A lens processing technology with sawtooth

A processing technology, sawtooth technology, applied in the field of lens processing technology, can solve the problems of light leakage, inability to make full use of light, light waste, etc., and achieve the effect of sharp corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

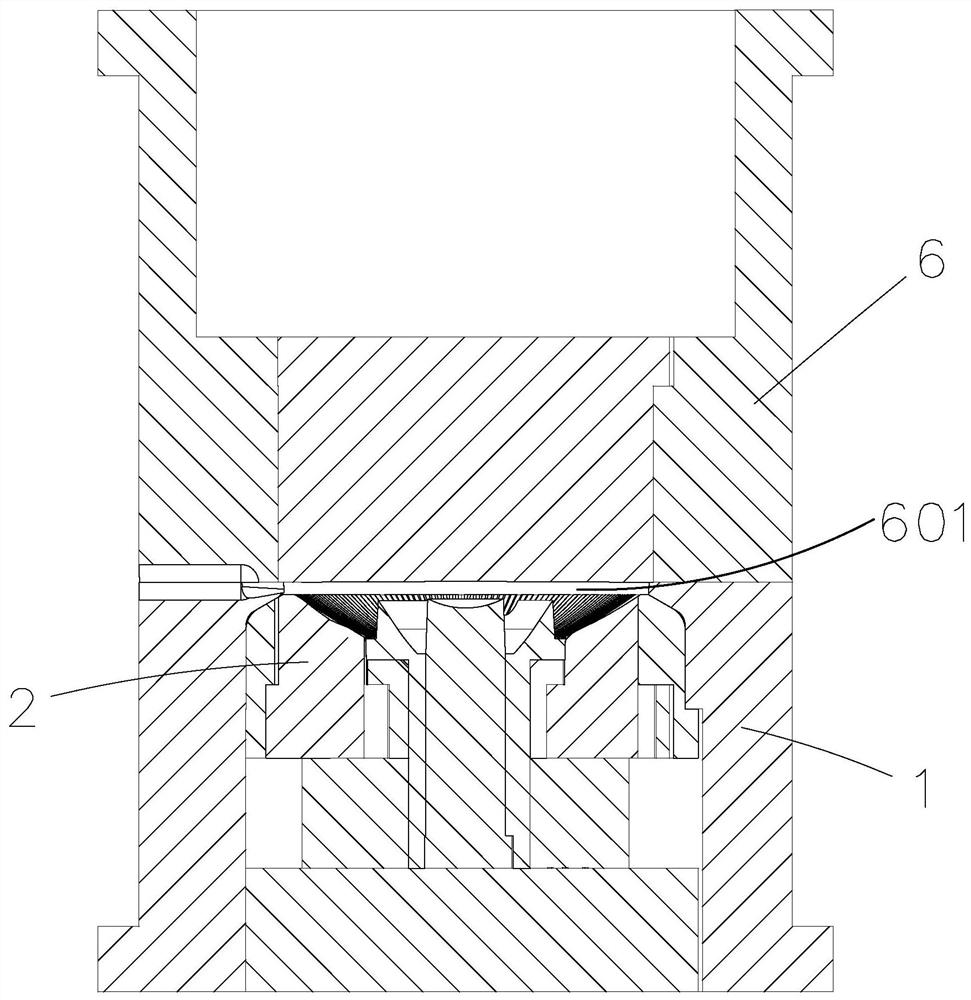

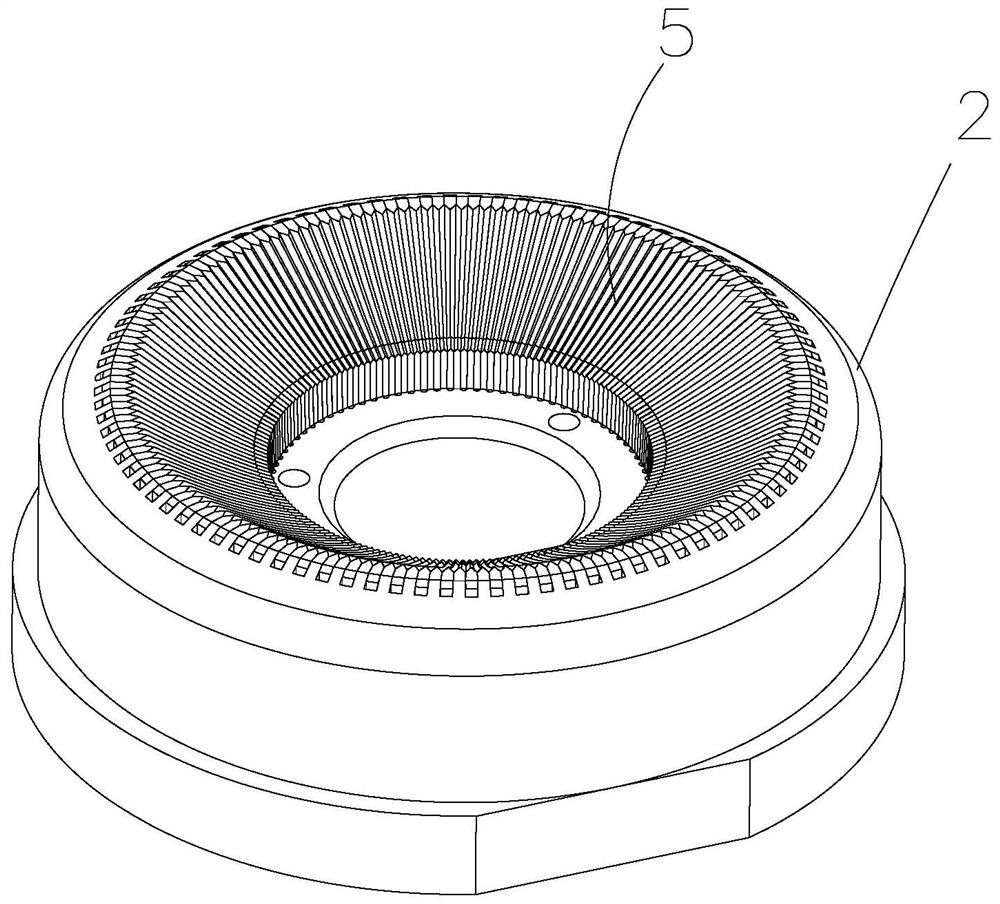

[0022] Such as Figure 1 to Figure 6 As shown, in this embodiment, a lens processing technology with sawtooth comprises the following steps:

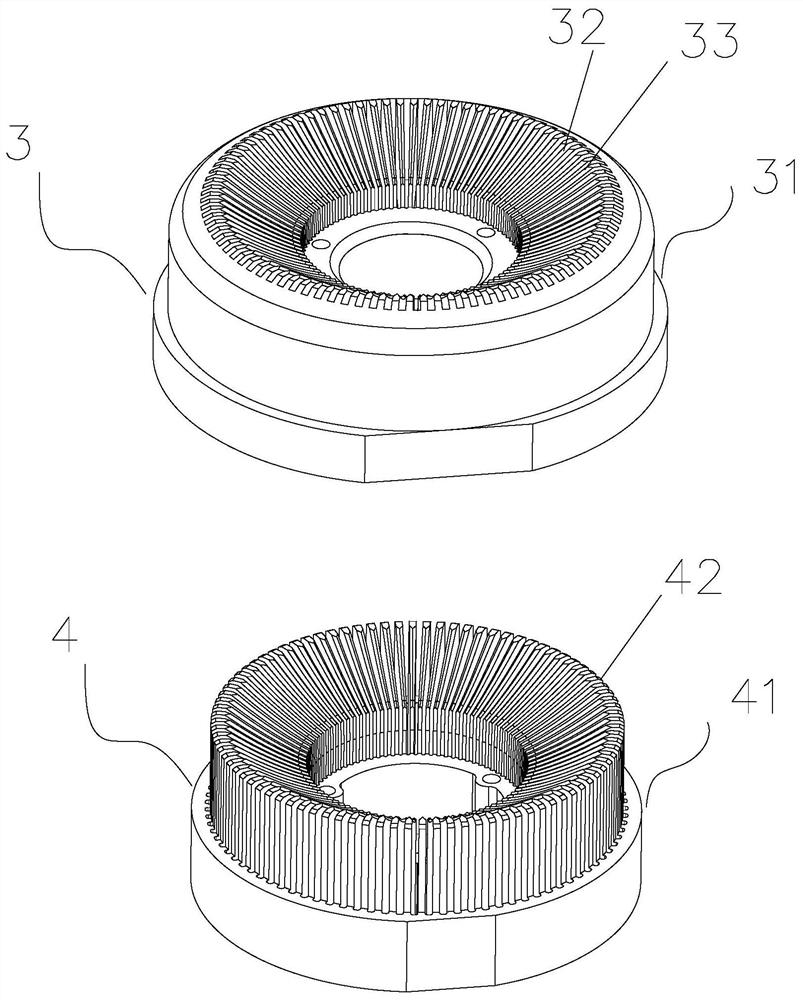

[0023] A. Install the rear mold insert 2 on the rear mold base 1, the rear mold insert 2 includes a first molding insert 3 and a second molding insert 4 spliced together, the first molding insert 3 Including the first splicing piece 31, the first splicing piece 31 is provided with several sawtooth grooves 32 along the circumferential direction, the part on the first splicing piece 31 and located between the adjacent sawtooth grooves 32 constitutes the first Forming sawtooth 33, the second forming insert 4 includes a second splicing piece 41, and the second splicing piece 41 is provided with a plurality of second forming sawtooth 42 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com