Patents

Literature

52results about How to "Mild handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare-earth oxide modified high-selectivity catalyst for adiponitrile hydrogenation and hexylenediamine production, preparation method and application thereof

InactiveCN109647419AHigh mechanical strengthReduce pollutionOrganic compound preparationAmino compound preparationRare earthSolvent

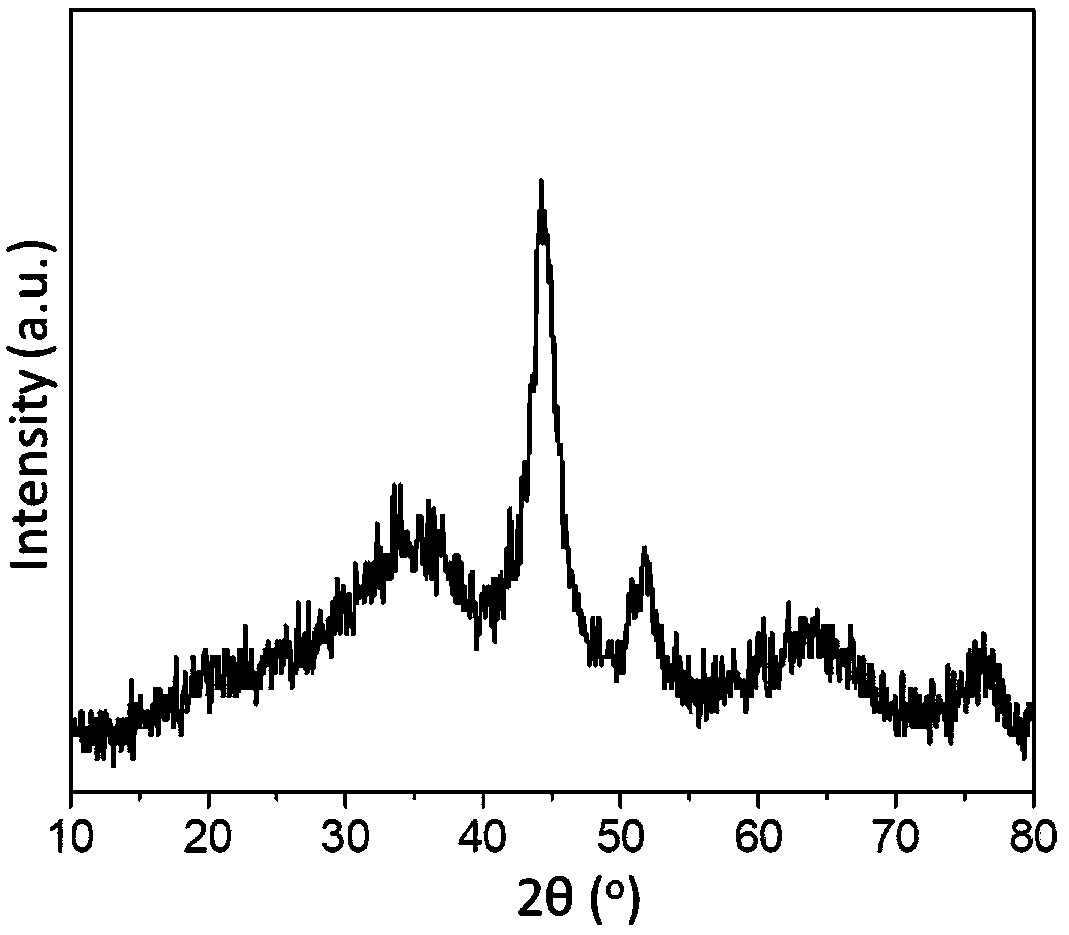

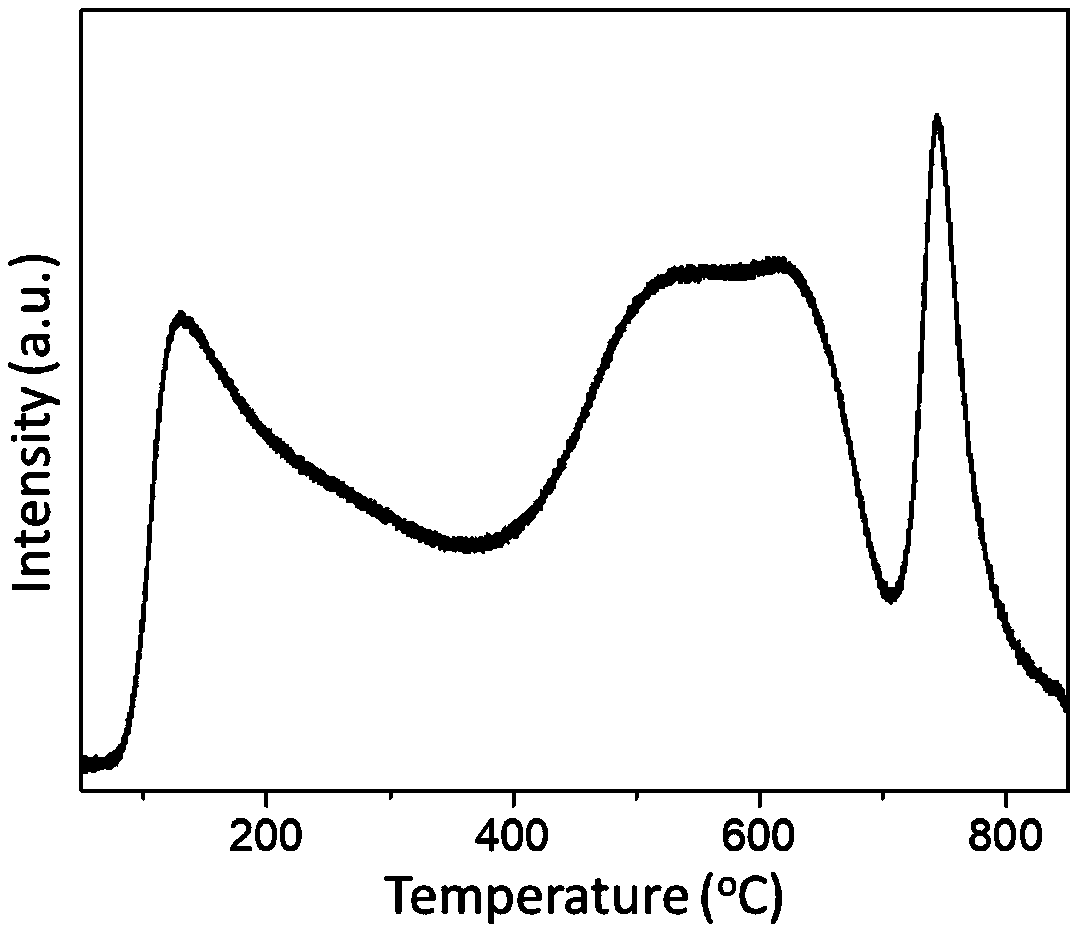

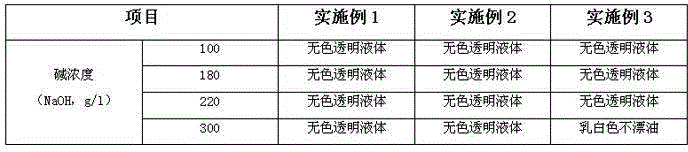

The invention discloses a rare-earth oxide modified high-selectivity catalyst for adiponitrile hydrogenation and hexylenediamine production, a preparation method and application thereof. An alumina-supported nickel-based catalyst is used as an active component, and at 25-90 DEG C and through a parallel flow precipitation process, a low-content rare-earth oxide is used for the modification. A tankreactor is adopted at the low temperature and without an alkaline reagent to carry out a reaction at the pressure of 1-9 MPa for 1-6 h so as to achieve adiponitrile catalytic conversion for high-selectivity preparation of hexylenediamine. No alkaline reagent or NH3 is added during the reaction process to inhibit side reaction of cyclization. The environmental pollution is reduced; and the catalysthas high mechanical strength, the reaction post-treatment is simple and the reaction condition is relatively mild. According to the method and in part of the embodiments, the conversion rate of adiponitrile reaches up to 100% according to set reaction parameters, and selectivity of the product hexylenediamine can reach up to 90%. The invention has good economic benefit and industrial applicationprospects.

Owner:DALIAN UNIV OF TECH

Dyeing process of nylon fiber

InactiveCN104711874AMild handling environmentReduce damageBiochemical fibre treatmentFibre typesColour fastnessPolymer chemistry

The invention provides a dyeing process of nylon fiber. The dyeing process comprises the following steps: pretreatment, presetting, dyeing soaping, color fixing, after finishing, drying, setting, calendering and winding. The dyeing process provided by the invention has the advantages that in the dyeing procedure, disperse dyes and acidic dyes are used for carrying out dyeing according to the own property of the nylon fiber, so that the dyeing effect is improved; the soaping and color-fixing processes are added, so that the dyeing firmness is good; in the color fixing process, environment-friendly formaldehyde-free TCD-R is adopted, and the fiber is dried in a step-by-step manner after color fixation, so that the firmness of the fiber is greatly improved; the after-finishing process is added, so that the color firmness and softness of the fabrics are improved and increased, the roughness of the fabrics is reduced, and further the fabrics are fluffy and elastic.

Owner:袁英英

Process of dyeing silk fabric

InactiveCN104727165AMild handling environmentReduce damageBiochemical fibre treatmentHeating/cooling textile fabricsColour fastnessPolymer chemistry

The invention provides a process for dyeing a silk fabric. The process comprises the steps of pre-treatment, pre-shaping, modifying treatment, dyeing, soaping, color fixing, post-arrangement, drying, shaping, calendering and rolling. According to the method, the fabric is modified in advance by chitosan to improve the dyeing rate, and the difficulty of the subsequent dyeing step is reduced; in the dyeing step, the chitosan is used as a mordant, and mangosteen hull serving as a natural dye is used and is free of poison and environmentally friendly; the dyeing firmness is good by additionally arranging the soaping and color fixing steps, environment-friendly formaldehyde-free TCD-R is adopted in the color fixing step, color-fixed fibers are stepwise dried, so that the fiber firmness degree is greatly improved; the post-arrangement process is additionally added, so that the color firmness and softness of the fabric is improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG CHENGLE CHEM FIBER

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Staining method for aramid fiber

ActiveCN104695239AReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesColour fastnessAramid

The invention provides a staining method for aramid fiber. The staining method comprises the steps of preprocessing, preshaping, staining, reduction clearing, color fixing, soft processing, drying, shaping, calendaring and rolling. According to the staining method, DEET is added in to serve as a dye carrier, and the staining effect and efficiency are improved; meanwhile, substitute alkali is adopted to replace a conventional soda substance, and not only is the usage amount decreased, but also the color fixing effect is enhanced to enable the washability of the aramid fiber is further enhanced; the reduction clearing and color fixing processes are added, and therefore the staining fastness is good; green and environmental-friendly non-formaldehyde TCD-R is adopted in the color fixing process, the fiber is dried step by step after color fixing, and therefore the firmness of the fiber is greatly improved; the soft processing process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and therefore the fabric is fluffy and rich in elasticity.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Salt-free dyeing process for natural silk fabric

InactiveCN104746365AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsFiberInorganic salts

The invention provides a salt-free dyeing process for natural silk fabric. The salt-free dyeing process comprises the following steps: pre-treatment, pre-setting, modified treatment, dyeing, soaping, fixation, after-treatment, drying, setting, calendaring and rolling. The fabric is subjected to modified treatment with a cationic modifying agent, so that the dyeing rate of the fabric is increased; and the difficulty in the subsequent dyeing step is reduced. In the dyeing procedure, inorganic salts such as anhydrous sodium sulphate or table salt are not used, so that the pollution is reduced. Due to the addition of the soaping and fixation processes, the dyeing fastness is good. Green environment-friendly aldehyde-free TCD-R is adopted in the fixation process; and the fiber is gradually dried after fixation, so that the fastness of the fiber is greatly improved. Due to the addition of the after-treatment process, the color fastness and the softness of the fabric are improved; the roughness sense of the fabric is relieved; and the fabric is fluffy and elastic.

