Modular chemical installation of water-stop steel plate and its construction method

A technology of water-stop steel plate and construction method, which is applied in water conservancy projects, artificial islands, protection devices, etc., and can solve problems such as difficulty in guaranteeing the construction quality of water-stop steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated below by specific examples.

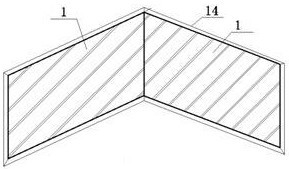

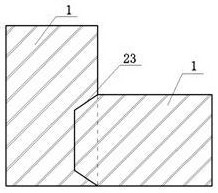

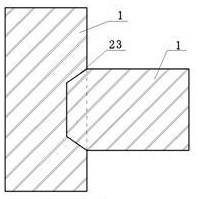

[0029] Such as Figure 1~Figure 5 As shown, a modular chemical equipment for water-stop steel plates, which includes at least two water-stop steel plate bodies 1, one of the edges of each water-stop steel plate body 1 has a chamfer structure 23, and each water-stop steel plate body 1 One side or two sides have a groove structure, and the cross-sectional shape of the groove structure is the same as the cross-sectional shape of the chamfering structure 23 of the edge of the other waterproof steel plate body 1 .

[0030] In the modular chemical equipment of the water-stop steel plate, two water-stop steel plate bodies 1 are spliced in such a way that one of the edges and one of the sides are perpendicular to each other to form a C-shaped connection structure, an L-shaped structure, or a T-shaped structure; The water steel plate bodies 1 are vertically spliced together to form a cross-shaped con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com