Precise screw cap

A nut, precision technology, applied in nuts, threaded fasteners, connecting components, etc., can solve problems such as equipment accuracy decline, equipment failure, industrial safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

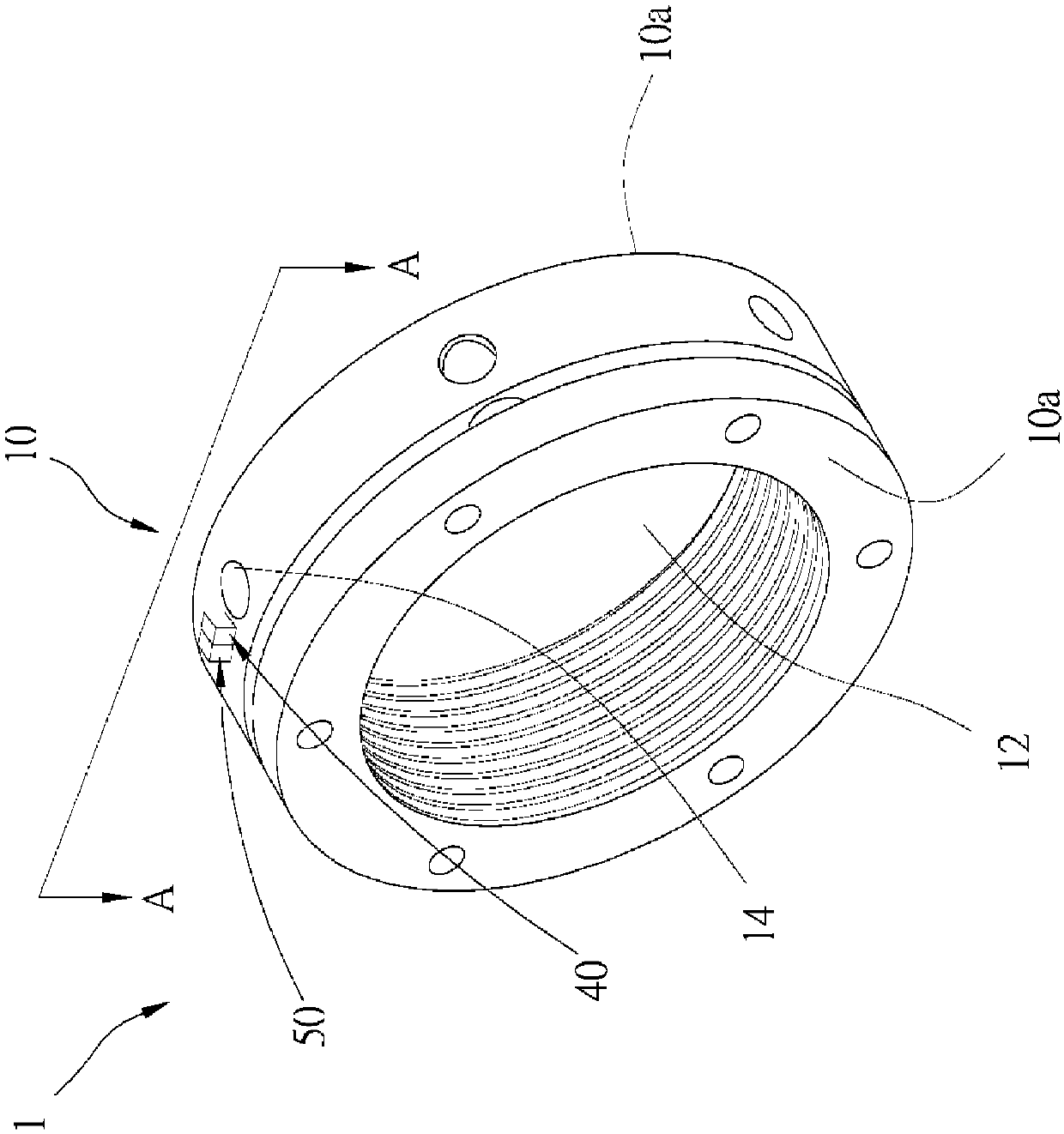

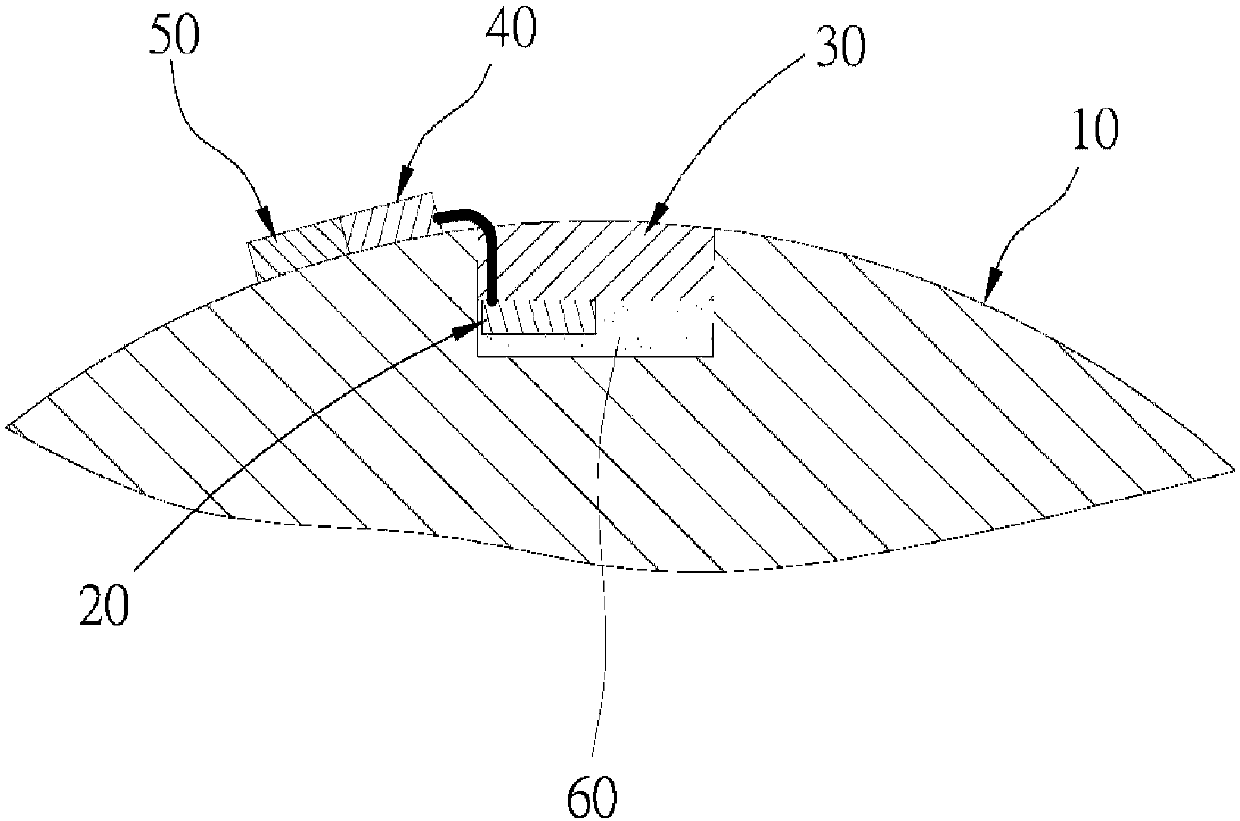

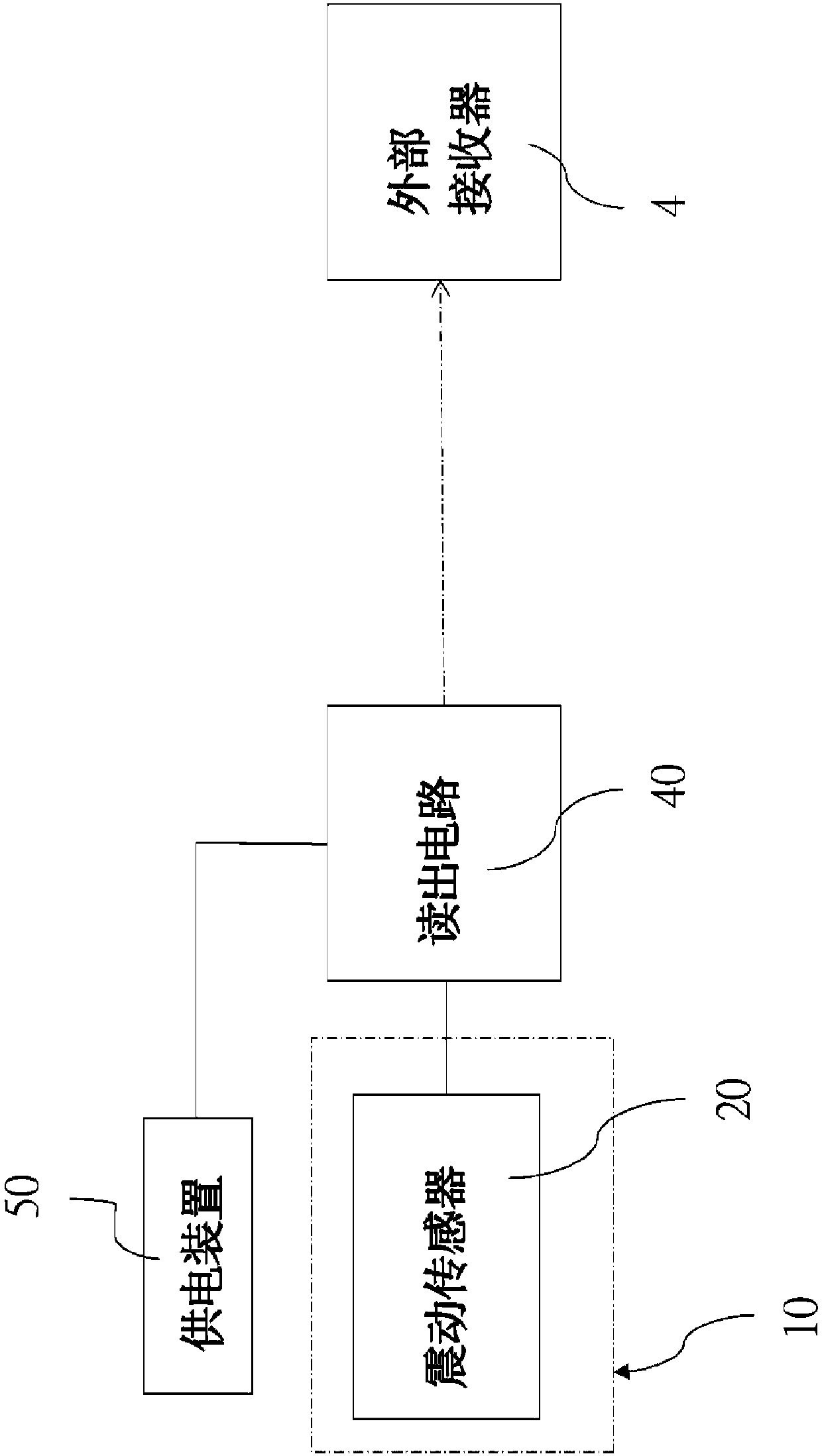

[0041] In order to illustrate the present invention more clearly, preferred embodiments and drawings are given in detail as follows. Please refer to Figure 1 to Figure 3 As shown, the precision nut 1 according to the first preferred embodiment of the present invention includes a body 10 , a vibration sensor 20 , a closure 30 , a readout circuit 40 and a power supply device 50 .

[0042] The body 10 has a screw hole 12 and a recess 14, wherein the screw hole 12 runs through the opposite end surfaces 10a of the body 10, and the screw hole 12 is screwed with a screw (not shown) of the device (not shown). The cavity 14 is formed by indenting from the outer peripheral surface of the body 10 , and is not limited thereto, and may also be formed by indenting from one end surface 10 a of the body 10 .

[0043] The shock sensor 20 is disposed in the cavity 14 and electrically connected to the readout circuit 40 . When the shock sensor 20 detects the vibration of the main body 10 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com