Owner:太仓市宝明化纤有限公司

Dyeing process of mulberry silk fabrics

InactiveCN104711873AMild handling environmentReduce damageBiochemical fibre treatmentDry-cleaning apparatus for textilesColour fastnessPolymer chemistry

The invention provides a dyeing process of mulberry silk fabrics. The dyeing process comprises the steps of: pretreatment, presetting, low-temperature freezing treatment, dyeing, soaping, color fixing, after finishing, drying, setting, calendering and winding. The dyeing process provided by the invention has the advantages that the step of low-temperature freezing treatment is added, so that the modifying treatment is carried out on the properties of the mulberry silk fabrics fundamentally; a salt-free dyeing additive is added in the dyeing procedure, so that the use of inorganic salts is reduced on the premise of guaranteeing the dyeing effect; the soaping and color-fixing processes are added, so that the dyeing firmness is good; in the color fixing process, environment-friendly formaldehyde-free TCD-R is adopted, and the fiber is dried in a step-by-step manner after color fixation, so that the firmness of the fiber is greatly improved; the after-finishing process is added, so that the color firmness and softness of the fabrics are improved and increased, the roughness of the fabrics is reduced, and further the fabrics are fluffy and elastic.

Owner:太仓市宝明化纤有限公司

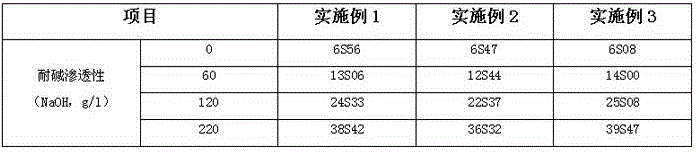

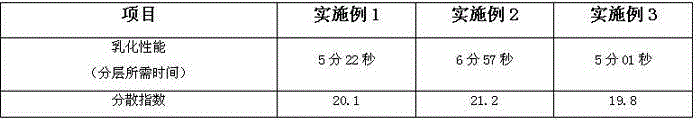

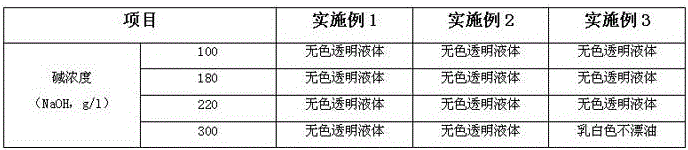

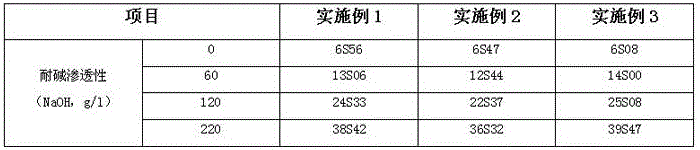

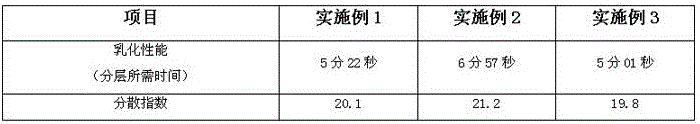

High-alkali-resistance type textile scouring agent and preparation method thereof

InactiveCN104532556AExcellent decontaminationGood hair effectFibre treatmentPolymer scienceActive agent

The invention provides a high-alkali-resistance mild-performance safe and environment-friendly textile scouring agent. The textile scouring agent is prepared from the following components in percentage by weight: 20 to 25% of alcohol alkoxylate, 15 to 25% of alkyl glycoside, 10 to 15% of ethoxy alkyl sodium sulfate, 5% of ethylene glycol monobutyl ether, 2 to 4% of organic solvents, 0.2 to 0.8% of edetic acid, 0.5 to 1.0% of defoaming agents, and 20 to 45% of water. According to the textile scouring agent, the alcohol alkoxylate with high penetration, the alkyl glycoside with a mild performance, and the ethoxy alkyl sodium sulfate which serves as an anionic surfactant are used as active matter raw materials which almost do not irritate the skin and damage cotton, hemp, silk, leather and other high-level fabrics; the formula is basically free of harmful substance residue, high in penetration, high in cleaning capacity, and outstanding in detergency capacity, and the hand feel of a processed fabric is good.

Owner:YANSHI RANHE BIOMATERIAL

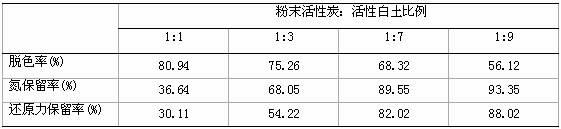

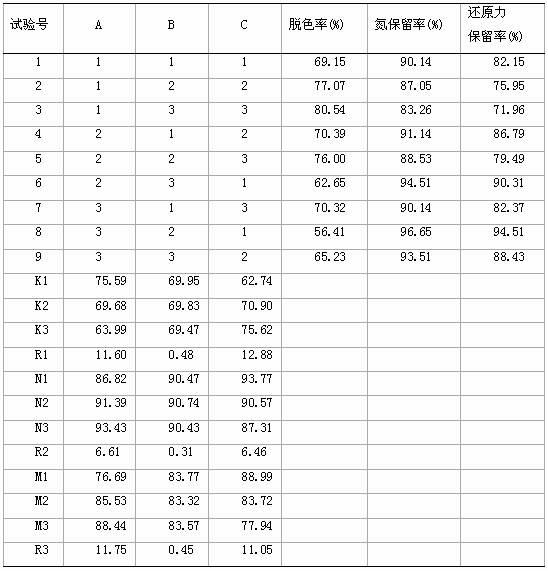

Method for decolorizing silkworm chrysalis protein enzymatic hydrolysis peptide

InactiveCN102690322ASimple processEasy to operatePeptide preparation methodsBiotechnologyActivated carbon

The invention relates to a method for decolorizing silkworm chrysalis protein enzymatic hydrolysis peptide. The method comprises the following steps of: adjusting pH of a 1 percent silkworm chrysalis protein enzymatic hydrolysis peptide solution to be 8, adding 30g of powdery activated carbon and activated clay composite decolorizer in a ratio of 1:7 into each liter of the solution, placing in an oscillatory type water bath kettle at the temperature of 30 DEG C, adjusting the rotation speed to be 200r / min, decolorizing for 30 minutes, and centrifuging by using a disk centrifuge at the speed of 5,000 to 6,000r / min for 30 minutes, wherein the decolorization rate is 70.39 percent, the nitrogen retention rate is 91.14 percent, and the reducing power retention rate is 86.79 percent. The process is simple and easy to operate, the treatment process is mild, and the method can be widely applied to health food industry in which silkworm chrysalis polypeptide and other bioactive peptides are produced.

Owner:SHANGHAI UNIV

Direct dyeing process for chemical fiber

InactiveCN104762828AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsColour fastness

The invention provides a direct dyeing process for a chemical fiber. The direct dyeing process for the chemical fiber comprises the steps of pretreatment, pre-shaping, modification treatment, dyeing, soaping, color fixing, after-treatment, drying, sizing, calendaring and rolling. According to the direct dyeing process for the chemical fiber, the modification treatment is added, so that performances of a chemical fabric are subjected to the modification treatment basically, the dyeing degree of the fabric is increased, and the difficulty of a subsequent dyeing step is reduced; during dyeing, the mass utilization of inorganic salt is avoided; furthermore, substitute alkali is used for replacing a conventional sodium carbonate substance, so that the consumption is reduced, a color fixation effect is also improved, and the washing fastness of the chemical fiber is further improved; soaping and color fixing processes are added, so that the dyeing fastness is good; environment-protection formaldehyde-free TCD-R is utilized in the color fixing process, and color-fixed fibers are gradually dried, so that the firmness of the fibers is greatly improved; the post-treatment process is added, so that the color fastness and the flexibility of the fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and has high resilience.

Owner:TAICANG CHENGLE CHEM FIBER

Chemical fiber dyeing technology with ultraviolet protection function

InactiveCN104695240AReduce pollutionAvoid damageFibre treatmentHeating/cooling textile fabricsFiberAnti bacteria

The invention provides a chemical fiber dyeing technology with the ultraviolet protection function. The chemical fiber dyeing technology comprises pretreatment, pre-shaping, dyeing, washing, soaping, color fixing, softening treatment, drying, shaping and rolling. The natural dyestuff of sophora flower bud is adopted, aluminum potassium sulfate dodecahydrate is used as a mordant, the dyeing effect is better, and the washability is greatly enhanced; meanwhile, due to the performance of the sophora flower bud, dyed chemical fiber has the good ultraviolet protection performance and the antibacterial and oxidation resistance; the washing technology and the color fixing technology are added, the dyeing firmness is good, green and environment-friendly and aldehyde-free TCD-R is adopted in the color fixing technology, and the chemical fiber obtained after color fixing is dried step by step, so that the firmness of the chemical fiber is greatly improved; the softening treatment technology is added, the fabric color firmness and flexibility are improved, the fabric roughness is lightened, and the fabric is fluffy and full of elasticity.

Owner:TAICANG TIANLONG CHEM FIBER

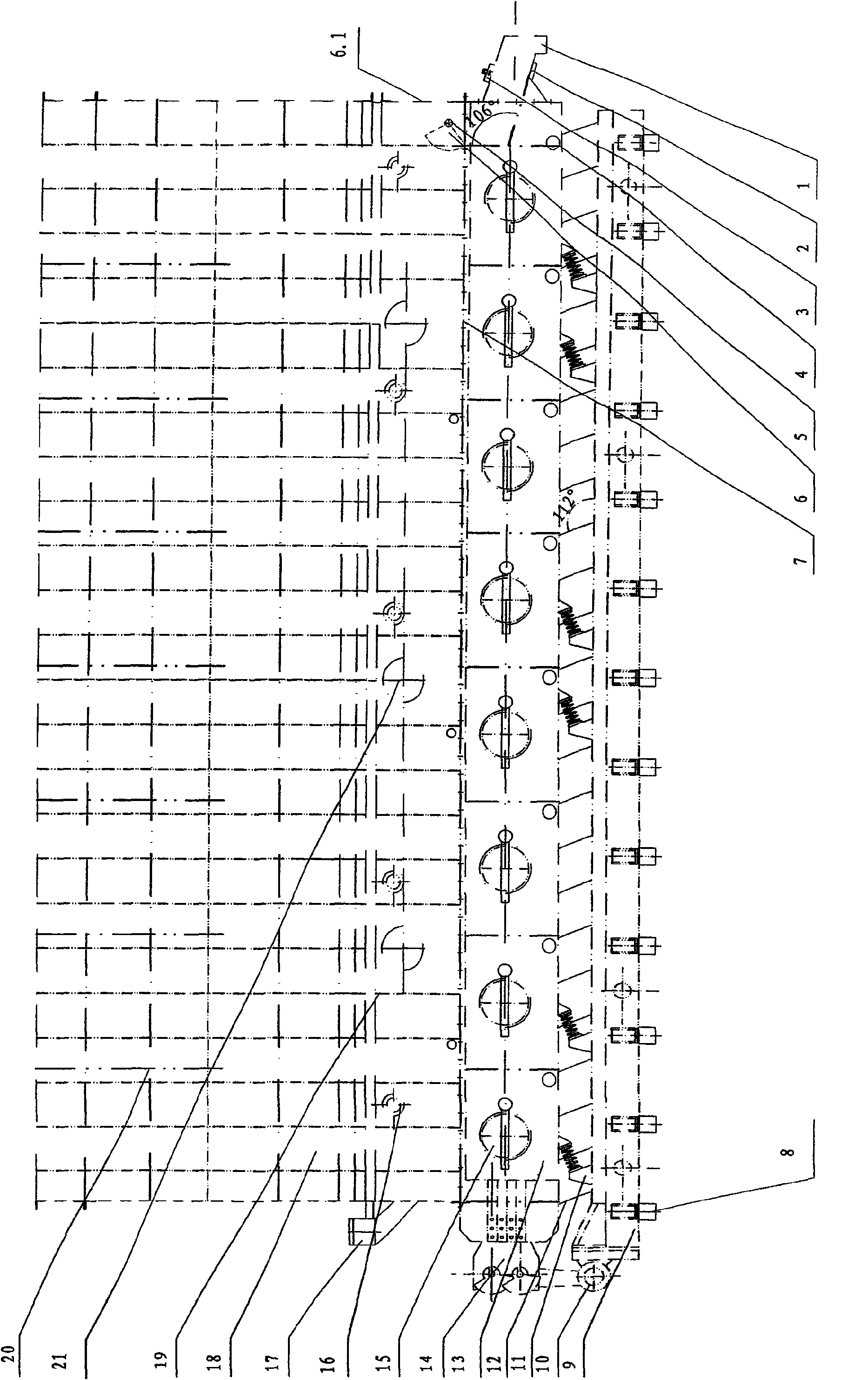

Three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer

InactiveCN101598484ASmooth vibrationConstant amplitudeDrying solid materials with heatHearth type furnacesVibratory fluidized bedEnvironmentally friendly

The invention relates to a three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer which is suitable for drying powder material of regular shape such as Laroflex MP with granularity ranging from 50mu m to 5000mu m. The drier comprises a foundation (9), a lower housing (13), a fluidized bed body (6), an upper housing (18) and a bag type dust collector (24); wherein the lower housing (13) is supported on the foundation (9) by a slantly arranged plate spring (12), a case type vibration exciter (14) is arranged at the front end of the lower housing (13), the fluidized bed body (6) is arranged above the lower housing (13) and internally provided with a hood-shaped fluidized bed plate (7), the upper housing (18) is arranged above the fluidized bed body (6) and internally provided with a plurality of groups of bag type dust collectors (24). An air-reserve tank (24.6) is arranged outside the upper housing (18), a plurality of air branch pipes (24.3) are internally arranged in the air-reserve tank (24.6), wherein each air branch pipe (24.3) is provided with a pulse solenoid valve (24.5), the bottom part thereof is provided with an air source hole (24.7). The drier of the invention features low energy consumption, high production efficiency, good operation stability and good uniformity of products.

