A cationic coated flocculant and its preparation method

A flocculant and cationic technology, which is applied in the field of cationic coated flocculant and its preparation, can solve the problems of limited flocculation performance and poor coating performance of coating agent, so as to improve temperature resistance and hydrolysis resistance, and improve coating flocculation effect, the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

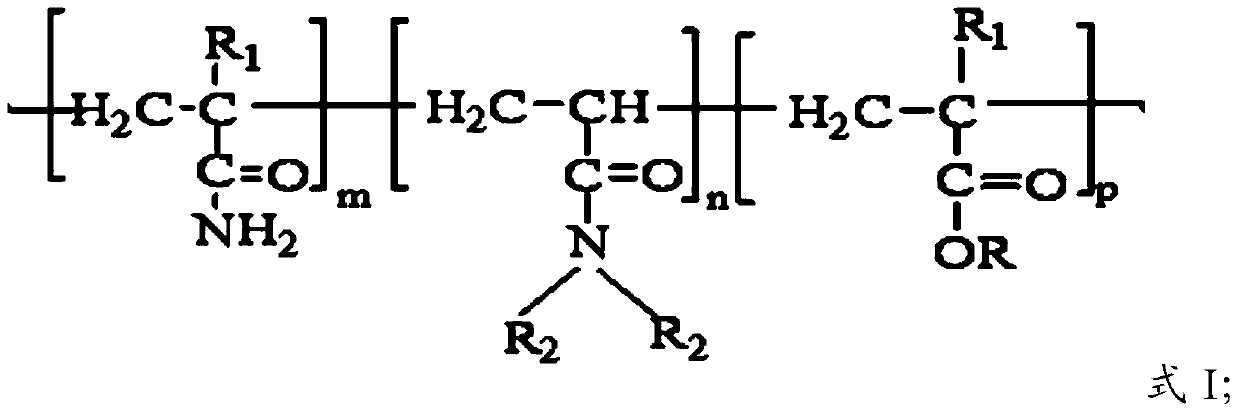

[0029] The invention also discloses a preparation method of a cationic coated flocculant, comprising the following steps:

[0030] After mixing monomer A, monomer B and monomer C according to the mass percentage of (40~80):(0~30):(20~30), adjust the pH value to 9~11, and add the initiator in nitrogen atmosphere agent, after the reaction, a cationic coated flocculant is obtained;

[0031] The monomer A is one or both of acrylamide or methacrylamide;

[0032] The monomer B is one or both of N,N-dimethylacrylamide or N,N-diethylacrylamide;

[0033] The monomer C is methacryloyloxyethyltrimethylammonium chloride, acryloyloxyethyltrimethylammonium chloride, dimethylaminoethyl acrylate or dimethylaminoethyl methacrylate.

[0034] The invention uses monomer A, monomer B and monomer C as raw materials to prepare cationic coated flocculant. The monomer A is one or both of acrylamide and methacrylamide. The function of the monomer B is to provide temperature resistance and hydrolysi...

Embodiment 1

[0040]Add 56g of acrylamide, 19g of N,N-dimethylacrylamide, and 25g of methacryloyloxyethyltrimethylammonium chloride into 344g of water and adjust the pH value to 11 after fully dissolving it. Slowly add 0.04g of ammonium persulfate and 0.04g of sodium bisulfite initiator, and keep warm at 40°C for 8 hours to obtain a gel-like polymer. The product is sheared, granulated, dried and pulverized at 60°C to obtain Cationic coated flocculant.

