Energy-absorbing and decompressing protective frame device installed on the rear frame of heavy-duty vehicles

A technology for heavy-duty vehicles and protective frames, which is applied to vehicle safety arrangements, bumpers, and vehicle components. It can solve the problems of flexibility, low safety protection, single shock-absorbing structure, and poor effect, and achieve good shock-absorbing effects. High security and the effect of preventing subsequent impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

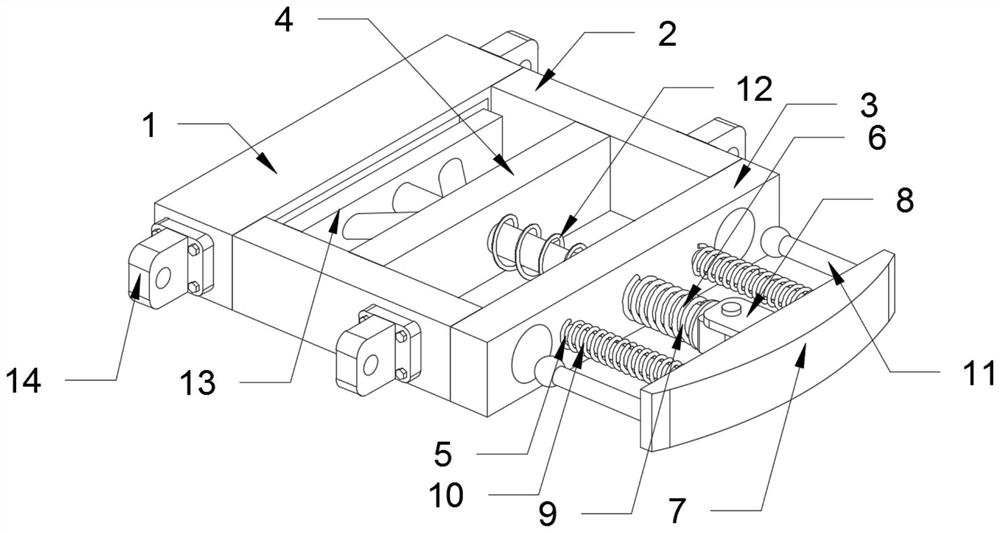

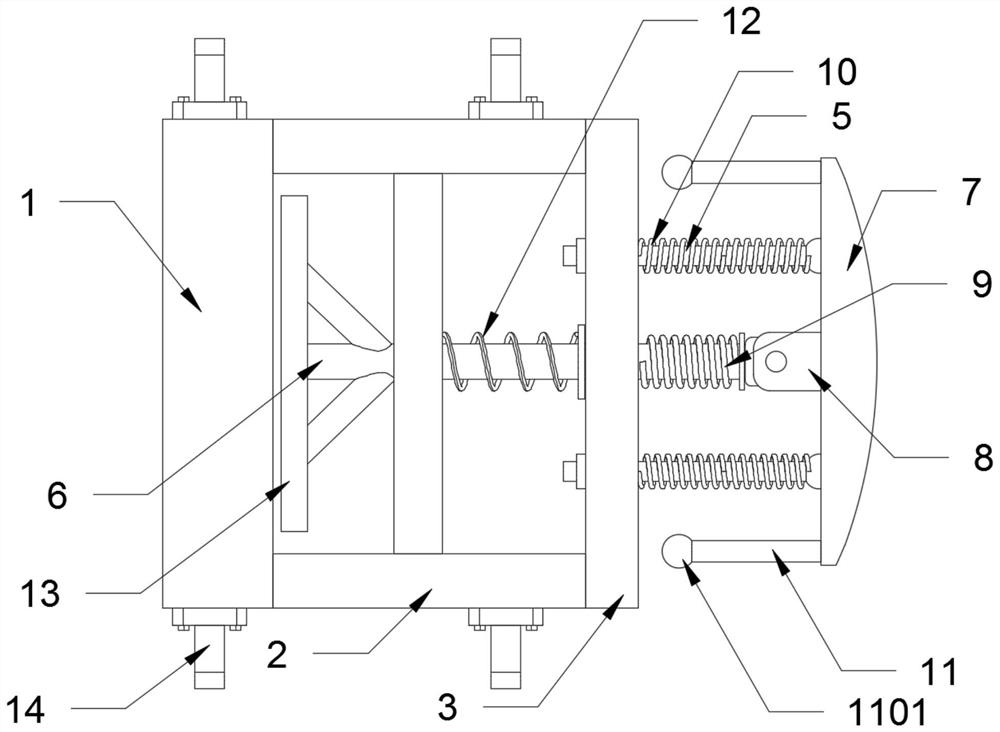

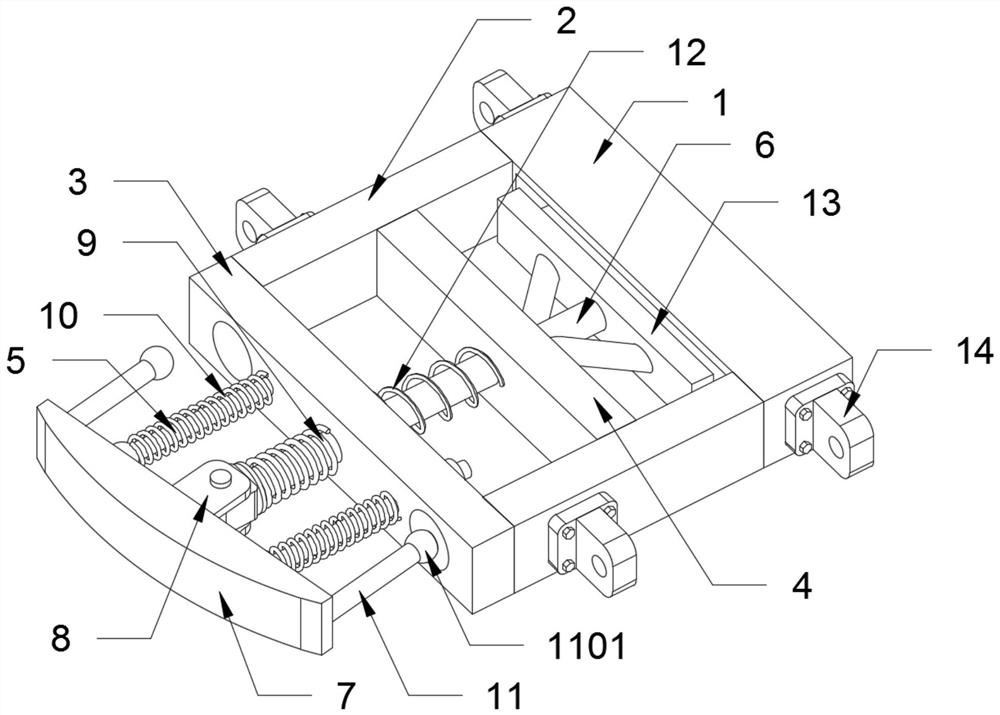

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The present invention provides an energy-absorbing and decompression protective frame device installed on the rear frame of a heavy-duty vehicle, comprising: a bottom plate 1, a rectangular groove 101, a rectangular rubber block 102, a support column 2, a rectangular plate A3, a circular hole 301, a cylindrical rubber 302, rectangular plate B4, cylindrical rod A5, iron ball A501, cylindrical rod B6, annular baffle A601, annular baffle B602, force plate 7, semicircular groove 701, rotating connection seat 8, spring A9, spring B10, cylindrical rod C11, iron ball B1101, spring C12, rectangular plate C13 and holder 14; the front end of the base plate 1 is provided with a rectangular groove 101, and a piece of the rectangular groove 101 is provided in the rectangular groove 101. Rectangular rubber block 102; the left end surface and the right end surface of the base plate 1 are all fixedly connected with a described f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com