Automatic gluing equipment suitable for aluminum alloy windows

A technology of aluminum alloy and gluing, which is applied in the direction of coating and liquid coating device on the surface, which can solve the problems of product quality loss and error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

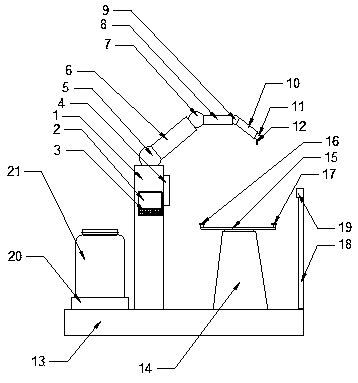

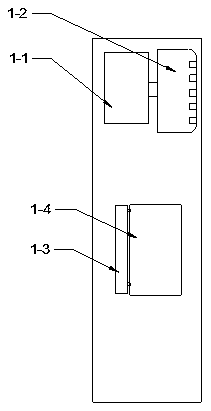

[0013] Such as Figure 1 to Figure 2 As shown, this machine is suitable for automatic gluing equipment for aluminum alloy windows, including gluing machine chassis 1, gluing machine management display 2, gluing machine control keyboard 3, main three-dimensional photoelectric sensor 4, gluing machine motion base 5. The main arm of the gluing machine 6, the motion base of the auxiliary arm of the gluing machine 7, the auxiliary arm of the gluing machine 8, the moving base of the auxiliary arm of the gluing machine 9, the auxiliary arm of the gluing machine 10, the gluing gun 11, the gluing machine Port 12, equipment base 13, workbench 14, workbench main beam 15, No. 1 suction cup 16, No. 2 suction cup 17, auxiliary three-dimensional sensor bracket 18, auxiliary three-dimensional sensor 19, rubber bucket base 20 and rubber bucket 21, The surface of the equipment base 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com