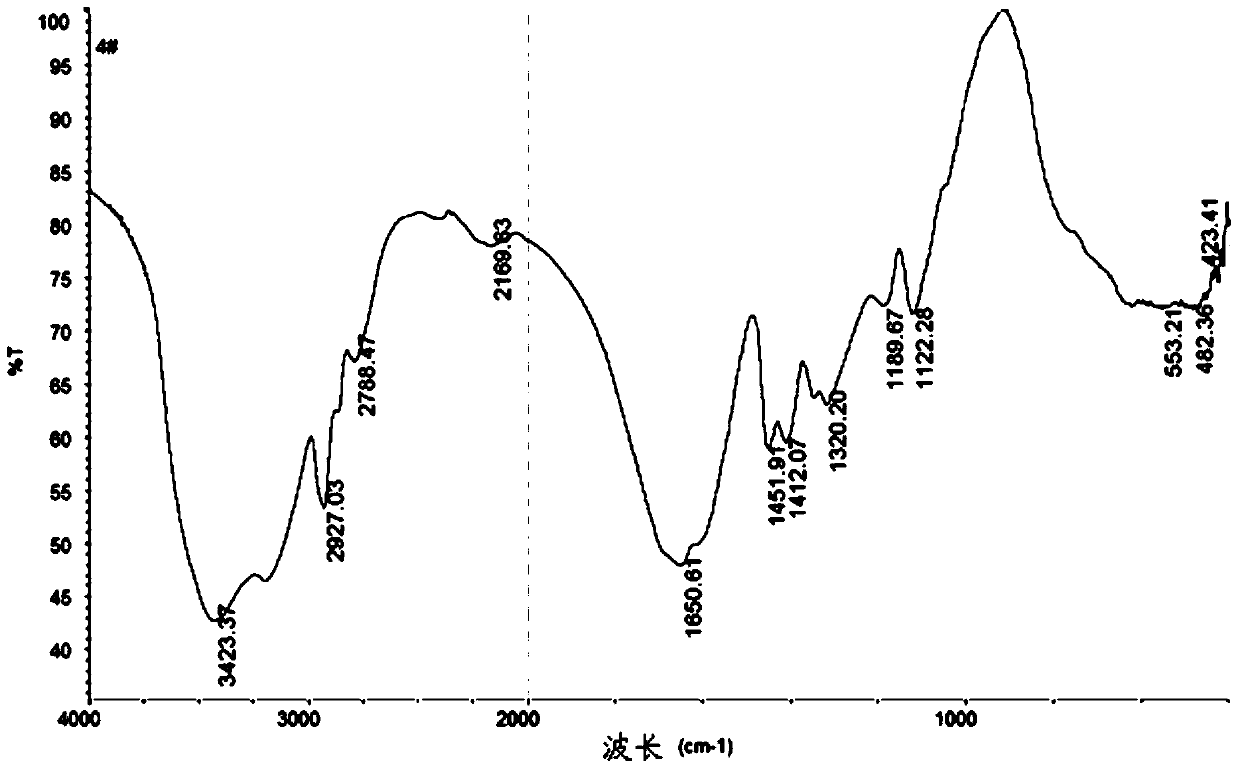

[0041] figure 1 It is the infrared spectrogram of the first part of cationic coating flocculant prepared by embodiment 1:

[0042] Depend on figure 1 Visible, 3423cm in the picture -1 It is the absorption peak of the N-H stretching vibration of -amide; 2927cm -1 Asymmetric absorption peaks for methyl and methylene; 1650cm -1 It is the characteristic absorption peak of the carbonyl group in the amide group; 1451.91cm -1 for -CH 2 -N(CH 3 ) 3 The characteristic absorption peaks of the bending vibration absorption peak of the methylene...

Embodiment 2

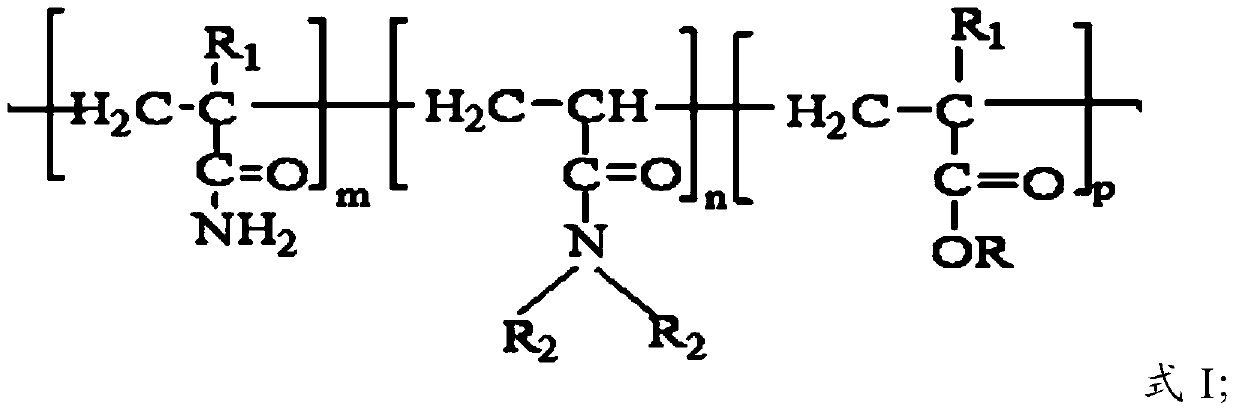

[0046] Add 67g of acrylamide, 7g of N,N-diethylacrylamide, and 26g of acryloyloxyethyltrimethylammonium chloride to 300g of water, adjust the pH value to 9 after fully dissolving, blow nitrogen gas for 40min, and slowly add 0.03g of ammonium persulfate and 0.03g of sodium bisulfite initiator were incubated at 20°C for 16 hours to obtain a gel-like polymer. The product was sheared and granulated, dried and crushed at 90°C to obtain a cationic By flocculant. Its structural formula is as follows:

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com