Rotor and motor using same

A technology of rotors and rotor cores, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve problems such as uneven magnetic flux and magnetic imbalance, reduce cogging torque and torque fluctuations, and improve magnetic unbalanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

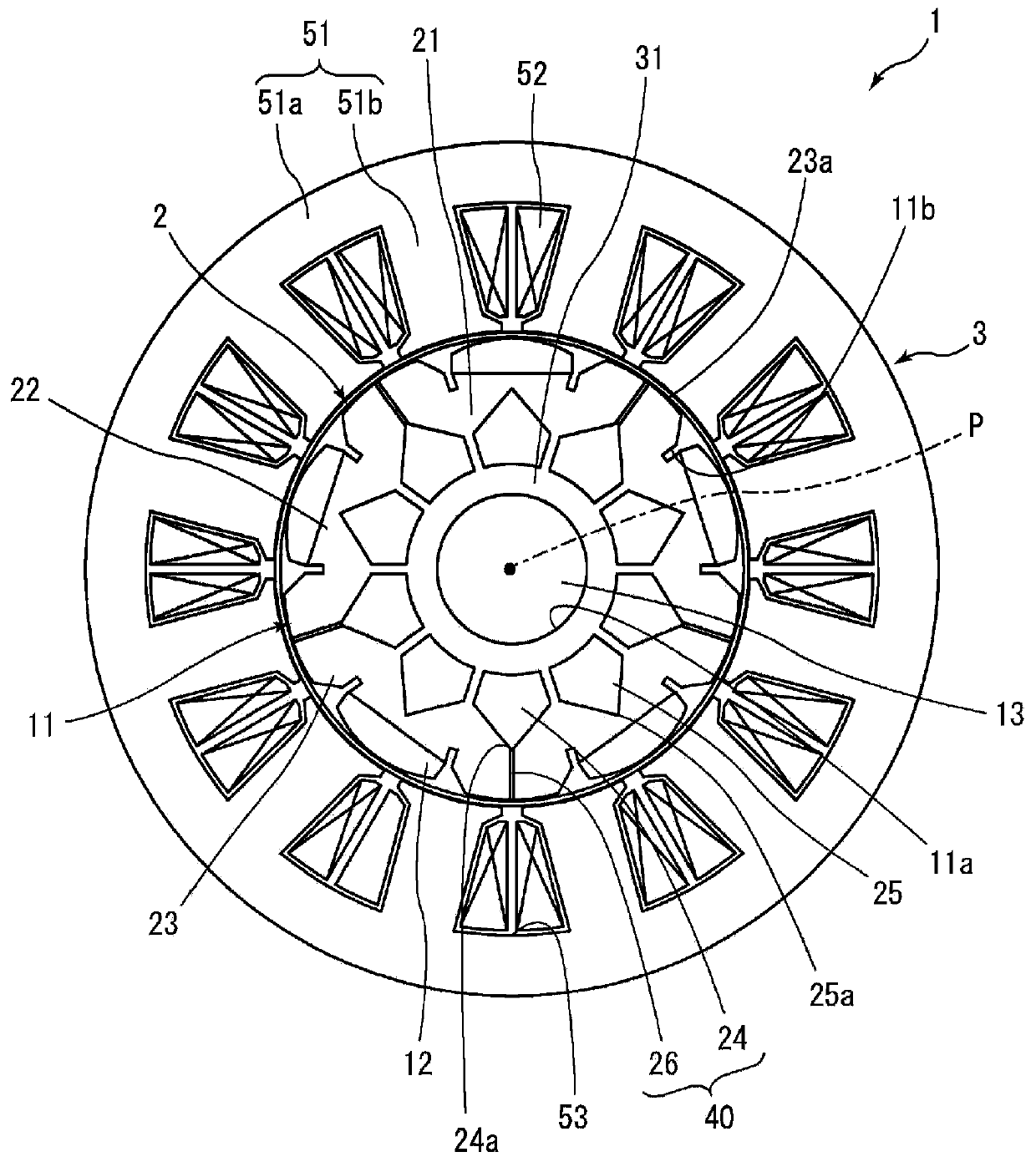

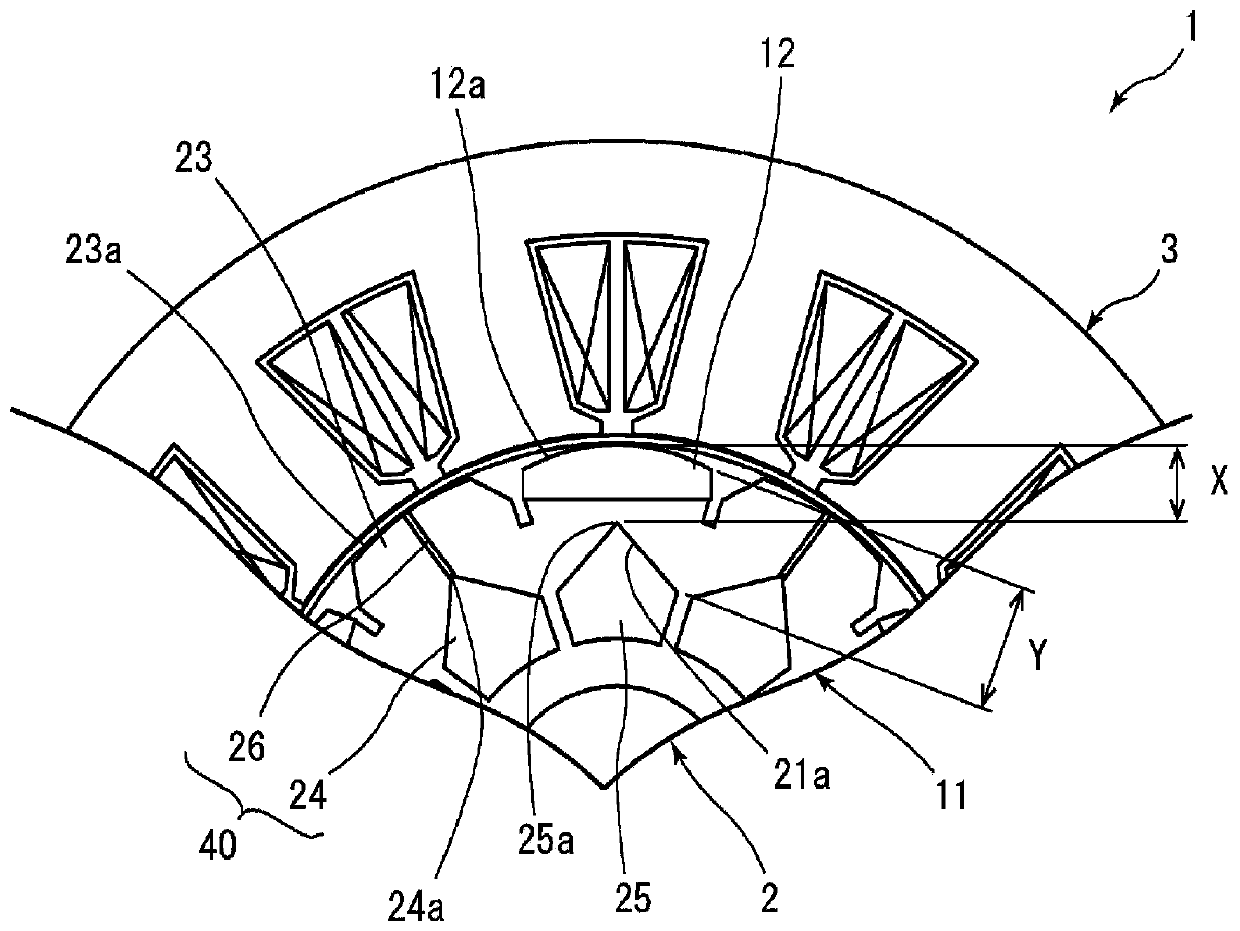

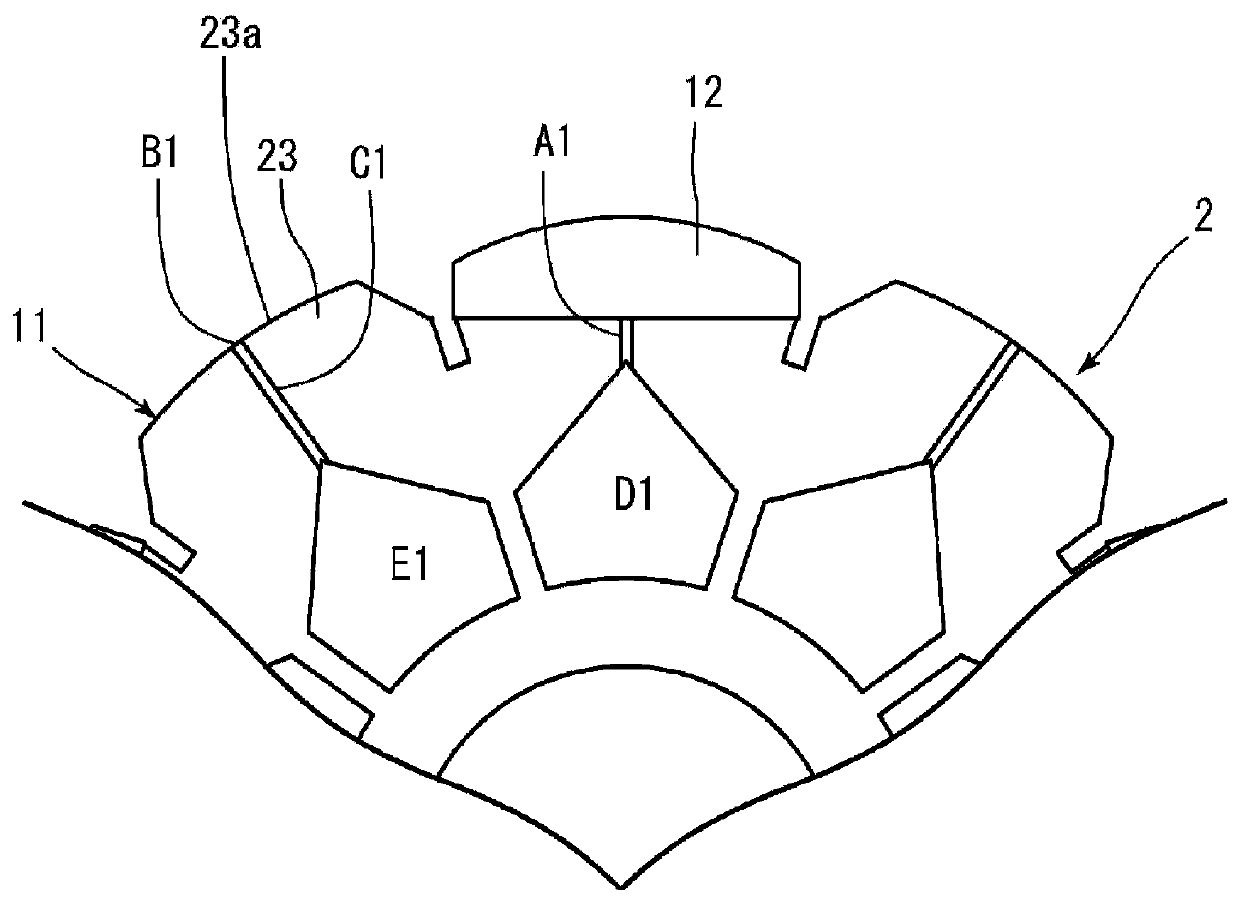

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same or corresponding part in a figure, and the description is not repeated. In addition, the dimensions of the components in the drawings do not fully represent the dimensions of the actual components, the dimensional ratios of the components, and the like.

[0029] In addition, in the following description, the direction parallel to the central axis of the rotor is referred to as "axial direction", the direction perpendicular to the central axis is referred to as "radial direction", and the direction along an arc centered on the central axis is referred to as The direction is called "circumferential". However, the definition of this direction is not intended to limit the orientation when using the rotor and motor of the present invention.

[0030] (the whole frame)

[0031] exist figure 1 A sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com