Method for testing thermal expansion coefficient of small sample by using nanomechanical tester

A thermal expansion coefficient and tester technology, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of complex sample preparation and special shape requirements, and achieve the effect of wide application, low sample requirements, and simple sample preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Thermal expansion coefficient test of aluminum sample

[0034] Test piece: aluminum wedge sample.

[0035] The test steps are as follows:

[0036] (1) Fix the aluminum wedge-shaped sample on the heating platform of the nanomechanical tester;

[0037] (2) Calibrate the equipment according to the equipment manual to ensure the normal operation of the equipment;

[0038] (3) Set the loading function, the maximum load is 8mN, the holding time is 240s, and the temperature rise program is set, the temperature is raised from 25°C to 45°C, the heating rate is 5°C / min, and the heating time is consistent with the holding time.

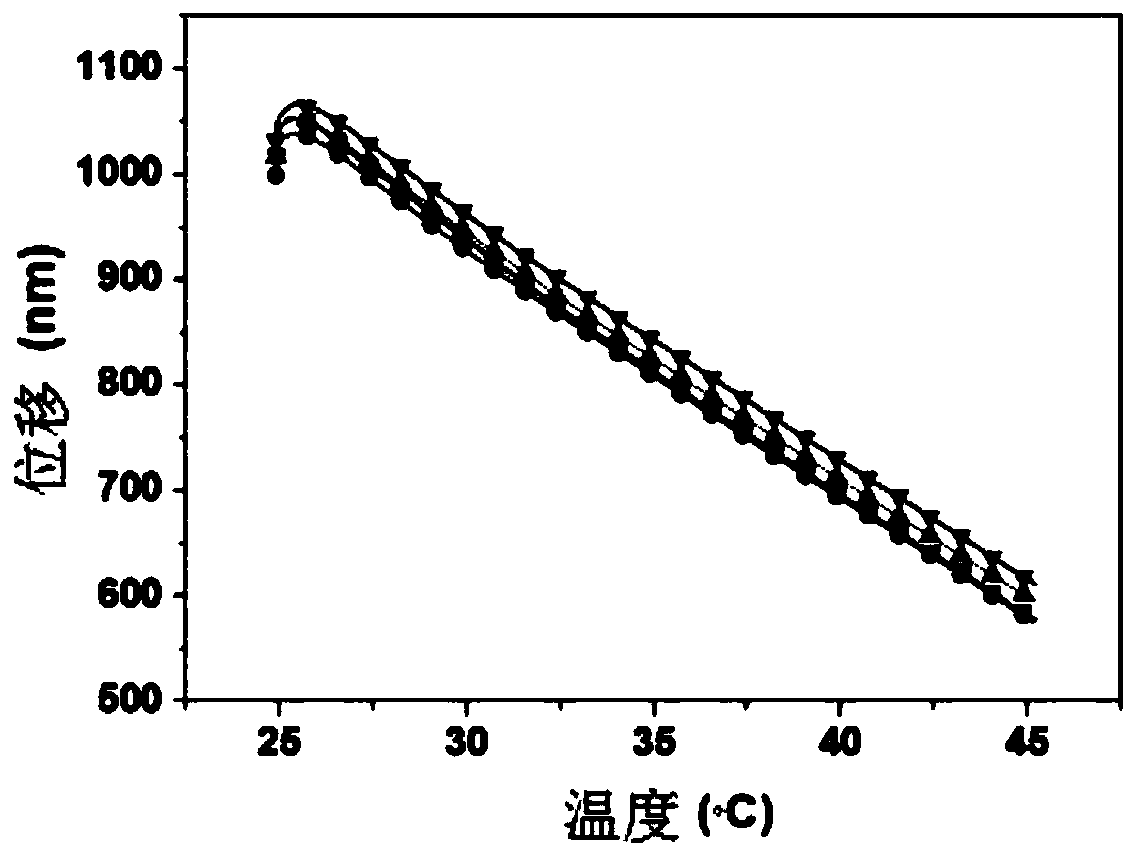

[0039] (4) At height h 1 The position 1 is tested, the temperature starts to rise when the load reaches 8mN, and the displacement of the indenter changes with time (in the nanomechanical tester used this time, the displacement is positive downward), and the height h of position 1 is recorded at the same time 1 , in order to reduce the me...

