A semi-automatic punching device for cylindrical jade

A punching device and semi-automatic technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as dangerous punching methods, and achieve the effect of convenient use of equipment and good punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

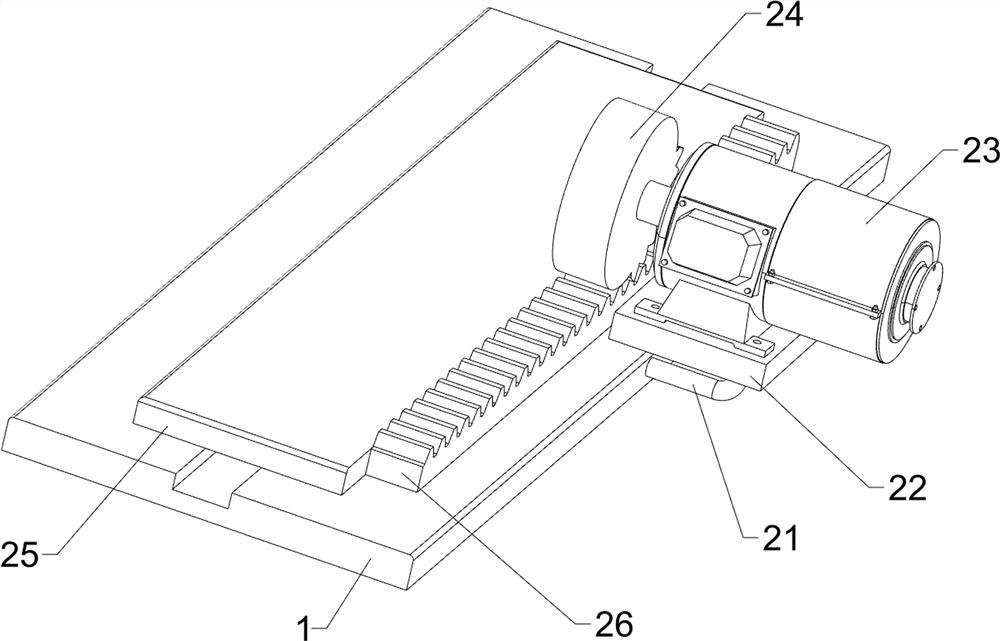

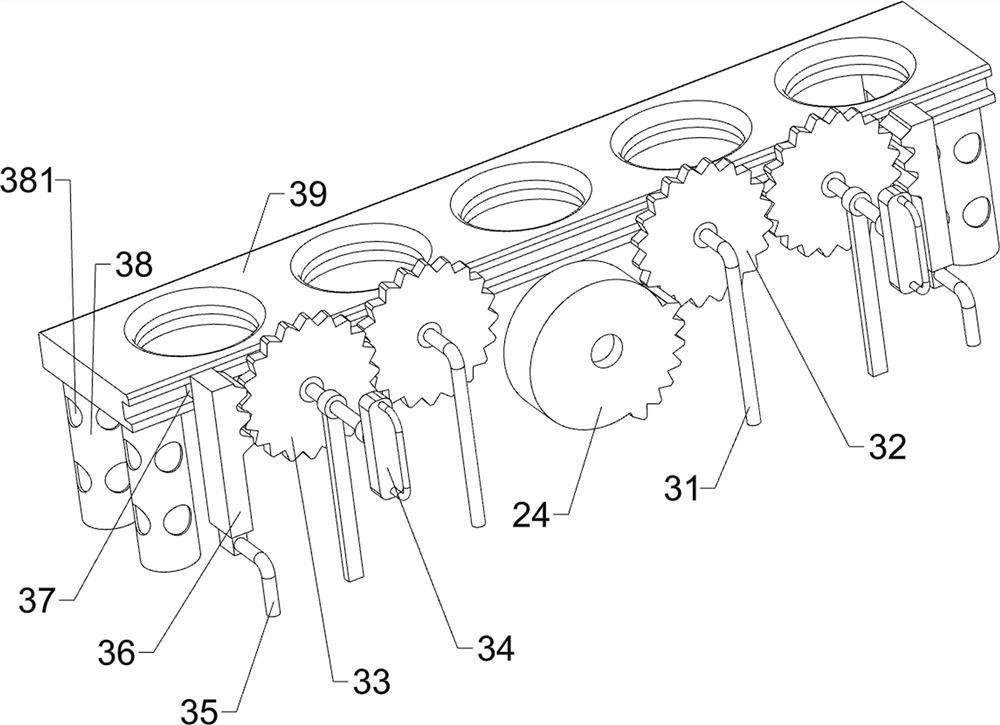

[0020] A cylindrical jade semi-automatic punching device, such as Figure 1-3 As shown, it includes a support plate 1, a moving mechanism 2 and a lifting mechanism 3. A moving mechanism 2 is installed in the middle of the right side of the support plate 1 to move by rotating, and a lifting mechanism 2 is installed on the right side of the top of the support plate 1 to move up and down by rotating. Institution 3.

