Tire

A tire and tread technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of reduced pattern rigidity, inability to discharge water, and poor turning performance on dry roads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, one embodiment of the present invention will be described based on the drawings.

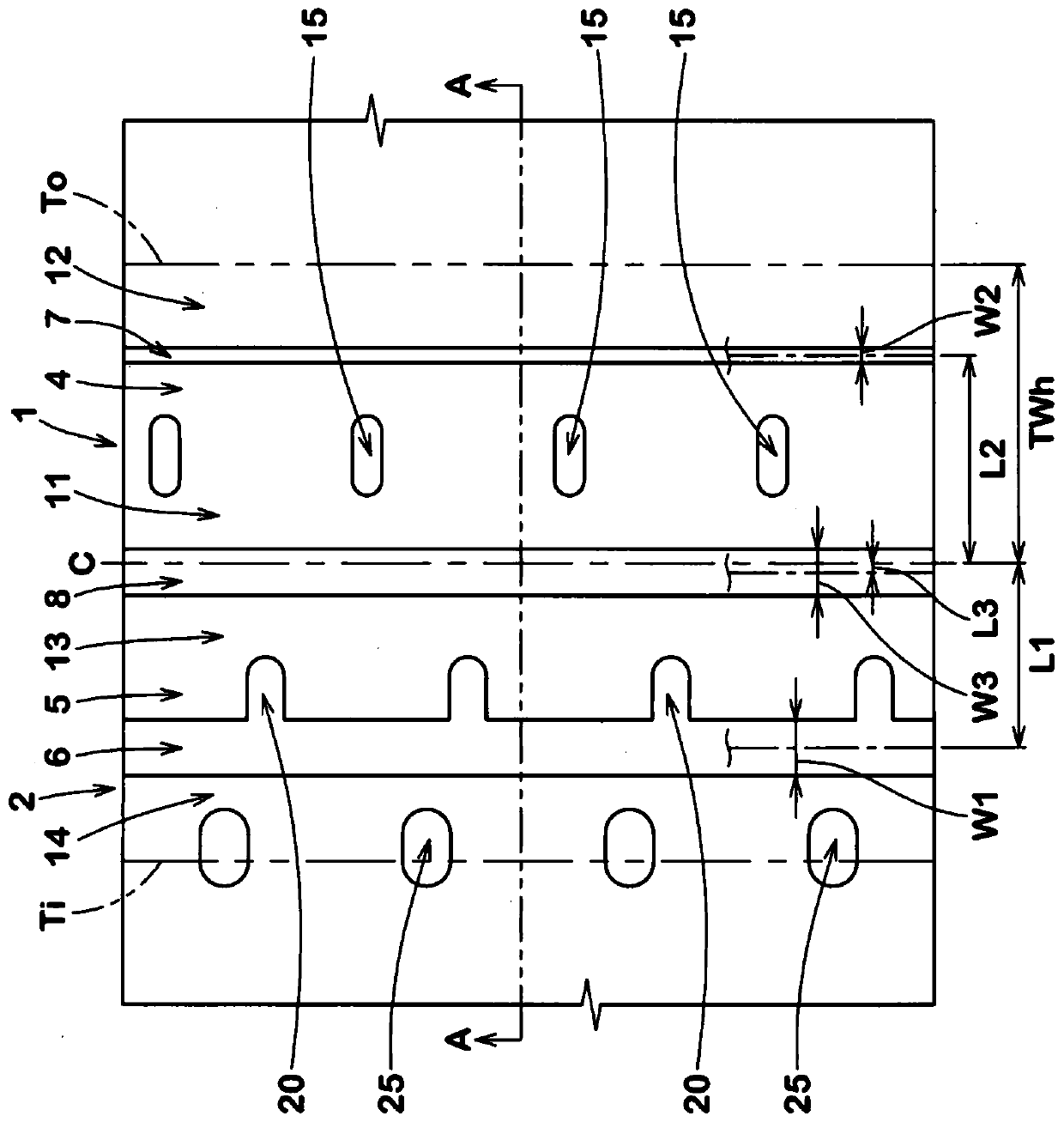

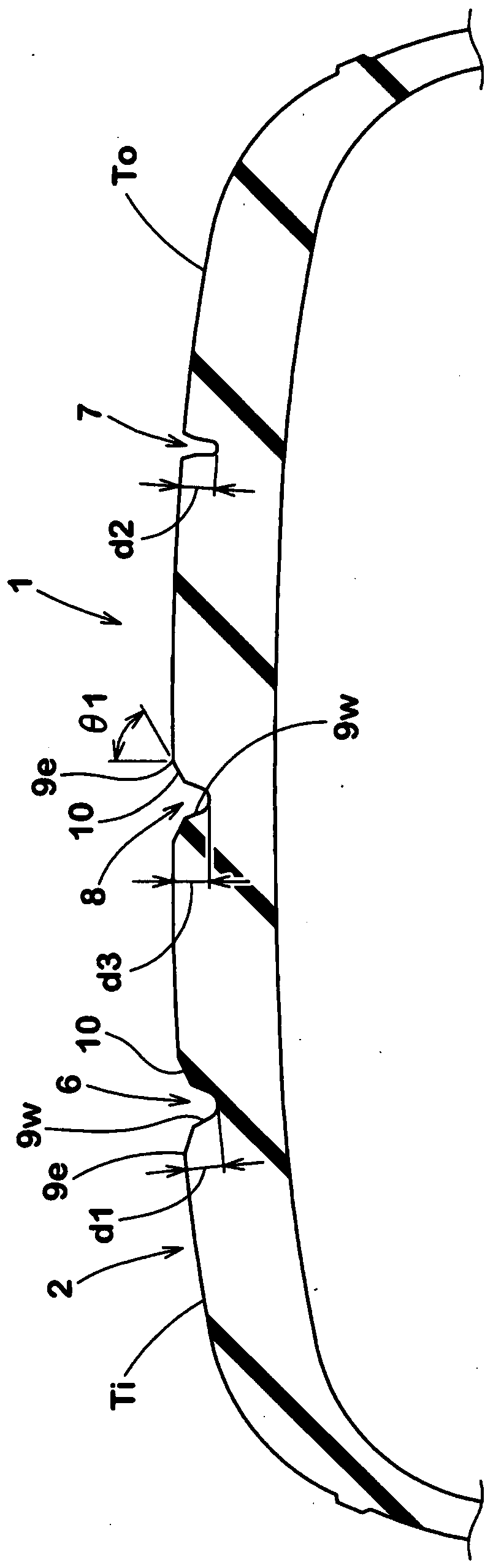

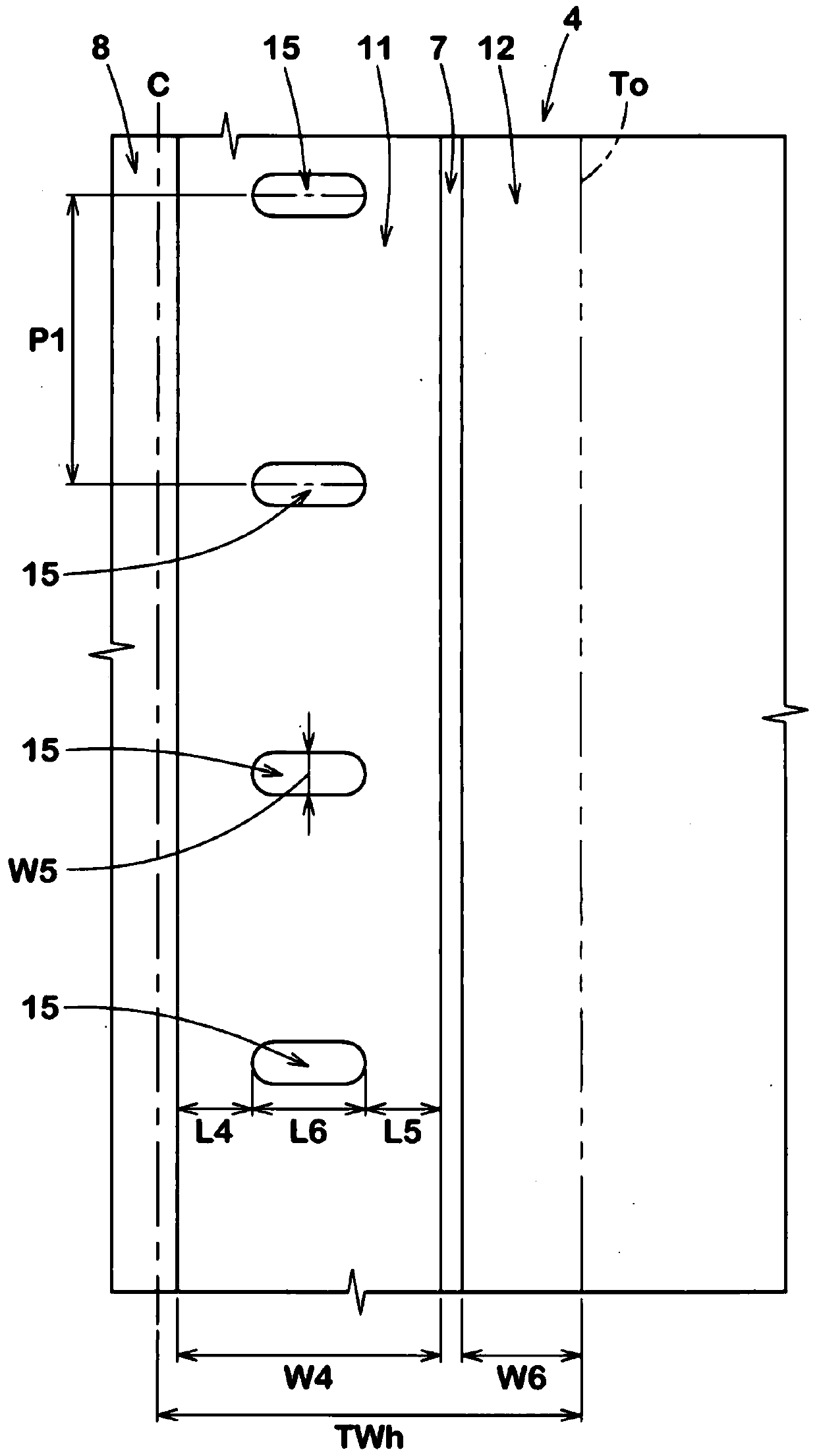

[0025] figure 1 It is a developed view of the tread portion 2 of the tire 1 of the present embodiment. figure 2 show figure 1 A-A line sectional view of the tread portion 2 of . Such as figure 1 and figure 2 As shown, the tire 1 according to the present embodiment is used, for example, as a pneumatic tire for passenger cars, and is particularly suitable as a high-performance tire presupposed to be used in both public road driving and circuit driving.

[0026] The tire 1 has a tread portion 2 designated in the direction of installation on a vehicle. The direction of attachment to the vehicle is displayed on the sidewall portion (not shown) by characters or symbols, for example. exist figure 1 and figure 2 Among them, when the tire 1 is mounted on a vehicle, the left side corresponds to the vehicle inner side, and the right side corresponds to the vehicle outer side....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com