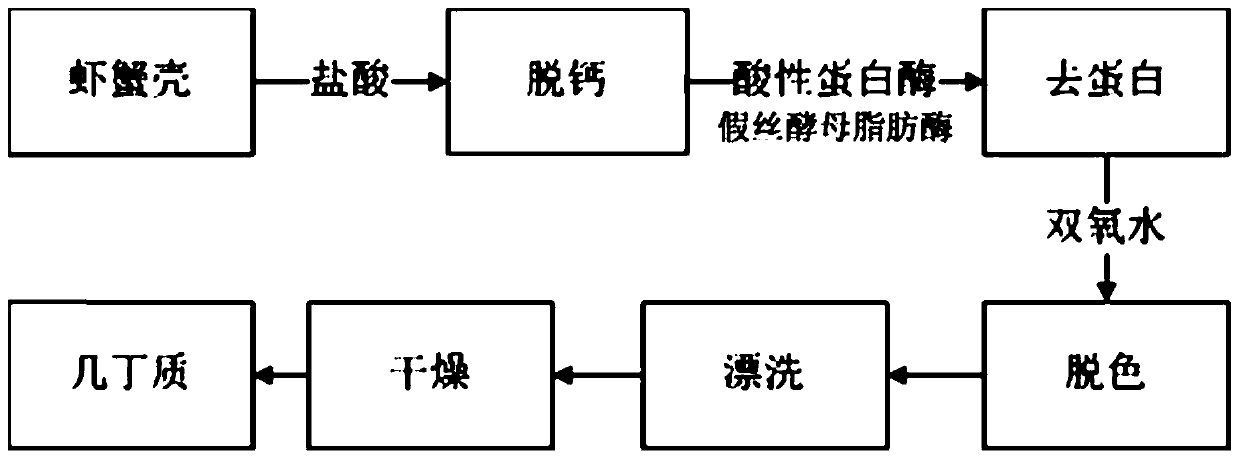

A method of enzymatic treatment and extraction of chitin

A technology of chitin and quality, applied in the field of bioengineering, can solve the problems that have not yet been applied in large-scale industrial production, and achieve the effect of increasing hydrolysis rate, improving conversion rate, and mild separation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] After washing the crab shells with clean water, weigh 10g of crab shells and break them into pieces, each with an area less than 1cm 2 , Put it in a 100ml conical flask, add 20ml of 1mol / L hydrochloric acid, soak for 12 hours, filter to remove the liquid to obtain a solid substance. Pour the solid material back into the Erlenmeyer flask, add 20ml of fresh 1mol / L hydrochloric acid again, and soak for 12 hours until the crab shell becomes soft to remove the calcium component in the crab shell.

Embodiment 2

[0024] Filter the product obtained in Example (1), remove the liquid, pour the solid material back into the Erlenmeyer flask, add 20ml of deionized water, use 1mol / L hydrochloric acid or 1mol / L sodium hydroxide, carefully adjust the pH to about 3 About, add 100,000 U of acid protease (Zhengzhou Shiquanshimei Trading Co., Ltd. 100,000 U / g~300,000 U / g, or Zhengzhou Junkai Chemical Products Co., Ltd. 100,000 u / g) and substrate 1% by mass of Candida lipase was reacted in a shaker at 300 rpm and 40°C for 12 hours to remove protein components. At this time, the sample gradually changed from white to transparent, and a transparent product after hydrolysis was obtained.

Embodiment 3

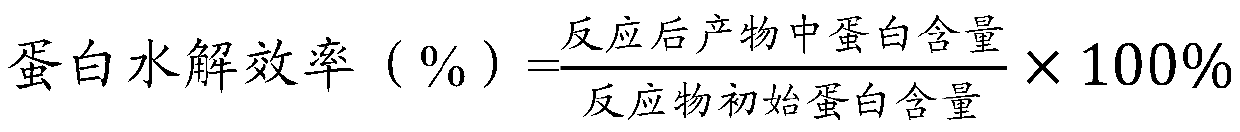

[0026] Determination of product protein content after reaction:

[0027] Take 1 g of the transparent product obtained in Example 2 and use the BCA protein quantification kit (Tiangen Biochemical Technology (Beijing) Co., Ltd.) standard method to quantify the residual protein content in the product, and define the residual protein content as the protein content of the product after the reaction.

[0028] Determination of the protein content of the initial product:

[0029] After washing the crab shells with clean water, weigh 10g of crab shells and break them into pieces, each with an area less than 1cm 2 , Put it into a 100ml conical flask, add 20ml of 1mol / L hydrochloric acid, soak for 12 hours, filter to remove the liquid to obtain a solid. After taking a small amount of solids and adding 100,000 enzymatic (U) acid protease, take 1g of enzymatic hydrolysate, measure the protein content and define the measured protein content as the initial protein content.

[0030] The proteolysis e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com