Collagenase-containing complex enzyme preparation and application thereof in treatment of leather leftovers

A compound enzyme preparation, collagenase-containing technology, applied in the direction of enzymes, peptidases, hydrolytic enzymes, etc., can solve the problems of wool fiber hydrolysis, low hydrolysis efficiency, and post-processing difficulties, achieving less addition, simple steps, and beneficial The effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

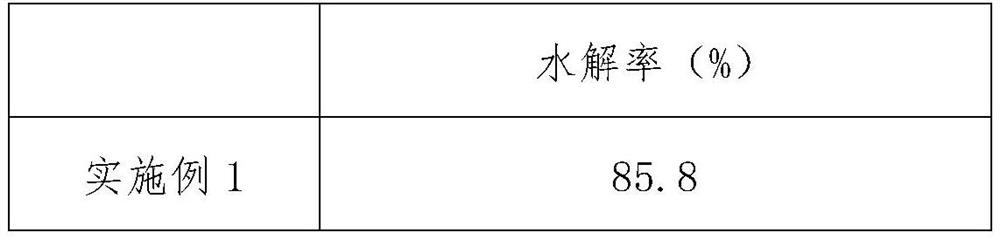

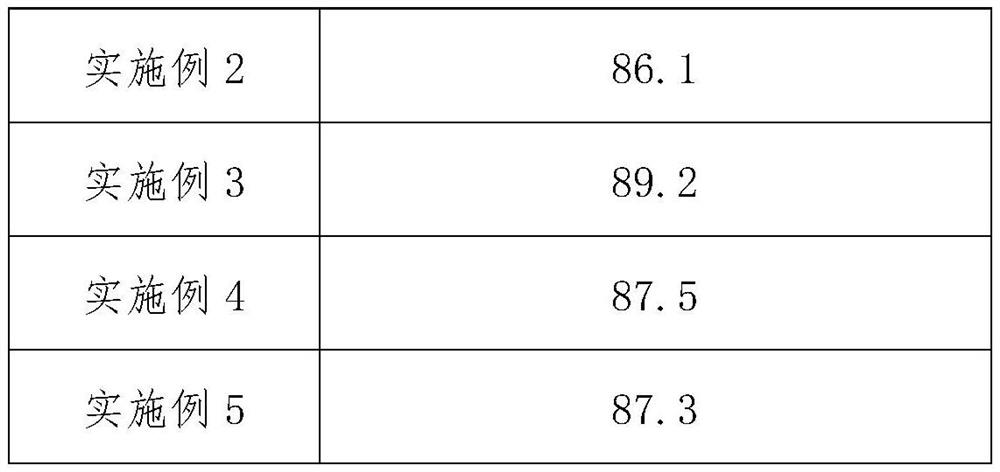

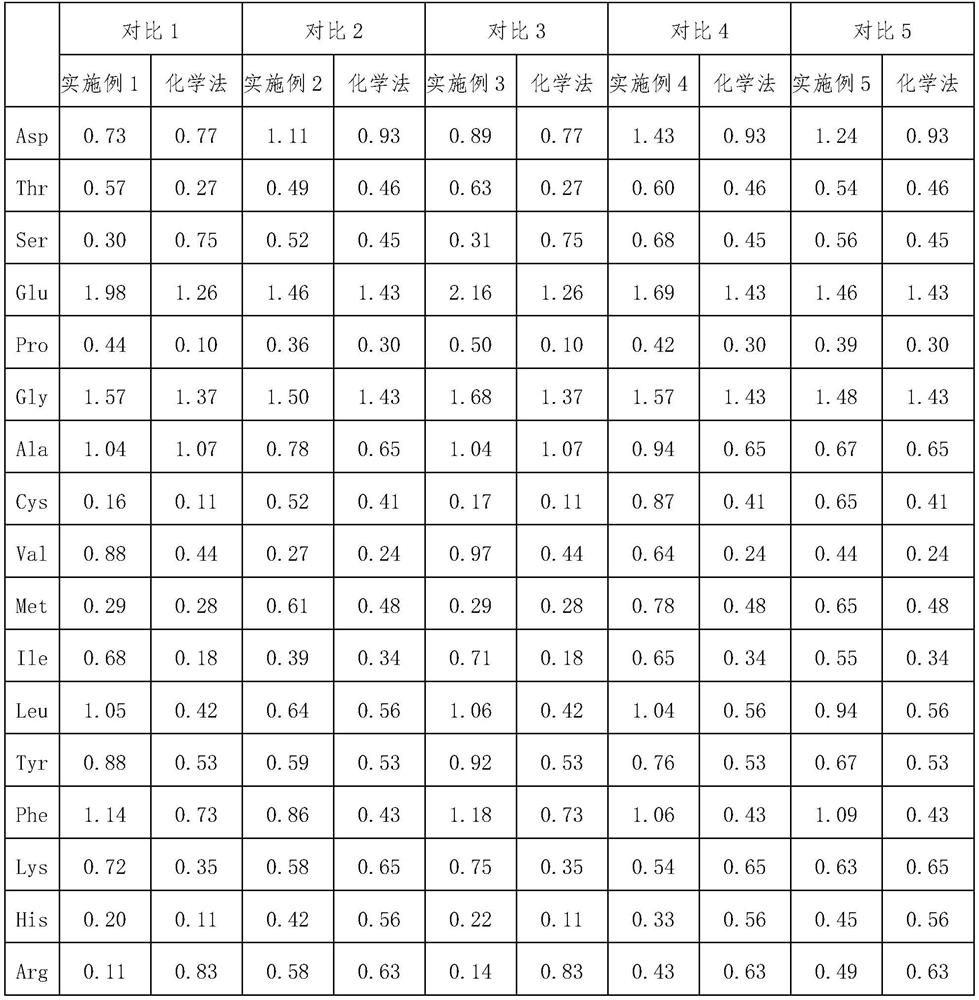

Examples

Embodiment 1

[0037] The compound enzyme preparation containing collagenase is composed of the following raw materials in unit mass parts:

[0038] Alkaline protease: alkaline lipase: keratinase: collagenase = 1.5: 1.5: 1.5: 2.5; wherein the parameters of each component are as follows:

[0039] The enzyme activity of alkaline protease is 700000U / g~800000U / g, the reaction temperature is 20℃~60℃, and the reaction pH is 8~12;

[0040] The enzyme activity of alkaline lipase is 1500U / g~2000U / g, the reaction temperature is 30℃~60℃, and the reaction pH is 7~10;

[0041] The enzyme activity of keratinase is 5000U / g~10000U / g, the reaction temperature is 25℃~60℃, and the reaction pH is 8~10;

[0042] The enzyme activity of collagenase is 1000U / g-1500U / g, the reaction temperature is 10°C-45°C, and the reaction pH is 8-10.

[0043] The application of the composite enzyme preparation containing collagenase in the treatment of leather scraps comprises the following process steps:

[0044] A. Put the l...

Embodiment 2

[0050] The compound enzyme preparation containing collagenase is composed of the following raw materials in unit mass parts:

[0051] Alkaline protease: alkaline lipase: keratinase: collagenase=0.5:0.5:0.5:1.5; wherein the parameters of each component are as follows:

