Multiaxial tensile test method for rubber materials under the same Mullins effect

A rubber material, tensile test technology, applied in the direction of analyzing materials, applying stable tension/pressure to test material strength, instruments, etc., can solve the problems of no material mechanical properties, errors, etc., to achieve accurate elastic properties, accurate prediction and the calculated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

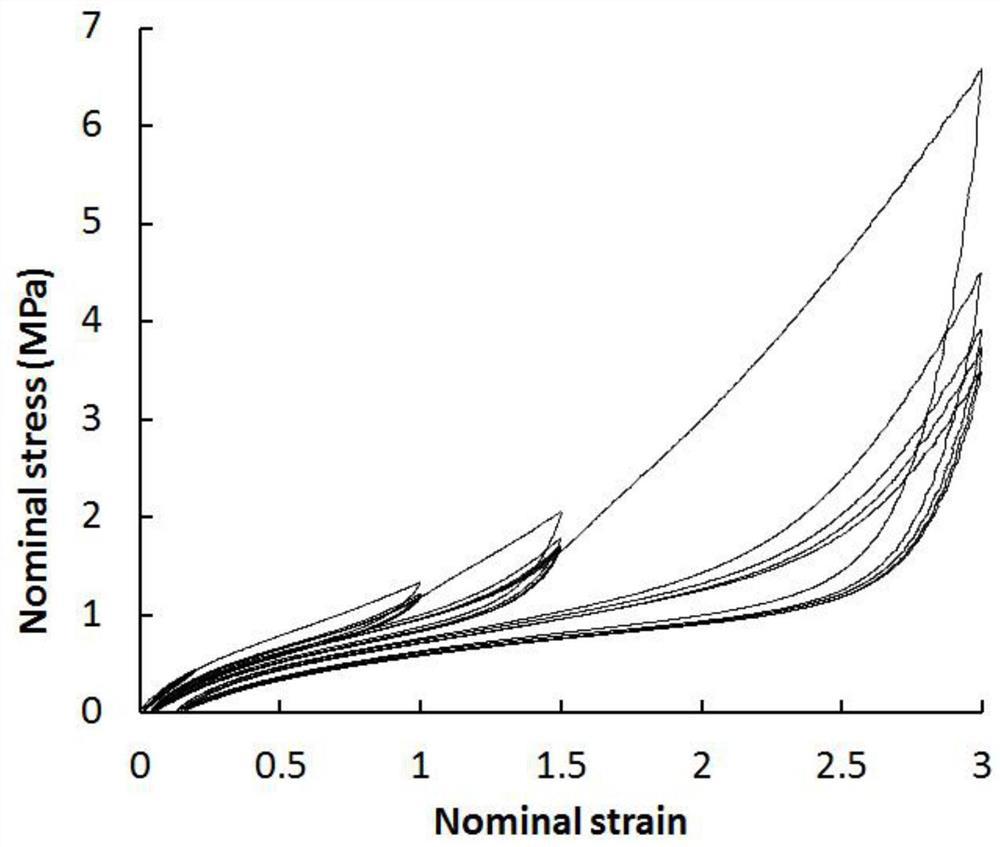

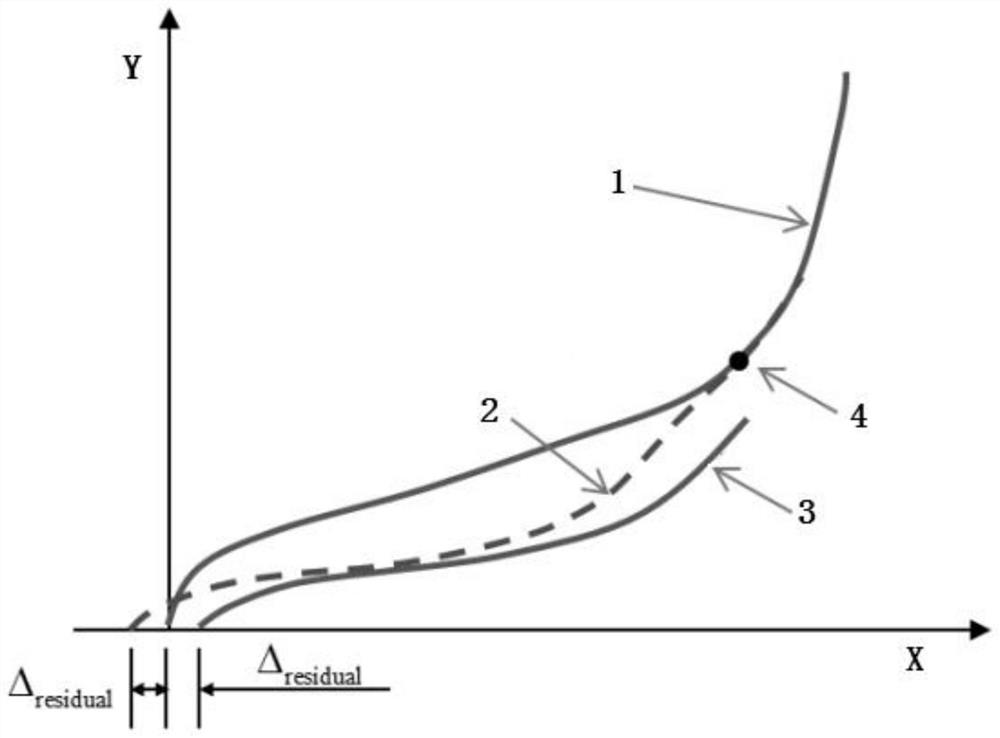

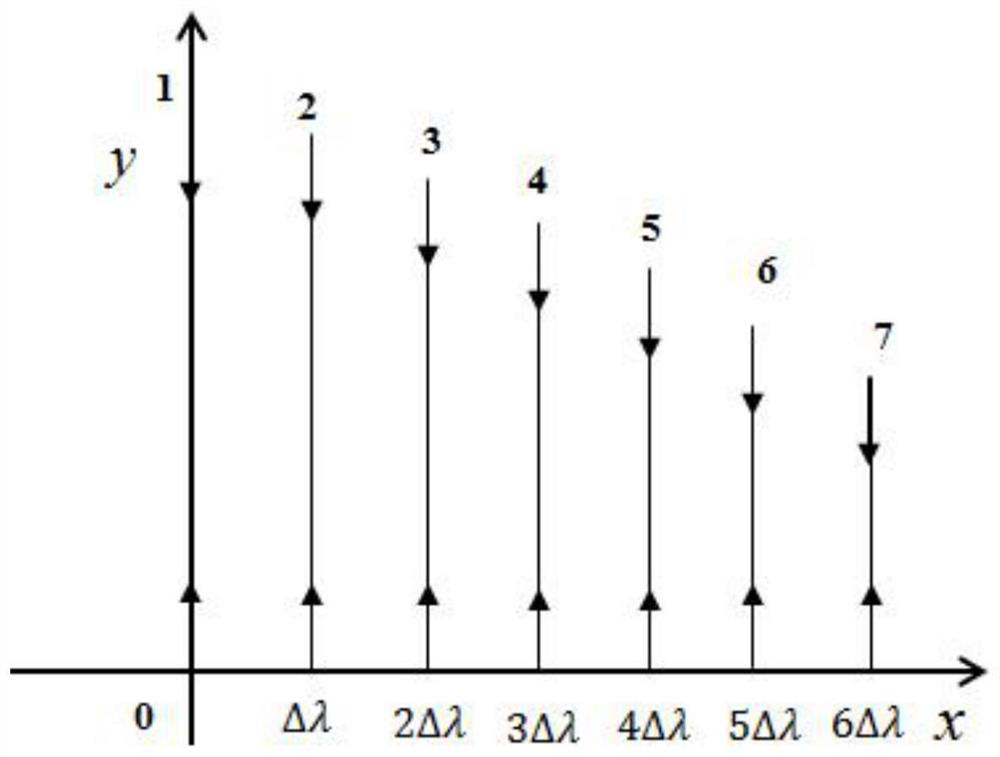

[0029] The multiaxial tensile test method of rubber materials under the same Mullins effect can be used in engineering to measure the mechanical properties of rubber materials in a certain damage state. The specific experimental program flow is shown in the attached drawing Figure 5shown. Assume that the lateral (x-direction) constraints are 0, Δ, 2Δ, 3Δ four fixed elongation ratios, and the y-direction is also Δ, 2Δ, 3Δ four kinds of elongation ratios. That requires making 4 biaxial tensile test specimens. Each test sample is first stretched in the y-direction with no constraints in the x-direction and three fixed constraints of Δ, 2Δ, and 3Δ, and the stretching length in the y-direction is Δ, so that the material tensile curves in four cases are measured. Then select a new sample 5 to carry out an unconstrained x-direction, two cyclic stretches in the y-direction, and three single stretches in the y-direction with constant elongation in the x-direction, Δ, 2Δ, and 3Δ. If t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com