A screening method for the consistency of soft-pack lithium-ion batteries

A technology of ion battery and screening method, which is applied in the direction of secondary battery, electrolyte storage battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve the problems of performance difference, charge and discharge curve without obvious boundaries, and battery consistency cannot be guaranteed, etc. The effect of increased group consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Table 1

[0016]

[0017]

[0018] Extract a small amount of batteries for matching

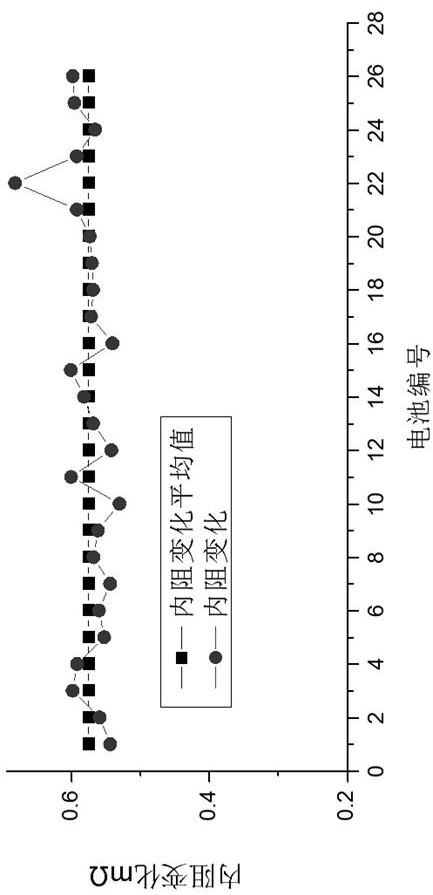

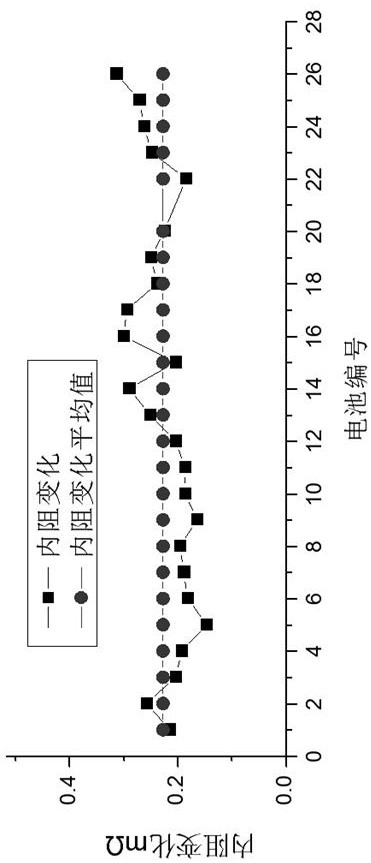

[0019] 1. Take out the 1-26 sets of batteries after liquid injection at 40°C for 24 hours, record the internal resistance R1 of the battery after placing it at room temperature, record the internal resistance R2 of the battery after the formation, and calculate the change of internal resistance of the battery ΔR=R2-R1 , and then calculate the average value of battery internal resistance change (see Table 1), and make a curve of internal resistance change deviating from the average value, such as figure 1 As shown, the deviation of the internal resistance change is required to be less than 0.05mΩ. Since the deviation of the 22# battery is relatively large, it is picked out and placed separately;

[0020] 2. Record the first charge capacity and discharge capacity of the battery after formation, pick out the batteries with low and high capacity according to the rated capacity requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com