Owner:江阴丰力生化工程装备有限公司

Method for extracting Tie Guanyin tea seed oil via supercritical carbon dioxide fluid technology

InactiveCN101906352AHas a delicate smellNo residueFatty-oils/fats productionResidual oilSupercritical carbon dioxide

The invention discloses a method for extracting Tie Guanyin tea seed oil via a supercritical carbon dioxide fluid technology, comprising the following steps of: 1) pre-processing the Tie Guanyin tea seeds; 2) adjusting and controlling the parameters of the supercritical carbon dioxide fluid; and 3) extracting the tea seed oil in the Tie Guanyin tea seeds by using the supercritical carbon dioxide fluid. The invention not only overcomes the defect that the traditional extraction technology has the defects of high residual oil, residual solvent and complicated post-processing and refining process, and the like, but also improves the use value and economic value of the tea seed resource and promotes the development of tea industry.

Owner:HUAQIAO UNIVERSITY

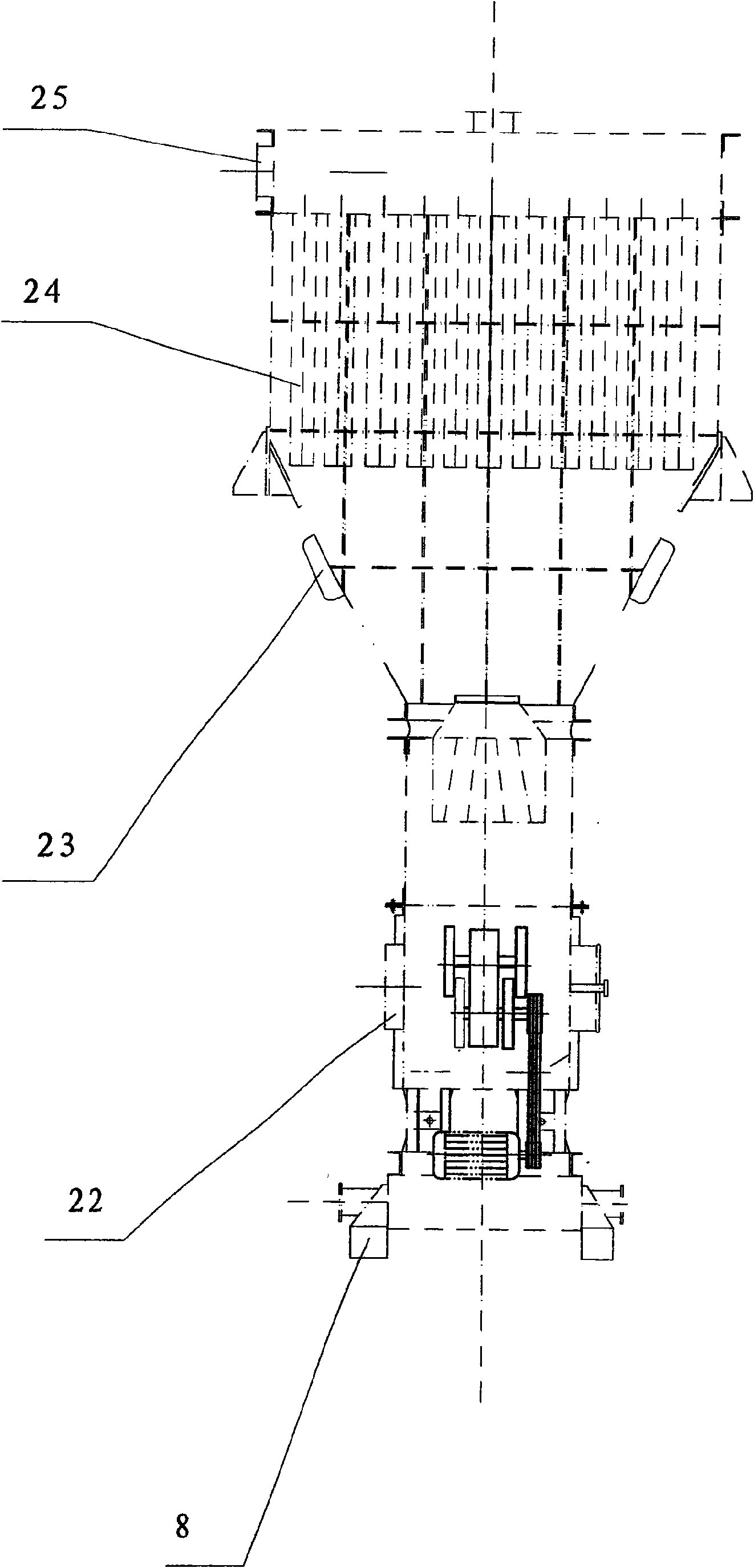

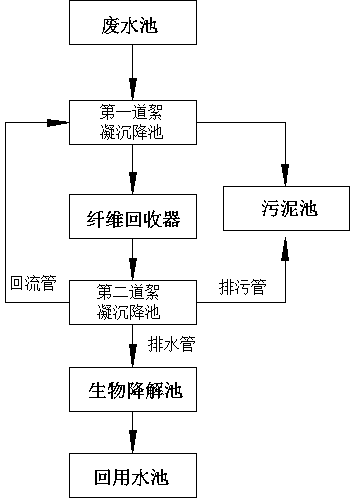

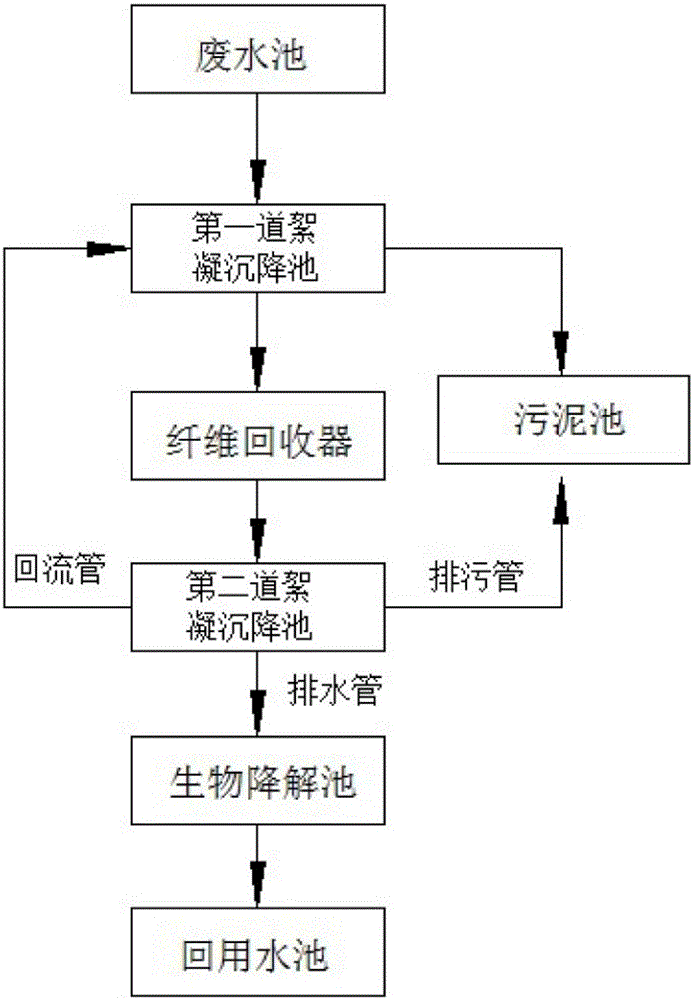

Low-consumption papermaking wastewater treatment system

ActiveCN104355486AReduce energy consumptionLower requirementWater treatment parameter controlSpecific water treatment objectivesFiberWater treatment system

The invention discloses a low-consumption papermaking wastewater treatment system which comprises a wastewater pool, a first flocculating settling pool, a fiber recoverer, a second flocculating settling pool, a biological degrading pool and a reused water pool, wherein the wastewater pool is connected to the water inlet end of the first flocculating settling pool; the water discharging end of the first flocculating settling pool is connected to the water inlet end of the fiber recoverer through a pipeline; the water discharging end of the fiber recoverer is connected to the water inlet end of the second flocculating settling pool; the water discharging end of the second flocculating settling pool is connected to the water inlet end of the biological degrading pool; the water discharging end of the biological degrading pool is connected to the reused water pool; a sludge pool is arranged at the bottom of the first flocculating settling pool; the second flocculating settling pool comprises an upper layer, a middle layer and a bottom layer; a water drain pipe connected to a biological settling pool, a backflow pipe connected to the first flocculating settling pool and a sewage drain pipe connected to the sludge pool are respectively arranged at the upper layer, the middle layer and the bottom layer of the second flocculating settling pool. The low-consumption papermaking wastewater treatment system is thorough in wastewater treatment effect and low in energy consumption, and is favorable for popularization and application.