[0052] Alkaline protease activity 700000U / g~800000U / g, reaction temperature 40℃~50℃, pH 10~11;

[0053] The enzyme activity of alkaline lipase is 1500U / g~2000U / g, the reaction temperature is 35℃~45℃, and the reaction pH is 7.5~8.5;

[0054] The enzyme activity of keratinase is 5000U / g~10000U / g, the reaction temperature is 35℃~45℃, and the reaction pH is 7.5~8.5;

[0055]The enzyme activity of collagenase is 1000U / g-1500U / g, the reaction temperature is 25°C-35°C, and the reaction pH is 7.5-8.5.

[0056] The application of the composite enzyme preparation containing collagenase in the treatment of leather scraps comprises the following process steps:

[0057] A. Put the leather solid waste in a 65°C water bath ...

Embodiment 3

[0063] The compound enzyme preparation containing collagenase is composed of the following raw materials in unit mass parts:

[0064] Alkaline protease: alkaline lipase: keratinase: collagenase = 1:1:1:2; the parameters of each component are as follows:

[0065] The enzyme activity of alkaline protease is 700000U / g~800000U / g, the reaction temperature is 20℃~60℃, and the reaction pH is 8~12;

[0066] The enzyme activity of alkaline lipase is 1500U / g~2000U / g, the reaction temperature is 30℃~60℃, and the reaction pH is 7~10;

[0067] The enzyme activity of keratinase is 5000U / g~10000U / g, the reaction temperature is 25℃~60℃, and the reaction pH is 8~10;

[0068] The enzyme activity of collagenase is 1000U / g-1500U / g, the reaction temperature is 10°C-45°C, and the reaction pH is 8-10.

[0069] The application of the composite enzyme preparation containing collagenase in the treatment of leather scraps comprises the following process steps:

[0070] A. Put the leather solid waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com