Special tool for punching thick rubber sheet used for water seal device of gate of hydropower plant

A technology of a water sealing device and a special tool, applied in the field of tools, can solve the problems of low work efficiency, difficult installation of splints, inconsistent spacing, etc., and achieves improved safety and quality, difficult positioning of punching holes, and good quality of hole forming rules. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

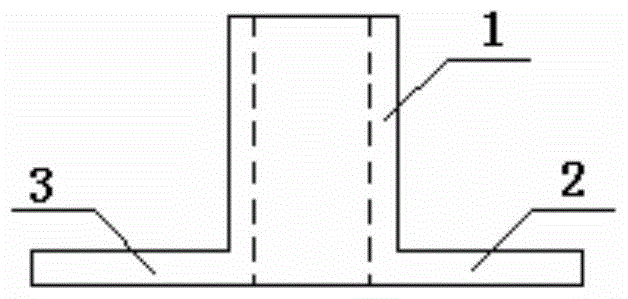

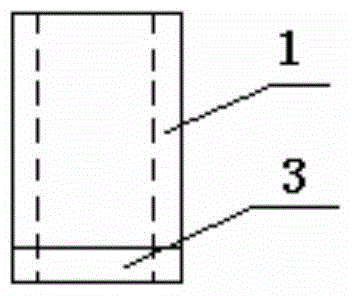

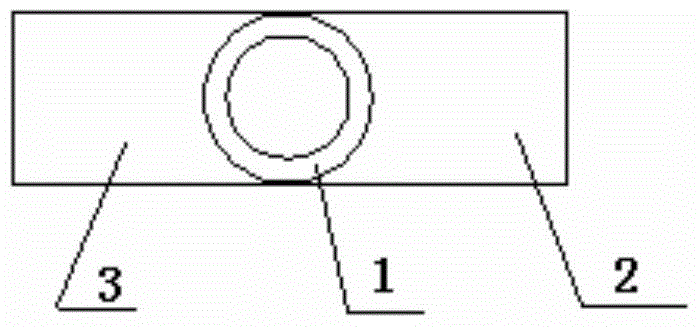

[0017] The following is a further description of the invention of the special tool for punching thick rubber sheets in conjunction with the accompanying drawings:

[0018] The thick rubber plate punching tool of the present invention is mainly composed of a guide body 1 and two left and right support plates 2,3. Guide body 1 is a hollow cylinder, and the hollow part is a hollow circular hole, and its diameter is slightly larger than the outer diameter of the required belt punch, and is used for inserting the required belt punch. The left support plate 3 and the right support plate 2 are respectively welded to the positions on both sides of the bottom end of the guide body 1 by welding and ensure that the guide body 1 and the support plate are perpendicular to each other, and both support plates are on the same plane, so that the guide body The body is integrated with the support plate. The central round hole of the guide body is used to observe and locate the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com