Low-noise and low-static-pressure air-conditioning system of railway vehicle

A technology for rail vehicles and air conditioning systems, applied in the field of rail vehicle air conditioning systems, can solve the problems of complex structure, high noise, uncomfortable riding, etc., and achieve the effects of small changes in static pressure, reduced dynamic pressure, and reduced local resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

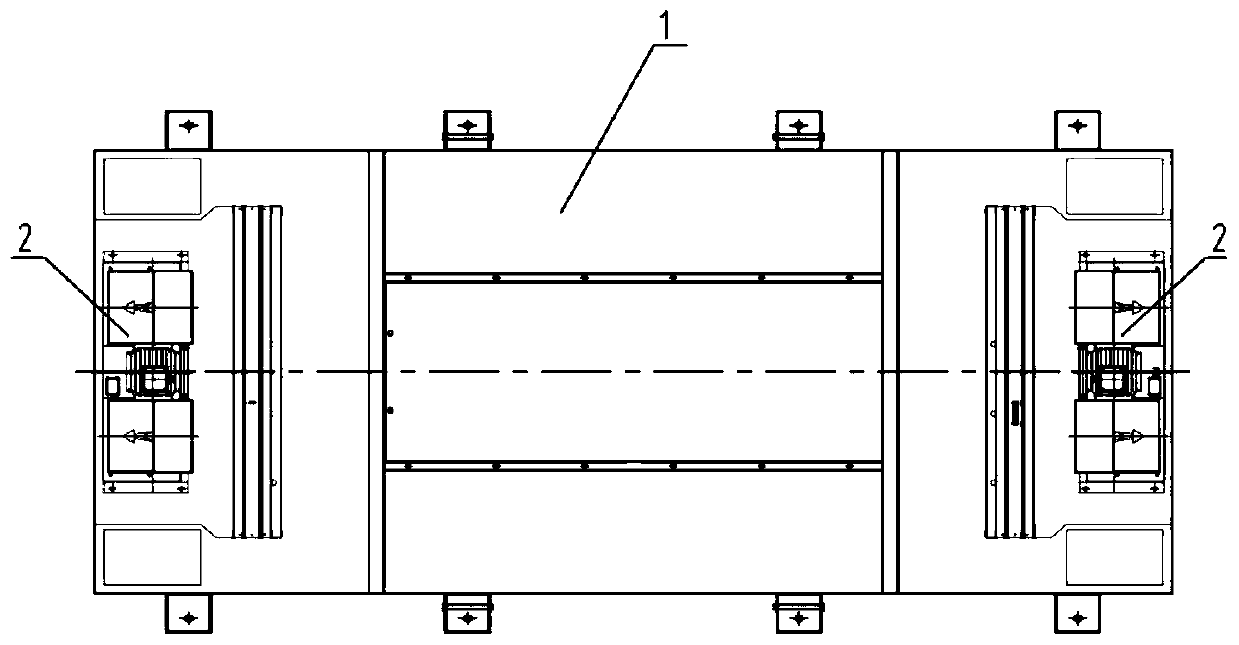

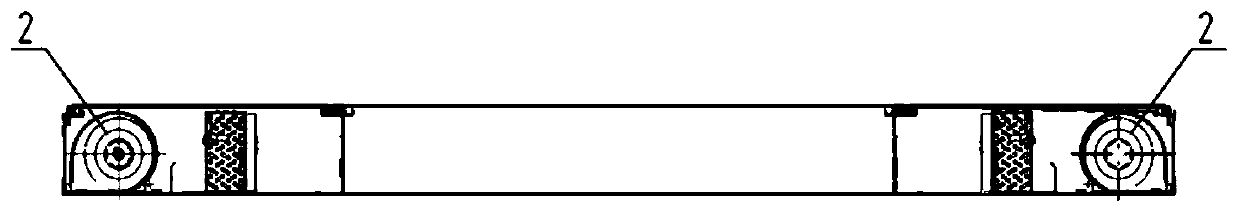

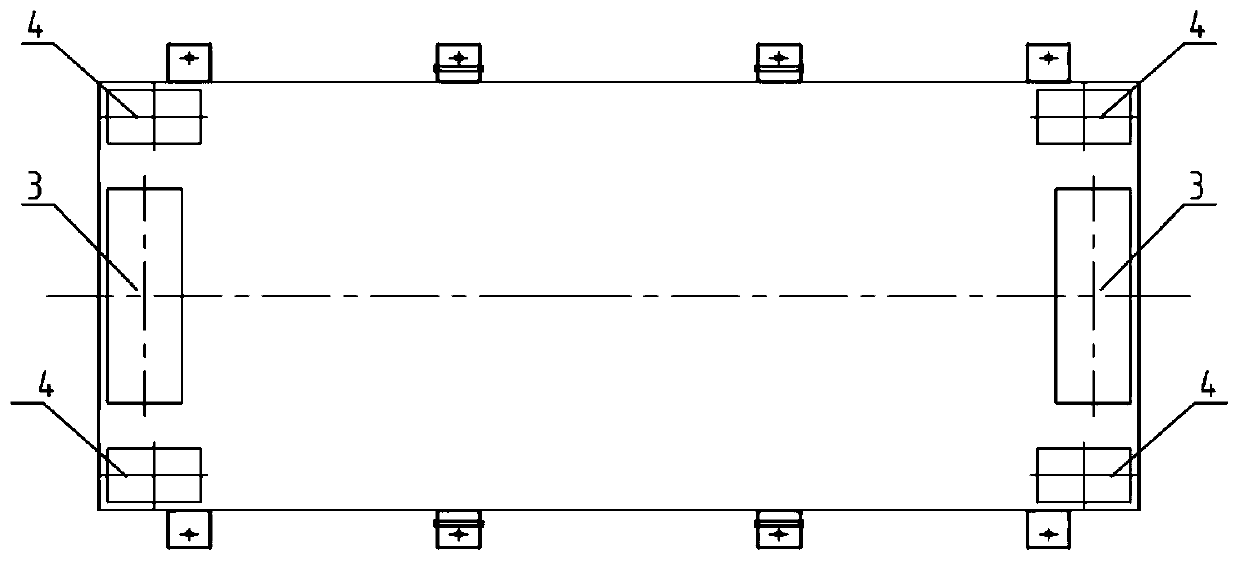

[0021] refer to Figure 1-Figure 4 , the air-conditioning system of the present invention comprises: air-conditioning unit 1, air supply duct 5, air supply grille 7 and return air grille 8 at both ends, and two air supply fans 2 are arranged for each unit. At both ends of the unit and down the air. Two unit air supply outlets 3 are arranged at the bottom of both ends of the unit, and two return air outlets 4 are arranged on both sides of each unit air supply outlet 3, and each unit provides two unit air supply outlets and four return air outlets. Each rail vehicle is equipped with two air-conditioning units 1, which are respectively arranged at 1 / 4 and 3 / 4 of the length direction of the roof. Since the return air outlets are arranged at the bottom of both ends of the unit, the corresponding roof is at 1 / 8 and 3 / 4 of the length direction. 3 / 8, 5 / 8, and 7 / 8 have roof air supply outlets 6, which greatly reduce the air supply distance, air supply speed, unit static pressure and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com