High-precision angular limiting displacement vibration isolation buffering platform for photoelectric equipment

A technology of optoelectronic equipment and buffer platform, applied in mechanical equipment, machine/support, non-rotational vibration suppression, etc., it can solve the problems that vibration and shock cannot be compensated, and cannot meet the requirements of the working state of optoelectronic equipment. The vibration performance is not affected, the friction coefficient is small, and the movement is smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

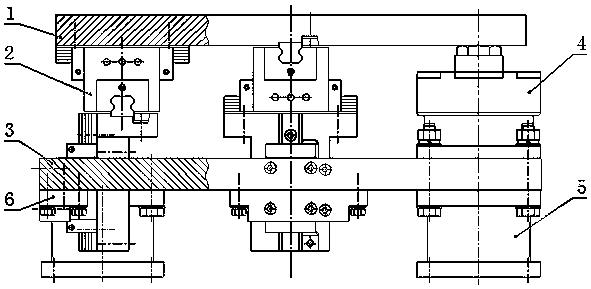

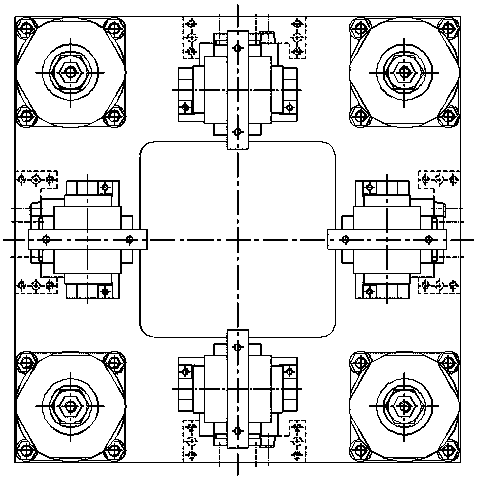

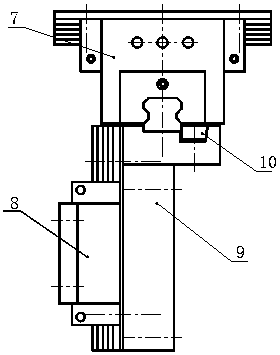

[0024] A specific embodiment of the present invention is as figure 1 , figure 2 As shown, it includes an upper mounting plate 1 and a lower mounting plate 3 connected by four vibration isolators 4, and the four vibration isolators 4 are evenly distributed at the four corners to form a vibration isolation buffer system; the upper mounting plate 1 is equipped with photoelectric equipment, The lower mounting plate 3 is connected to the mounting base 5; between the upper mounting plate 1 and the lower mounting plate 3, four corner limiting devices 2 are installed symmetrically and uniformly along the x and y axes, and the corner limiting devices 2 limit the upper mounting plate 1 and the The relative angular displacement around the three coordinate axes of x, y, and z generated between the lower mounting plates 3 when subjected to vibration and impact ensures that the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com