Owner:山西云冈纸业有限公司

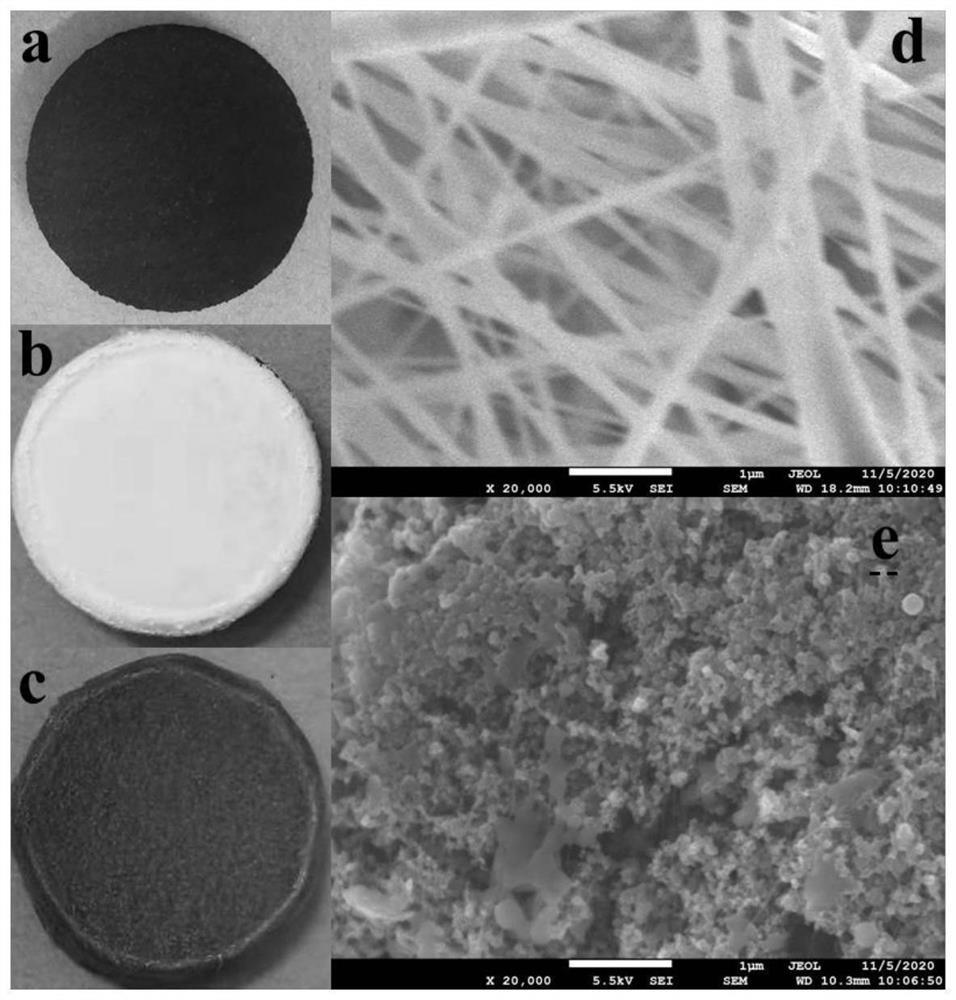

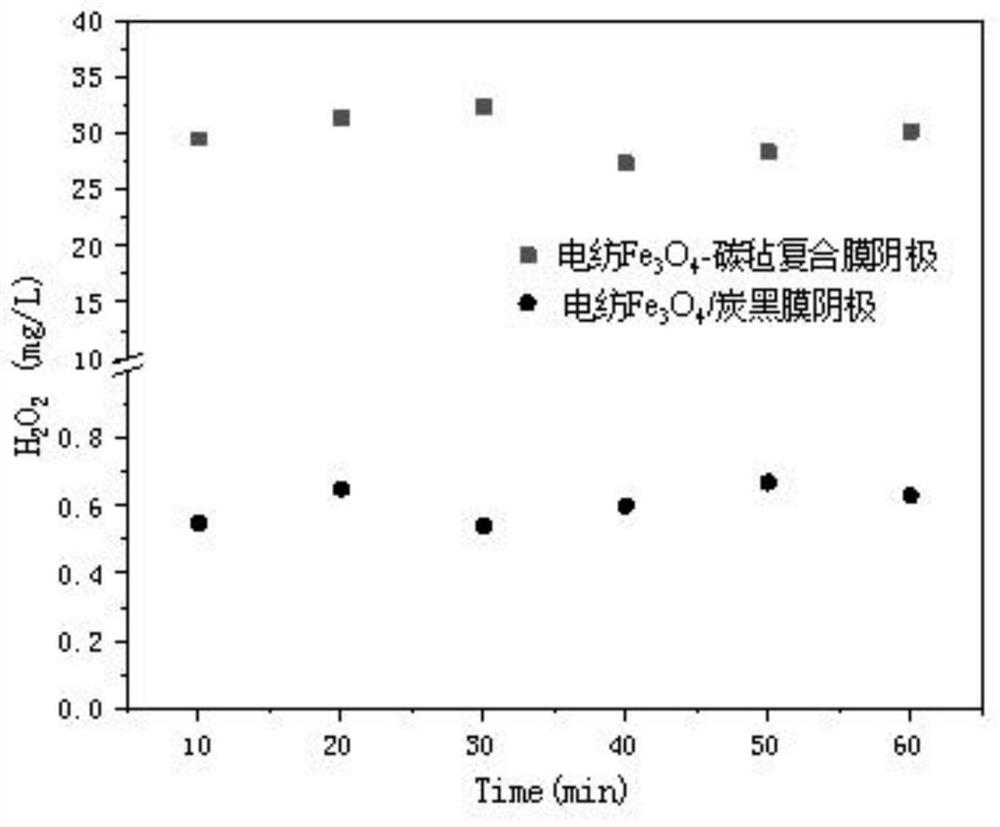

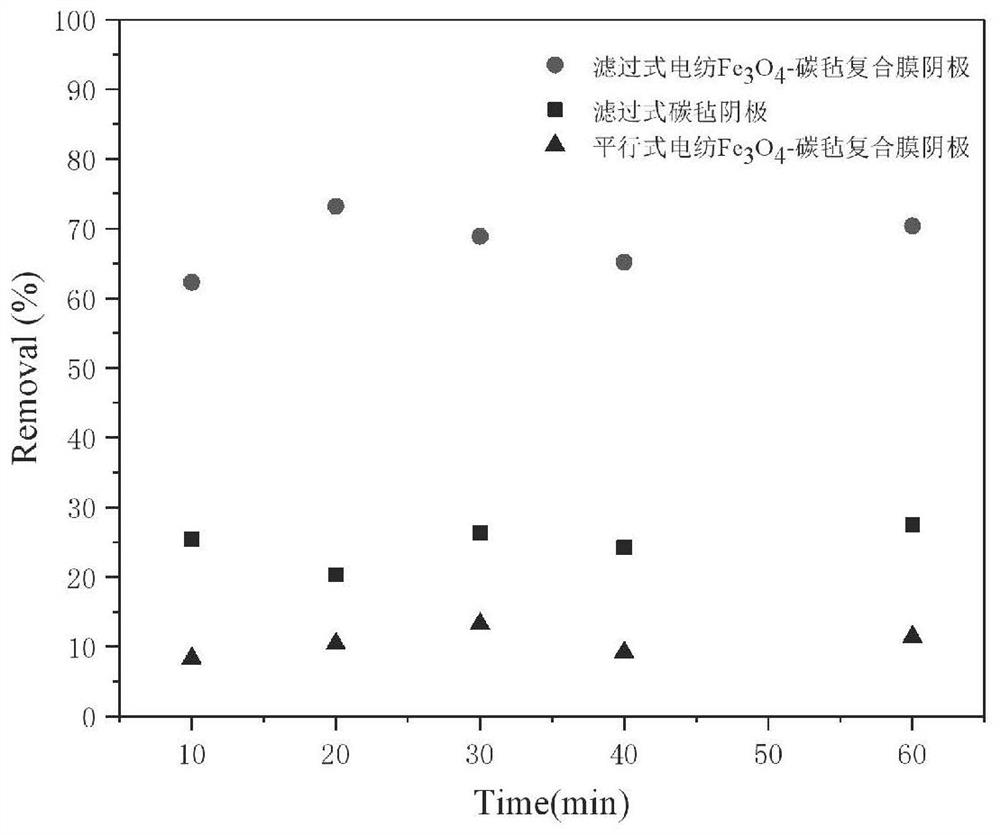

Preparation method and application method of electro-Fenton composite membrane cathode

ActiveCN112803030AAvoid reunionImprove dispersion performanceCell electrodesWater/sewage treatment by electrochemical methodsChemistryCatalytic membrane

The invention relates to a preparation method and an application method of an electro-Fenton composite membrane cathode, and the method comprises the following steps: uniformly dispersing nano-particles of a heterogeneous iron-containing catalyst in an electrostatic spinning solution, and collecting electrostatic fibers on a conductive carbon material carrier capable of producing hydrogen peroxide by adopting an electrostatic spinning technology, enabling the nano-particles to form an electrospinning catalytic membrane along with the electrostatic fiber generation process and loading the nano-particles on the carrier. According to the preparation method, the yield of hydrogen peroxide can be remarkably improved, especially in the electrostatic fiber generation process, a carbon felt which is modified by graphene and carbon black and has good conductivity is adopted as a fiber receiving device, hydrogen peroxide is efficiently generated in situ on the interface of the modified carbon felt, and .OH is generated in situ on the nano-particle catalysis interface. The yield of hydrogen peroxide is greatly improved, and the micro-pollutants enriched on the surface of the membrane cathode are efficiently catalyzed, so that the efficient removal of the micro-pollutants is realized.

Owner:HEBEI UNIV OF TECH

Seedling method for cyclocarya paliurus seeds

ActiveCN105165578ASuit one's needsSeedling needs are metGrowth substratesCulture mediaCyclocaryaSeed treatment

The present invention relates to a seedling method for cyclocarya paliurus seeds. The method is characterized in comprising the following steps: a. seed selecting; b. seed treating; c. seed germination accelerating; and d. seed seedling. According to the method provided by the present invention, the seedlings emerge in 30-60 days after sowing of the cyclocarya paliurus seeds, the emergence rate is over 90%, and the seedling survival rate is over 95%.

Owner:湖北思慧生物科技有限公司

Device and method for recovering gases during coking of carbon-containing feedstock, and use

ActiveCN110520506ALess stress/crackEffective desired effectVertical chamber coke ovensIndirect heating destructive distillationProcess engineeringBituminous coal

Owner:THYSSENKRUPP IND SOLUTIONS AG +1

A kind of dyeing process of nylon fiber

InactiveCN104711874BReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesDisperse dyeAcid dye

The invention provides a dyeing process of nylon fiber. The dyeing process comprises the following steps: pretreatment, presetting, dyeing soaping, color fixing, after finishing, drying, setting, calendering and winding. The dyeing process provided by the invention has the advantages that in the dyeing procedure, disperse dyes and acidic dyes are used for carrying out dyeing according to the own property of the nylon fiber, so that the dyeing effect is improved; the soaping and color-fixing processes are added, so that the dyeing firmness is good; in the color fixing process, environment-friendly formaldehyde-free TCD-R is adopted, and the fiber is dried in a step-by-step manner after color fixation, so that the firmness of the fiber is greatly improved; the after-finishing process is added, so that the color firmness and softness of the fabrics are improved and increased, the roughness of the fabrics is reduced, and further the fabrics are fluffy and elastic.

Owner:袁英英

Treatment method of non-ionic surfactant wastewater

InactiveCN107311386AHigh removal rateGood processing effectWater treatment parameter controlWater contaminantsActivated carbonTherapeutic effect

