Novel axle fatigue test bench

A fatigue test, axle technology, applied in the direction of railway vehicle testing, etc., can solve the problem that the load transmission does not match the actual situation, does not have the effect of reflecting the real load, etc., and achieves accurate and reliable fatigue test results, accurate reflection, and improved accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

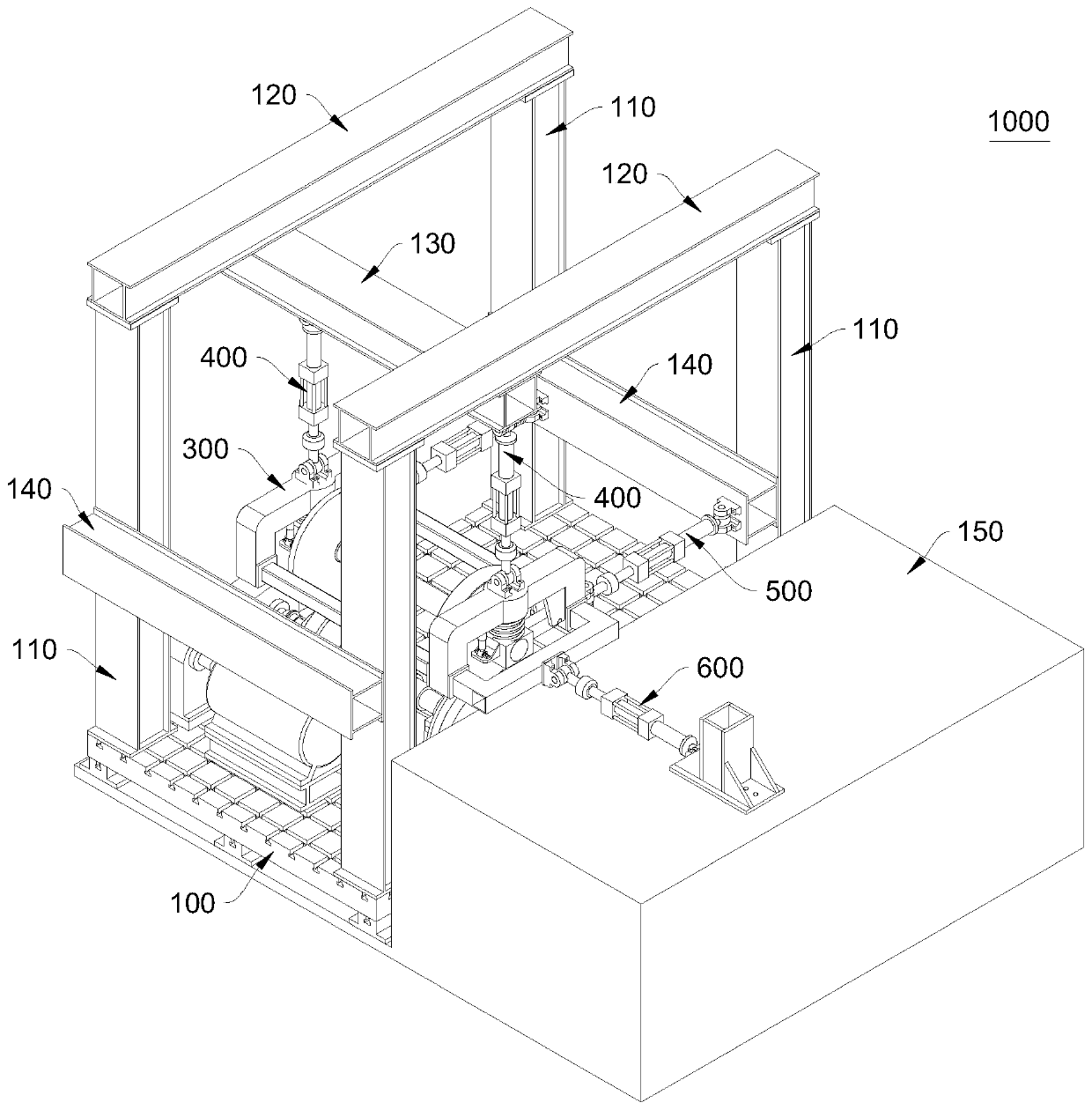

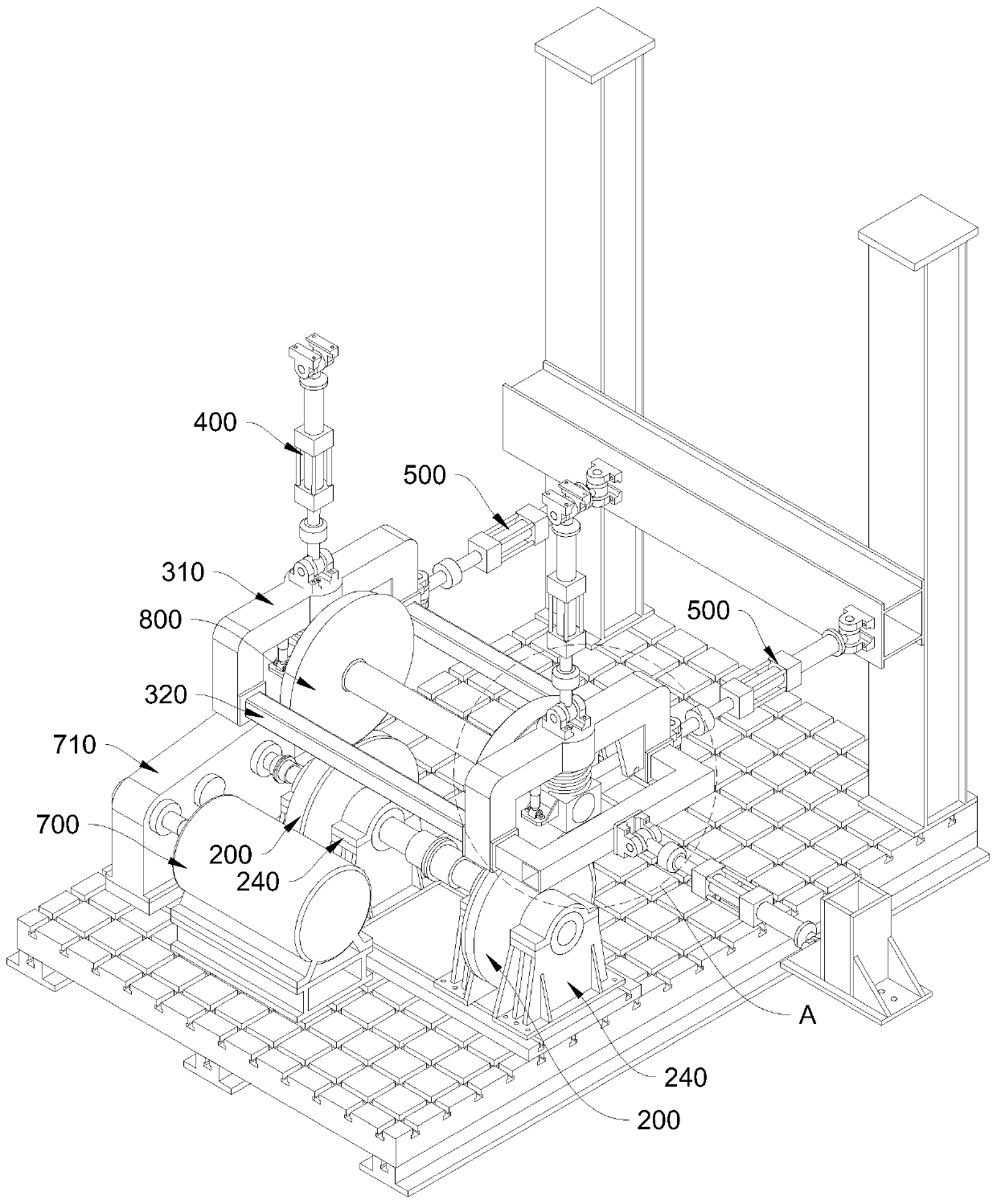

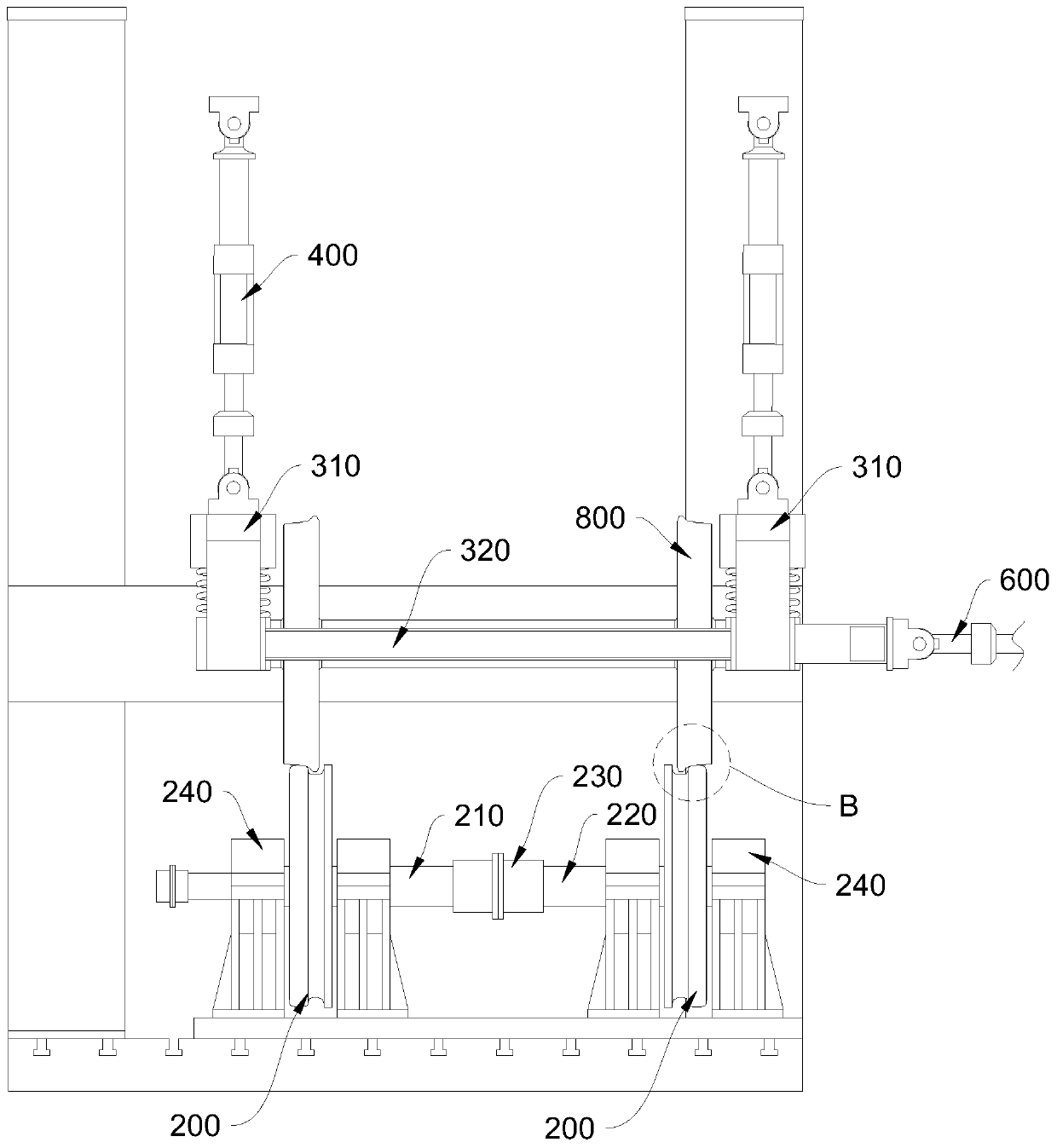

[0031] Please refer to Figure 1~3 , this embodiment provides a new axle fatigue test bench 1000 . The axle fatigue test bench 1000 includes: a base 100, a track wheel 200, an experimental wheel set fixture 300, a first actuator 400 and a second actuator 500.

[0032] The track wheel 200 is rotatably arranged on the base 100 and is driven by the driver 700. The track wheel 200 has a matching part for carrying the tested wheel pair 800 and for cooperating with the tested wheel pair 800. The experimental wheel set fixture 300 is mounted on the base 100 and has a mounting portion for installing the tested wheel set 800.

[0033] The first actuator 400 is arranged vertically and above the experimental wheel set holder 300 for applying a vertical load to the tested wheel set 800 mounted on the experimental wheel set holder 300 . The second actuator 500 is arranged in the horizontal direction and is separately arranged on both sides of the experimental wheel set fixture 300, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com