On-line observer and method of global concentration in distillation process based on tray temperature

A rectification process and observer technology, applied in the direction of instruments, distillation adjustment/control, complex mathematical operations, etc., can solve unrealistic problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

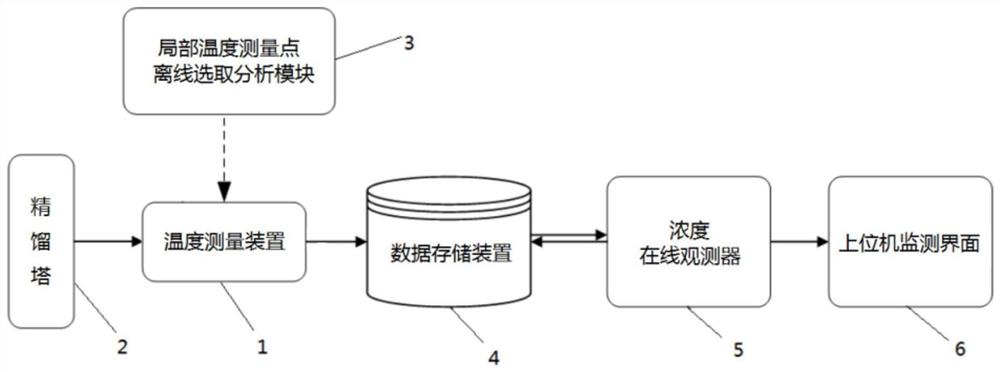

[0079] see figure 1 and figure 2 , the present invention discloses a global concentration online observer of the rectification process based on tray temperature, comprising:

[0080] A temperature measuring device 1 is connected with the rectification tower 2, and is used to measure the tray temperature in the rectification tower;

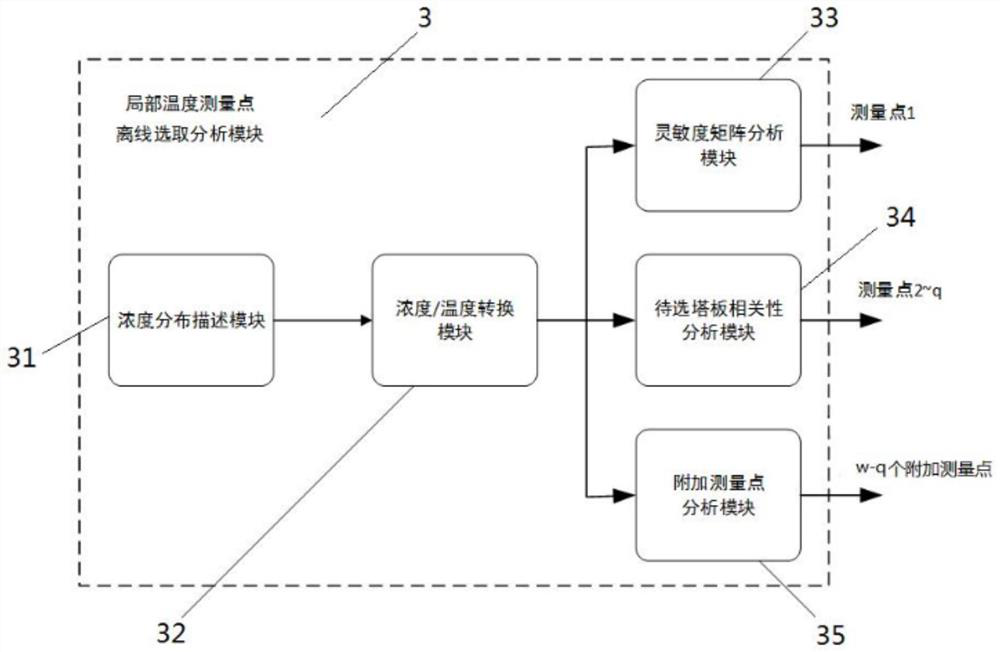

[0081] The local temperature measurement point offline selection analysis module 3 is connected with the temperature measurement device 1 for offline analysis and decision-making of the quantity of the local temperature measurement point, and determines the installation position of the temperature measurement device 1 according to the local temperature measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com