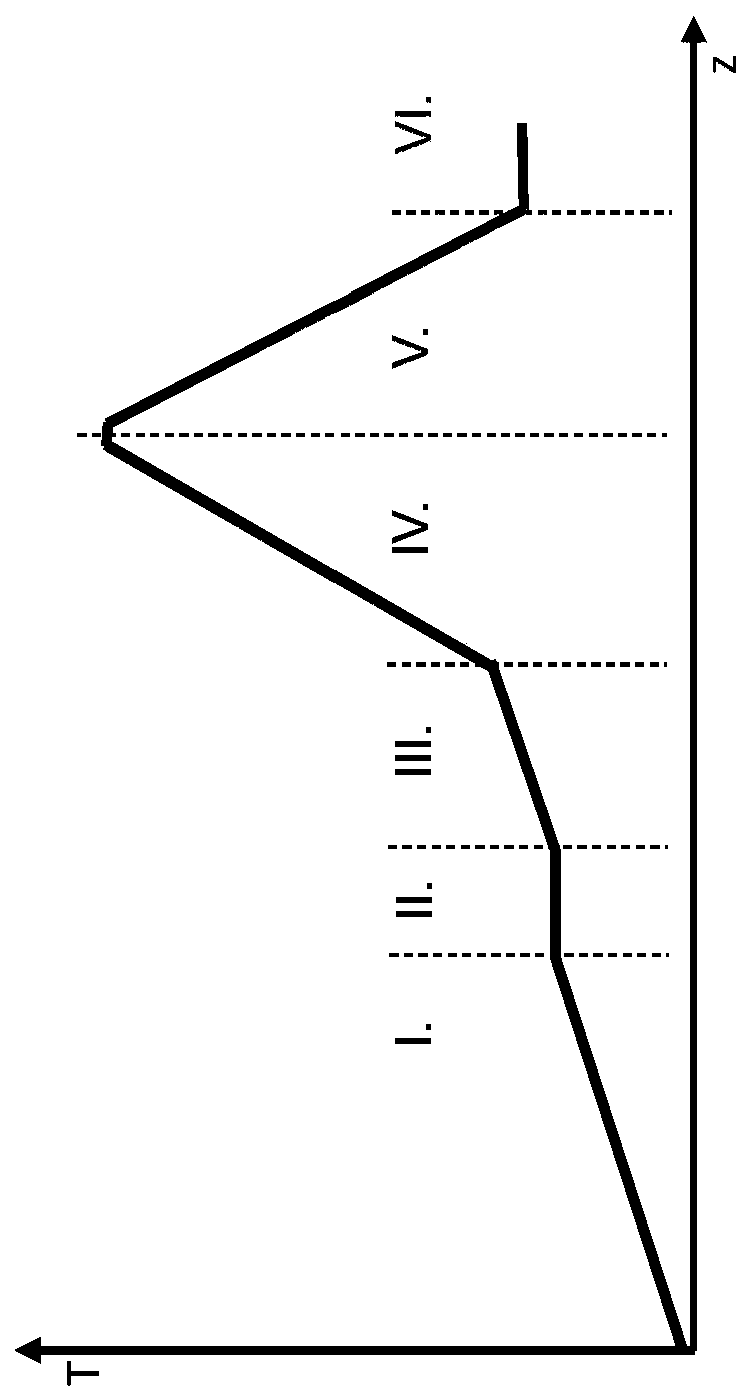

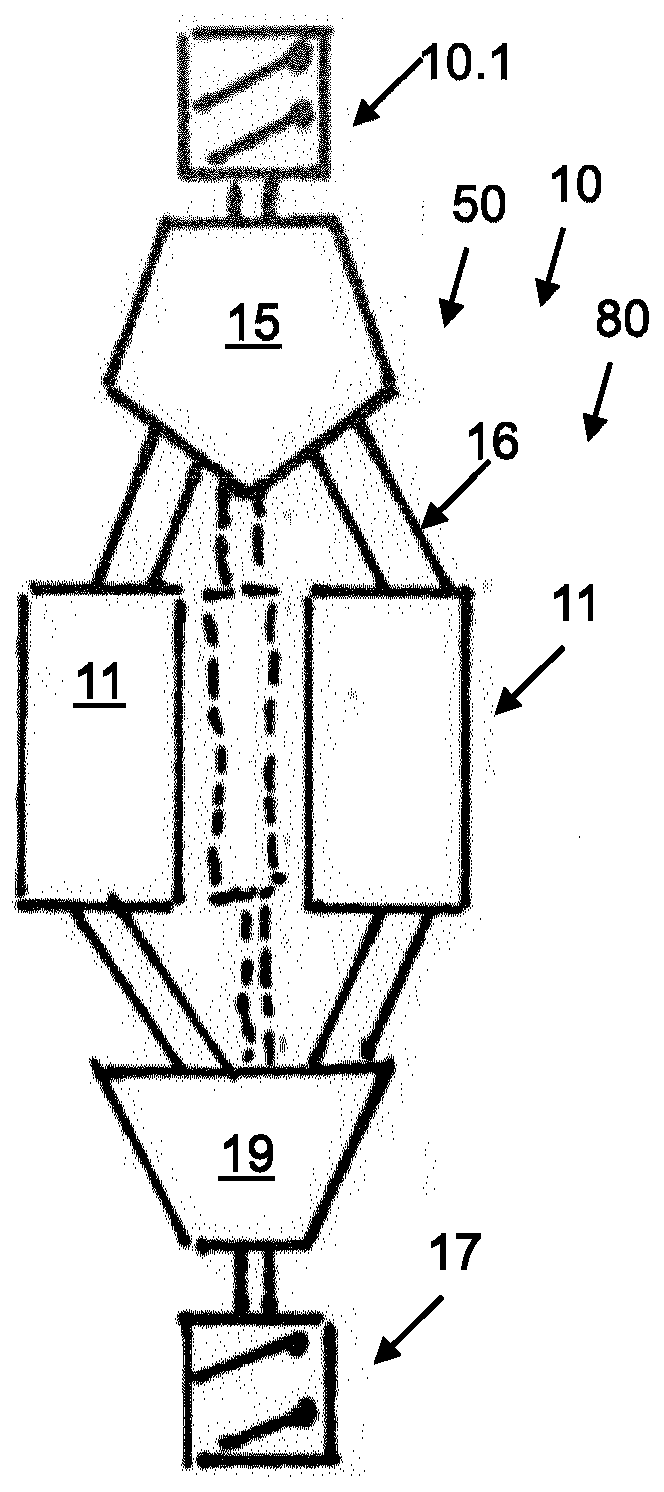

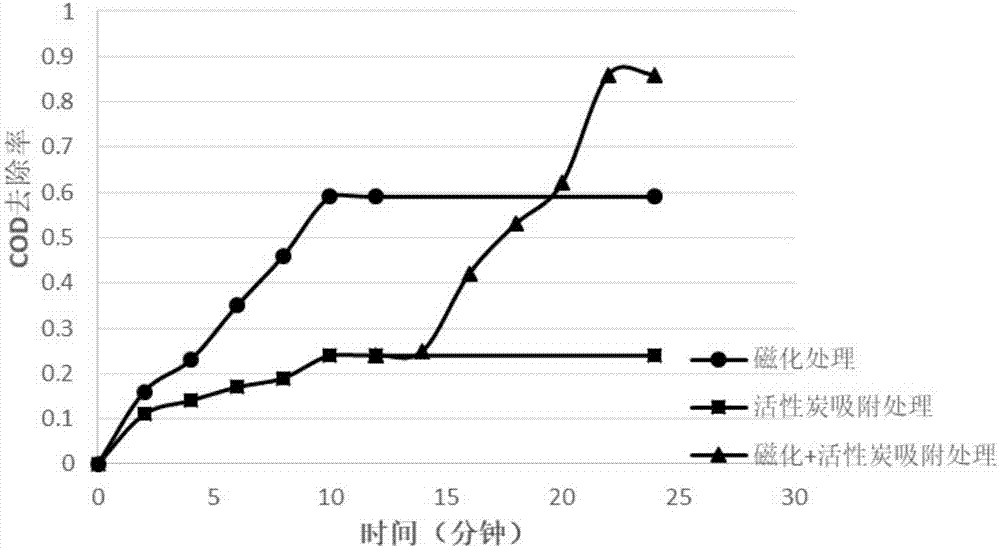

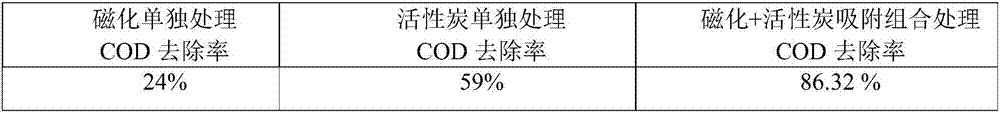

The invention discloses a treatment method of non-ionic surfactant wastewater and belongs to the technical field of wastewater treatment. The treatment method includes that a magnetizing treatment step is adopted to preliminarily treat wastewater, the wastewater is further treated through an activated carbon adsorption step, a magnetizing treatment device is adopted to magnetize the wastewater in the magnetizing treatment step and comprises a magnetizing container and a permanent magnet, and magnetic induction intensity in the magnetizing treatment device should not be lower than 100mT; a magnetic field in the process of magnetizing the wastewater enables pollutants in the wastewater to generate advanced oxidation effect, the wastewater is further treated through activated carbon adsorption, and magnetizing treatment and activated carbon adsorption have certain synergistic effect, so that the whole treatment process does not need to consume energy and reagents. The treatment method is environment-friendly, low in time consumption, simple in equipment, low in cost, excellent in treatment effect and conducive to popularization.

Owner:NANJING UNIV OF TECH

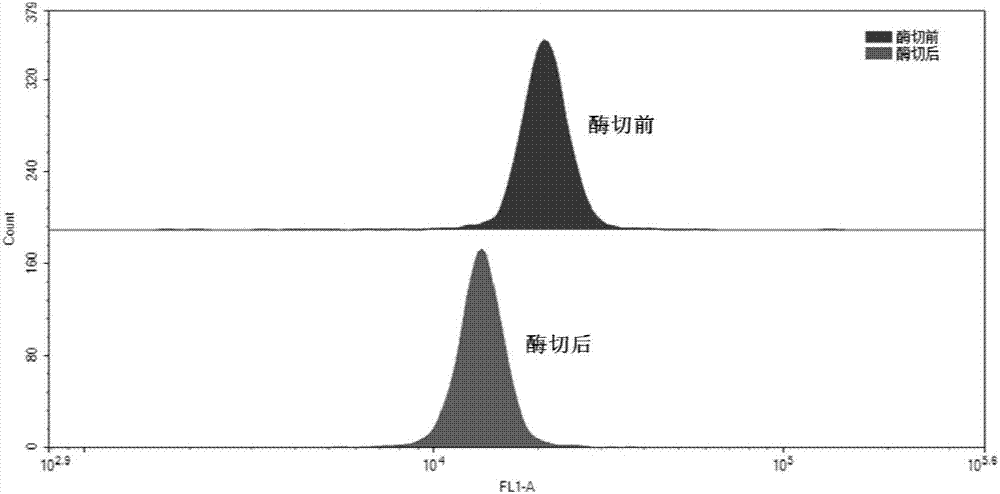

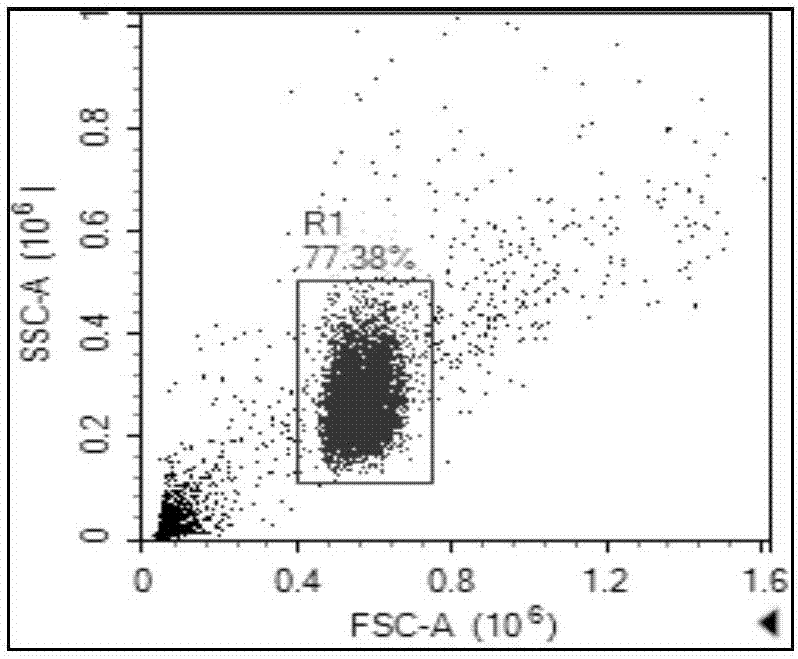

Quick sperm acrosin extraction method and sperm acrosin activity flow cytometry detection method

ActiveCN106896016AMaintain enzyme activityMeet needsPreparing sample for investigationIndividual particle analysisCouplingSemen

The invention discloses a quick sperm acrosin extraction method and a sperm acrosin activity flow cytometry detection method. The extraction method is characterized by including: adding seminal fluid into a centrifuge tube, centrifuging to remove seminal plasma, keeping lower sperm precipitates, adding membrane rupture liquid to enable uniform suspension of sperm precipitates, centrifuging to remove supernatant, adding extracting solution to make sperms suspended, and centrifuging to collect supernatant, so that acrosin extract is obtained. The sperm acrosin activity flow cytometry detection method is characterized in that by means of polypeptide or protein microsphere coupling and polypeptide or protein fluorescence labeling, an acrosin digested substrate is subjected to fluorescence labeling and then connected to the microspheres, fluorescent microspheres in certain particle diameters can be recognized by a flow cytometry instrument, and fluorescence intensity directly reflects activity level of acrosin in a sample. By combination of quick extraction and flow cytometry, detection efficiency is greatly improved, and detection sensitivity is improved.

