Oil and fat modification method and application thereof

An oil and modification technology, applied in application, climate change adaptation, nitrogen fertilizer, etc., can solve the problems of unfavorable cost control, high price, harsh conditions, etc., and achieve the effect of favorable cost control, less equipment use, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A method for modifying waste grease includes the following steps:

[0083] Take 80mL soybean acidified oil (acid value is 70mgKOH / g, mass percentage of water is less than 5%) in a scrubber, under the condition of 20~30℃, use air source ozone machine to continuously pass in at a flow rate of 10g / h Ozone for 5 hours to obtain ozonized waste grease (oil modified material), and use sodium thiosulfate solution to absorb residual ozone.

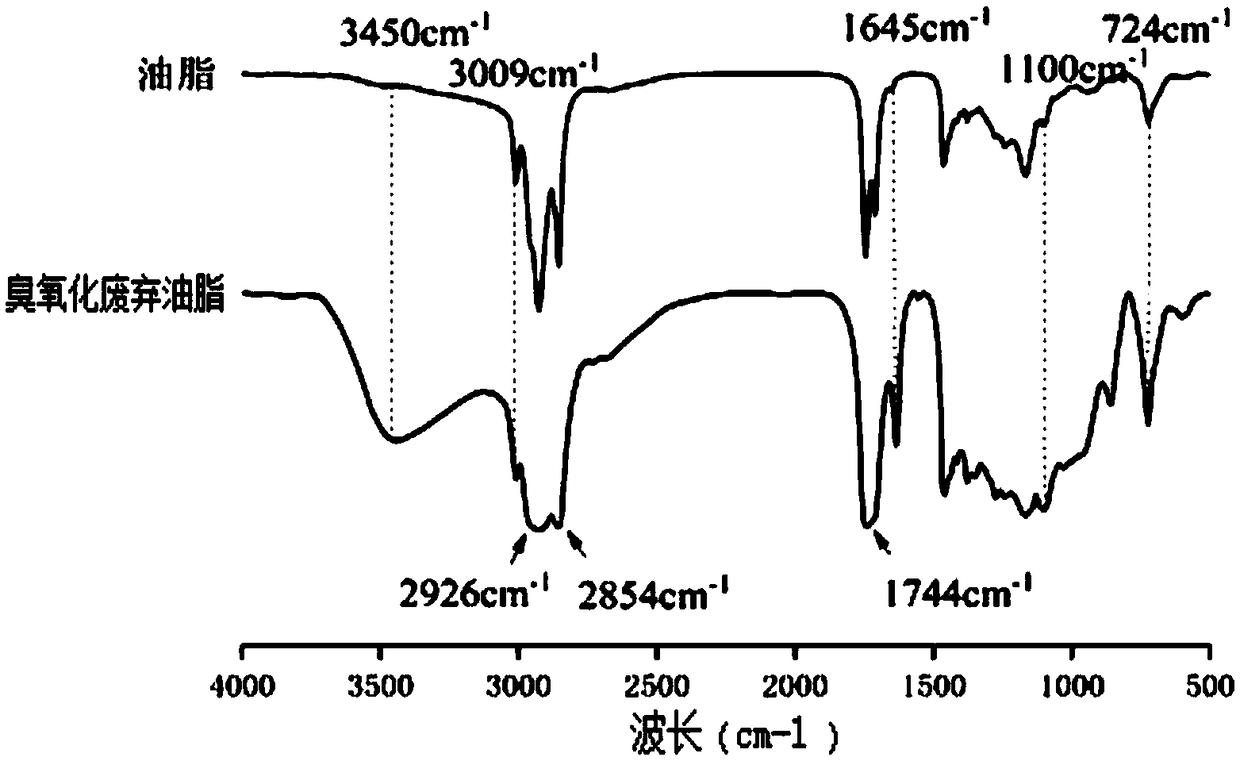

[0084] by figure 1 It can be seen that the acidified soybean oil after ozone modification is at 3009cm -1 The stretching vibration of the alkene hydrogen (=C-H) is significantly reduced, which indicates that the carbon-carbon double bond (C=C) in the modified product is reduced; at 3450cm -1 The hydroxyl peak (-OH) of water is generated at the place, because the instrument used in this experiment is an air source ozone machine, which uses air as raw material to generate ozone by high-voltage discharge, and the oxygen content in the air is 21%, whi...

Embodiment 2~9

[0086] The preparation methods of Examples 2-9 are the same as those of the Examples, but the difference lies in that the ozone introduction time of Examples 2-9 is 1h, 2h, 3h, 4h, 6h, 7h, 8h, 9h, respectively.

