Rebar Bending Machine

A hoop bending machine and steel bar technology, applied in the field of steel bar bending, can solve the problem of laborious bending process of steel bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

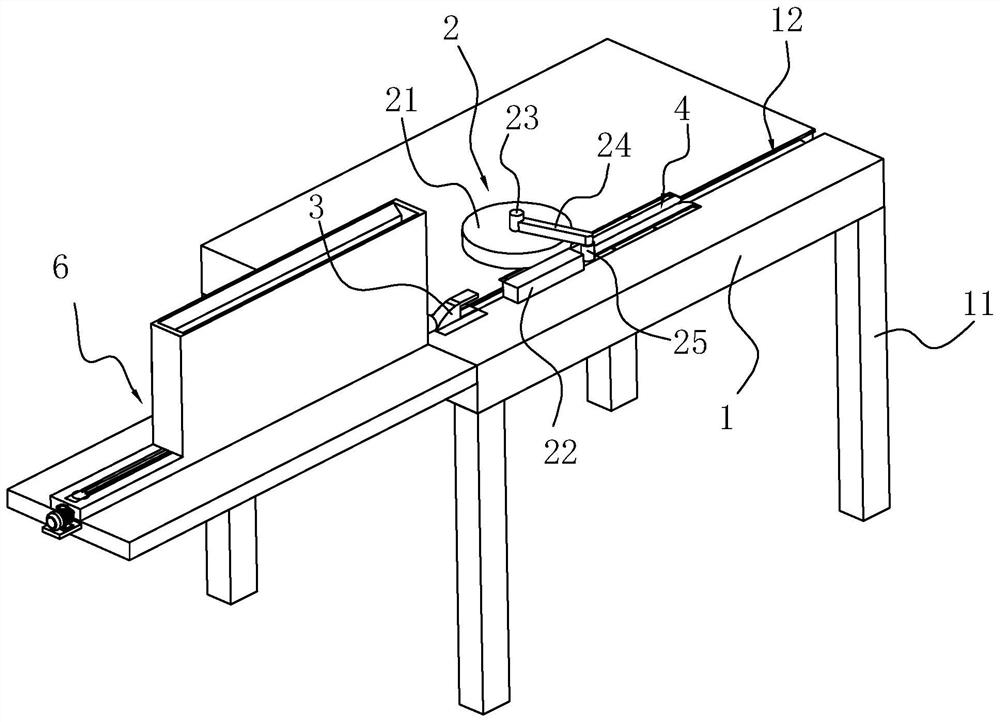

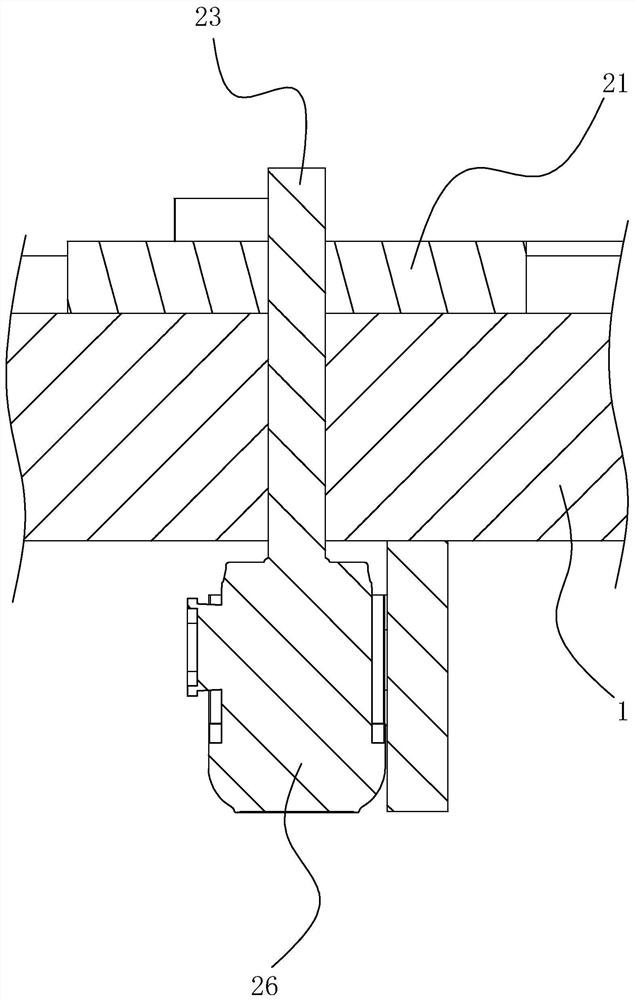

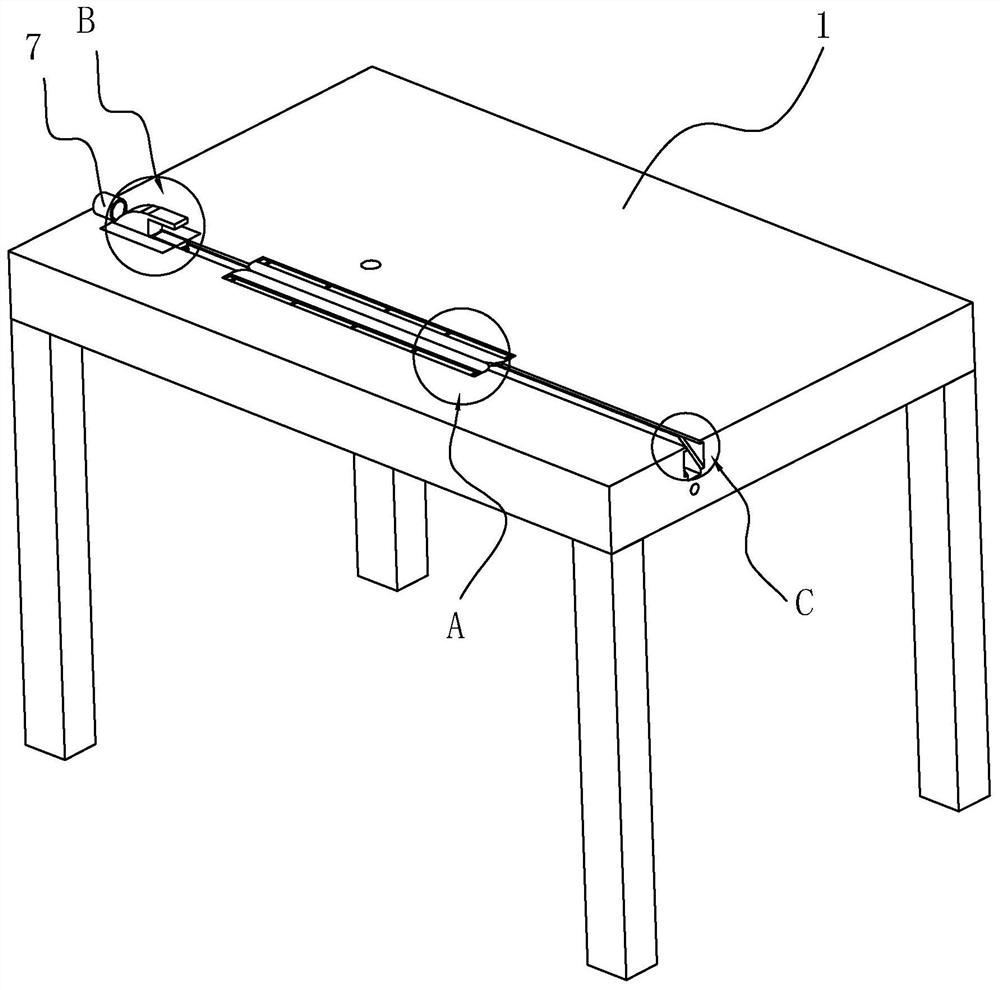

[0046] Embodiment: a kind of steel bar hoop bending machine, see attached figure 1 , including a workbench 1 arranged in a rectangular shape, four outriggers 11 fixedly connected to the four corners of the bottom of the workbench 1 for supporting the workbench 1, and a support for bending steel bars arranged on the top of the workbench 1 Bending mechanism 2, the support mechanism 4 that is arranged on the workbench 1 and is used to support the steel bar, the feed mechanism 6 that is arranged on the workbench 1 side and is used to send the steel bar into the top of the workbench 1 and is arranged on the workbench 1 The blanking block 3 on the table 1 is used to send the bent steel bar from the top of the workbench 1. The side of the top of the workbench 1 close to the feed mechanism 6 is the feed side, and the side away from the feed mechanism 6 is the discharge side. The blanking block 3 slides on the top of the workbench 1 along the feeding direction of the steel bar. There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com