Preparation and testing method of a non-conjugated fluorescent polymer

A fluorescent polymer, non-conjugated technology, used in luminescent materials, fluorescence/phosphorescence, chemical instruments and methods, etc., can solve the problem of not finding yellow and red emission, and achieve the effect of expanding the test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

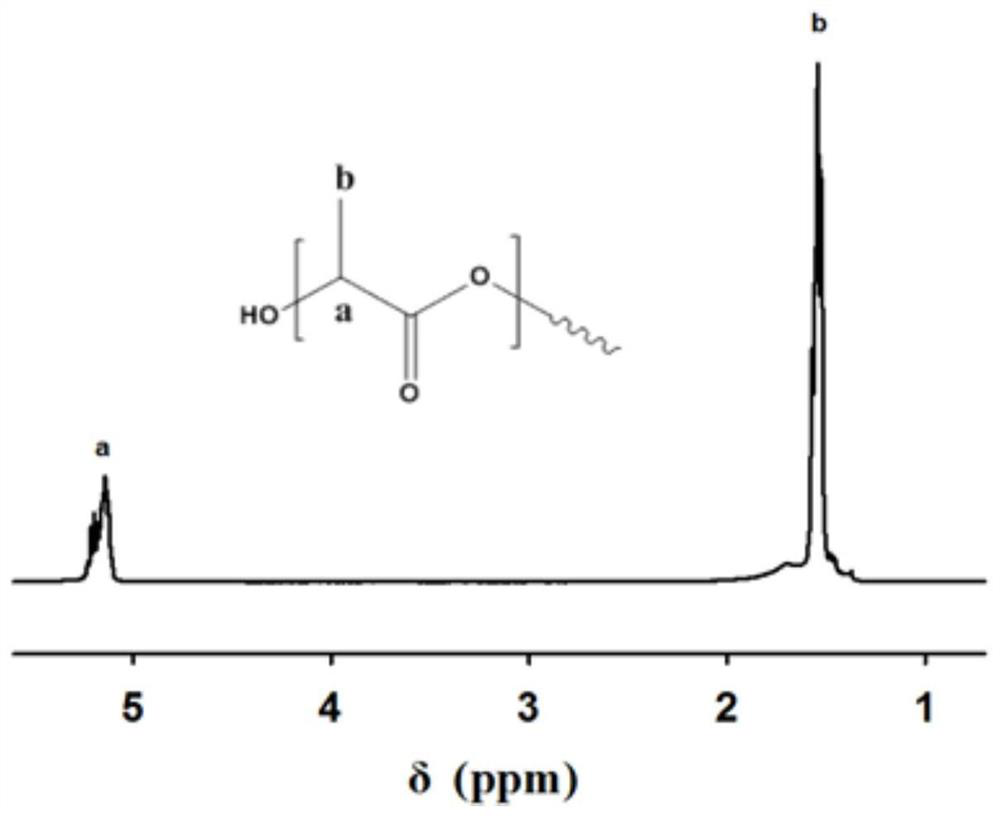

[0025] Preparation of fluorescent polylactic acid: anhydrous glucose, lactide, stannous octoate Sn(Oct) 2 The molar ratio is 1:70:0.35; weigh anhydrous glucose, lactide, stannous octoate Sn(Oct) according to the above molar ratio 2 In the flask, add a small amount of toluene to dissolve, and reflux at 140°C for 24 hours. After the reaction solution was concentrated, it was dropped into anhydrous ether for recrystallization, filtered, and the obtained solid was vacuum-dried for 12 hours to obtain a brown solid. For NMR characterization, see figure 1 .