[0021] When it is necessary to use the device to drill a cylindrical jade, first install the device above the drilling bit, then place the jade on the lifting mechanism 3, and then control the moving mechanism 2 to start working, and the moving mechanism 2 first drives the lifting and lowering The placing part on the mechanism 3 moves upward, so that the jade moves upward for drilling. After the jade under the drill bit is punched, the moving mechanism 2 drives the placing part on the lifting mechanism 3 to move backward, so that the jade moves backward, and the next...

Embodiment 2

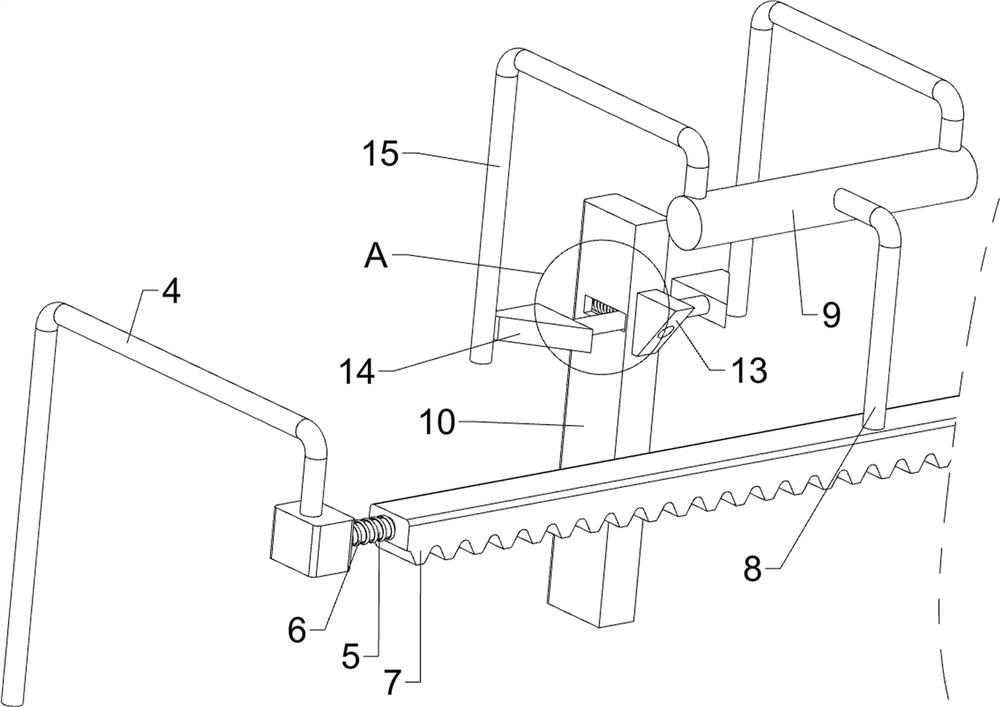

[0027] On the basis of Example 1, as figure 1 , 4As shown in and 5, it also includes a fixing frame 4, a connecting rod 5, a first spring 6, a third rack 7, a first connecting frame 8 and a rubber tube 9. Frame 4, the tail end of the fixing frame 4 is slidably provided with a connecting rod 5, a first spring 6 is connected between the connecting rod 5 and the tail end of the fixing frame 4, a third rack 7 is welded between the connecting rod 5, and a third rack 7 is welded between the connecting rod 5. The rack 7 is matched with the fan gear 24 , the top of the third rack 7 is welded with a first connecting frame 8 , and the top end of the first connecting frame 8 is connected with a rubber tube 9 .

[0028] When the sector gear 24 rotates to mesh with the third rack 7, it drives the third rack 7 to move forward or backward, and then drives the first connecting frame 8 to move forward or backward, so that the rubber tube 9 moves forward or backward. Backward movement, when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com