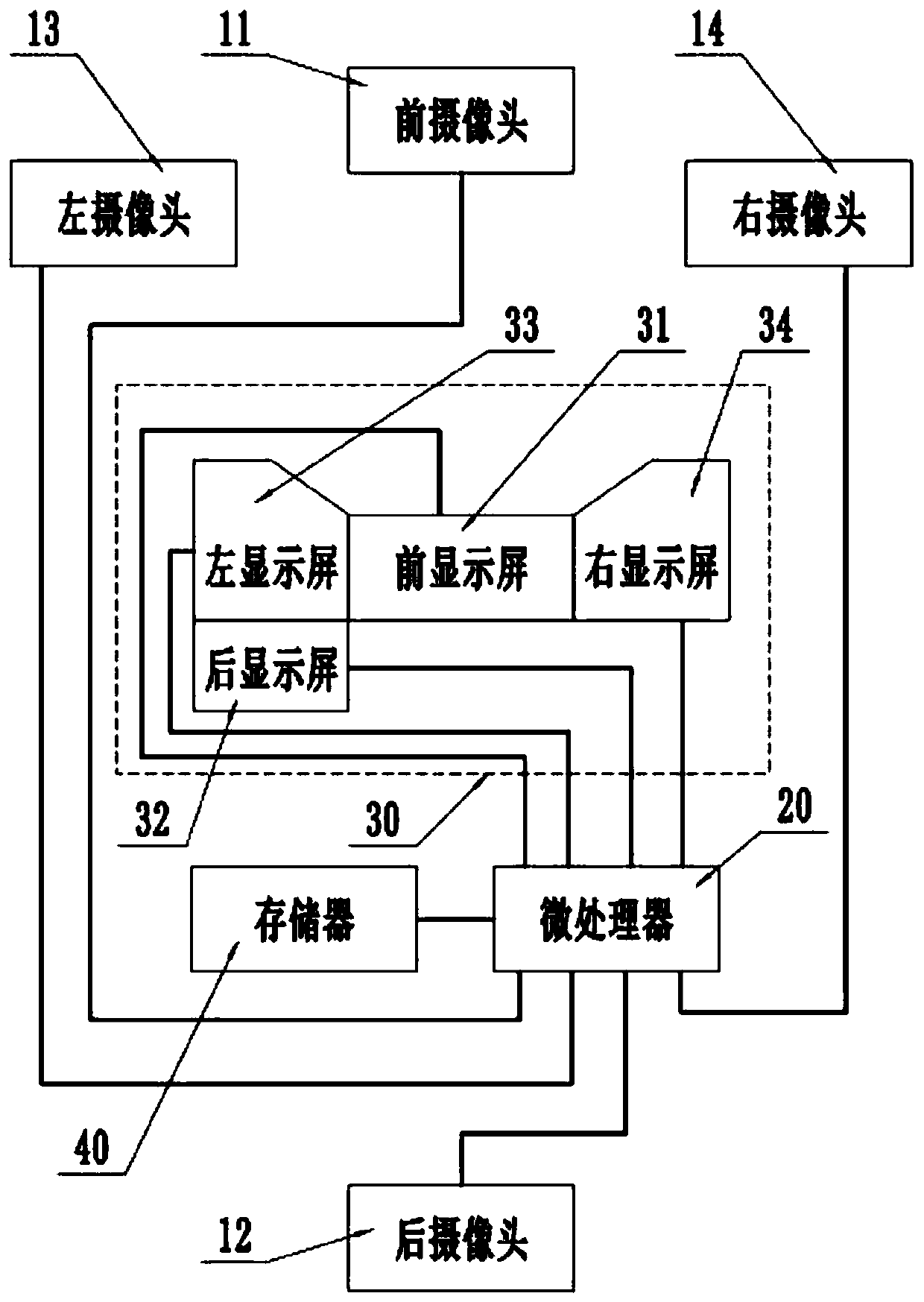

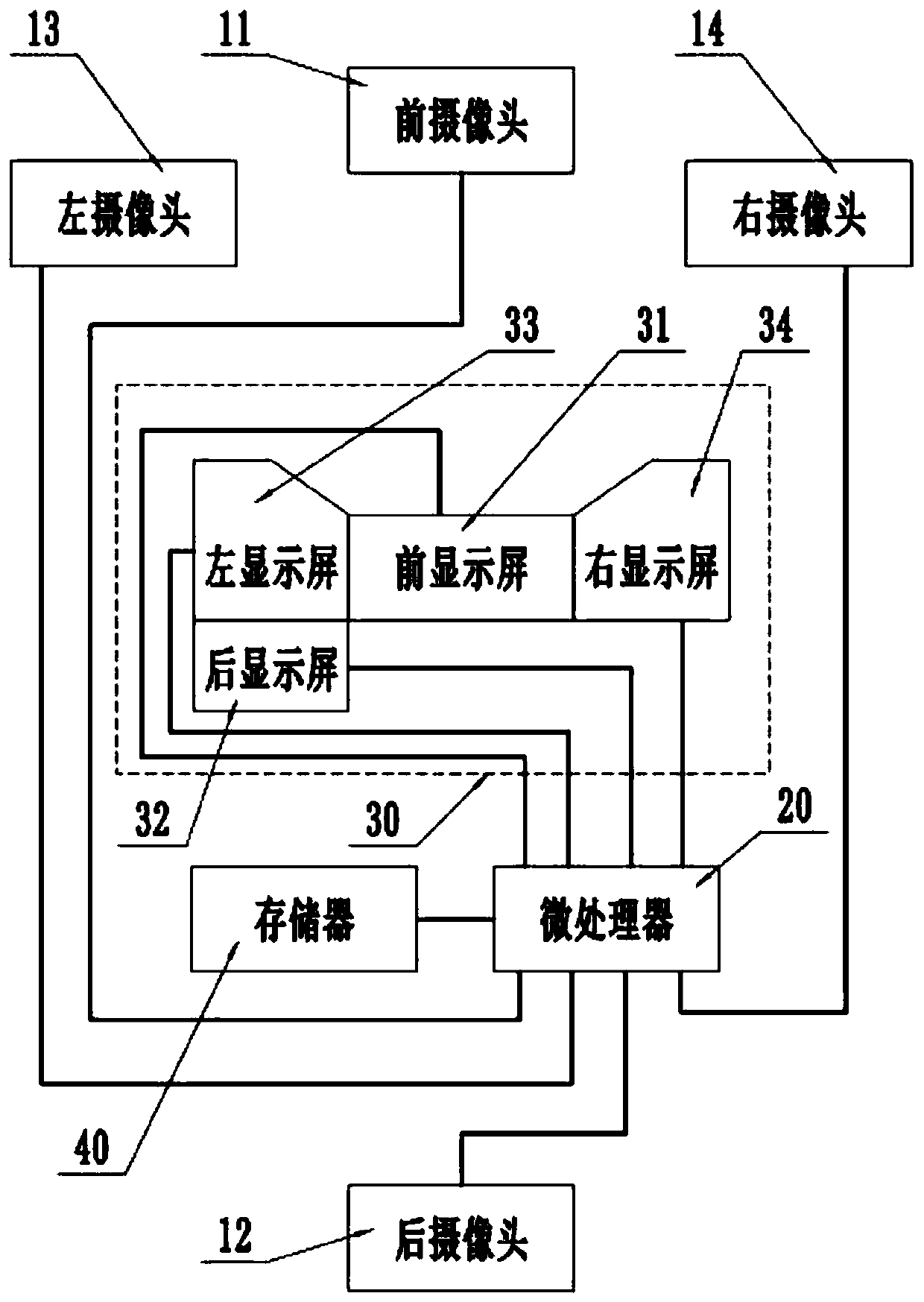

[0022] like figure 1 As shown, Embodiment 1 provides an omnidirectional mirror system, which includes a camera device, a microprocessor 20 , a display device 30 and a memory 40 . The imaging device, the imaging device, the display device 30 and the memory 40 are electrically connected to the microprocessor 20 respectively, and the microprocessor 20, the memory 40 and the display device 30 are all arranged in the car, and the display device 30 can be integrated on the instrument panel or can be separately It is arranged on the front panel on the instrument panel, wherein the camera device is used to collect pictures of the surrounding environment of the vehicle, and the microprocessor 20 is used to transmit the pictures collected by the camera device to the display device 30 and the memory 40, and the display device 30 uses In order to display the images captured by the imaging device, the memory 40 is used to store the images captured by the imaging device. Among them, the di...

Embodiment 2

[0031] Embodiment 2 provides another omnidirectional mirror system, which is basically the same as the omnidirectional mirror system provided by Embodiment 1. The difference is that there are two front cameras installed above the left and right headlights of the vehicle respectively. , the front display screen is divided into left and right screens to display the picture information taken by two front cameras; the rear camera is provided with two, one of which is in the same position as the rear camera in embodiment 1, and the other is installed near the roof of the car, preferably built into the car. Inside, the rear display screen displays the images captured by the two rear cameras in the upper and lower screens. In this embodiment, the microprocessor uses a 6-channel or 8-channel video capture card.

[0032] The omni-directional mirror system provided in this embodiment can more comprehensively and clearly display the existing blind spots of the vehicle and improve driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com