Method for decolorizing silkworm chrysalis protein enzymatic hydrolysis peptide

A technology of proteolysis and anti-oxidation peptides, which is applied in the field of decolorization of silkworm chrysalis proteolysis anti-oxidation peptides, can solve the problems of difficult color, loss of active peptide activity, high protein loss rate, etc., and achieves mild treatment process, easy operation and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment one: the selection of decolorizing agent

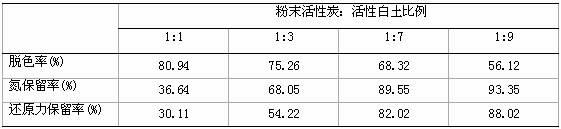

[0013] 1% silkworm chrysalis proteolytic hydrolyzed antioxidant peptide solution, adjust the pH to 7, then add 20 g / L of powdered activated carbon and activated clay respectively, put it into the oscillating water bath, the temperature is 30 ° C, the speed is adjusted to 200 r / min, and after decolorization for 30 min, Centrifuge at 5000-6000r / min for 30 min in a disc centrifuge. Take the supernatant to measure its decolorization rate, nitrogen retention rate and reducing power retention rate. The results are shown in Table 1.

[0014] It can be seen from Table 1 that powdered activated carbon has a good decolorization effect, but at the same time of decolorization, the active polypeptide is also lost, which in turn affects the antioxidant activity of the supernatant. On the basis of a certain decolorization effect, activated clay better retains nitrogen content and reducing power.

[0015] Table 1 Decolorization e...

Embodiment 2

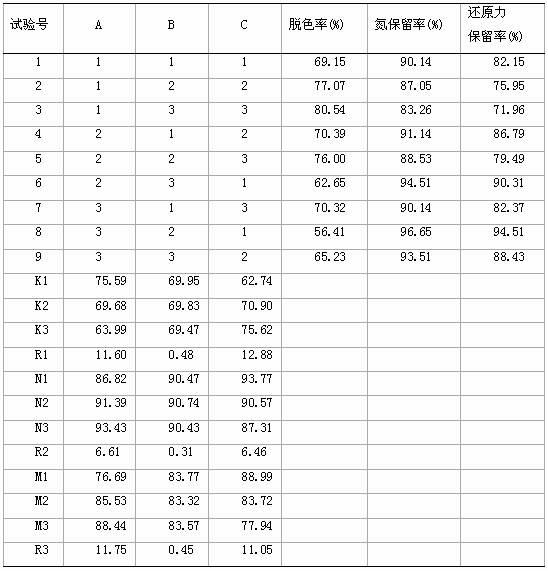

[0017] Embodiment two: the proportioning of composite decolorizing agent

[0018] 1% silkworm chrysalis protein enzymatic hydrolysis antioxidant peptide solution, adjust the pH to 7, add different proportions of powdered activated carbon and activated clay composite decolorizer 20 g / L, put it into an oscillating water bath, temperature 30°C, adjust the speed 200 r / min, decolorize After 30 min, centrifuge at 5000-6000 r / min for 30 min in a disc centrifuge. Take the supernatant to measure its decolorization rate, nitrogen retention rate and reducing power retention rate. The results are shown in Table 2.

[0019] It can be seen from Table 2 that with the decrease of the proportion of powdered activated carbon and the increase of the proportion of activated clay, the decolorization rate decreased, and the nitrogen retention rate and reducing power retention rate increased significantly. When the ratio of powdered activated carbon: activated clay is 1:7, the decolorization effec...

Embodiment 3

[0023] Embodiment three: the single factor optimization of the decolorization condition of compound decolorizer

[0024] 1% silkworm chrysalis protein enzymatic hydrolysis antioxidant peptide solution, adjust pH 5-9, add powdered activated carbon and activated clay compound decolorizer (1:7) 10-50 g / L, put it into an oscillating water bath, temperature 20-100 ℃, Adjust the rotation speed to 200 r / min, and after decolorization for 30 min, centrifuge at 5000-6000 r / min for 30 min in a disc centrifuge. Take the supernatant to measure its decolorization rate, nitrogen retention rate and reducing power retention rate. The results are shown in Table 3-5.

[0025] It can be seen from Table 3 that as the pH increases, the decolorization rate decreases, but the nitrogen retention rate and reducing power retention rate increase significantly.

[0026] It can be seen from Table 4 that the decolorization rate, nitrogen retention rate and reducing power retention rate do not change much ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com