An oil pipe anchor for pressure setting in oil sleeve annulus

A technology for pressure setting and oil casing annulus, applied in the directions of sealing/packing, wellbore/well components, earthwork drilling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

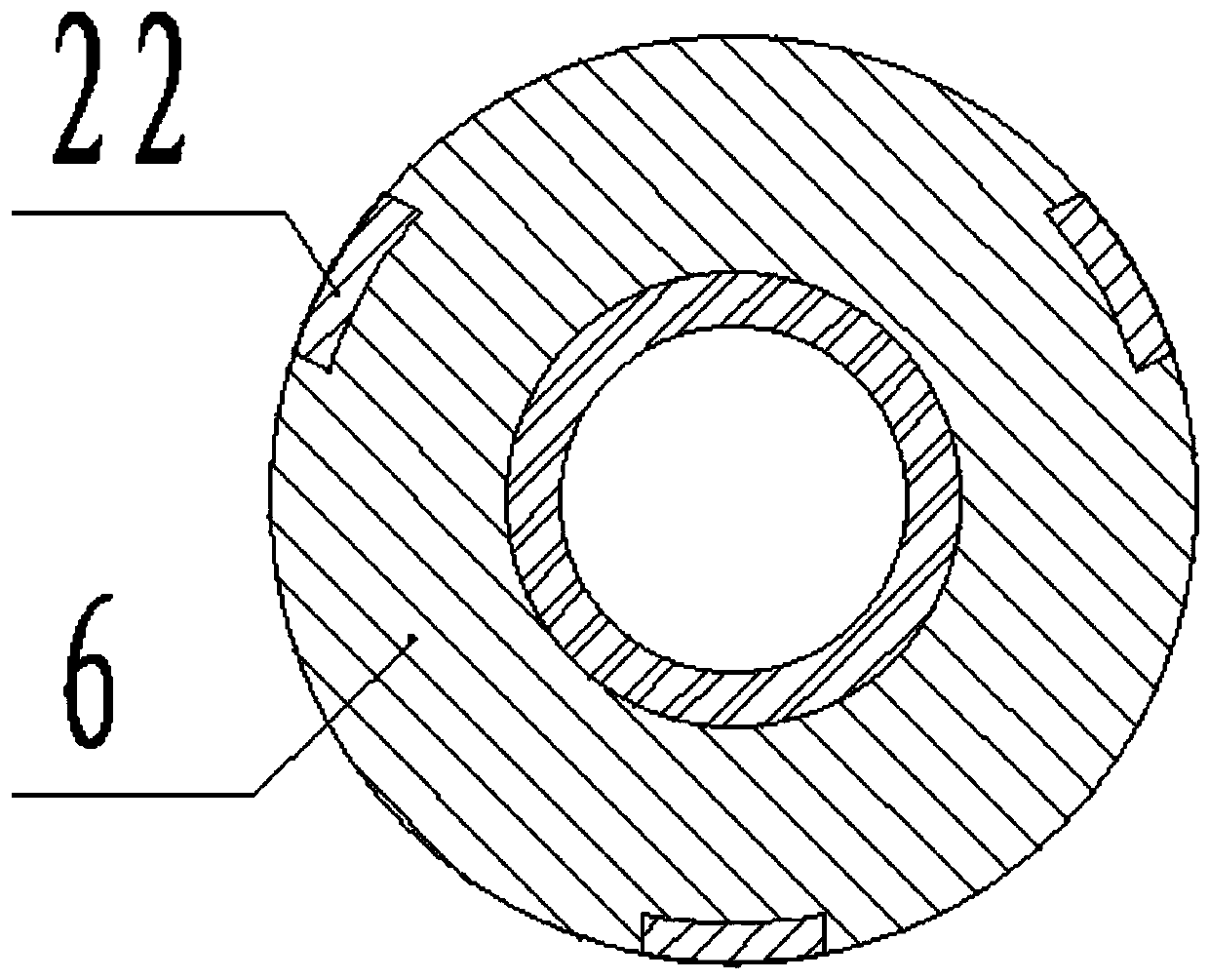

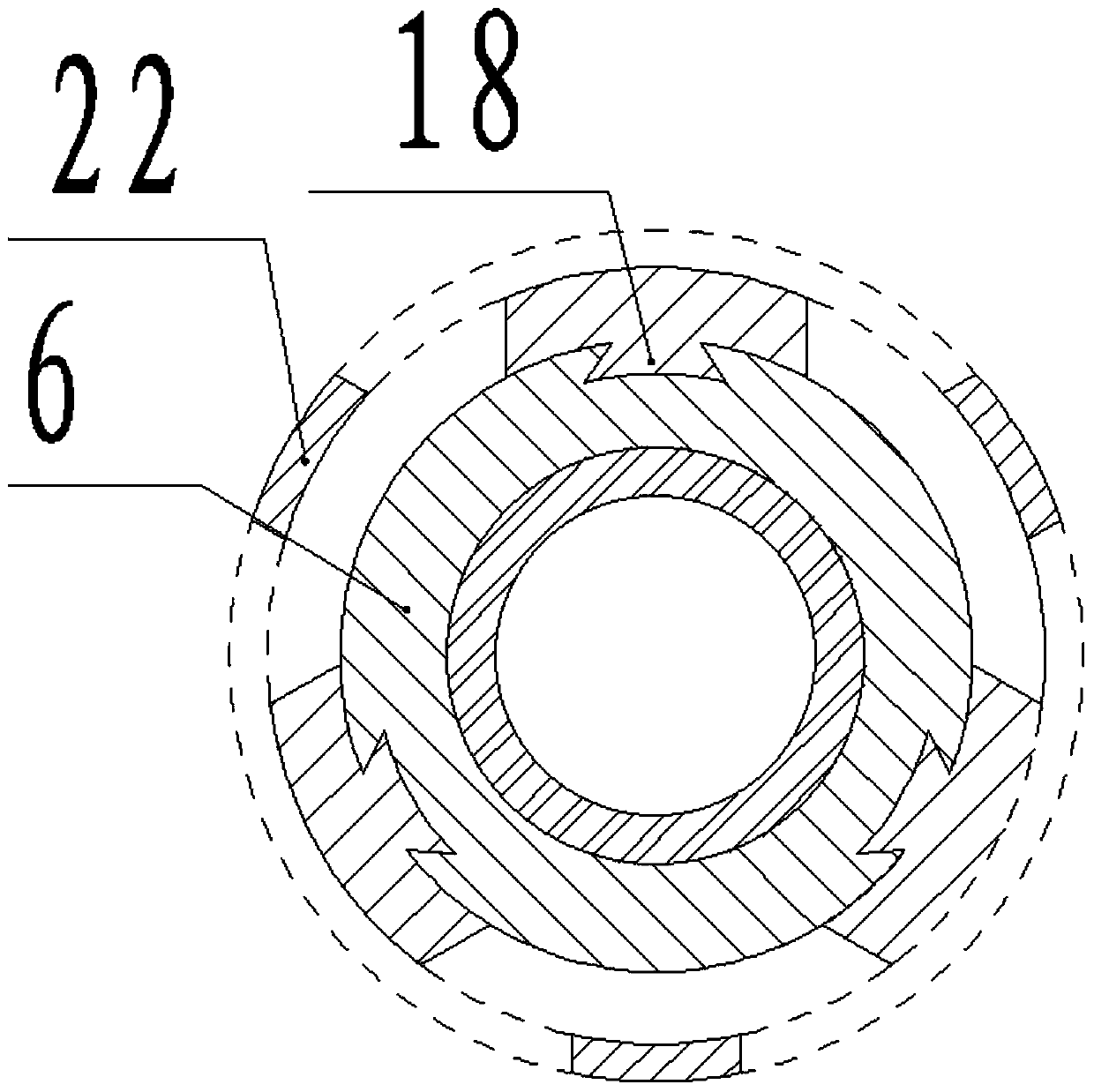

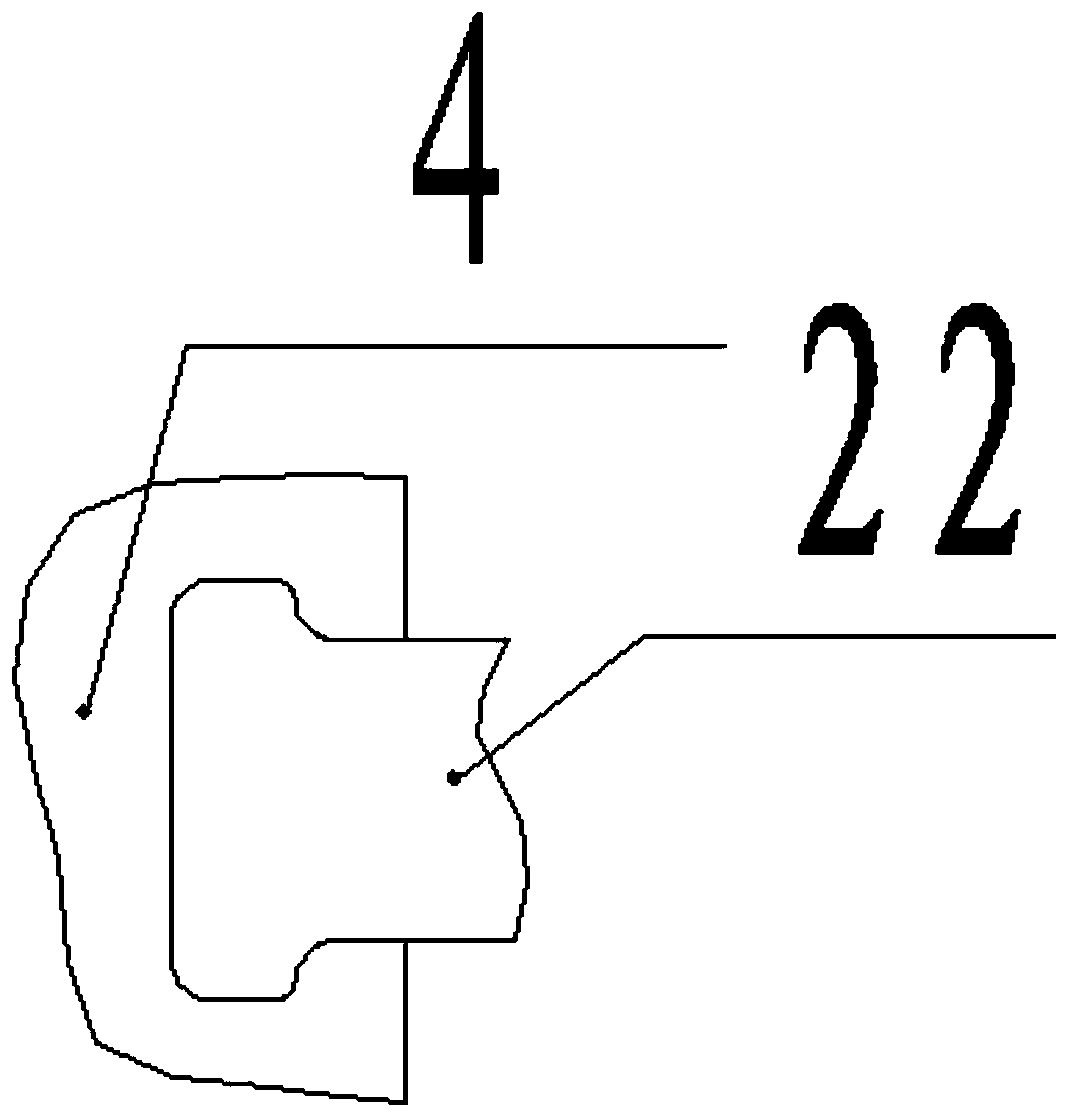

[0021] Such as figure 1 and Figure 5 As shown, the present embodiment includes an upper joint 1, a lower joint 14, a central pipe 3 and an anchoring mechanism. The upper joint 1 and the lower joint 14 are connected to the upper and lower ends of the central pipe 3 by threads respectively, and the anchoring mechanism is installed in the center On the outside of the tube 3, the anchoring mechanism includes a slip setting piston sleeve 4, a slip setting piston 5, a cone 6 and a slip 7. When setting, the slips in the piston sleeve 4 are set by pressing The setting piston 5 slides along the central tube 3, and the slip setting piston 5 pushes the cone 6 to slide along the central tube 3, and then the cone 6 is wedged inside the slip 7, and the slip 7 is pushed radially by the cone 6. Move, finally anchored on the inner wall of the casing, the slips 7 are installed on the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com