Owner:ZHEJIANG CELLPRO BIOTECH

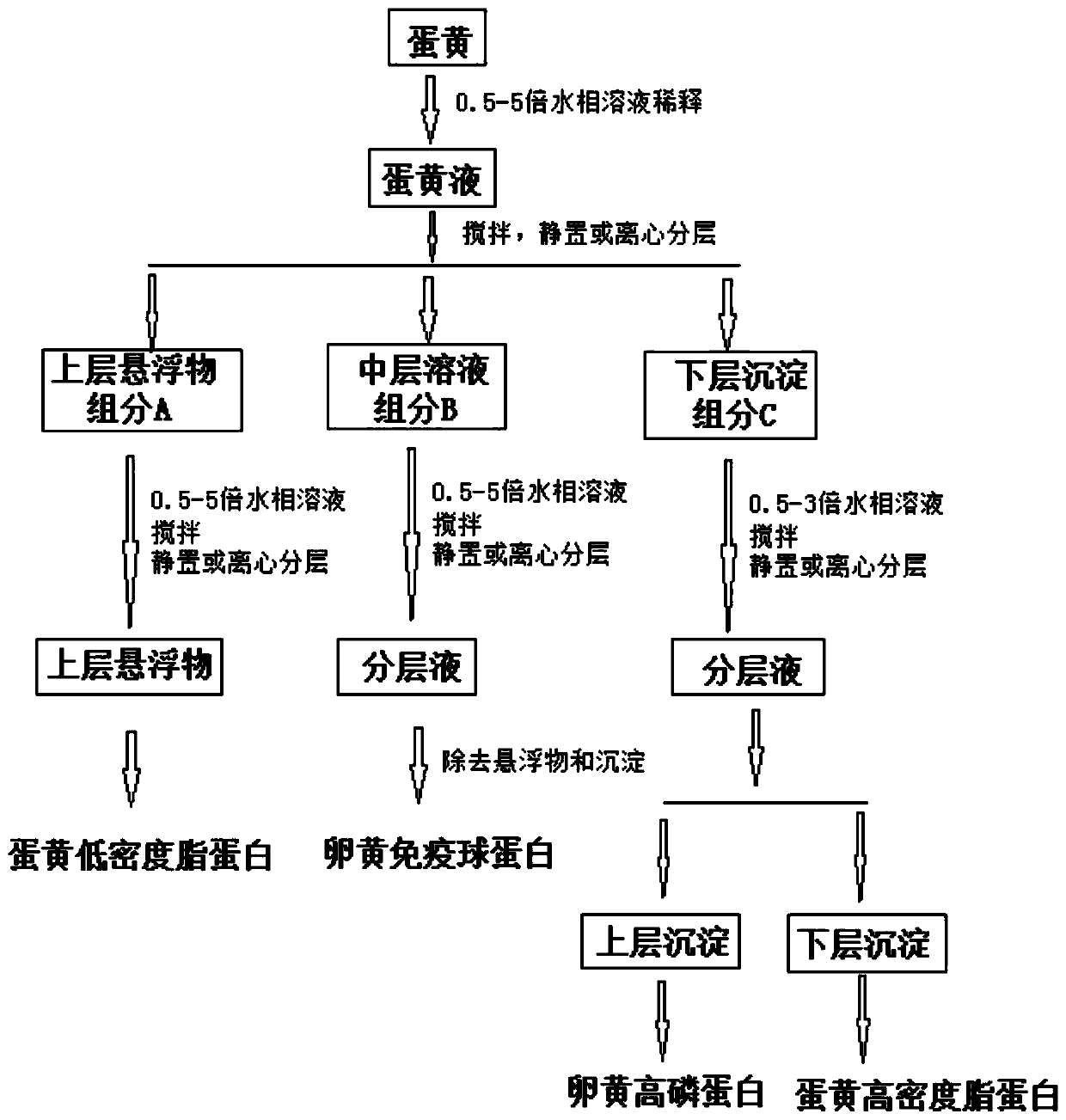

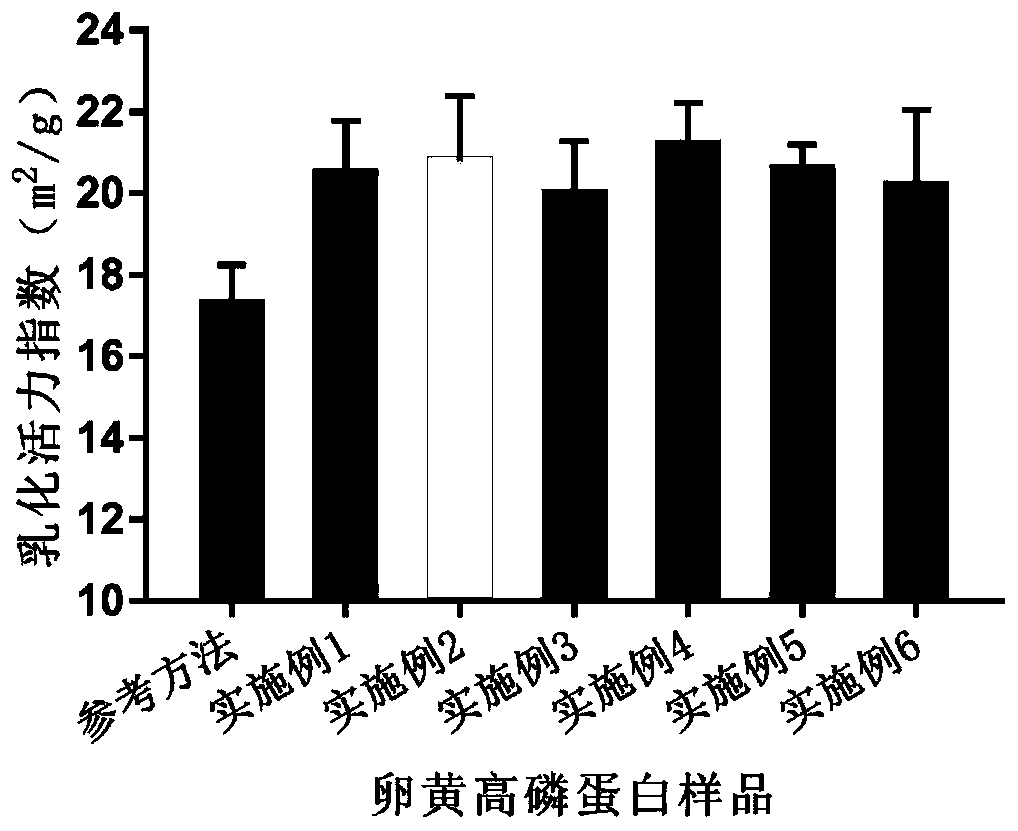

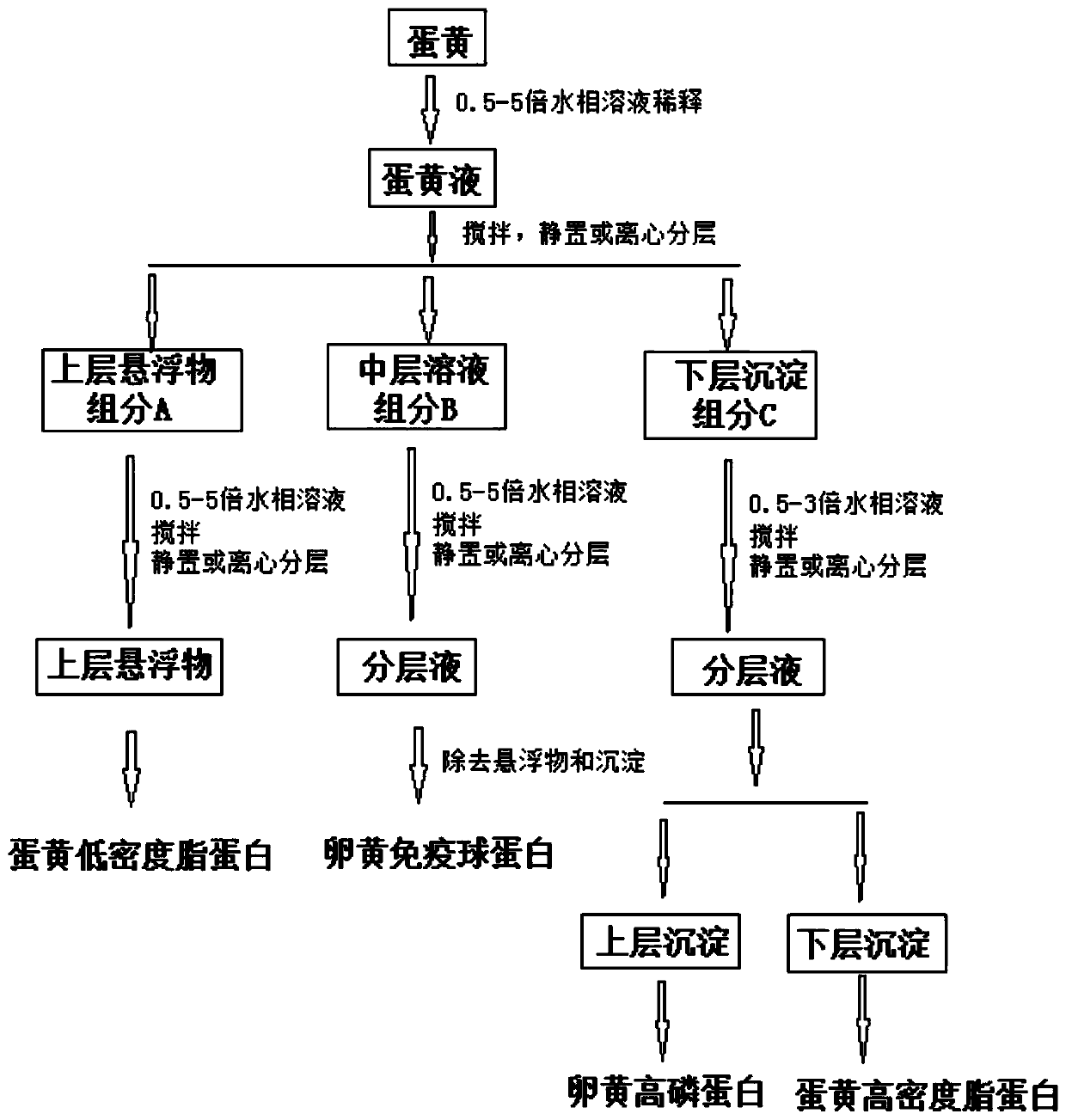

Method for jointly extracting multiple kinds of yolk protein based on water phase separation and product

ActiveCN110003319ATake advantage ofHigh outputPeptide preparation methodsDepsipeptidesFood gradeLow-density lipoprotein

The invention provides a method for jointly extracting multiple kinds of yolk protein based on water phase separation and a product. The method includes the steps that (1), fresh yolk is taken, a water phase solution with the volume 0.5-5 times that of the yolk is added for dilution, and the material is stirred, and is subjected to standing or is centrifugally layered; an upper-layer component A,a middle-layer component B and a lower-layer component C are obtained, wherein the water phase solution is polysaccharide matter with the mass percentage concentration of 0.1-0.5% or 2-8% of a water solution of low-molecular polymers; (2), the component A is taken, and yolk low-density lipoprotein is prepared; (3), the component B is taken, and yolk immune globulin is prepared; (4), the componentC is taken, and phosvitin and yolk high-density lipoprotein are prepared. The process is simple and short, the operation is easy, four kinds of yolk protein can be jointly extracted, the extracting efficiency is high, and the unit raw material output is high; extraction is carried out based on water phase separation, reagents used in the method are all food-grade or medicine-grade components, andthe reagents are green and safe; the treatment process is mild, and the functional characteristics and the bio-activity of the protein can be reserved to the maximum degree.