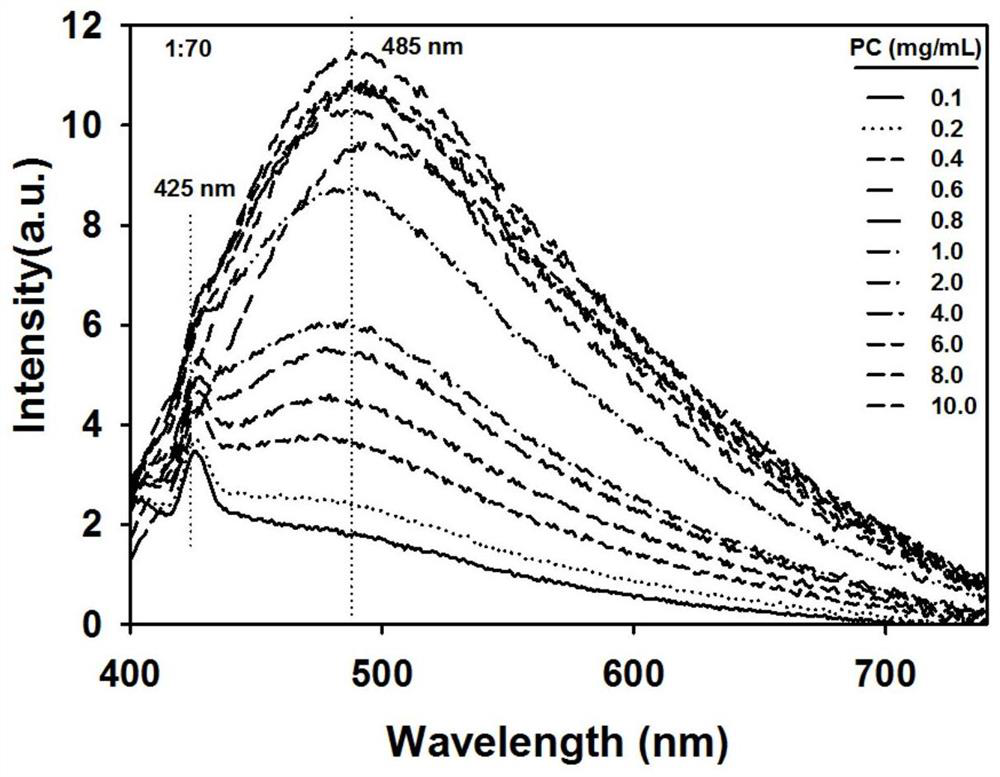

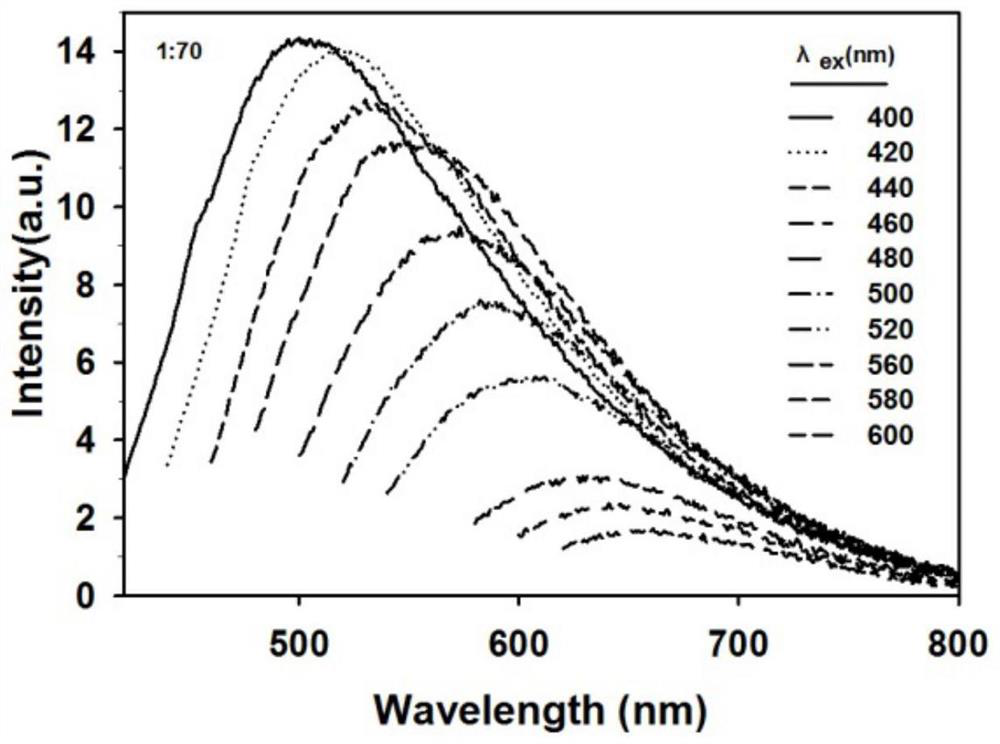

[0026] Dissolve 0.1 g of the prepared brown solid in 5 mL of DMF solution with a concentration of 10 mg / mL, gradually dilute and prepare polymer solutions of various concentrations, and test the fluorescence spectrum from low concentration to high concentration, the entrance slit is 1.75 nm, and the exit slit is 1.25nm, the excitation wavelength is 380nm, the emission wavelength is 425nm and 485nm, and the maximum concentratio...

Embodiment 2

[0028] Preparation of fluorescent polylactic acid: anhydrous glucose, lactide, stannous octoate Sn(Oct) 2 The molar ratio is 1:120:0.6, weigh anhydrous glucose, lactide, stannous octanoate Sn(Oct) according to the above molar ratio 2 In the flask, add a small amount of toluene to dissolve, and reflux at 140°C for 24 hours. After the reaction solution was concentrated, it was dropped into anhydrous ether for recrystallization, filtered, and the obtained solid was vacuum-dried for 12 hours to obtain a brown solid.

[0029] Dissolve 0.3g of the prepared brown solid in 5mL of DMF solution, the concentration is 60mg / mL, gradually dilute and prepare polymer solutions of various concentrations, and test the fluorescence spectrum from low concentration to high concentration, the incident slit is 1.75nm, and the exit slit is 1.25nm, the excitation wavelength is 380nm, the emission wavelength is 425nm and 485nm, and the maximum concentration of fluorescence intensity is determined to b...

Embodiment 3

[0031] Preparation of fluorescent polylactic acid: anhydrous glucose, lactide, stannous octoate Sn(Oct) 2 The molar ratio is 1:180:0.9, and anhydrous glucose, lactide, stannous octoate Sn(Oct) are weighed according to the above molar ratio 2 In the flask, add a small amount of toluene to dissolve, and reflux at 140°C for 24 hours. After the reaction solution was concentrated, it was dropped into anhydrous ether for recrystallization, filtered, and the obtained solid was vacuum-dried for 12 hours to obtain a brown solid.

[0032] Dissolve 0.3g of the prepared brown solid in 5mL of DMF solution, the concentration is 60mg / mL, gradually dilute and prepare polymer solutions of various concentrations, and test the fluorescence spectrum from low concentration to high concentration, the incident slit is 1.75nm, and the exit slit is 1.25nm, the excitation wavelength is 380nm, the emission wavelength is 425nm and 485nm, and the maximum concentration of fluorescence intensity is determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com