Embodiment 2

[0042] Embodiment two: the thermal expansion coefficient test of titanium sample

[0043] Test piece: titanium wedge sample.

[0044] The test steps are as follows:

[0045] (1) Fix the titanium wedge-shaped sample on the heating platform of the nanomechanical tester;

[0046] (2) Calibrate the equipment according to the equipment manual to ensure the normal operation of the equipment;

[0047] (3) Set the loading function, the maximum load is 8mN, the holding time is 240s, and the temperature rise program is set, the temperature is raised from 30°C to 50°C, the heating rate is 5°C / min, and the heating time is consistent with the holding time.

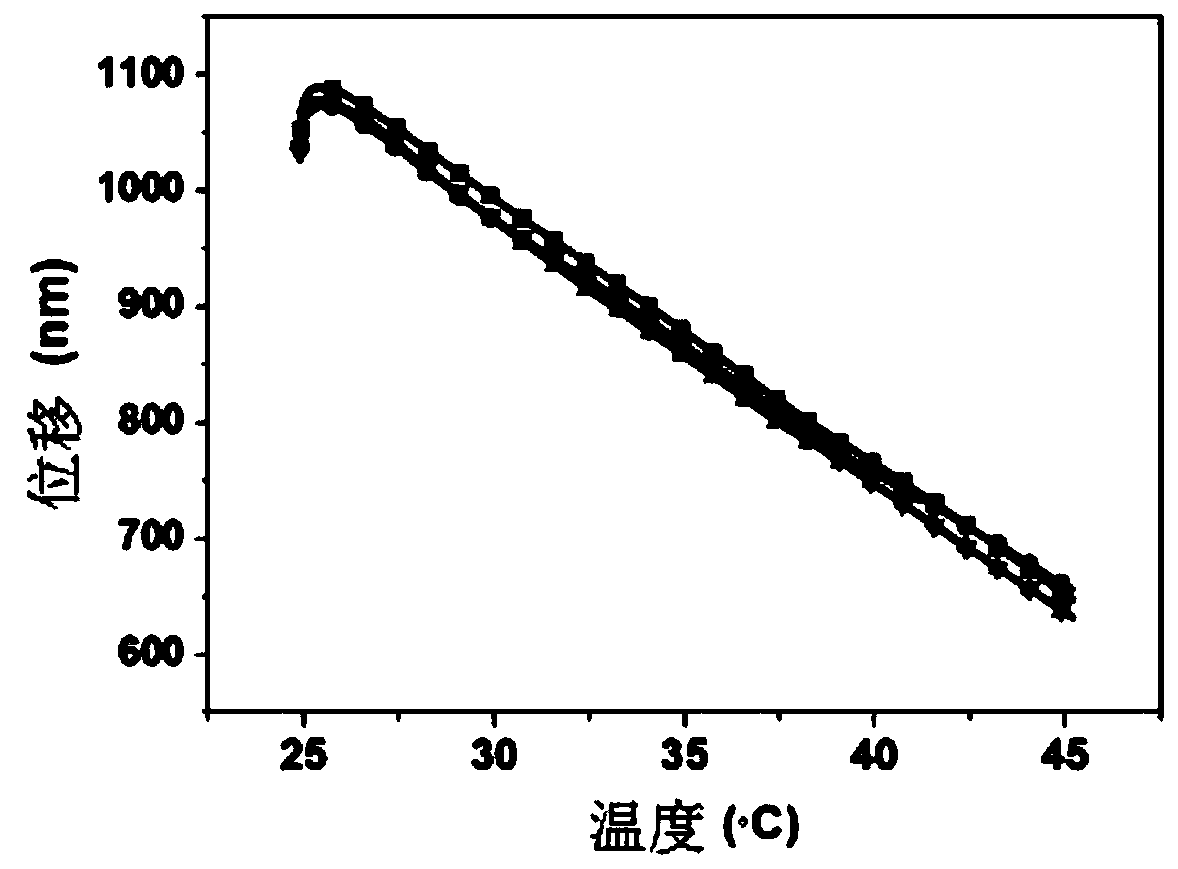

[0048] (4) At height h 1 When the load reaches 8mN, the temperature starts to rise, and the displacement of the indenter changes with time (note: in the nanomechanical tester used this time, the downward displacement is positive), and the height h of position 1 is recorded at the same time 1 , in order to reduce the measurement err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com