Owner:CHENGDU UNIV

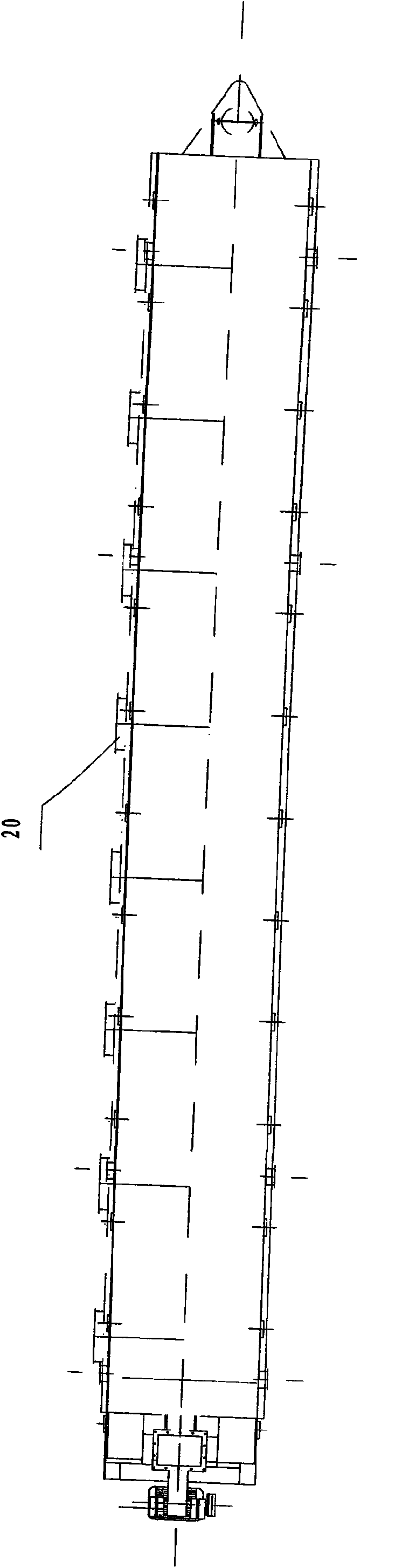

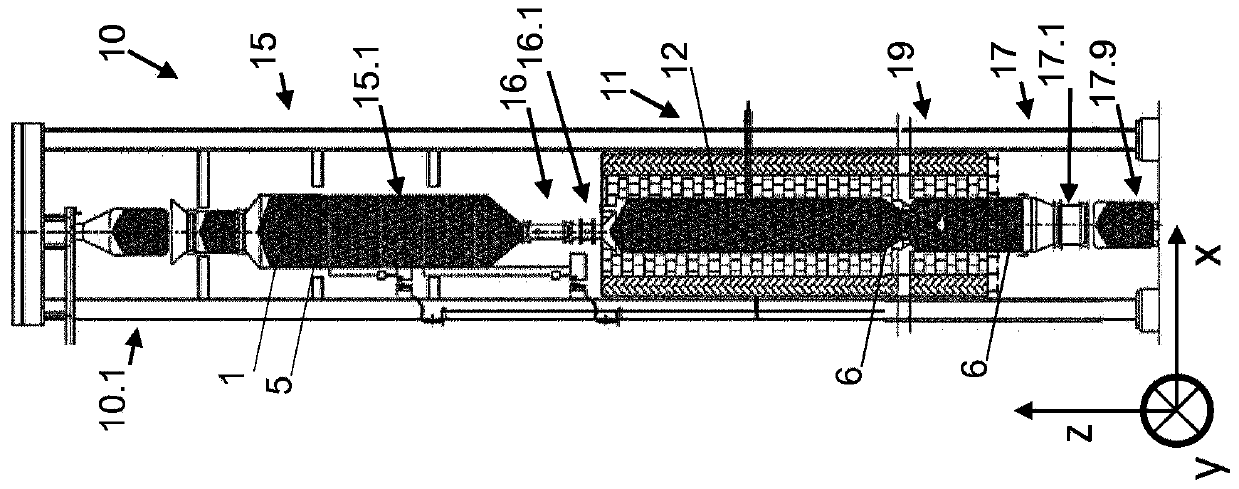

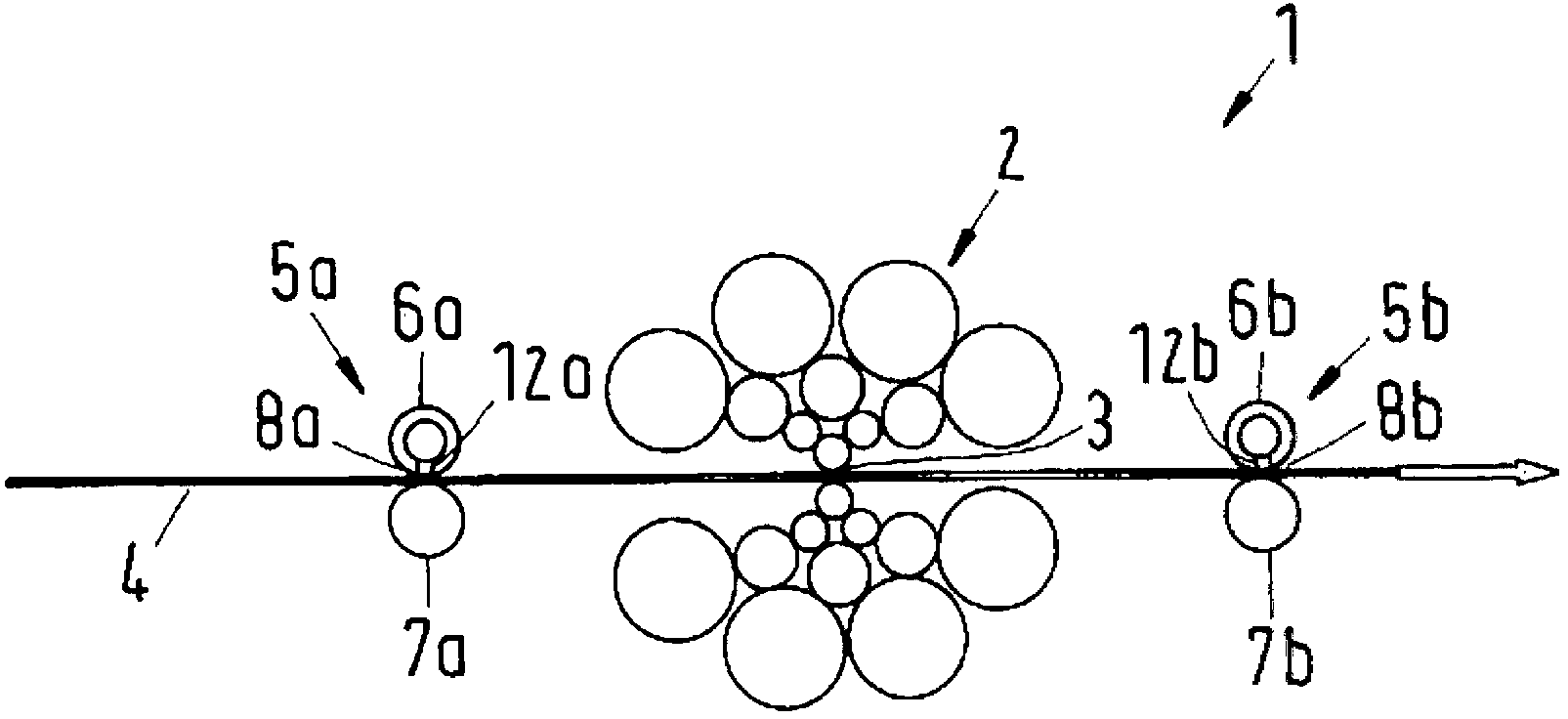

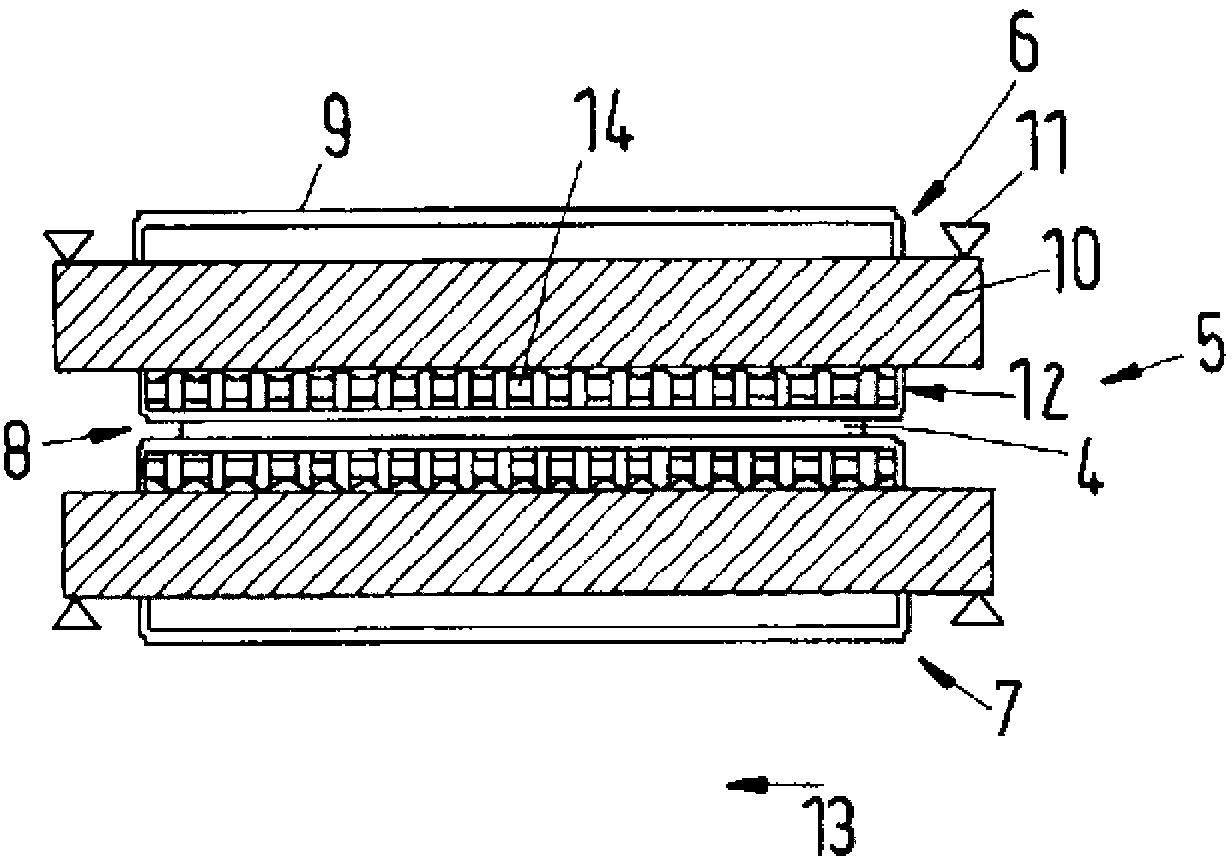

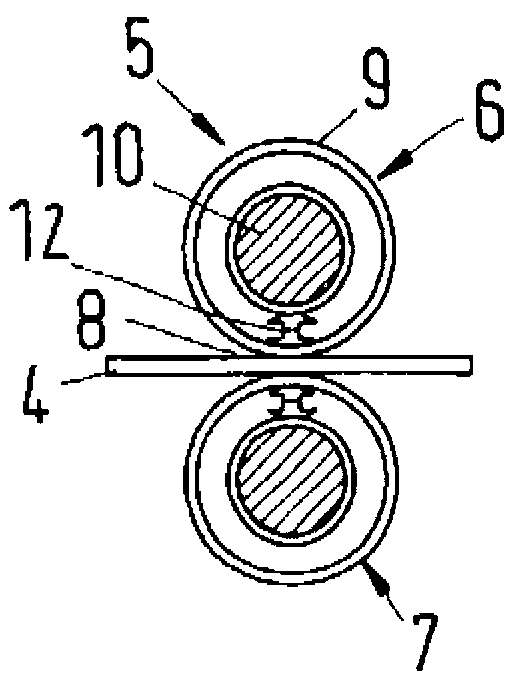

Squeezing unit for a strip rolling mill and strip rolling mill

ActiveCN102939172ASimple and precise zone controlSimple and exact widthShaft and bearingsMetal rolling stand detailsStrip millRolling mill

The invention relates to a squeezing unit (5) for a strip rolling mill and to a strip rolling mill comprising such a squeezing unit, wherein the squeezing unit (5) has an upper roller (6) and a lower roller (7), between which a squeezing nip (8) is formed. To achieve long service lives, ensure low residual moisture and minimize surface damage on the strip, at least one of the rollers (6, 7) is provided with a revolving shell (9) and a stationary yoke (10), which passes axially through the shell (9), wherein a pressing device (12) is arranged between the yoke (10) and the shell (9). The pressing device (12) subjects the shell (9) to an outward bearing pressure in a radial direction, wherein the bearing pressure is variable over a roller width such that zonal control and active width adjustment are effected.

Owner:瓜奈里科技股份有限公司

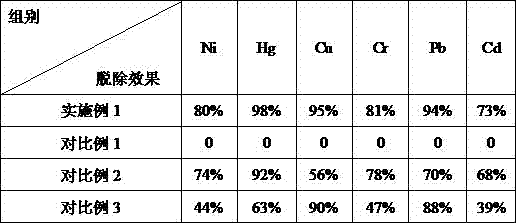

Method for removing heavy metal in enzymatic hydrolysate of sea cucumber by joint use of chelating resins

InactiveCN106993713AStandards compliantDoes not affect removalProtein composition from fishAnimal proteins working-upHydrolysateAdditive ingredient

The invention discloses a method for removing heavy metal in enzymatic hydrolysate of sea cucumber by joint use of chelating resins. The method comprises the following steps of connecting chelating resin containing ethylsuleenyl and 2-aminopyridine and PS-EDTA chelating resin in series, and eluting the enzymatic hydrolysate of sea cucumber by the serially connected chelating resin; decomposing the sea cucumber into polypeptide under the action of enzyme, and removing the heavy metal in supernatant by the chelating resins. While the heavy metal ion is removed, the influence to the content and property of other effective ingredients in the enzymatic hydrolysate is avoided; the Hg, Ni, Cu, Cr, Pb and Cd in the enzymatic hydrolysate of sea cucumber can be effectively removed, the other components are used as raw materials of health-care products, and the standard of health-care products is met. The method has the advantages that the method is simple, and the effect is obvious; under the condition of higher selectivity, the influence to the effective ingredients of the product is avoided, multiple types of metal ions can be removed at one time, the adsorbing rate is high, the resin regeneration is easy, the cost is low, and the scaled production requirement is met.

