pneumatic tire

A pneumatic tire, tire technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as difficulty in providing tires, and achieve improved wear resistance, reduced energy loss, and groove volume. zoom out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

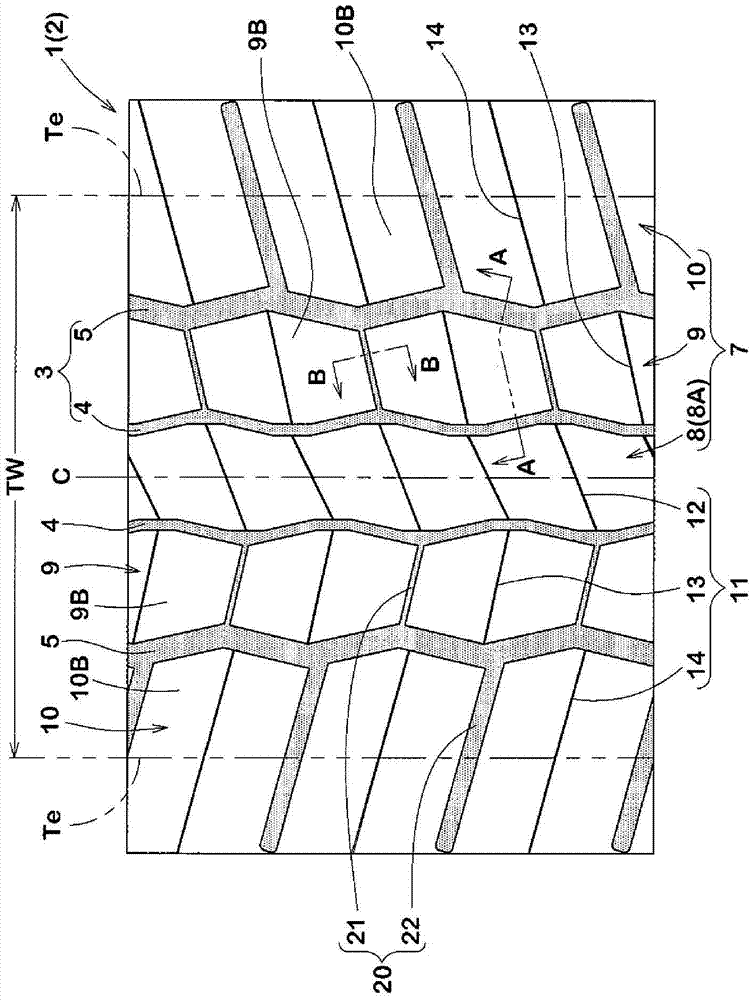

[0060] Prototype has figure 1 The tires (tire size: 315 / 80R22.5) with the basic pattern shown and based on the specifications in Table 1 were tested.

[0061] Each test method is as follows.

[0062]

[0063] The rolling resistance of each test tire was measured using a rolling resistance testing machine. The detailed conditions are as follows. The result was shown by the reciprocal of the rolling resistance, and the value of "Example 1" was set to 100 by the index. The larger the numerical value, the better the rolling performance.

[0064] Rim: 22.5×9.00

[0065] Internal pressure: 850kPa

[0066] Longitudinal load: 33.34kN

[0067] Speed: 80km / h

[0068]

[0069] Based on the single tire noise test method specified in ECE-R117-02, the passing noise level of each test tire was measured when driving at a center speed of 70km / h. The results are represented by an index that takes the reciprocal of the passing noise level and assumes that the value of "Example 1" is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com