Double twisting strander spool unwinding device

A pay-off device and machinist's technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of unfavorable influence on wire rope production, easy loosening, and affecting the work of I-shaped wheel pay-off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

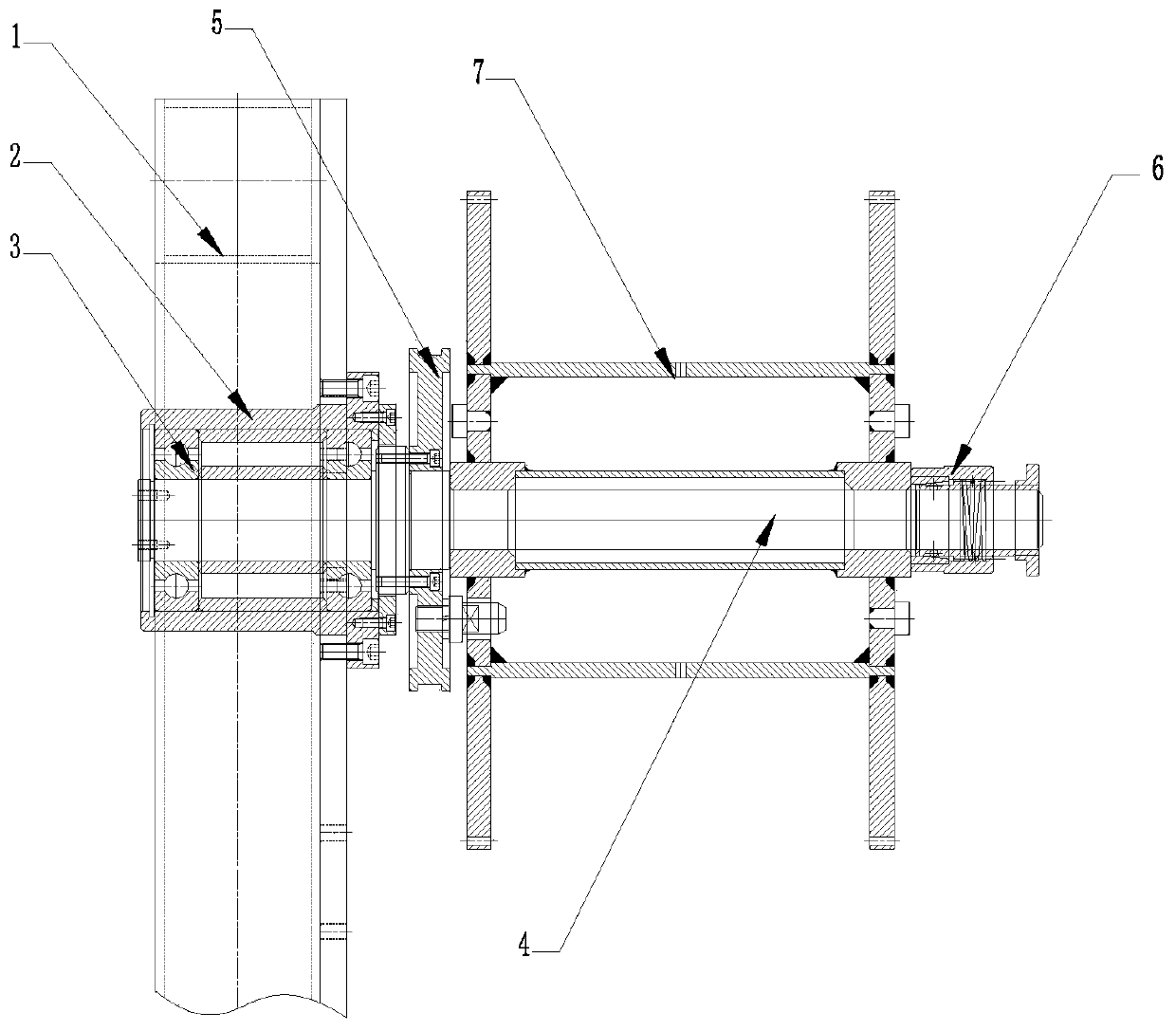

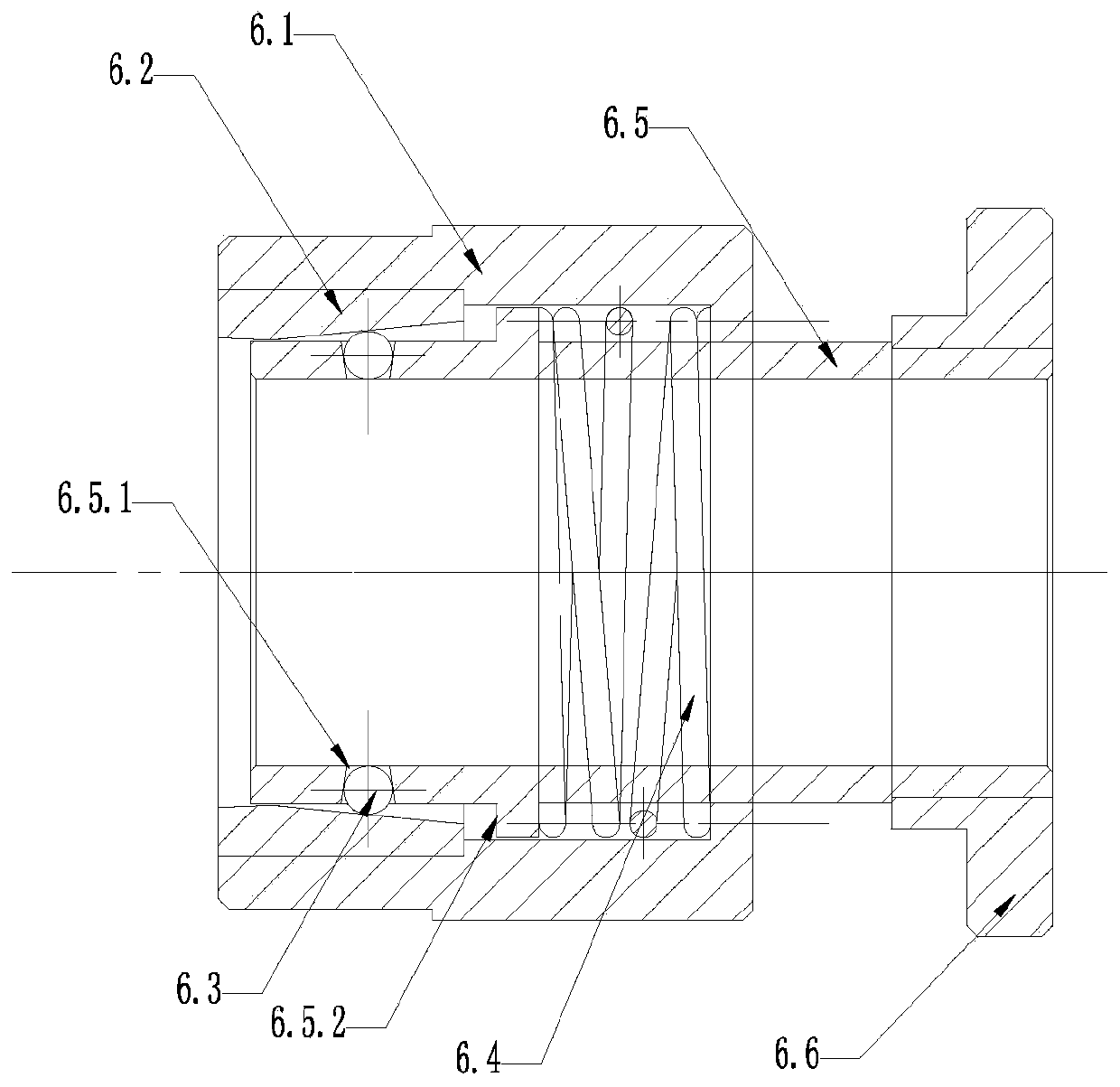

[0008] Such as figure 1 and figure 2 As shown, a double-twisting machine I-shaped wheel pay-off device is characterized in that it includes a frame 1, a bearing seat 2, a bearing 3, a pay-off shaft 4, a pay-off damping disc 5 and a locking device 6; the bearing seat 2 Set on the frame 1, the front end of the pay-off shaft 4 is horizontally set on the bearing seat 2 through the bearing 3; the pay-off damping disc 5 is fixedly arranged on the pay-off shaft 4 close to the bearing seat 2; 6.1, inner sleeve 6.2, steel ball 6.3, spring 6.4, pull sleeve 6.5 and pull handle 6.6; inner sleeve 6.2 is set in the port at the front end of outer sleeve 6.1, and the inner wall on the rear side of inner sleeve 6.2 is conical; the front end of pull sleeve 6.5 Extending from the rear end of the outer jacket 6.1 into the inner sleeve, several tapered through holes 6.5.1 are provided on the side wall of the front end of the pull sleeve 6.5, and a steel ball 6.3 is arranged in the tapered throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com