Owner:山东圣洲海洋生物科技股份有限公司

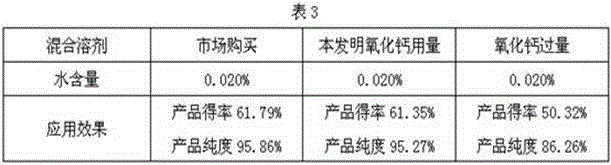

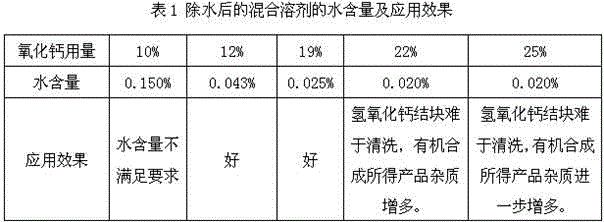

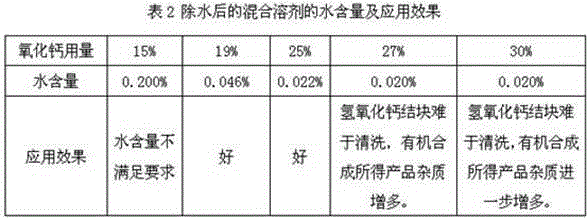

Method for removing water from ethyl acetate and butanone mixed solvent

ActiveCN102180790BReduce dosageLow priceOrganic compound preparationCarboxylic acid esters preparationButanoneEthyl acetate

The invention discloses a method for removing water from an ethyl acetate and butanone mixed solvent. The method comprises a step of adding a drying agent into a water-containing mixture of ethyl acetate and butanone to remove water, wherein the drying agent is solid calcium oxide in an amount which is 12 to 25 percent of the weight of the water-containing mixture of the ethyl acetate and the butanone. A small amount of water is removed from the water-containing mixture of the ethyl acetate and the butanone by a drying method; the method is easy to operate, time-saving and labor-saving; the drying agent is the calcium oxide and has low price; the processing process is mild without danger; and the posttreatment process is simple, namely a kettle can be directly washed with deionized water and can also be properly washed with diluted hydrochloric acid. By the method, production cost is greatly reduced; the treatment effect is good; the water content of the treated mixed solvent can be reduced to below 0.05 percent; the effect is remarkable; and the actual application requirement is met.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

A method for decolorizing silkworm chrysalis proteolysis of blood pressure-lowering peptide

ActiveCN103804467BThe decolorization method is simpleEasy to operatePeptide preparation methodsFermentationProteolysisUltrasonic oscillation

The invention discloses a decoloration method of silkworm chrysalis proteolysis antihypertensive peptide, which comprises the steps of adjusting the pH value of the silkworm chrysalis proteolysis antihypertensive peptide to 6-9; adding a mixture of bentonite, activated clay and alkaline calcium bentonite as a decoloration agent, wherein the mass volume ratio of the decoloration agent to the silkworm chrysalis proteolysis antihypertensive peptide is 10-45g / L; performing ultrasonic oscillation decoloration for 15-30 minutes at 30-45 DEG C; performing centrifugal separation, wherein the obtained supernate is the silkworm chrysalis proteolysis antihypertensive peptide after decoloration treatment. According to the method disclosed by the invention, by adopting the mixture of bentonite, activated clay and alkaline calcium bentonite as the decoloration agent, a relatively high decoloration rate is guaranteed, and the antihypertensive inhibition activity (ACE inhibition activity) is effectively maintained; moreover, the method is simple and easy to operate, has mild treatment processes, and can be widely applied to the production processes of the silkworm chrysalis polypeptide and other active peptides.

Owner:GUANGXI UNIV

Method for producing edible food package paper with bean peel as raw material

ActiveCN101413226BRaise the ratioReduce energy consumptionNon-fibrous pulp additionPulp beating/refining methodsCelluloseSoybean hulls

The invention discloses a method for producing edible food packaging paper with soybean hull as a raw material. The method comprises the following steps: the soybean hulls are subject to superfine comminution, are treated by pressurization for 20 minutes to 2 hours under the pressure of between 130 and 320kPa, and are cooled; an enzymatic reaction is performed under the conditions that the mass concentration of soybean hull powder is between 1 and 25 percent, the mass ratio of cellulose to the soybean hull powder is between 0.1 to 1 and 10 to 1, the temperature is between 25 and 70 DEG C, andthe rotating speed is between 50 and 350rpm; the reaction is terminated when the hydrolysis degree of the reaction reaches between 5 and 20 percent; a filtrate is vacuum concentrated and decolorized by hydrogen peroxide, and then a food thickener and a food plasticizer are added for stirring evenly; the ultrasonic degassing is performed for 30 to 120 minutes after the beating; the filtrate is placed into a mold for molding; and the edible food packaging paper is obtained through drying at a temperature of between 55 and 70 DEG C. The method has green raw material and chloride-free environment-friendly process, has no discharge of acid liquids or alkaline liquids, provides a new approach for the utilization of high added values of biomass resources, and also provides broad prospect for thedevelopment of special paper.

Owner:SOUTH CHINA UNIV OF TECH

Operating method of wastewater treatment system

ActiveCN106116023AReduce energy consumptionLower requirementWater treatment parameter controlSpecific water treatment objectivesFiberFlocculation

The invention discloses an operating method of a wastewater treatment system. The wastewater treatment system comprises a wastewater tank, a first flocculation sedimentation tank, a fiber recovery device, a second flocculation sedimentation tank, a biodegradation tank and a reuse water tank, wherein the wastewater tank is connected to the water inlet end of the first flocculation sedimentation tank; the water outlet end of the first flocculation sedimentation tank is connected to the water inlet end of the fiber recovery device through a pipeline; the water outlet end of the fiber recovery device is connected to the water inlet end of the second flocculation sedimentation tank; the water outlet end of the second flocculation sedimentation tank is connected to the water inlet end of the biodegradation tank; the water outlet end of the biodegradation tank is connected to the reuse water tank; a sludge tank is arranged at the bottom of the first flocculation sedimentation tank; the second flocculation sedimentation tank comprises an upper layer, a middle layer and a bottom layer; a water discharge pipe connected to the biodegradation tank, a return pipe connected to the first flocculation sedimentation tank and a sludge discharge pipe connected to the sludge tank are respectively connected to the upper layer, the middle layer and the bottom layer. The operating method is thorough in wastewater treatment effect, low in energy consumption and beneficial to popularization and application.

Owner:JIANGXI CHENMING PAPER CO LTD

A kind of high alkali-resistant textile scouring agent and preparation method thereof

InactiveCN104532556BExcellent decontaminationGood hair effectFibre treatmentHazardous substanceDefoaming Agents

The invention provides a high-alkali-resistance mild-performance safe and environment-friendly textile scouring agent. The textile scouring agent is prepared from the following components in percentage by weight: 20 to 25% of alcohol alkoxylate, 15 to 25% of alkyl glycoside, 10 to 15% of ethoxy alkyl sodium sulfate, 5% of ethylene glycol monobutyl ether, 2 to 4% of organic solvents, 0.2 to 0.8% of edetic acid, 0.5 to 1.0% of defoaming agents, and 20 to 45% of water. According to the textile scouring agent, the alcohol alkoxylate with high penetration, the alkyl glycoside with a mild performance, and the ethoxy alkyl sodium sulfate which serves as an anionic surfactant are used as active matter raw materials which almost do not irritate the skin and damage cotton, hemp, silk, leather and other high-level fabrics; the formula is basically free of harmful substance residue, high in penetration, high in cleaning capacity, and outstanding in detergency capacity, and the hand feel of a processed fabric is good.

Owner:YANSHI RANHE BIOMATERIAL

Fresh bean noodles rich in soluble dietary fibers and easy to cook without breakage and preparation method of fresh bean noodles

The invention discloses fresh bean noodles rich in soluble dietary fibers and easy to cook without breakage and a preparation method of the fresh bean noodles. The noodles are prepared from the following ingredients in parts by weight: 1000-1200 parts of low-gluten flour, 500-550 parts of bean dregs, 50-60 parts of perilla fruit leaves, 300-320 parts of pineapple peel dregs, 30-35 parts of fermented glutinous rice, 6-7 parts of table salt, 10-12 parts of agar, 15-18 parts of pineapple peel pectin, 30-35 parts of coconut milk, 20-23 parts of sesame oil and 3-3.5 parts of dietary alkali. The fresh bean noodles rich in soluble dietary fibers and easy to cook without breakage are rich in nutrition, have chewy and fresh taste, are easy to cook without breakage, are fresh without greasy taste and are particularly suitable for being eaten by special crowds such as diabetes patients due to low total sugar content in pineapple peel dietary fibers.

Owner:YINGSHANG GUANSHI FLOUR PROD

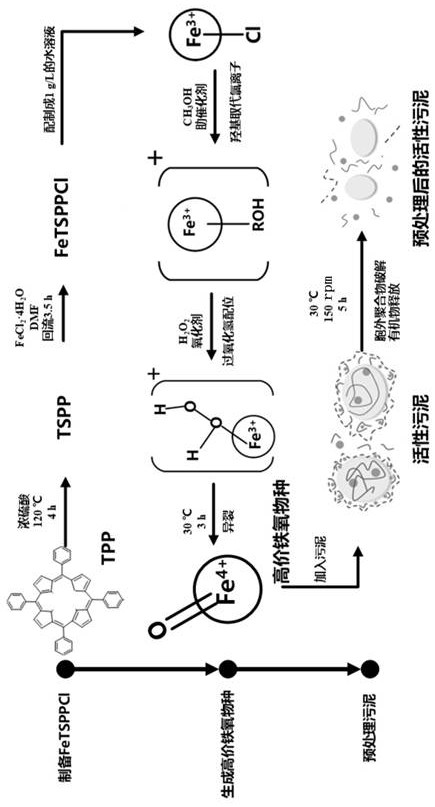

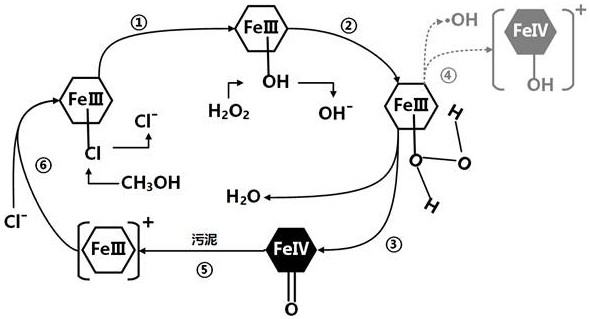

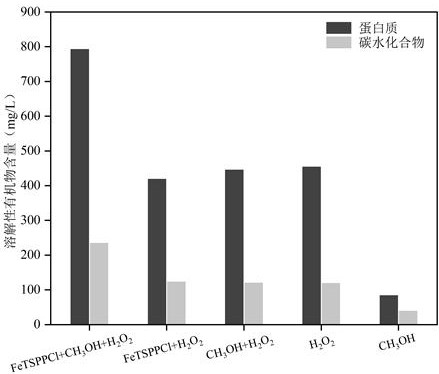

A kind of sludge pretreatment method based on sulfonic acid porphyrin iron catalyst Fenton system

ActiveCN113698058BEffective for hydrolysisLower pHSludge treatment by oxidationWater treatment compoundsPtru catalystPorphyrin

The invention discloses a sludge pretreatment method based on a sulfonic acid porphyrin iron catalyst Fenton-like system, comprising the following steps: mixing the sulfonic acid porphyrin iron catalyst, methanol and hydrogen peroxide solution, stirring, and mixing the obtained The liquid is mixed with the sludge for hydrolysis treatment to complete the pretreatment of the sludge. The present invention is based on the sludge pretreatment method of the sulfonic acid porphyrin iron catalyst Fenton system, by first mixing and stirring the sulfonic acid porphyrin iron catalyst, methanol and hydrogen peroxide solution to generate a mixed solution containing high-valent iron species , and then mixed with sludge, using high-valent iron species to achieve effective treatment of sludge, has the advantages of low catalyst and oxidant consumption, mild reaction conditions, high treatment efficiency, good treatment effect, and good adaptability. The effect of resource utilization is of great significance, with high use value and good application prospect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com