Coral sandstone and coral gravel limestone similar materials and their preparation methods and applications

A technology similar to materials and coral sand, applied in the direction of analysis materials, test sample preparation, instruments, etc., can solve the problems that restrict the progress of reef limestone test research, difficulty in collecting reef limestone samples, and low success rate, and achieve The effect of wide coverage, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

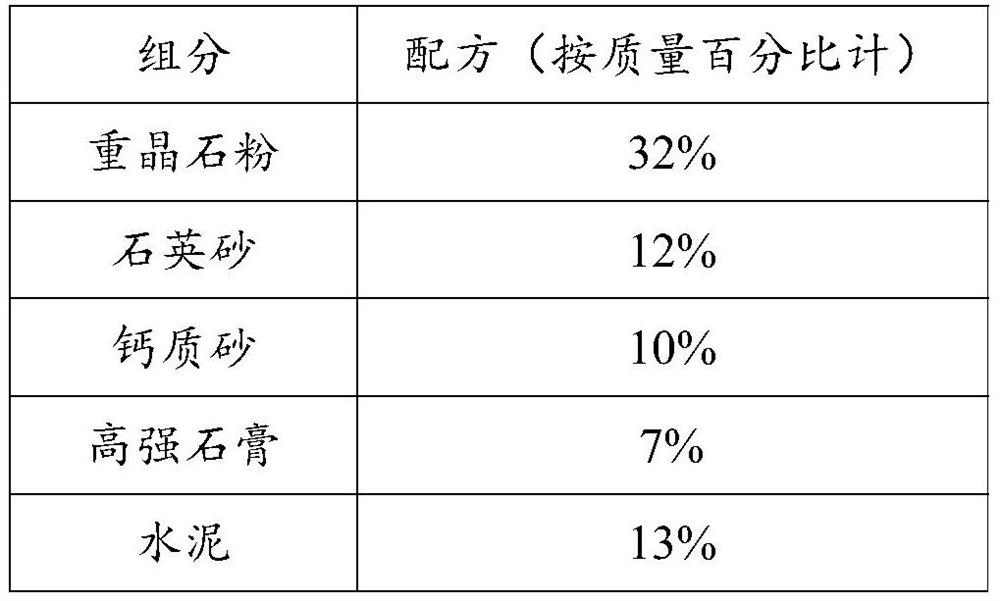

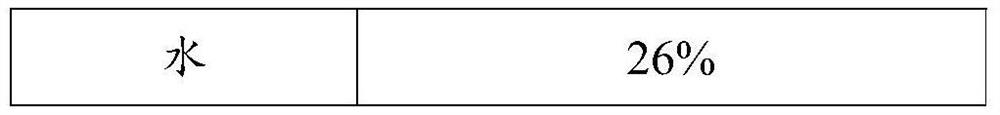

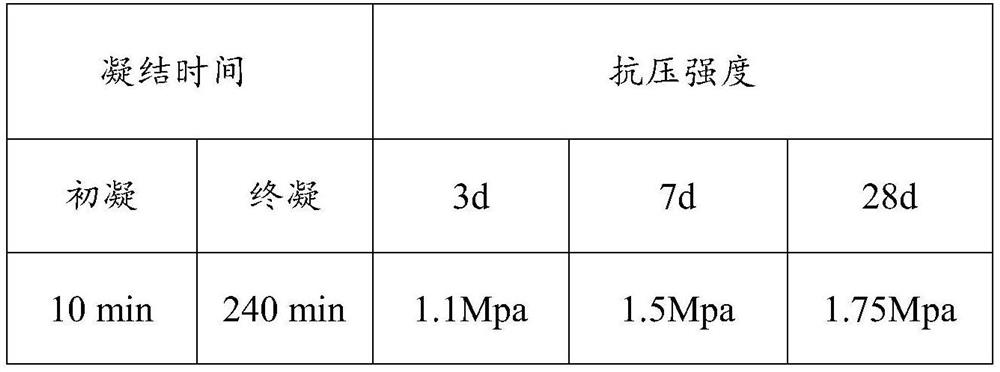

[0032] The formulations of similar materials for coral reef limestone are shown in Table 1.

[0033] Table 1

[0034]

[0035]

[0036] The particle size of the barite powder selected in Table 1 is 600 mesh, the particle size of the calcareous sand is 30 mesh, the particle size of the quartz sand is 40 mesh, the cement is P.O 42.5 cement, and the particle size of the high-strength gypsum is 1600 mesh.

[0037] The preparation method comprises the following steps: mixing and stirring the weighed barite powder, quartz sand, calcareous sand, cement and high-strength gypsum to make a mixed powder; weighing water in proportion, and adding the mixed powder into the weighed In the water, fully stir and mix evenly; pour the mixed material into the mold, and manually vibrate to shape; after the material is solidified (about 10 minutes), demould the model, and under the conditions of temperature 25°C and humidity ≥ 80% After curing for 7 days, similar materials can be obtained. ...

Embodiment 2

[0042] The formulations of similar materials for coral reef limestone are shown in Table 3.

[0043] table 3

[0044]

[0045]

[0046] The particle size of the barite powder selected in Table 3 is 700 mesh, the particle size of the calcareous sand is 40 mesh, the particle size of the quartz sand is 50 mesh, the cement is P.O 42.5 cement, and the particle size of the high-strength gypsum is 1600 mesh.

[0047] The preparation method comprises the following steps: mixing and stirring the weighed barite powder, quartz sand, calcareous sand, cement and high-strength gypsum to make a mixed powder; weighing water in proportion, and adding the mixed powder into the weighed In the water, fully stir and mix evenly; pour the mixed material into the mold, and manually vibrate to shape; after the material is solidified (about 10 minutes), demould the model, and under the conditions of temperature 25°C and humidity ≥ 80% After curing for 7 days, similar materials can be obtained. ...

Embodiment 3

[0052] The formulations of similar materials for coral reef limestone are shown in Table 5.

[0053] table 5

[0054] components Formula (by mass percentage) barite powder 29% Quartz sand 14% calcareous sand 10% High Strength Gypsum 8.5% cement 14.5% water 25%

[0055] The particle size of the barite powder selected in Table 3 is 700 mesh, the particle size of the calcareous sand is 40 mesh, the particle size of the quartz sand is 50 mesh, the cement is P.O 42.5 cement, and the particle size of the high-strength gypsum is 1600 mesh.

[0056] The preparation method comprises the following steps: mixing and stirring the weighed barite powder, quartz sand, calcareous sand, cement and high-strength gypsum to make a mixed powder; weighing water in proportion, and adding the mixed powder to weigh In the water, fully stir and mix evenly; pour the mixed material into the mold, and manually vibrate to shape; after the material is solidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com