Vacuum Cleaner Nozzle Equipped With A Main Suction Channel And A Secondary Suction Channel

A technology for vacuuming channels and vacuum cleaners, applied in the direction of suction nozzles, etc., can solve problems such as insufficient to ensure large waste, and achieve the effects of improving dusting performance, increasing air flow speed, and optimizing dusting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

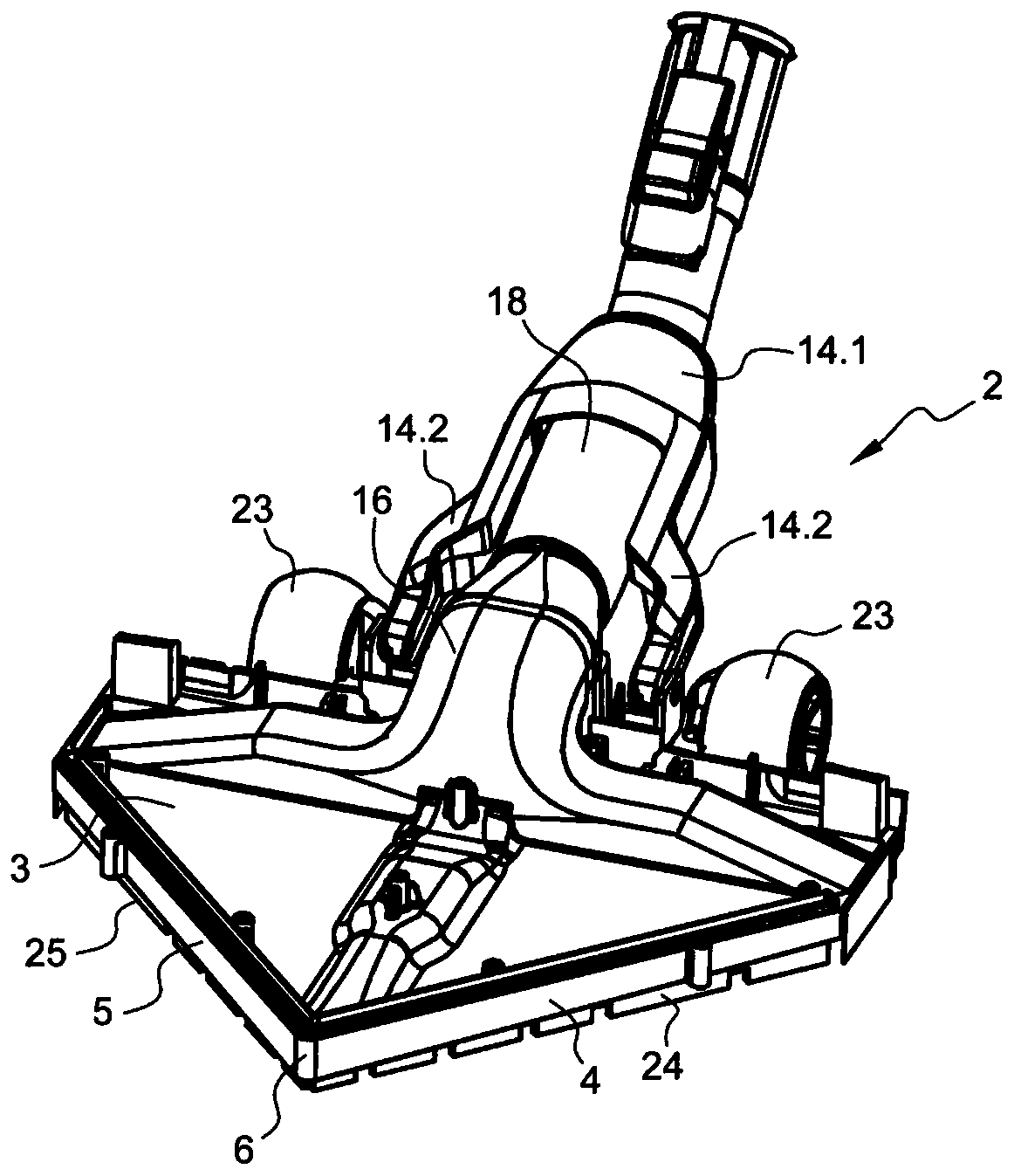

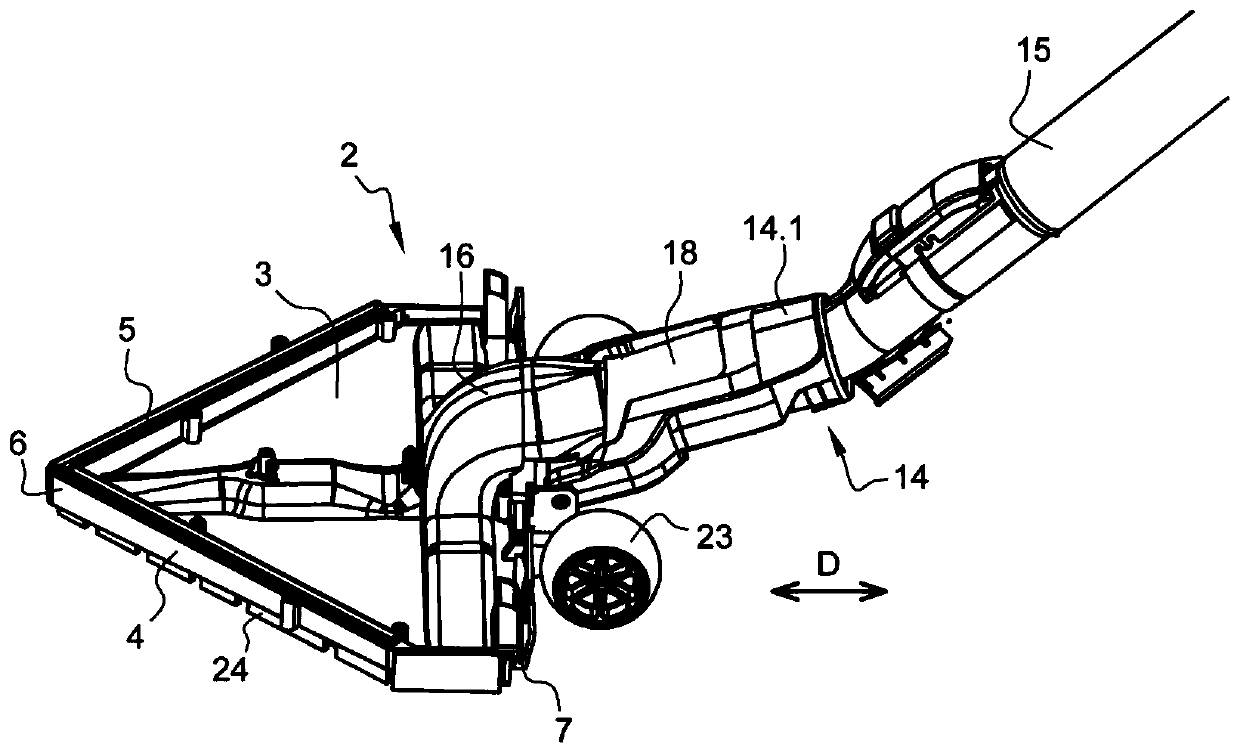

[0046] Figure 1 to Figure 6 A vacuum cleaner nozzle 2 is shown, comprising a base plate 3, eg made of plastic material, having a generally triangular shape. The base plate 3 comprises a first side edge 4 and a second side edge 5 forming the front tip 6 of the vacuum cleaner nozzle 2 and a rear edge 7 which is substantially perpendicular to the vacuum cleaner nozzle 2 in the direction of movement D. Advantageously, the first side edge 4 and the second side edge 5 of the bottom plate 3 form an acute angle.

[0047] The base plate 3 is notably equipped with a lower surface 8 comprising a front part 9 which is substantially flat and has a substantially triangular shape and a rear part 11 which has a substantially rectangular shape.

[0048]The floor 3 also comprises a main suction channel 12 which extends over the rear part 11 of the lower surface 8 and opens into the rear part 11 of the lower surface 8 . Advantageously, the main suction duct 12 extends along a first direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com