Device and method for recovering gases during coking of carbon-containing feedstock, and use

A gas, feedstock technology, applied in the field of devices and uses for recovering gas during coking of carbonaceous feedstocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

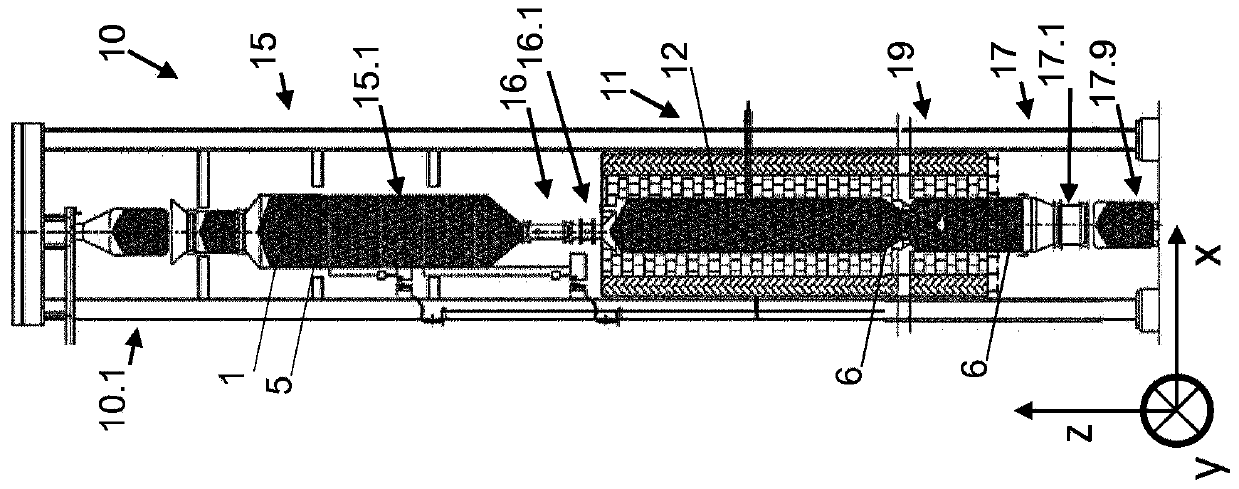

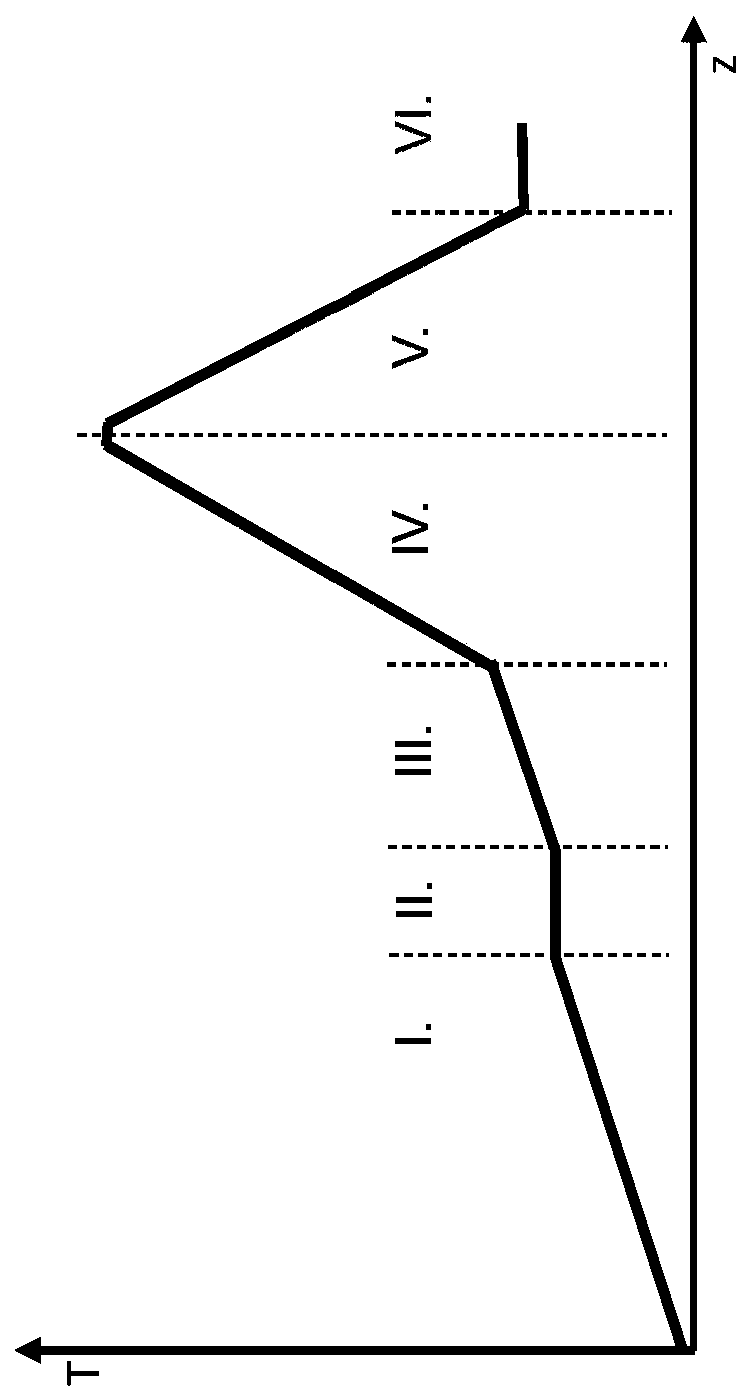

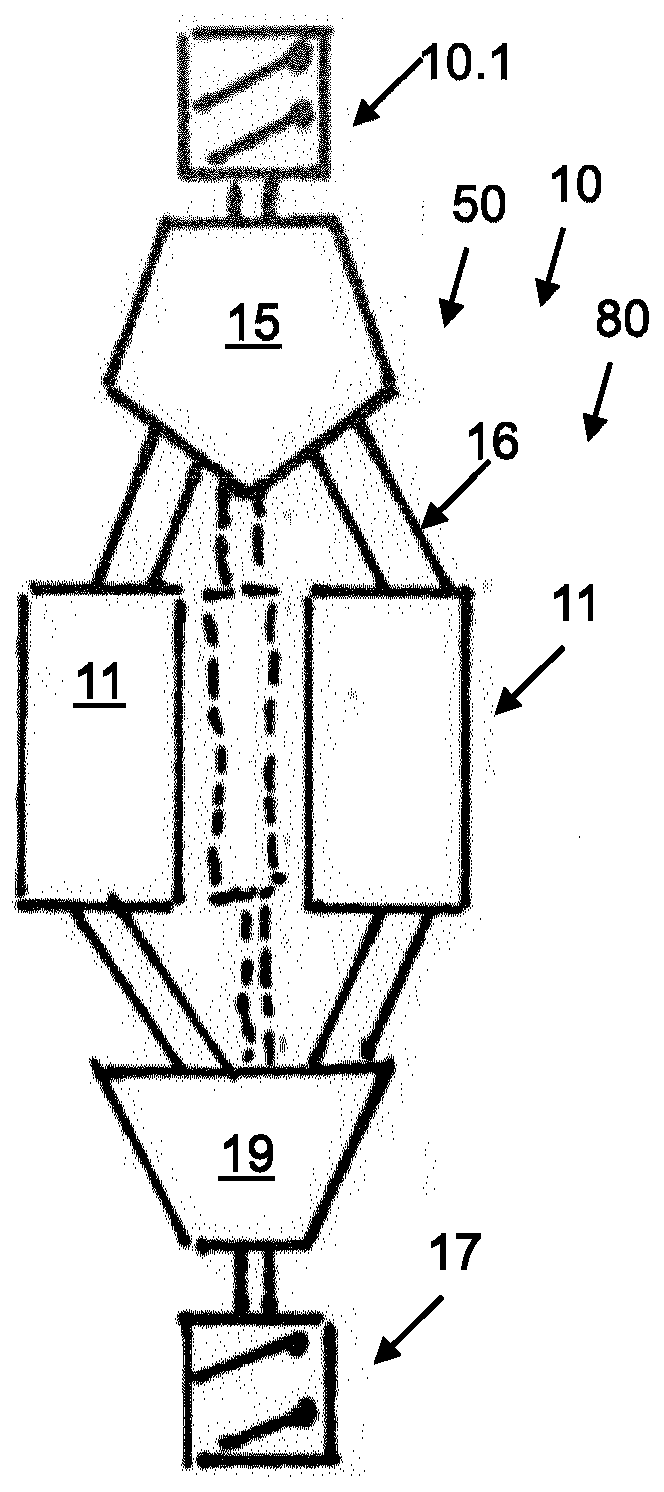

[0250] Figure 1A A furnace installation 10 is shown, in particular a coking furnace with a plurality of vertical chambers 11 . The raw material 1 in the form of briquettes 5 is supplied via a supply unit 10.1 to and preheated in a briquette dryer 15 arranged above the furnace chamber 11 and preheated therein. The pre-dried raw material 5 can then be charred by indirect heating via the heated walls 12 of the furnace chamber 11, in particular according to a precisely predeterminable temperature profile, as explained in more detail below (in particular Figure 4A , Figure 4B ). Coking can be followed by drying. To this end, an apparatus 19 for coke dry cooling is coupled at the bottom to the corresponding furnace chamber 11 . The supply and removal of raw materials 1, 5, 6 can be done elegantly by means of an input system 16 and an output system 17, each comprising one or more locks 16.1, 17.1, in particular driven by gravity. In the interception facility 17.9, the charred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com