Box washing machine for bottle crates and method for cleaning bottle crates

A technology for washing machines and bottling boxes, which is applied in the directions of cleaning methods, cleaning methods and utensils using liquids, cleaning hollow objects, etc., and can solve the problems of high space requirements and high cost consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

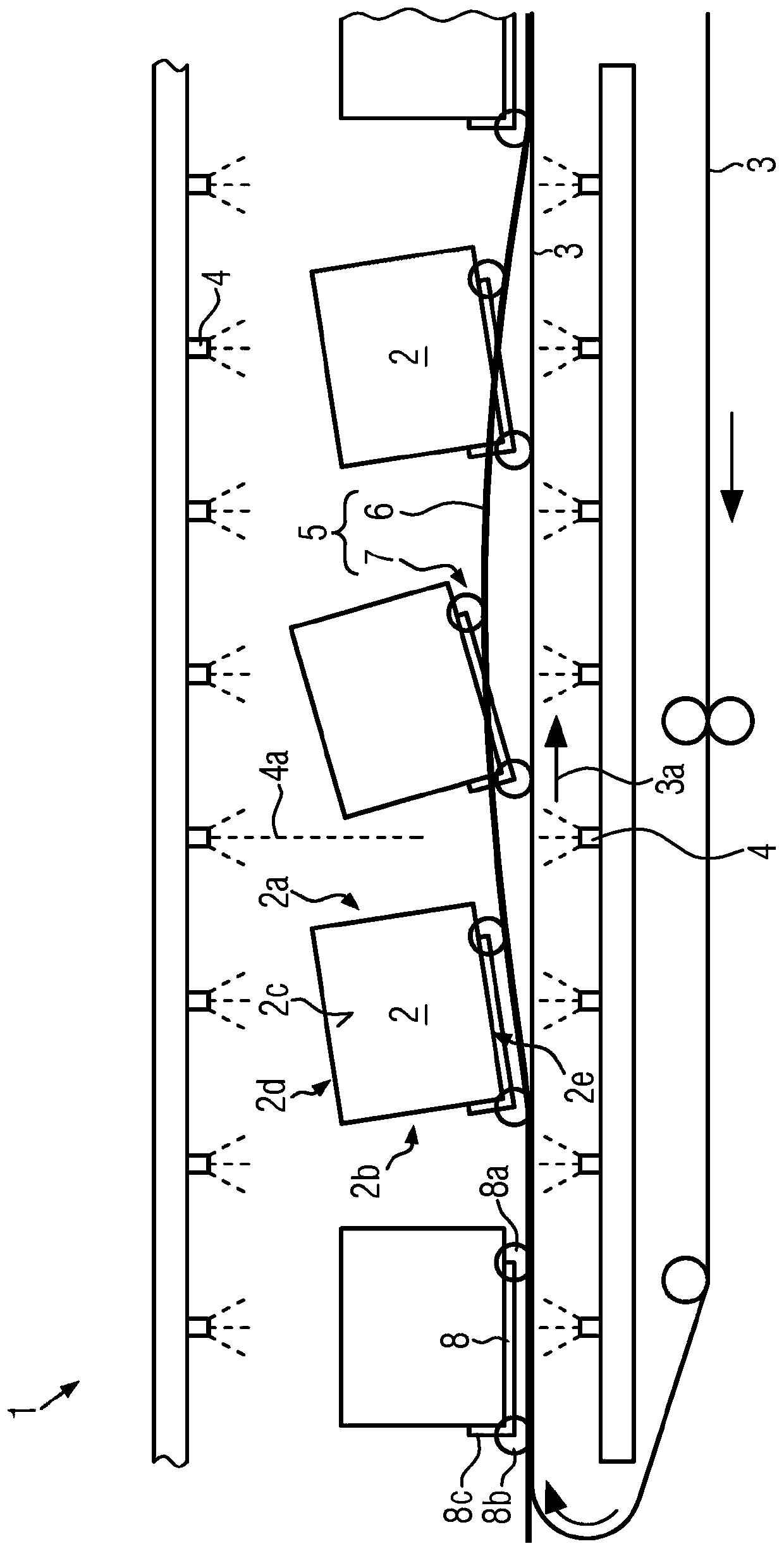

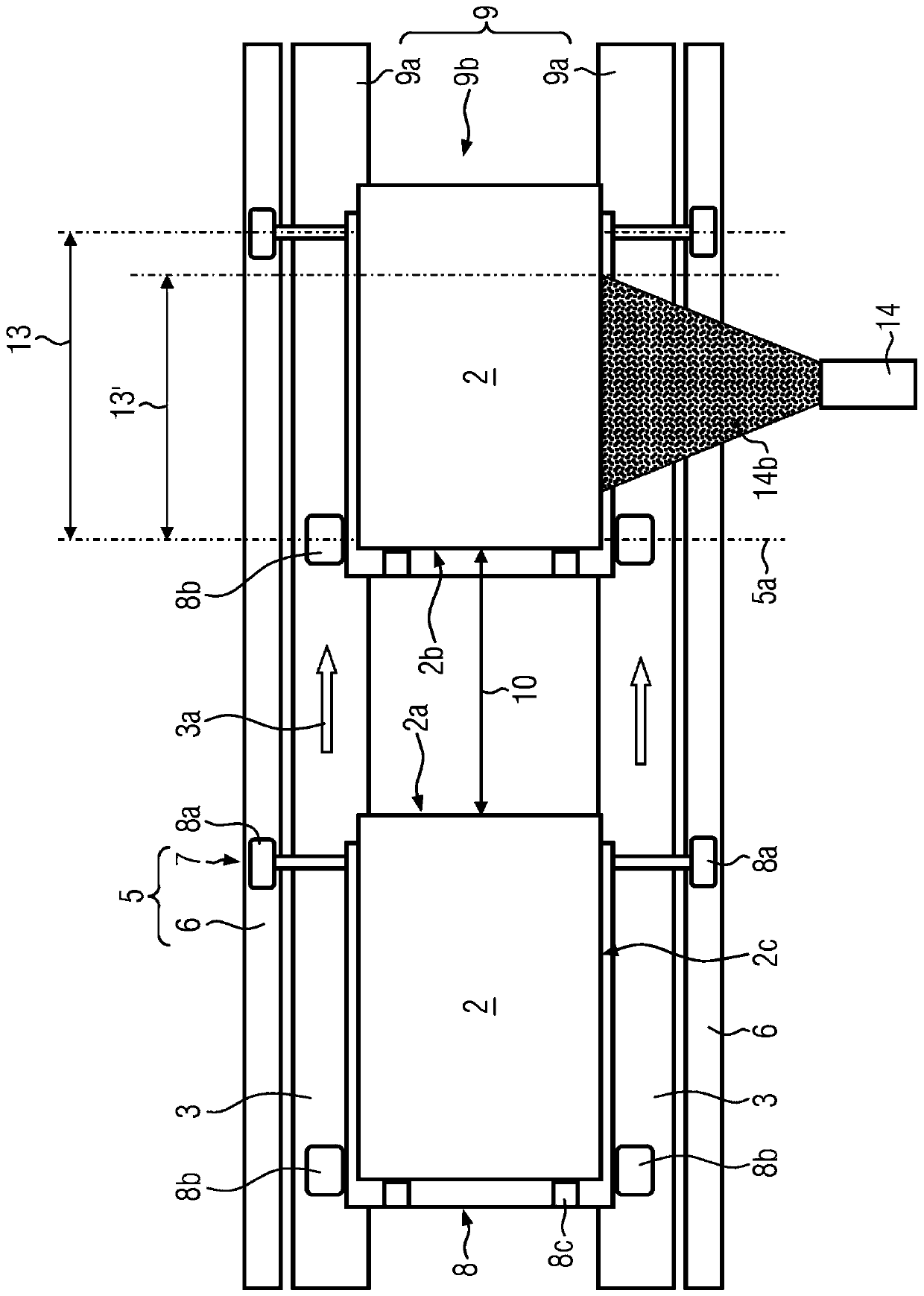

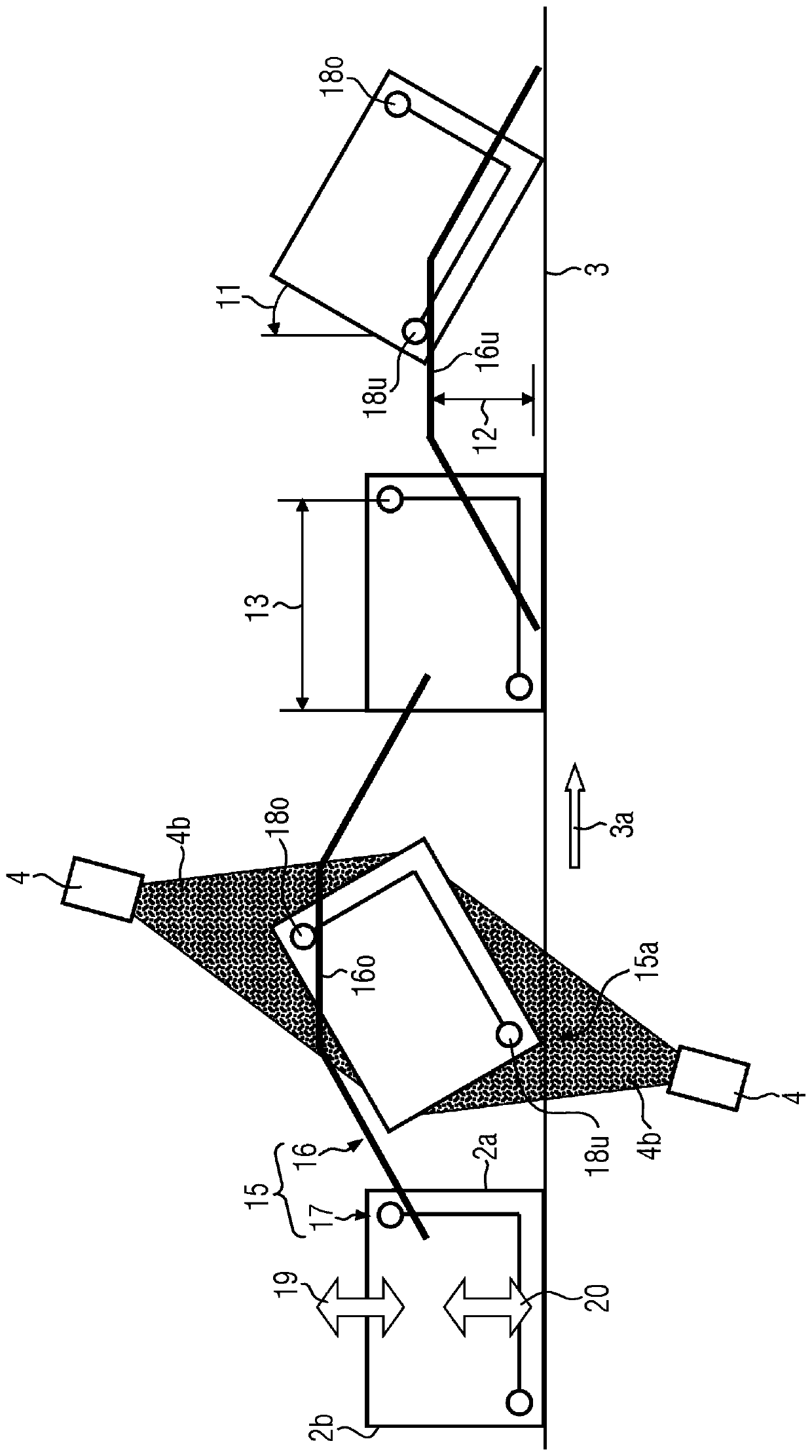

[0042] as figure 1 As shown in , the case washing machine 1 for empty bottling cases 2 comprises a transport mechanism 3 for the bottling cases 2 and a cleaning agent arranged above and below the transport mechanism 3 and facing the transport mechanism 3 Nozzle 4. A component of the case washer 1 also includes a tilting device 5 for the bottle case 2 for tilting the front wall 2 a and the rear wall 2 b of the bottle case upwards / downwards towards the nozzles 4 . The front wall 2 a and the rear wall 2 b are, by definition, box walls arranged at the front and rear with respect to the transport direction 3 a of the transport mechanism 3 .

[0043] Correspondingly, the bottling box 2 further comprises side walls 2c, a bottom 2d and an opening 2e for inserting and removing (not shown) bottles, bags or the like. Via the downwardly directed openings 2 e in the case washer 1 , the bottling cases 2 can also be sprayed from the inside by the nozzles 4 . In addition, cleaning agent ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com