Special rectangular punching mechanism and process

A rectangular, special technology, applied in high-precision cold stamping and machining fields, to achieve the effect of saving manufacturing cycle and saving mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

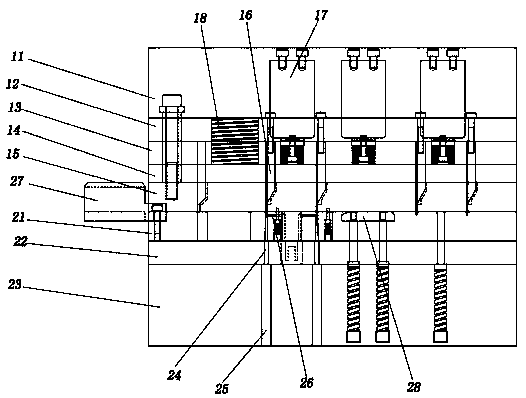

[0042] The utility model will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0043] The present invention provides a special rectangular punching mechanism, which includes an upper mold assembly and a lower mold assembly, and the lower mold assembly is vertically directly below the upper mold assembly;

[0044] It is characterized in that,

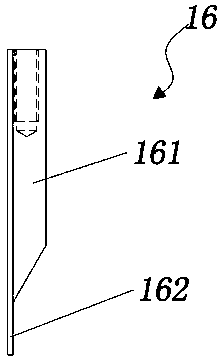

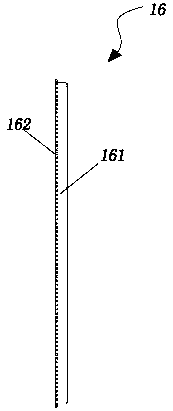

[0045] The upper mold assembly includes an upper mold base 11, an upper backing plate 12, an upper splint 13, a discharge backing plate 14, a discharge plate 15, a punch 16, a nitrogen pressure pump 17, and a nitrogen spring 18;

[0046] The lower mold assembly includes a lower template 21, a lower backing plate 22, a lower mold base 23, a die 24, a lower ejector pin 25, a blanking device 26, a material guide block 27, and a floating block 28;

[0047] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com