Method for removing heavy metal in enzymatic hydrolysate of sea cucumber by joint use of chelating resins

A technology of chelating resin and enzymatic hydrolysis solution, which is applied in the fields of application, fish protein components, animal protein processing, etc., can solve problems such as unsuitable for large-scale use, loss of nutrients, complex regeneration process, etc., and achieve investment and operation costs Inexpensive, less nutrient loss, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

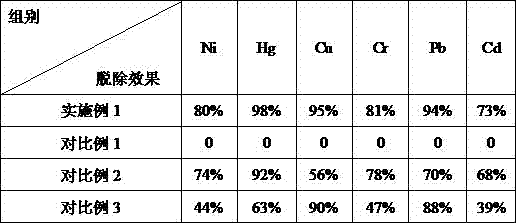

Examples

Embodiment 1

[0024] (1) Preparation of enzymatic hydrolyzate of sea cucumber. After washing the fresh sea cucumber, add 1 volume of deionized water to homogenate for 10 minutes, sonicate for 10 minutes, add papain and compound protease, and form a multi-enzyme system with the autolytic enzyme contained in the fresh sea cucumber itself. After enzymolysis, add flavor protease to continue the enzymolysis Until the enzymatic hydrolysis is completed, the amount of enzyme added is 1000U / g, the enzymatic hydrolysis condition is pH 6, the enzymatic hydrolysis time is 5, and the enzymatic hydrolysis temperature is 37°C. After the enzymatic hydrolysis reaction, inactivate the enzyme at 100°C for 10 minutes, centrifuge at high speed for 15-20 minutes, and the supernatant after filtration is the protein enzymatic hydrolysis solution (ie sea cucumber enzymatic hydrolysis solution).

[0025] (2) Selection and treatment of chelating resin. The method that two kinds of resins are used together, A: the ch...

Embodiment 2

[0028] (1) Preparation of enzymatic hydrolyzate of sea cucumber. After washing the fresh sea cucumber, add 2 volumes of deionized water to homogenate for 10 minutes, sonicate for 10 minutes, add papain and compound protease, and form a multi-enzyme system with the autolytic enzyme contained in the fresh sea cucumber itself. After enzymolysis, add flavor protease to continue the enzymolysis Until the enzymatic hydrolysis is completed, the amount of enzyme added is 3000U / g, the enzymatic hydrolysis condition is pH 7, the enzymatic hydrolysis time is 7h, and the enzymatic hydrolysis temperature is 40°C. After the enzymatic hydrolysis reaction, inactivate the enzyme at 100°C for 10 minutes, centrifuge at high speed for 15-20 minutes, and filter the supernatant as the proteolysis solution.

[0029] (2) Selection and treatment of chelating resin. The method that two kinds of resins are used together, A: the chelating resin containing ethylthio group and 2-aminopyridine, B: PS-EDTA / ...

Embodiment 3

[0032] (1) Preparation of enzymatic hydrolyzate of sea cucumber. After washing the fresh sea cucumber, add 3 volumes of deionized water to homogenate for 10 minutes, sonicate for 10 minutes, add papain and compound protease, and form a multi-enzyme system with the autolytic enzyme contained in the fresh sea cucumber itself. After enzymolysis, add flavor protease to continue the enzymolysis Until the enzymatic hydrolysis is completed, the amount of enzyme added is 7000U / g, the enzymatic hydrolysis condition is pH 9, the enzymatic hydrolysis time is 10h, and the enzymatic hydrolysis temperature is 43°C. After the enzymatic hydrolysis reaction, inactivate the enzyme at 100°C for 10 minutes, centrifuge at high speed for 15-20 minutes, and filter the supernatant as the proteolysis solution.

[0033](2) Selection and treatment of chelating resin. The method that two kinds of resins are used together, A: the chelating resin containing ethylthio group and 2-aminopyridine, B: PS-EDTA / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com