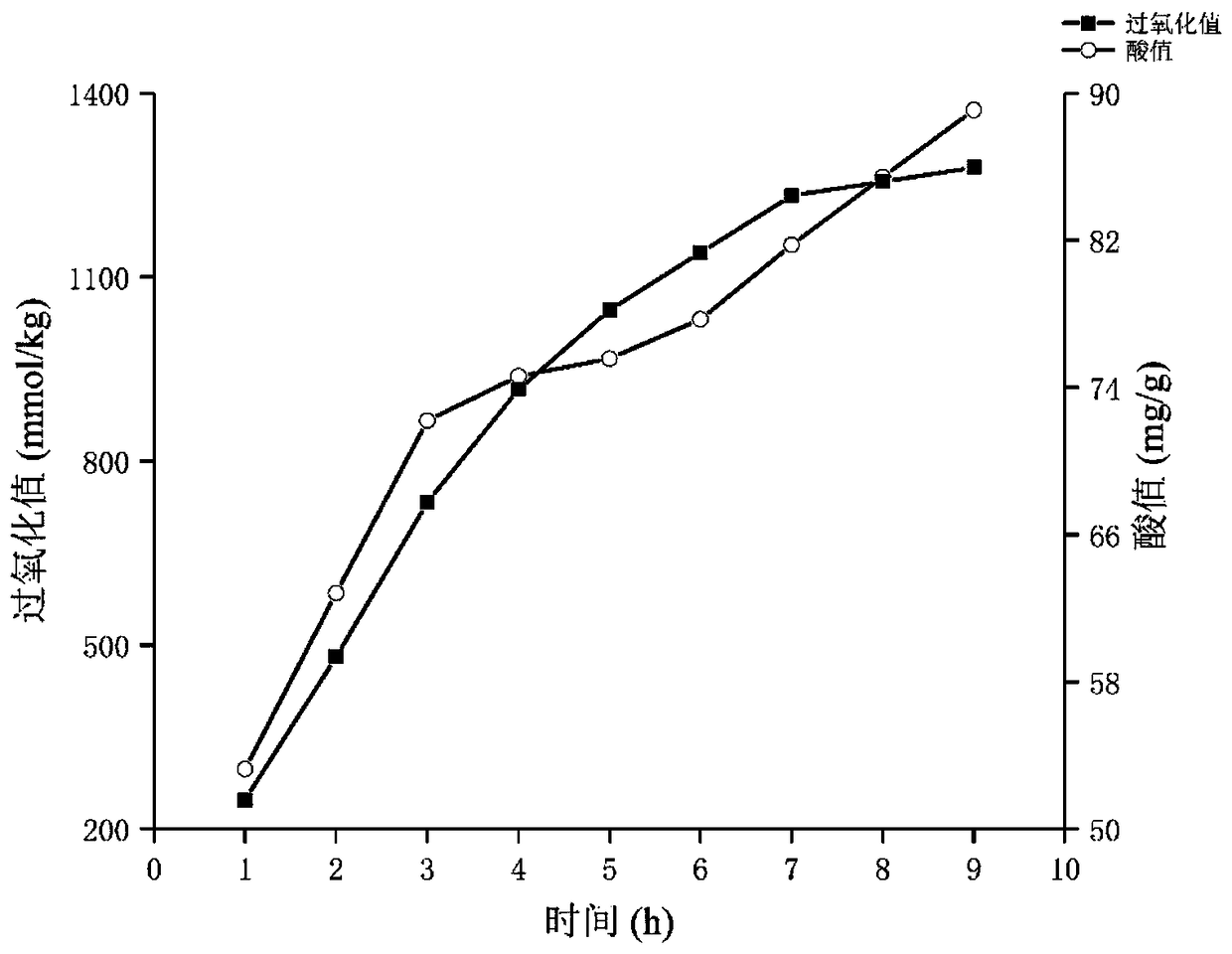

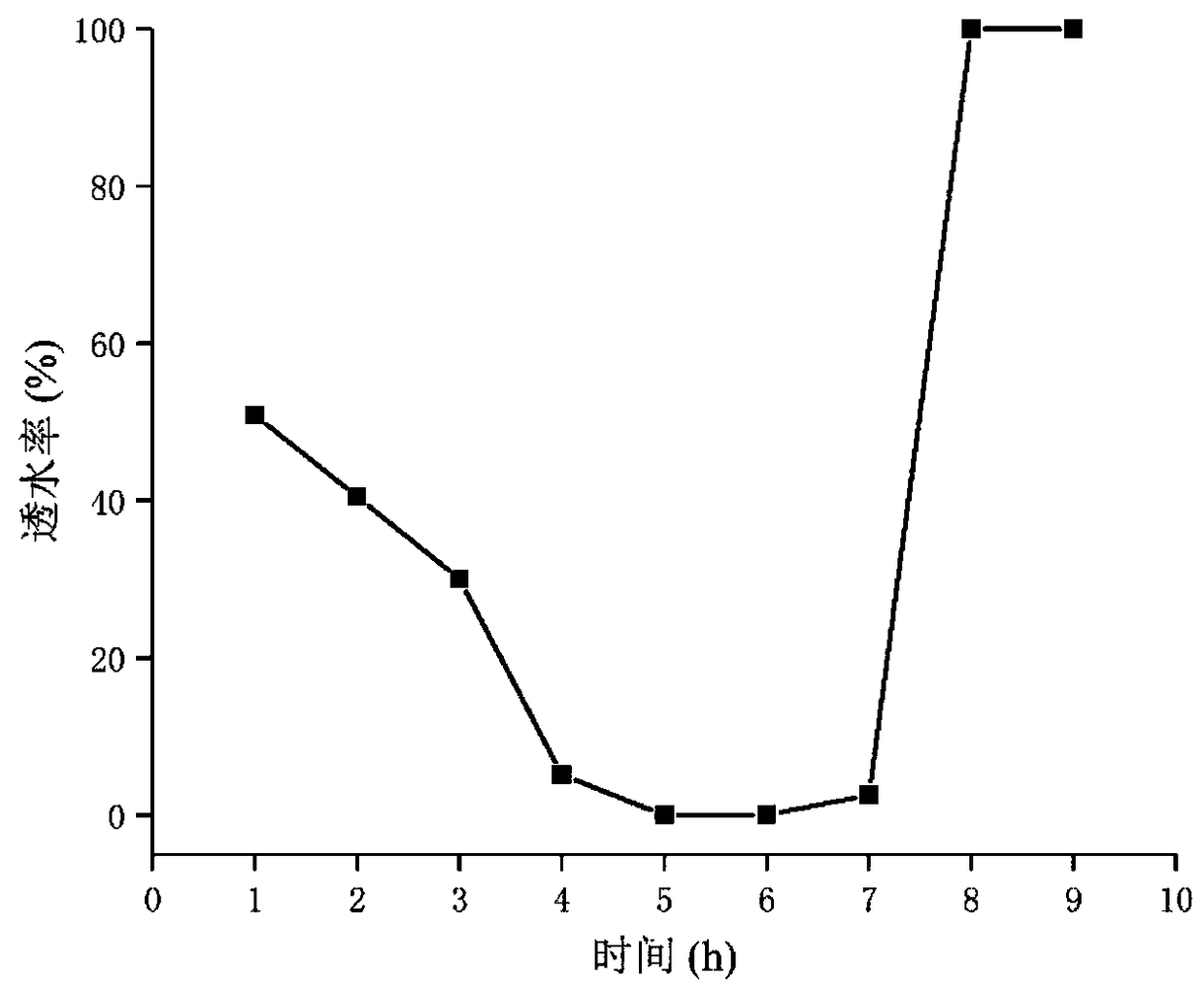

[0087] by figure 2 It can be seen that the acid value in the waste grease system increases continuously when the ozone treatment time is increased, and the oxidation value tends to be stable when the reaction time is 7 hours. As a very strong oxidant, ozone is used to treat waste grease. The products contain different oxygen-containing compounds, such as peroxides, ozonides and aldehydes. Among them, peroxides are the most important products, including hydroperoxides, Hydrogen peroxide, polymeric peroxides and other organic peroxides increase the peroxide value. At the same time, aldehydes can be oxidized into acids, and peroxides can also be decomposed into acids, resulting in increased acid values. However, when the reaction time exceeds 7 hours, the generation and de...

Embodiment 10

[0090] A method for modifying waste grease includes the following steps:

[0091] Take 80mL soybean acidified oil (acid value 75mgKOH / g, mass percentage of water is less than 5%) in a scrubber, under the condition of 0~5℃, use an air source ozone machine to continuously pass in at a flow rate of 10g / h Ozone is 4.5h to obtain ozonized waste grease (oil modified material), and sodium thiosulfate solution is used to absorb residual ozone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com