A kind of sludge pretreatment method based on sulfonic acid porphyrin iron catalyst Fenton system

A technology of iron sulfonate porphyrin and catalyst, which is applied in water/sludge/sewage treatment, oxidation treatment of sludge, chemical instruments and methods, etc., can solve the problem of limited sludge hydrolysis ability, reduced Fenton system oxidation ability, Problems such as the complexity and changeability of the sludge system, to achieve the effect of improving the subsequent utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

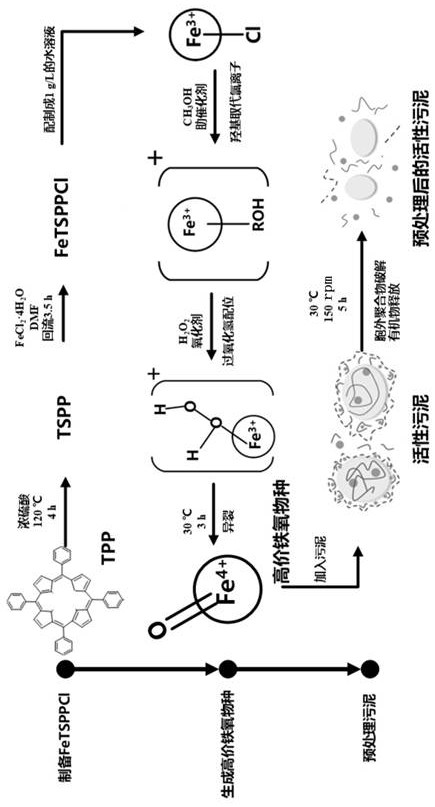

[0039] A kind of sludge pretreatment method based on sulfonic acid-based porphyrin iron catalyst class Fenton system, its process flow chart is as follows figure 1 shown, including the following steps:

[0040] S1. The sulfonic acid-based porphyrin iron catalyst (tetrakis (4-sulfonic acid phenyl) porphyrin ferric chloride, FeTSPPCl) was prepared into an aqueous solution with a concentration of 1 g / L, 1 mL was placed in the reactor, and successively added to 0.36 mL of anhydrous methanol and 2.5 mL of hydrogen peroxide solution with a mass concentration of 30% were added to the reactor, and stirred, specifically, the reactor was placed in a 30°C shaker to fully shake and react for 3 hours to obtain a mixed solution.

[0041] S2. Add 100 mL of activated sludge (TSS=40.39 g / L, pH=6.98) into the reactor containing the mixed solution in step S1 for hydrolysis treatment, specifically, using a sealing film to bind the bottle mouth of the reactor, and at the same time The reactor was...

Embodiment 2

[0070] A sludge pretreatment method based on a sulfonic acid-based porphyrin iron catalyst class Fenton system, comprising the following steps:

[0071] S1. The sulfonic acid-based porphyrin iron catalyst prepared in Example 1 (tetrakis (4-sulfonic acid phenyl) porphyrin iron chloride, FeTSPPCl) was prepared into an aqueous solution with a concentration of 1 g / L, and 0, 1 mL of , 2mL, 4mL, and 8mL were placed in different reactors, and 0.36mL of anhydrous methanol and 2.5mL of hydrogen peroxide solution with a mass concentration of 30% were added to these reactors in turn, and stirred. Placed in a shaker at 30°C and reacted with sufficient shaking for 3 h to obtain a mixed solution.

[0072] S2. Add 100 mL of activated sludge (TSS=40.39 g / L, pH=6.98) to different reactors with mixed solution in step S1 (the corresponding FeTSPPCl concentrations in these reactors are 0 mg / L, 10 mg in turn / L, 20mg / L, 40mg / L, 80mg / L) for hydrolysis treatment, specifically, using sealing film to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com